Assembler Resume Examples

Mar 31, 2025

|

12 min read

Craft an assembler resume with precision to fit any position. Highlight your knack for putting it all together. From assembling achievements to aligning career goals, ensure every piece of your work experience clicks into place seamlessly.

Rated by 348 people

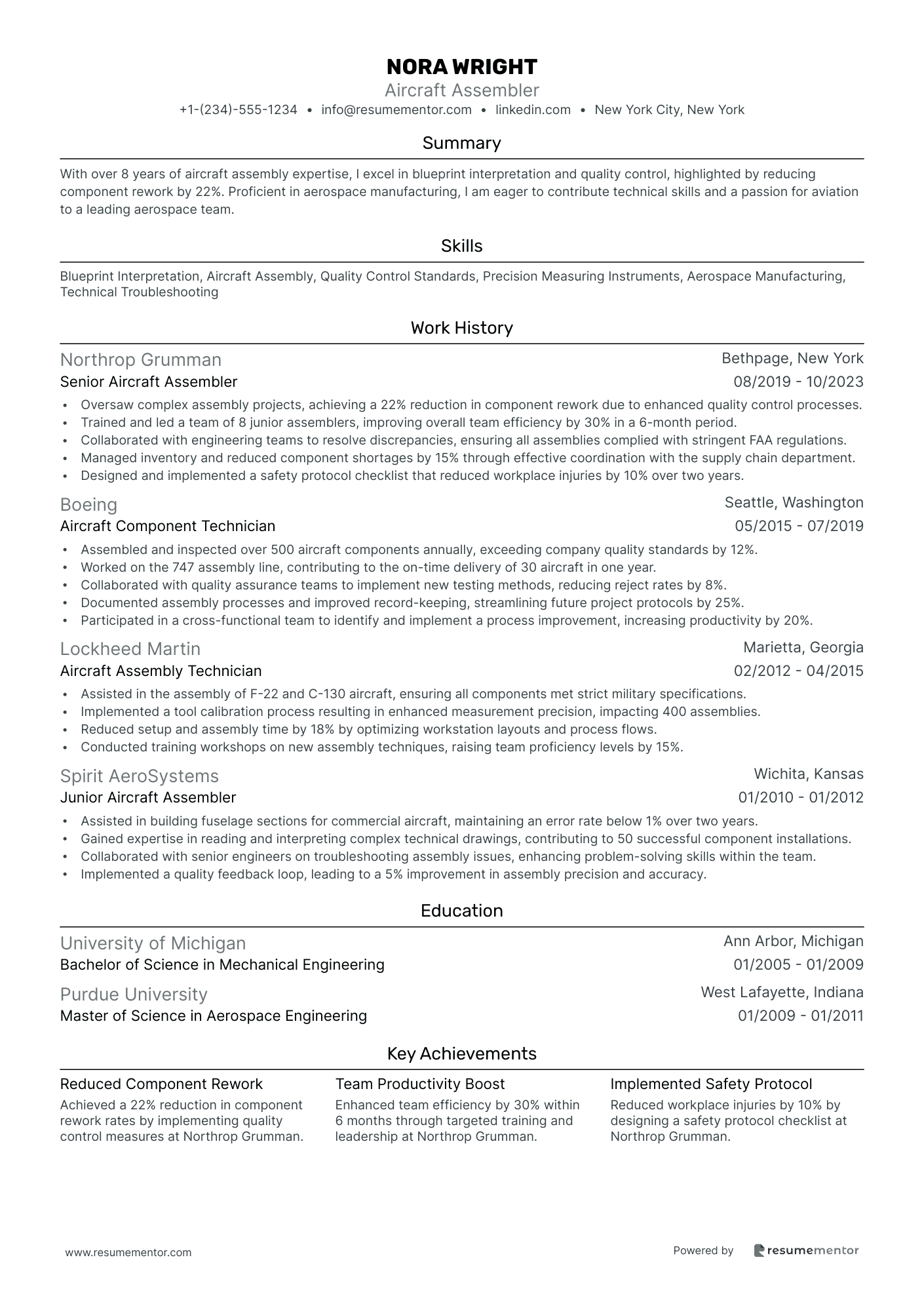

Aircraft Assembler

Electronics Assembler

Automotive Assembler

Medical Device Assembler

Furniture Assembler

Precision Instrument Assembler

Mechanical Assembly Technician

Computer Hardware Assembler

Electrical Assembly Specialist

Optical Products Assembler

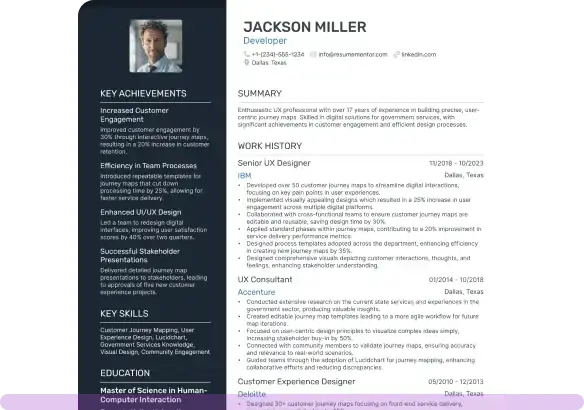

Aircraft Assembler resume sample

- •Oversaw complex assembly projects, achieving a 22% reduction in component rework due to enhanced quality control processes.

- •Trained and led a team of 8 junior assemblers, improving overall team efficiency by 30% in a 6-month period.

- •Collaborated with engineering teams to resolve discrepancies, ensuring all assemblies complied with stringent FAA regulations.

- •Managed inventory and reduced component shortages by 15% through effective coordination with the supply chain department.

- •Designed and implemented a safety protocol checklist that reduced workplace injuries by 10% over two years.

- •Assembled and inspected over 500 aircraft components annually, exceeding company quality standards by 12%.

- •Worked on the 747 assembly line, contributing to the on-time delivery of 30 aircraft in one year.

- •Collaborated with quality assurance teams to implement new testing methods, reducing reject rates by 8%.

- •Documented assembly processes and improved record-keeping, streamlining future project protocols by 25%.

- •Participated in a cross-functional team to identify and implement a process improvement, increasing productivity by 20%.

- •Assisted in the assembly of F-22 and C-130 aircraft, ensuring all components met strict military specifications.

- •Implemented a tool calibration process resulting in enhanced measurement precision, impacting 400 assemblies.

- •Reduced setup and assembly time by 18% by optimizing workstation layouts and process flows.

- •Conducted training workshops on new assembly techniques, raising team proficiency levels by 15%.

- •Assisted in building fuselage sections for commercial aircraft, maintaining an error rate below 1% over two years.

- •Gained expertise in reading and interpreting complex technical drawings, contributing to 50 successful component installations.

- •Collaborated with senior engineers on troubleshooting assembly issues, enhancing problem-solving skills within the team.

- •Implemented a quality feedback loop, leading to a 5% improvement in assembly precision and accuracy.

Electronics Assembler resume sample

- •Led a team to enhance assembly procedures, resulting in a 15% increase in productivity and a 95% defect-free output.

- •Implemented efficient quality control measures, reducing defect rates by 20% and improving client satisfaction scores by 12%.

- •Collaborated with engineering teams to execute design improvements on a new product line, improving functionality and reliability.

- •Trained and mentored new team members, witnessing a 25% decrease in onboarding time and a notable rise in team performance.

- •Utilized precise soldering techniques to construct high-density electronic assemblies, completing projects 10% ahead of schedule.

- •Maintained inventory accuracy and regulated supply levels, eliminating delays in project timelines and reducing waste by 8%.

- •Facilitated assembly processes for complex circuit boards, consistently achieving a 98% pass rate in quality assessments.

- •Developed wiring solutions that improved assembly efficiency, decreasing the average build time by 15%.

- •Contributed to the successful deployment of a new product by optimizing assembly line processes, increasing output by 10%.

- •Enhanced workplace safety by introducing standardized operating procedures, which decreased accident rates by 30% over two years.

- •Established a routine troubleshooting protocol, reducing equipment downtime by 20% and operational costs by 5%.

- •Assisted assembly teams in rectifying circuit anomalies, which improved product first-pass quality by 15%.

- •Executed efficient wire handling techniques, facilitating a 10% increase in overall assembly line speed.

- •Performed quality assurance tests on electronic devices, maintaining a 97% approval rate from quality assurance.

- •Worked with development teams to upgrade assembly protocols, creating a 12% increase in output efficiency.

- •Conducted thorough testing of high-volume electronic components, achieving a 90% first-time approval rate.

- •Streamlined component integration processes, leading to a 20% reduction in assembly time for pivotal projects.

- •Implemented routine maintenance checks and repairs on assembly tools, extending equipment lifespan by 18%.

- •Promoted a culture of quality and efficiency by implementing best practice sharing sessions, boosting team morale and productivity.

