Continuous Improvement Manager Resume Examples

Jul 18, 2024

|

12 min read

"Create a standout continuous improvement manager resume with these tips. Boost your chances of landing an interview by showing how you can 'improve' the future of any company you join."

Rated by 348 people

Lean Continuous Improvement Manager

Business Process Improvement Manager

Operational Excellence Manager

Quality Assurance and Improvement Manager

Continuous Improvement Strategy Manager