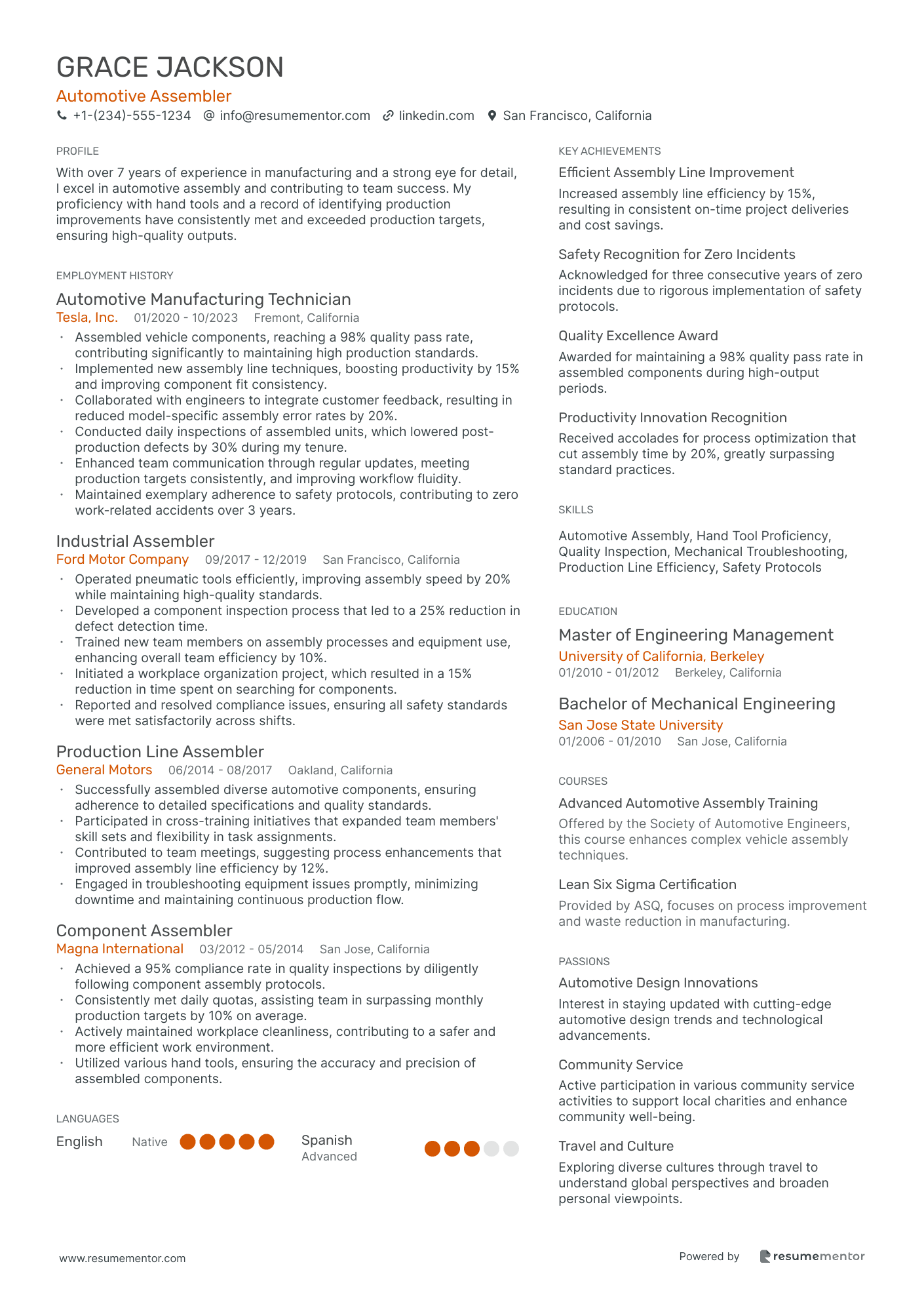

Automotive Assembler resume sample

- •Assembled vehicle components, reaching a 98% quality pass rate, contributing significantly to maintaining high production standards.

- •Implemented new assembly line techniques, boosting productivity by 15% and improving component fit consistency.

- •Collaborated with engineers to integrate customer feedback, resulting in reduced model-specific assembly error rates by 20%.

- •Conducted daily inspections of assembled units, which lowered post-production defects by 30% during my tenure.

- •Enhanced team communication through regular updates, meeting production targets consistently, and improving workflow fluidity.

- •Maintained exemplary adherence to safety protocols, contributing to zero work-related accidents over 3 years.

- •Operated pneumatic tools efficiently, improving assembly speed by 20% while maintaining high-quality standards.

- •Developed a component inspection process that led to a 25% reduction in defect detection time.

- •Trained new team members on assembly processes and equipment use, enhancing overall team efficiency by 10%.

- •Initiated a workplace organization project, which resulted in a 15% reduction in time spent on searching for components.

- •Reported and resolved compliance issues, ensuring all safety standards were met satisfactorily across shifts.

- •Successfully assembled diverse automotive components, ensuring adherence to detailed specifications and quality standards.

- •Participated in cross-training initiatives that expanded team members' skill sets and flexibility in task assignments.

- •Contributed to team meetings, suggesting process enhancements that improved assembly line efficiency by 12%.

- •Engaged in troubleshooting equipment issues promptly, minimizing downtime and maintaining continuous production flow.

- •Achieved a 95% compliance rate in quality inspections by diligently following component assembly protocols.

- •Consistently met daily quotas, assisting team in surpassing monthly production targets by 10% on average.

- •Actively maintained workplace cleanliness, contributing to a safer and more efficient work environment.

- •Utilized various hand tools, ensuring the accuracy and precision of assembled components.

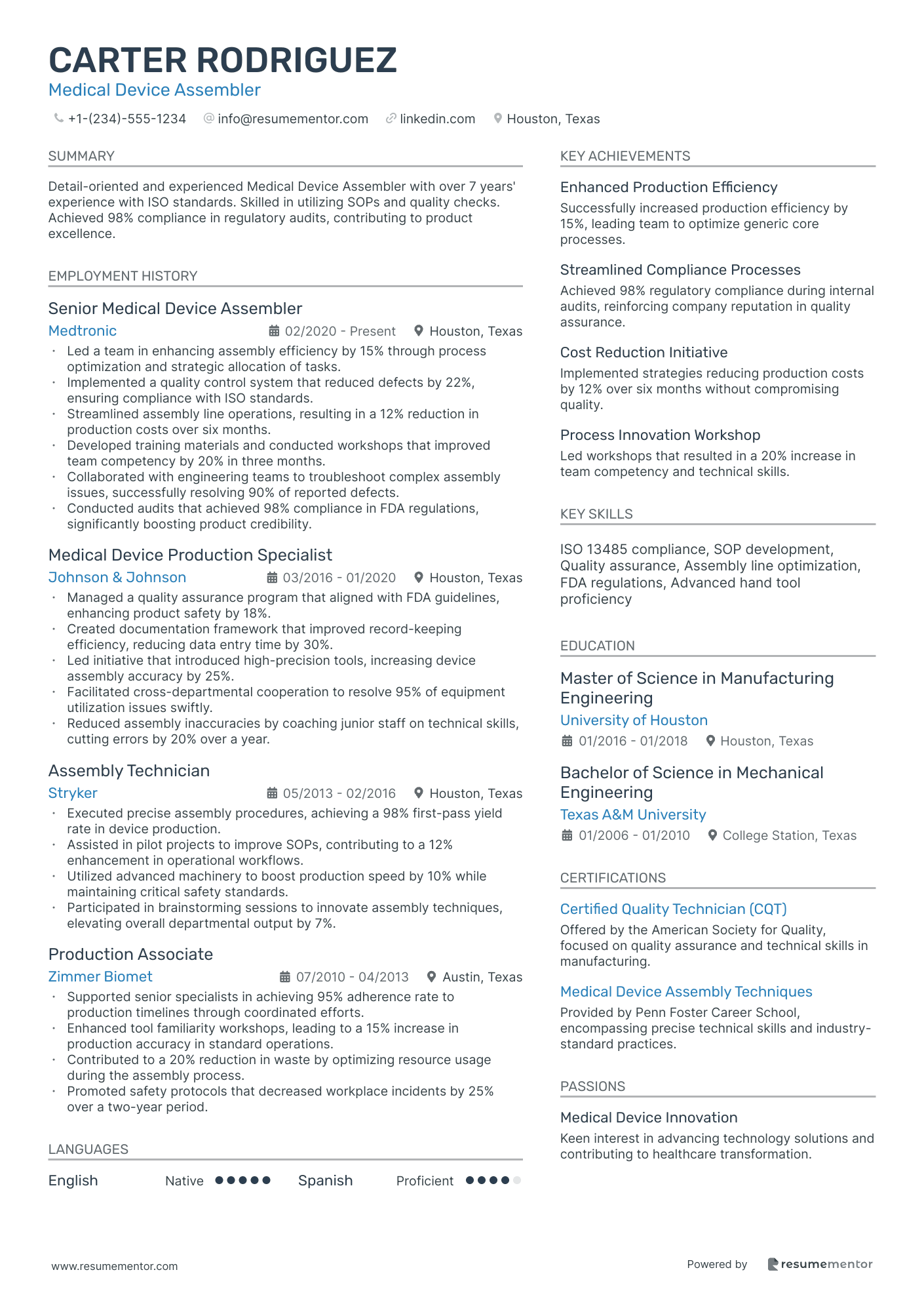

Medical Device Assembler resume sample

- •Led a team in enhancing assembly efficiency by 15% through process optimization and strategic allocation of tasks.

- •Implemented a quality control system that reduced defects by 22%, ensuring compliance with ISO standards.

- •Streamlined assembly line operations, resulting in a 12% reduction in production costs over six months.

- •Developed training materials and conducted workshops that improved team competency by 20% in three months.

- •Collaborated with engineering teams to troubleshoot complex assembly issues, successfully resolving 90% of reported defects.

- •Conducted audits that achieved 98% compliance in FDA regulations, significantly boosting product credibility.

- •Managed a quality assurance program that aligned with FDA guidelines, enhancing product safety by 18%.

- •Created documentation framework that improved record-keeping efficiency, reducing data entry time by 30%.

- •Led initiative that introduced high-precision tools, increasing device assembly accuracy by 25%.

- •Facilitated cross-departmental cooperation to resolve 95% of equipment utilization issues swiftly.

- •Reduced assembly inaccuracies by coaching junior staff on technical skills, cutting errors by 20% over a year.

- •Executed precise assembly procedures, achieving a 98% first-pass yield rate in device production.

- •Assisted in pilot projects to improve SOPs, contributing to a 12% enhancement in operational workflows.

- •Utilized advanced machinery to boost production speed by 10% while maintaining critical safety standards.

- •Participated in brainstorming sessions to innovate assembly techniques, elevating overall departmental output by 7%.

- •Supported senior specialists in achieving 95% adherence rate to production timelines through coordinated efforts.

- •Enhanced tool familiarity workshops, leading to a 15% increase in production accuracy in standard operations.

- •Contributed to a 20% reduction in waste by optimizing resource usage during the assembly process.

- •Promoted safety protocols that decreased workplace incidents by 25% over a two-year period.

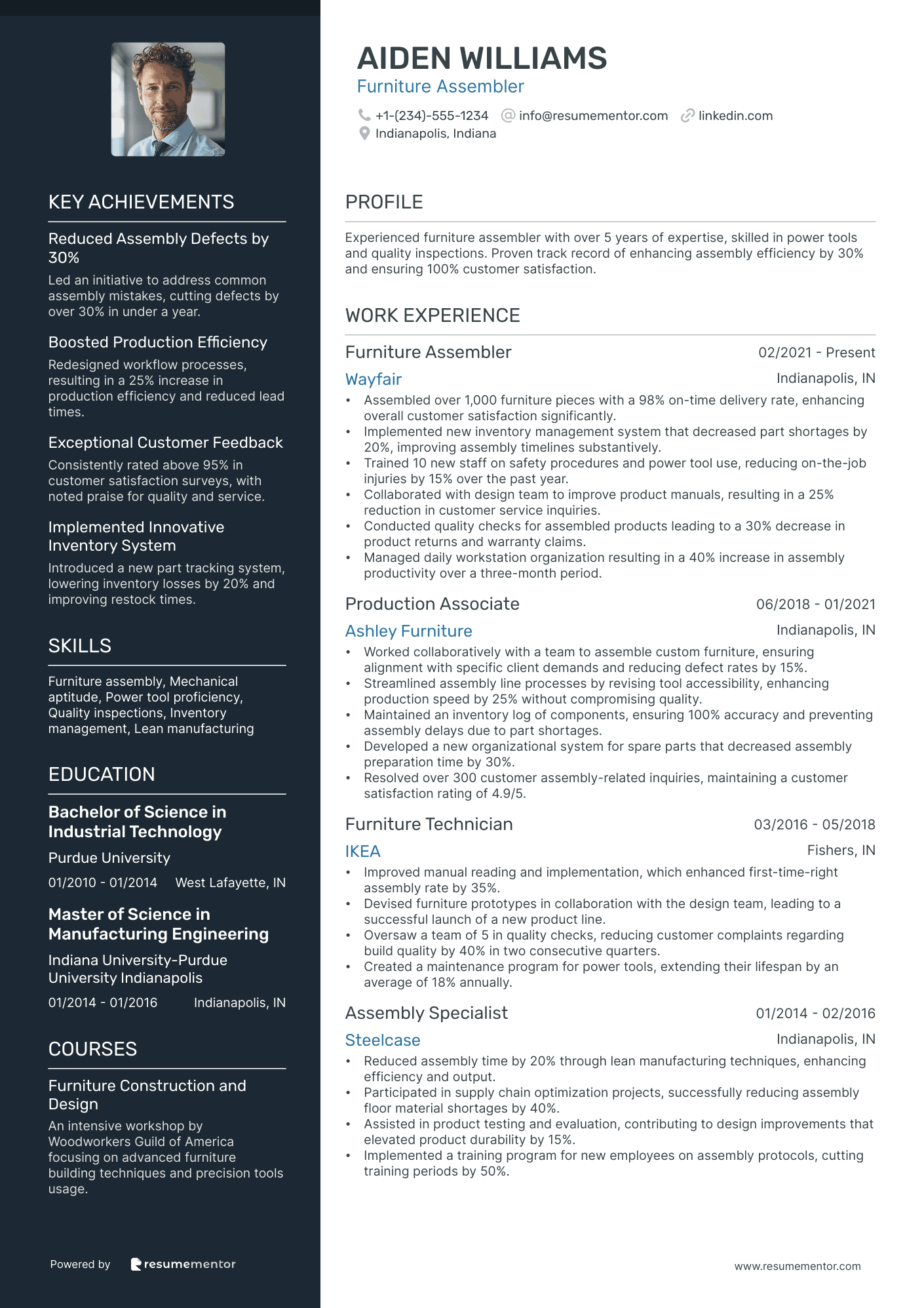

Furniture Assembler resume sample

- •Assembled over 1,000 furniture pieces with a 98% on-time delivery rate, enhancing overall customer satisfaction significantly.

- •Implemented new inventory management system that decreased part shortages by 20%, improving assembly timelines substantively.

- •Trained 10 new staff on safety procedures and power tool use, reducing on-the-job injuries by 15% over the past year.

- •Collaborated with design team to improve product manuals, resulting in a 25% reduction in customer service inquiries.

- •Conducted quality checks for assembled products leading to a 30% decrease in product returns and warranty claims.

- •Managed daily workstation organization resulting in a 40% increase in assembly productivity over a three-month period.

- •Worked collaboratively with a team to assemble custom furniture, ensuring alignment with specific client demands and reducing defect rates by 15%.

- •Streamlined assembly line processes by revising tool accessibility, enhancing production speed by 25% without compromising quality.

- •Maintained an inventory log of components, ensuring 100% accuracy and preventing assembly delays due to part shortages.

- •Developed a new organizational system for spare parts that decreased assembly preparation time by 30%.

- •Resolved over 300 customer assembly-related inquiries, maintaining a customer satisfaction rating of 4.9/5.

- •Improved manual reading and implementation, which enhanced first-time-right assembly rate by 35%.

- •Devised furniture prototypes in collaboration with the design team, leading to a successful launch of a new product line.

- •Oversaw a team of 5 in quality checks, reducing customer complaints regarding build quality by 40% in two consecutive quarters.

- •Created a maintenance program for power tools, extending their lifespan by an average of 18% annually.

- •Reduced assembly time by 20% through lean manufacturing techniques, enhancing efficiency and output.

- •Participated in supply chain optimization projects, successfully reducing assembly floor material shortages by 40%.

- •Assisted in product testing and evaluation, contributing to design improvements that elevated product durability by 15%.

- •Implemented a training program for new employees on assembly protocols, cutting training periods by 50%.

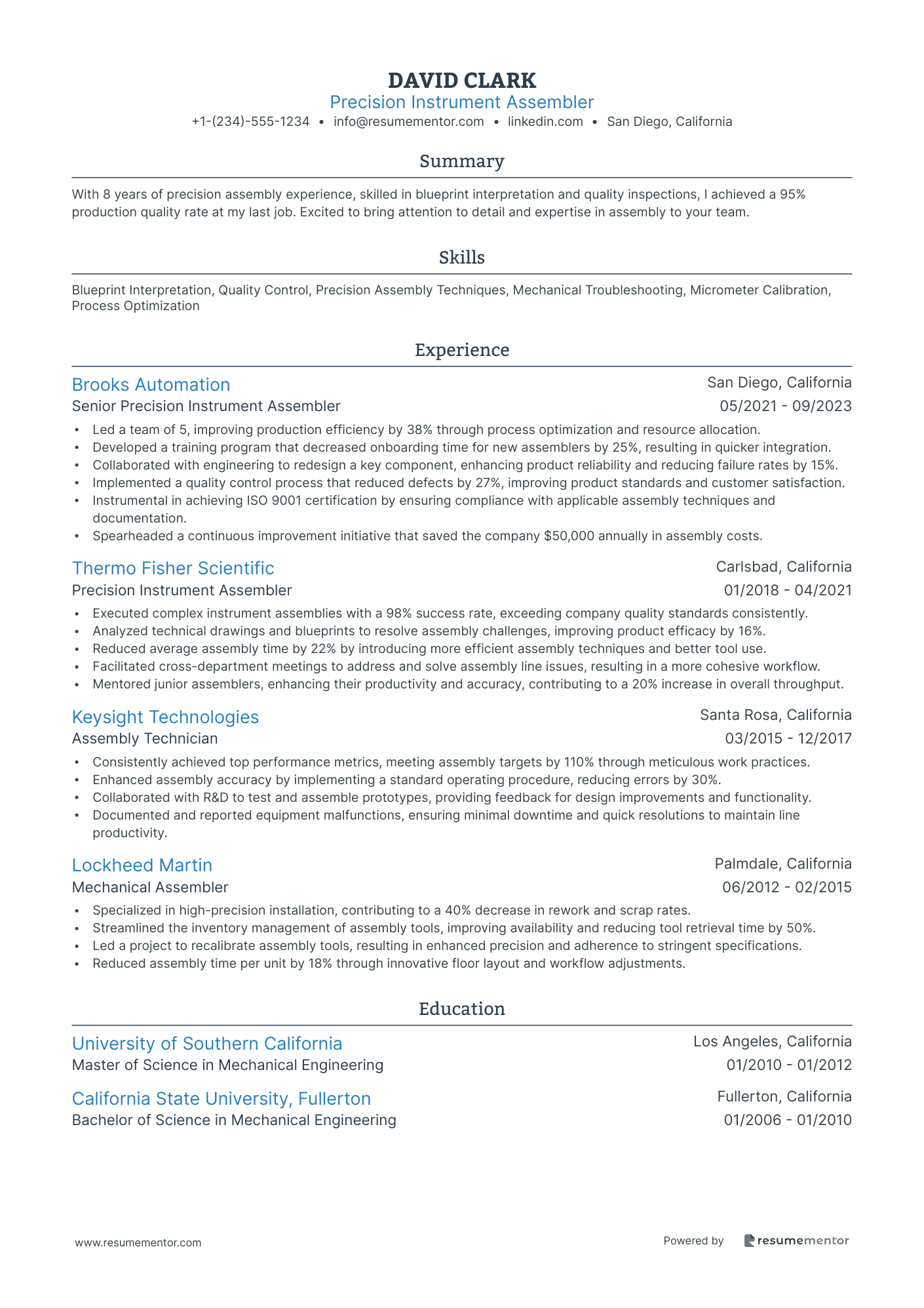

Precision Instrument Assembler resume sample

- •Led a team of 5, improving production efficiency by 38% through process optimization and resource allocation.

- •Developed a training program that decreased onboarding time for new assemblers by 25%, resulting in quicker integration.

- •Collaborated with engineering to redesign a key component, enhancing product reliability and reducing failure rates by 15%.

- •Implemented a quality control process that reduced defects by 27%, improving product standards and customer satisfaction.

- •Instrumental in achieving ISO 9001 certification by ensuring compliance with applicable assembly techniques and documentation.

- •Spearheaded a continuous improvement initiative that saved the company $50,000 annually in assembly costs.

- •Executed complex instrument assemblies with a 98% success rate, exceeding company quality standards consistently.

- •Analyzed technical drawings and blueprints to resolve assembly challenges, improving product efficacy by 16%.

- •Reduced average assembly time by 22% by introducing more efficient assembly techniques and better tool use.

- •Facilitated cross-department meetings to address and solve assembly line issues, resulting in a more cohesive workflow.

- •Mentored junior assemblers, enhancing their productivity and accuracy, contributing to a 20% increase in overall throughput.

- •Consistently achieved top performance metrics, meeting assembly targets by 110% through meticulous work practices.

- •Enhanced assembly accuracy by implementing a standard operating procedure, reducing errors by 30%.

- •Collaborated with R&D to test and assemble prototypes, providing feedback for design improvements and functionality.

- •Documented and reported equipment malfunctions, ensuring minimal downtime and quick resolutions to maintain line productivity.

- •Specialized in high-precision installation, contributing to a 40% decrease in rework and scrap rates.

- •Streamlined the inventory management of assembly tools, improving availability and reducing tool retrieval time by 50%.

- •Led a project to recalibrate assembly tools, resulting in enhanced precision and adherence to stringent specifications.

- •Reduced assembly time per unit by 18% through innovative floor layout and workflow adjustments.

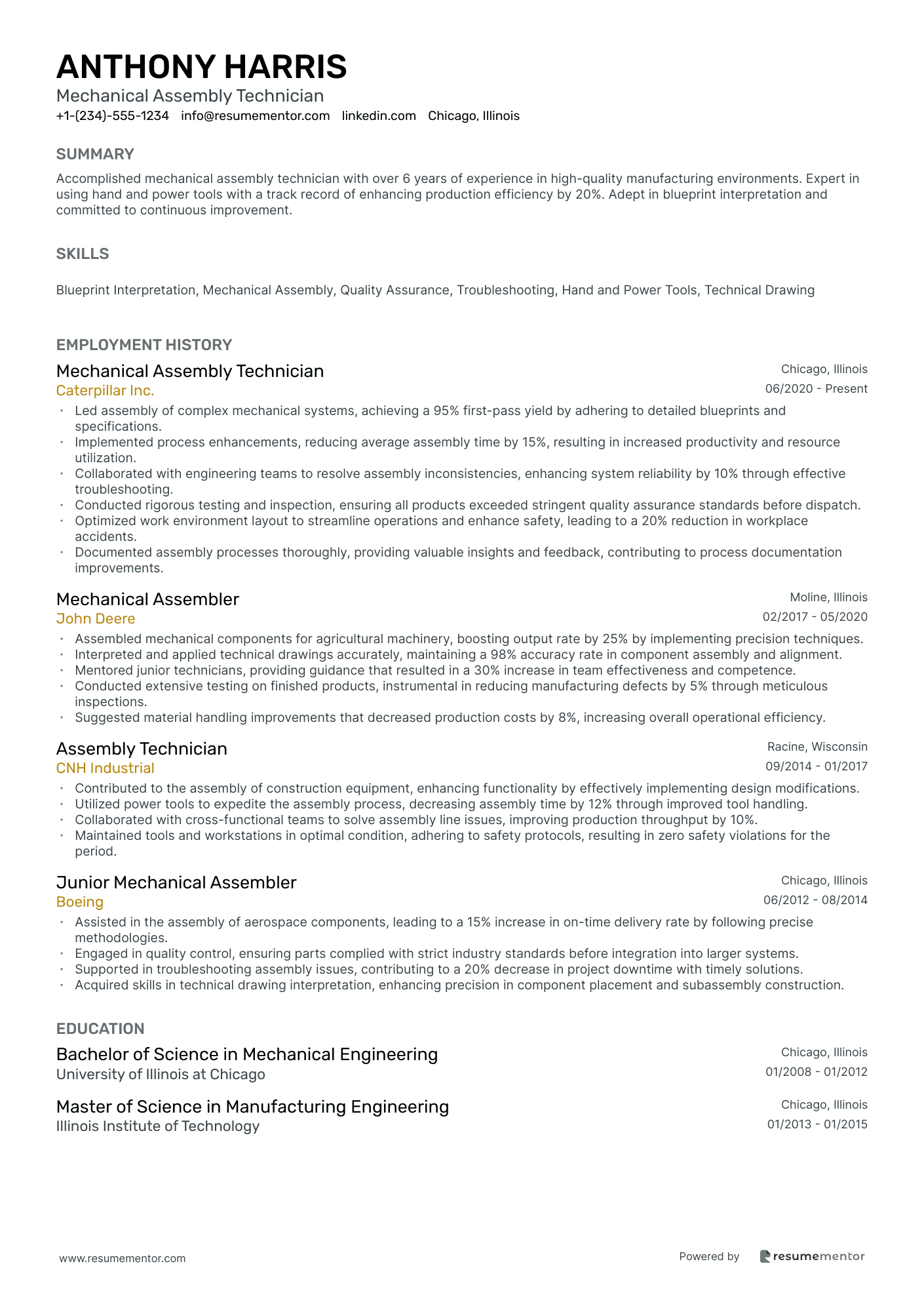

Mechanical Assembly Technician resume sample

- •Led assembly of complex mechanical systems, achieving a 95% first-pass yield by adhering to detailed blueprints and specifications.

- •Implemented process enhancements, reducing average assembly time by 15%, resulting in increased productivity and resource utilization.

- •Collaborated with engineering teams to resolve assembly inconsistencies, enhancing system reliability by 10% through effective troubleshooting.

- •Conducted rigorous testing and inspection, ensuring all products exceeded stringent quality assurance standards before dispatch.

- •Optimized work environment layout to streamline operations and enhance safety, leading to a 20% reduction in workplace accidents.

- •Documented assembly processes thoroughly, providing valuable insights and feedback, contributing to process documentation improvements.

- •Assembled mechanical components for agricultural machinery, boosting output rate by 25% by implementing precision techniques.

- •Interpreted and applied technical drawings accurately, maintaining a 98% accuracy rate in component assembly and alignment.

- •Mentored junior technicians, providing guidance that resulted in a 30% increase in team effectiveness and competence.

- •Conducted extensive testing on finished products, instrumental in reducing manufacturing defects by 5% through meticulous inspections.

- •Suggested material handling improvements that decreased production costs by 8%, increasing overall operational efficiency.

- •Contributed to the assembly of construction equipment, enhancing functionality by effectively implementing design modifications.

- •Utilized power tools to expedite the assembly process, decreasing assembly time by 12% through improved tool handling.

- •Collaborated with cross-functional teams to solve assembly line issues, improving production throughput by 10%.

- •Maintained tools and workstations in optimal condition, adhering to safety protocols, resulting in zero safety violations for the period.

- •Assisted in the assembly of aerospace components, leading to a 15% increase in on-time delivery rate by following precise methodologies.

- •Engaged in quality control, ensuring parts complied with strict industry standards before integration into larger systems.

- •Supported in troubleshooting assembly issues, contributing to a 20% decrease in project downtime with timely solutions.

- •Acquired skills in technical drawing interpretation, enhancing precision in component placement and subassembly construction.

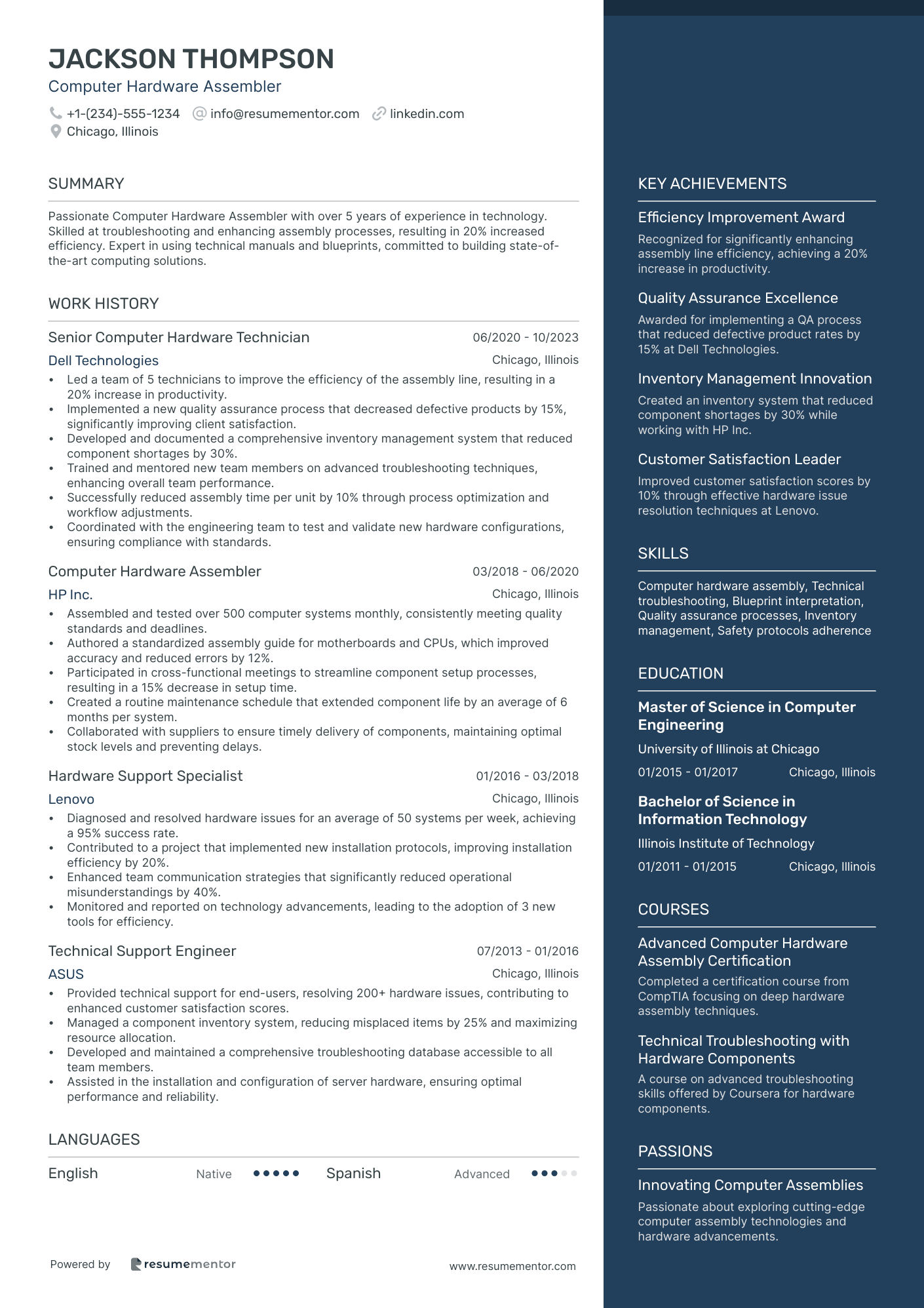

Computer Hardware Assembler resume sample

- •Led a team of 5 technicians to improve the efficiency of the assembly line, resulting in a 20% increase in productivity.

- •Implemented a new quality assurance process that decreased defective products by 15%, significantly improving client satisfaction.

- •Developed and documented a comprehensive inventory management system that reduced component shortages by 30%.

- •Trained and mentored new team members on advanced troubleshooting techniques, enhancing overall team performance.

- •Successfully reduced assembly time per unit by 10% through process optimization and workflow adjustments.

- •Coordinated with the engineering team to test and validate new hardware configurations, ensuring compliance with standards.

- •Assembled and tested over 500 computer systems monthly, consistently meeting quality standards and deadlines.

- •Authored a standardized assembly guide for motherboards and CPUs, which improved accuracy and reduced errors by 12%.

- •Participated in cross-functional meetings to streamline component setup processes, resulting in a 15% decrease in setup time.

- •Created a routine maintenance schedule that extended component life by an average of 6 months per system.

- •Collaborated with suppliers to ensure timely delivery of components, maintaining optimal stock levels and preventing delays.

- •Diagnosed and resolved hardware issues for an average of 50 systems per week, achieving a 95% success rate.

- •Contributed to a project that implemented new installation protocols, improving installation efficiency by 20%.

- •Enhanced team communication strategies that significantly reduced operational misunderstandings by 40%.

- •Monitored and reported on technology advancements, leading to the adoption of 3 new tools for efficiency.

- •Provided technical support for end-users, resolving 200+ hardware issues, contributing to enhanced customer satisfaction scores.

- •Managed a component inventory system, reducing misplaced items by 25% and maximizing resource allocation.

- •Developed and maintained a comprehensive troubleshooting database accessible to all team members.

- •Assisted in the installation and configuration of server hardware, ensuring optimal performance and reliability.

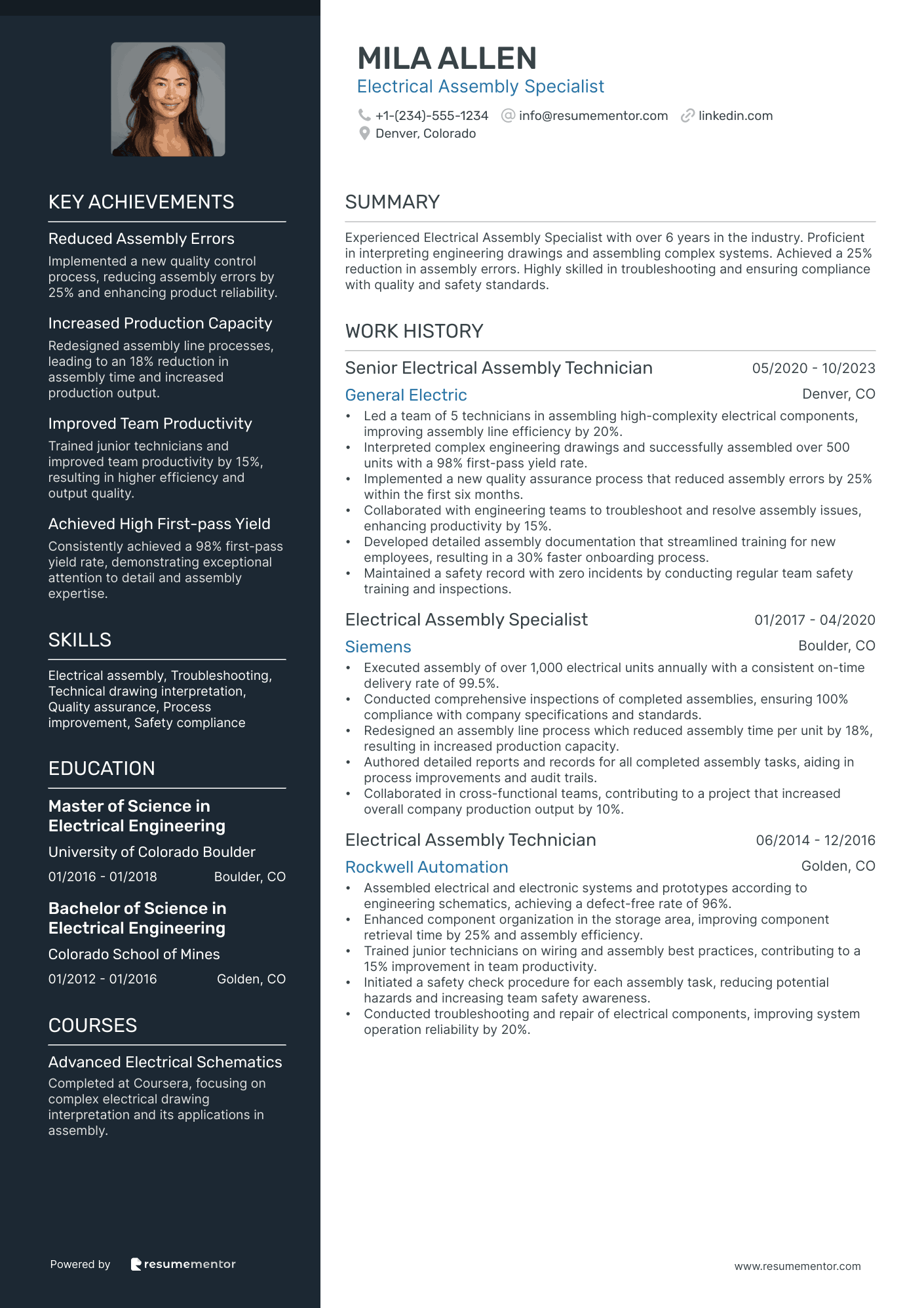

Electrical Assembly Specialist resume sample

- •Led a team of 5 technicians in assembling high-complexity electrical components, improving assembly line efficiency by 20%.

- •Interpreted complex engineering drawings and successfully assembled over 500 units with a 98% first-pass yield rate.

- •Implemented a new quality assurance process that reduced assembly errors by 25% within the first six months.

- •Collaborated with engineering teams to troubleshoot and resolve assembly issues, enhancing productivity by 15%.

- •Developed detailed assembly documentation that streamlined training for new employees, resulting in a 30% faster onboarding process.

- •Maintained a safety record with zero incidents by conducting regular team safety training and inspections.

- •Executed assembly of over 1,000 electrical units annually with a consistent on-time delivery rate of 99.5%.

- •Conducted comprehensive inspections of completed assemblies, ensuring 100% compliance with company specifications and standards.

- •Redesigned an assembly line process which reduced assembly time per unit by 18%, resulting in increased production capacity.

- •Authored detailed reports and records for all completed assembly tasks, aiding in process improvements and audit trails.

- •Collaborated in cross-functional teams, contributing to a project that increased overall company production output by 10%.

- •Assembled electrical and electronic systems and prototypes according to engineering schematics, achieving a defect-free rate of 96%.

- •Enhanced component organization in the storage area, improving component retrieval time by 25% and assembly efficiency.

- •Trained junior technicians on wiring and assembly best practices, contributing to a 15% improvement in team productivity.

- •Initiated a safety check procedure for each assembly task, reducing potential hazards and increasing team safety awareness.

- •Conducted troubleshooting and repair of electrical components, improving system operation reliability by 20%.

- •Performed assembly of electronic components in a fast-paced manufacturing environment, maintaining a 95% production schedule adherence.

- •Interpreted technical schematics to ensure accurate assembly of complex circuits, resulting in a significant reduction of rework rates.

- •Participated in cross-departmental quality improvement meetings, contributing innovative ideas that improved assembly precision.

- •Operated various hand and power tools to fabricate assembly parts, improving component fit and function in completed systems.

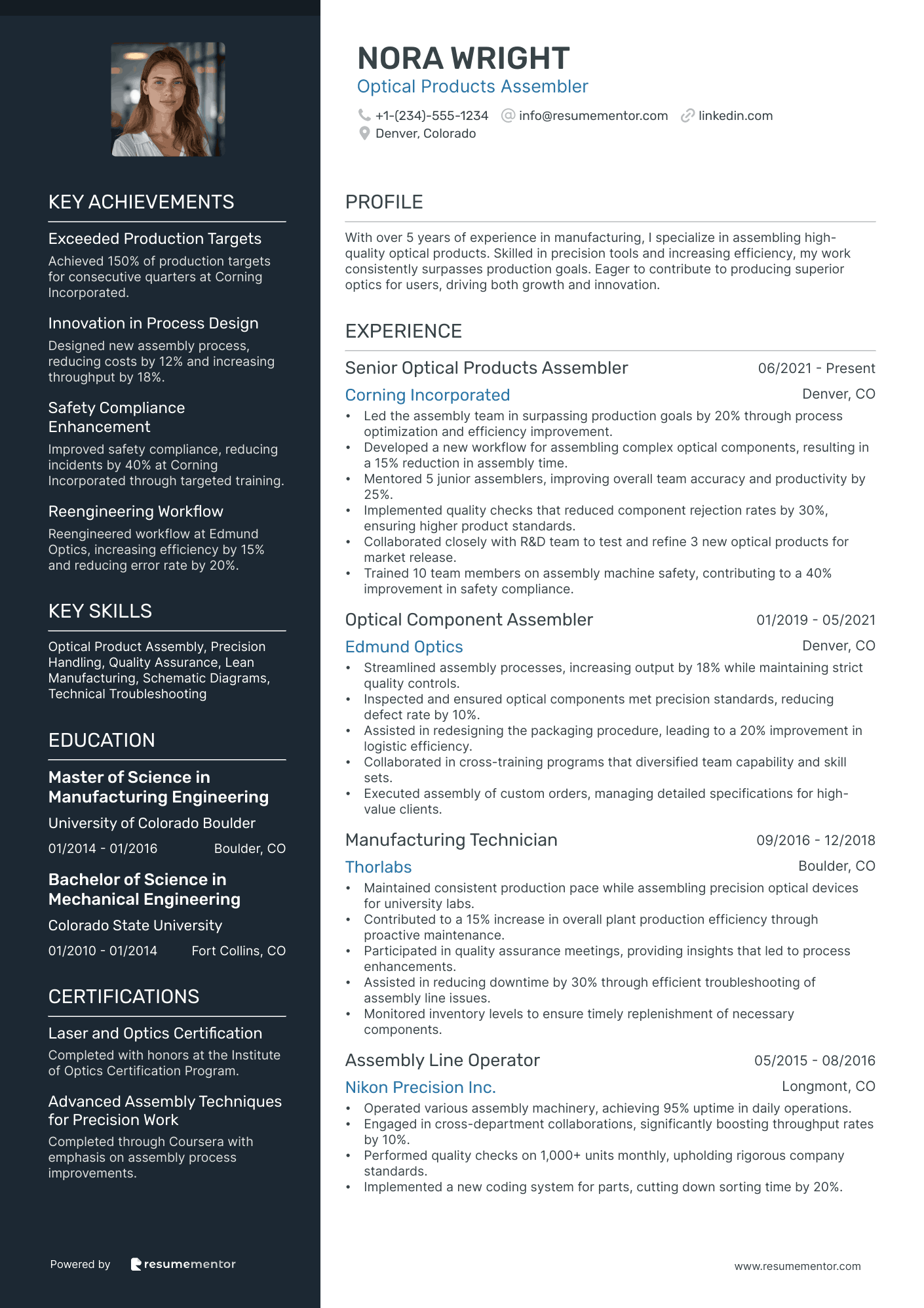

Optical Products Assembler resume sample

- •Led the assembly team in surpassing production goals by 20% through process optimization and efficiency improvement.

- •Developed a new workflow for assembling complex optical components, resulting in a 15% reduction in assembly time.

- •Mentored 5 junior assemblers, improving overall team accuracy and productivity by 25%.

- •Implemented quality checks that reduced component rejection rates by 30%, ensuring higher product standards.

- •Collaborated closely with R&D team to test and refine 3 new optical products for market release.

- •Trained 10 team members on assembly machine safety, contributing to a 40% improvement in safety compliance.

- •Streamlined assembly processes, increasing output by 18% while maintaining strict quality controls.

- •Inspected and ensured optical components met precision standards, reducing defect rate by 10%.

- •Assisted in redesigning the packaging procedure, leading to a 20% improvement in logistic efficiency.

- •Collaborated in cross-training programs that diversified team capability and skill sets.

- •Executed assembly of custom orders, managing detailed specifications for high-value clients.

- •Maintained consistent production pace while assembling precision optical devices for university labs.

- •Contributed to a 15% increase in overall plant production efficiency through proactive maintenance.

- •Participated in quality assurance meetings, providing insights that led to process enhancements.

- •Assisted in reducing downtime by 30% through efficient troubleshooting of assembly line issues.

- •Monitored inventory levels to ensure timely replenishment of necessary components.

- •Operated various assembly machinery, achieving 95% uptime in daily operations.

- •Engaged in cross-department collaborations, significantly boosting throughput rates by 10%.

- •Performed quality checks on 1,000+ units monthly, upholding rigorous company standards.

- •Implemented a new coding system for parts, cutting down sorting time by 20%.

As an assembler, you're a vital cog in the machinery that keeps industries moving smoothly. When it comes to crafting a resume, bringing out your hands-on skills and precision can be challenging. Balancing technical details with personal achievements often feels like fitting a puzzle together. This is where a resume template becomes invaluable, guiding you in organizing your experiences in a way that speaks to hiring managers. You can explore resume templates that simplify this task.

In today's job market, having a well-structured resume is essential for standing out among other candidates. Highlighting your ability to follow detailed instructions and demonstrating your precision is crucial. Employers look for evidence of your technical expertise, whether it's in assembly line strategies or quality control processes.

By focusing on these relevant skills and experiences, you ensure that your resume resonates with potential employers. A thoughtfully crafted resume opens doors and captures attention, paving the way for new opportunities. Just as each component in your work contributes to a final product, every detail you refine in your resume brings you closer to landing the job you want.

Key Takeaways

- A well-structured resume is essential for standing out in today's job market, especially in the manufacturing and assembly industries.

- Demonstrating technical expertise and precision in assembly processes is crucial for capturing the attention of potential employers.

- Focus on relevant skills, such as proficiency with hand tools, blueprint reading, and teamwork, to ensure your resume resonates with recruiters.

- Effective resume formatting includes using a chronological layout, modern fonts, and saving your document as a PDF to maintain its appearance.

- Including specific achievements, certifications, and skills in your resume can significantly enhance your appeal to employers.

What to focus on when writing your assembler resume

An assembler resume should clearly showcase your expertise in assembling components and operating machinery efficiently. It should emphasize your ability to read blueprints, prioritize attention to detail, and collaborate effectively with a team to ensure high-quality and precise production outcomes—this starts with making sure your contact information is current and easy to locate. Your full name, phone number, email address, and location are fundamental to establishing initial communication with potential employers.

How to structure your assembler resume

- Professional Summary: Your professional summary acts as a powerful introduction and should succinctly present your hands-on experience in manufacturing or assembly settings. Emphasize your success in achieving production targets and upholding quality assurance standards—this section will set the tone for how recruiters perceive your qualifications.

- Skills: Highlighting your skills provides recruiters with a snapshot of your capabilities; include competencies such as proficient use of hand tools, a keen understanding of assembly instructions, excellent teamwork skills, and a steadfast commitment to safety procedures—these are crucial elements of the assembling process and demonstrate your readiness for the role.

- Work Experience: Work experience is where you delve into the specifics of your career journey. By listing company names, job titles, locations, and employment dates, you provide context for your career path. Use this opportunity to detail accomplishments like boosting assembly line efficiency or leading successful large-scale projects which illustrate your proven track record.

- Education: Education is essential in establishing your foundation, so mention your highest completed level of education, including the school name, degree or certification, and graduation date—this demonstrates your commitment to learning and professional growth.

- Certifications: Certifications can further differentiate you from other candidates, so if you have relevant certifications like OSHA safety training or specialized equipment operation credentials, include them to reinforce your qualifications and preparedness for the job.

Now that you have an overview, it’s crucial to structure these sections within an effective resume format—below, we’ll explore each section more in-depth.

Which resume format to choose

Crafting a professional assembler resume can significantly enhance your chances of securing a role in the manufacturing industry. To best represent your experience and skills, consider using the chronological resume format. This style lays out your work history in a clear, straightforward timeline, emphasizing your growth and expertise in a way that's easy for employers to follow.

When it comes to font choice, selecting a modern option like Rubik, Lato, or Montserrat can give your resume a contemporary edge, enhancing readability and helping it stand out from those using traditional fonts like Arial or Times New Roman. These fonts offer a clean and fresh look that subtly emphasizes your attention to detail.

It's essential to save your resume as a PDF to maintain its formatting across various devices, ensuring that it appears professional and polished no matter who opens it. Pairing this with well-planned, one-inch margins around the document creates a balanced layout with enough white space, enhancing the document’s overall readability and inviting potential employers to read further.

By thoughtfully integrating these elements, you create a seamless and effective resume that highlights your qualifications as an assembler. This attention to detail can make a lasting impression on employers, increasing your chances of standing out in the competitive job market.

How to write a quantifiable resume experience section

- •Boosted assembly line efficiency by 15% through process improvements and teamwork.

- •Reduced product defects by 20% by introducing a new quality control protocol.

- •Trained 10 new hires, cutting onboarding time by 30%.

- •Worked with the engineering team to redesign a component, lowering costs by 25%.

Your experience section serves as the heart of your assembler resume, seamlessly weaving the story of your professional journey and achievements. Each role you list underscores your ability to add value, beginning with the most recent to keep your narrative clear and relevant. Tailoring your entries to match the job you're applying for highlights your adaptability and precision in meeting employer needs. Using strong action words like "boosted" and "trained" brings your accomplishments to life, painting a vivid picture of your impact. By focusing on the last 10-15 years, your resume remains relevant, emphasizing roles where you made significant contributions. With specific numbers and clearly defined improvements, the bullet points effectively convey how you've consistently driven success, ensuring potential employers quickly see how you can be a valuable asset to their team.

Innovation-Focused resume experience section

An innovation-focused resume experience section should emphasize your ability to bring fresh ideas to the table and solve problems creatively. Begin by selecting experiences where you implemented unique solutions that brought significant improvements. Clearly describe the context of each situation, the innovative actions you took, and the positive outcomes that resulted. Use vibrant, engaging language to highlight the benefits your innovations have provided to projects or the workplace. A strong focus on change and efficiency, supported by specific achievements and metrics, can make a compelling case for your capabilities.

Link your achievements by demonstrating the continuous impact of your innovative efforts. Use concise yet impactful language that ties together your accomplishments and how each step contributed to greater productivity. Including quantifiable results such as time savings or enhanced collaboration will strengthen the narrative of your proactive contributions and showcase your skill in driving meaningful improvements.

Innovation Specialist

ABC Tech Solutions

June 2020 - Present

- Introduced a new inventory tracking system that reduced errors by 30%

- Developed a streamlined process for team communications, improving efficiency by 25%

- Pioneered a green initiative that cut production waste by 15%

- Created a customer feedback loop that enhanced service quality and increased satisfaction scores

Achievement-Focused resume experience section

An achievement-focused assembler resume experience section should emphasize your accomplishments rather than just list your job duties. Begin by outlining specific contributions you made in your role as an assembler, using numbers and metrics to quantify your achievements. This approach highlights the impact of your actions on the company, showcasing improvements in processes or efficiencies that saved time and resources. Using action verbs will further enhance your accomplishments, making them stand out more clearly.

Your resume should effectively demonstrate how you've applied your skills in a professional setting. For instance, if you managed to cut assembly time, specify the percentage and describe how it improved overall productivity. Explain how your efforts supported company goals and broader objectives. Each of your achievements should align with skills and attributes that potential employers value, ensuring your resume captures their attention and leaves a memorable impression.

Senior Assembler

Tech Innovators Inc.

June 2020 – May 2023

- Improved assembly efficiency by 30% by streamlining workflow and introducing new techniques.

- Led a team to reduce production errors by 25%, enhancing product quality and cutting return rates.

- Implemented a new inventory system that decreased downtime by 20%, ensuring consistent production.

- Collaborated with cross-functional teams to devise cost-effective solutions, saving $50,000 annually.

Skills-Focused resume experience section

A skills-focused resume experience section should clearly highlight your strengths and demonstrate the impact you've made in past roles. Begin by emphasizing the key skills you used and the accomplishments you achieved, making sure to use strong action verbs that clearly convey your role and contributions. It's important to align these skills with the job you're pursuing, tailoring them to meet the specific needs of prospective employers. By doing so, you effectively show how your abilities can be transferred to the new position.

Organize your experience from the most recent to the oldest, ensuring each bullet point is concise and impactful—aim for just one line when possible. Quantifying your achievements with numbers can effectively illustrate your impact and highlight your successes. This approach showcases how your skills have evolved over time and how they align with future roles. By focusing on relevant experiences, you create a seamless narrative that positions you as the ideal candidate for the job.

Senior Project Manager

Tech Innovators Inc.

June 2020 - Present

- Led a team of 10 to complete a major project 20% under budget and ahead of schedule.

- Implemented a new planning strategy that increased efficiency by 30%.

- Coordinated cross-functional teams to streamline operations, resulting in a 15% reduction in delays.

- Facilitated weekly meetings to ensure clear communication and goal alignment across departments.

Collaboration-Focused resume experience section

A collaboration-focused resume experience section should begin by highlighting your ability to work well within a team and contribute to group achievements. Emphasize specific instances where your efforts helped achieve team goals, enhanced dynamics, or led joint projects. Use clear, concise language with strong action verbs to communicate your role and the positive impact you made. For each example, provide details about successful projects, including the strategies employed and the results obtained. Your ability to communicate effectively, resolve conflicts, and support team members should be woven throughout your descriptions.

When writing bullet points, aim for brevity while including enough detail to convey the significance of your contributions. Quantifiable results enhance clarity and demonstrate your accomplishments. Use language that highlights cooperation, such as "collaborated," "coordinated," or "worked closely with," to show your teamwork skills. By presenting your experiences this way, you convey to potential employers that you excel in collaborative environments and consistently support team success.

Project Coordinator

Tech Solutions Inc.

Jan 2020 - Present

- Coordinated with a team of five to improve project efficiency, leading to a 20% reduction in delivery time.

- Led weekly meetings to align team members, share updates, and tackle any roadblocks.

- Collaborated with cross-functional teams to craft a successful marketing strategy that increased product reach by 30%.

- Mentored junior team members, offering support and guidance to boost their professional growth.

Write your assembler resume summary section

A skill-focused assembler resume summary should effectively capture your professional strengths and achievements. It's essential to create a clear and cohesive statement that outlines your expertise and the unique value you offer. This section provides an opportunity to quickly engage the employer by spotlighting your key skills and accomplishments. For those with experience in assembly work, a summary could look like this:

This summary effectively weaves together your extensive experience, specific achievements, and technical skills. It not only highlights what you can do but also demonstrates the impact of your work. Mentioning specific efficiencies, such as a "20%" enhancement, adds credibility and depth to your profile.

For those entering the field, an objective is an excellent way to demonstrate enthusiasm and learning potential:

[here was the JSON object 2]

This objective connects your recent achievements and aspirations, making it suitable for someone at the beginning of their career. Understanding whether to use a resume summary or objective hinges on your experience level. A summary condenses your established skills and past successes, making it apt for seasoned professionals. An objective, however, communicates your career goals and fits those new to the field. Meanwhile, a resume profile offers a broader overview, blending skills with accomplishments, whereas a summary of qualifications highlights key points in a list form. Grasping these distinctions enables you to effectively present your career narrative in a manner that resonates with potential employers.

Listing your assembler skills on your resume

A skills-focused assembler resume should effectively communicate your technical abilities and personal strengths. When you're organizing your skills, you have a couple of options. You can choose to create a dedicated skills section or seamlessly incorporate your skills into areas like your experience or summary. Highlighting your strengths and soft skills is essential. Strengths represent the things you excel at, while soft skills such as teamwork, communication, and time management enhance your ability to collaborate with others. On the other hand, hard skills are specific abilities like operating machinery or using specialized software, crucial for assembler roles.

Using your skills and strengths as keywords can grab the attention of hiring managers and help your resume pass through resume-scanning software more effectively. Highlighting your capabilities in a straightforward manner helps employers easily identify what you can bring to the table.

Let's look at an example of a standalone skills section:

This section is effective because it provides a straightforward list of skills tailored to assembler roles. Each skill is clear and concise, allowing employers to quickly assess your suitability.

Best hard skills to feature on your assembler resume

Hard skills are crucial for an assembler, showcasing your technical expertise and operational efficiency. These skills highlight your ability to work safely and accurately within a production environment, proving your reliability in handling tools, equipment, and technology.

Hard Skills

- Assembly Line Techniques

- Precision Instrument Handling

- Blueprint Reading

- Quality Control

- Tool Calibration

- Mechanical Aptitude

- Inventory Management

- Use of Assembly Equipment

- Safety Protocol Compliance

- Component Installation

- Troubleshooting Machinery

- Production Process Efficiency

- Material Knowledge

- Welding Techniques

- Basic CNC Machine Operation

Best soft skills to feature on your assembler resume

In contrast, soft skills are key for fostering effective interaction and communication in the workplace. For an assembler, these skills demonstrate your capacity to work well in teams, adapt to change, and manage workloads efficiently.

Soft Skills

- Attention to Detail

- Teamwork

- Communication

- Time Management

- Adaptability

- Problem-Solving

- Reliability

- Patience

- Dedication

- Organization

- Initiative

- Flexibility

- Stress Management

- Conflict Resolution

- Accountability

How to include your education on your resume

An education section is an important part of your assembler resume. It shows employers your background and qualifications. Tailoring this section to the job you're applying for is crucial. Only include relevant education. Any unrelated education should be left out to keep the focus clear. If your GPA is impressive, consider including it. If you graduated with honors, like cum laude, add it to stand out. Listing your degree correctly is key: write the degree first, then the institution, and finish with the dates attended.

Here is an example of how not to write an education section:

Now, look at a well-written example:

- •Graduated cum laude

The second example is excellent because it highlights relevant education for an assembler position. Including a good GPA and cum laude honors adds credibility. These details make your resume more appealing to employers in the manufacturing industry. Tailoring this information helps convey your skills and dedication.

How to include assembler certificates on your resume

Including a certificates section in your resume is vital, especially for an assembler position. Certificates validate your skills and preparation for the job. Add this section to your resume to make your qualifications stand out. If you prefer a minimalistic design, consider placing your certifications in the header. For example: "Certified Assembly Technician, IPC, 2021."

List the certificate name first, which clearly states your qualification. Include the date you earned the certificate, as this shows how current your skills are. Add the issuing organization to provide credibility. A well-organized and relevant certificates section boosts your resume's impact.

This example is effective because the certifications are specific to the job. "Certified Assembly Technician" directly relates to assembly skills. "OSHA 10-Hour General Industry" is crucial for understanding safety standards. The use of the names and years makes it easy to understand your qualifications at a glance. With these details, hiring managers can quickly recognize your readiness for the role.

Extra sections to include on your assembler resume

Creating a well-rounded assembler resume can make a strong impression on potential employers. A concise resume not only highlights your skills but also reflects your personality and values. Including varied sections adds depth and showcases your diverse capabilities.

Language section — List additional languages you speak to show your ability to communicate in different settings. Highlighting language skills can enhance your ability to work with diverse teams and global partners.

Hobbies and interests section — Briefly share hobbies and interests that relate to teamwork or attention to detail. Employers might appreciate personal interests that align with company culture or promote soft skills.

Volunteer work section — Describe volunteer activities that involve technical or assembly-related skills. Demonstrating commitment to community service can reflect reliability and a strong work ethic.

Books section — Mention books you've read related to your field to showcase continuous learning and passion. This gives insight into your dedication and willingness to expand your industry knowledge.

Crafting a balanced resume with these sections can help you stand out as a well-rounded candidate and strengthen your application. Each section serves to personalize your resume and draw connections to the role you're applying for.

In Conclusion

In conclusion, crafting an effective assembler resume is an essential step in opening doors to new career opportunities. Your ability to balance technical details with personal achievements is crucial, and using a resume template can greatly aid in organizing this information. Highlighting your ability to follow instructions and your precision in work is highly valued by employers, and should be clearly demonstrated.

Focusing on relevant skills and experiences not only enhances the quality of your resume but also increases its appeal to potential employers. Sections such as your professional summary, skills, work experience, education, and any certifications should be detailed and tailored to reflect your unique contributions to the workplace. Every section and bullet point should work together, painting a vivid picture of your professional journey and making a compelling case for you as a prospective employee.

Choosing the right format and structure can make a significant difference, especially the chronological resume format, which effectively showcases your growth and expertise in a clear timeline. Additionally, pay attention to small details like font choice, file format, and margin sizes, as these can impact your resume's readability and overall appearance.

Incorporating a well-rounded approach by including extra sections such as languages, hobbies, and volunteer work can further distinguish you from other candidates. They provide a glimpse into your personality and values, which can help you connect with potential employers on a more personal level.

By focusing on these elements and carefully curating each section, you can create an assembler resume that not only stands out but also effectively communicates your qualifications and readiness for the next step in your career journey.

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2026. All rights reserved.

Made with love by people who care.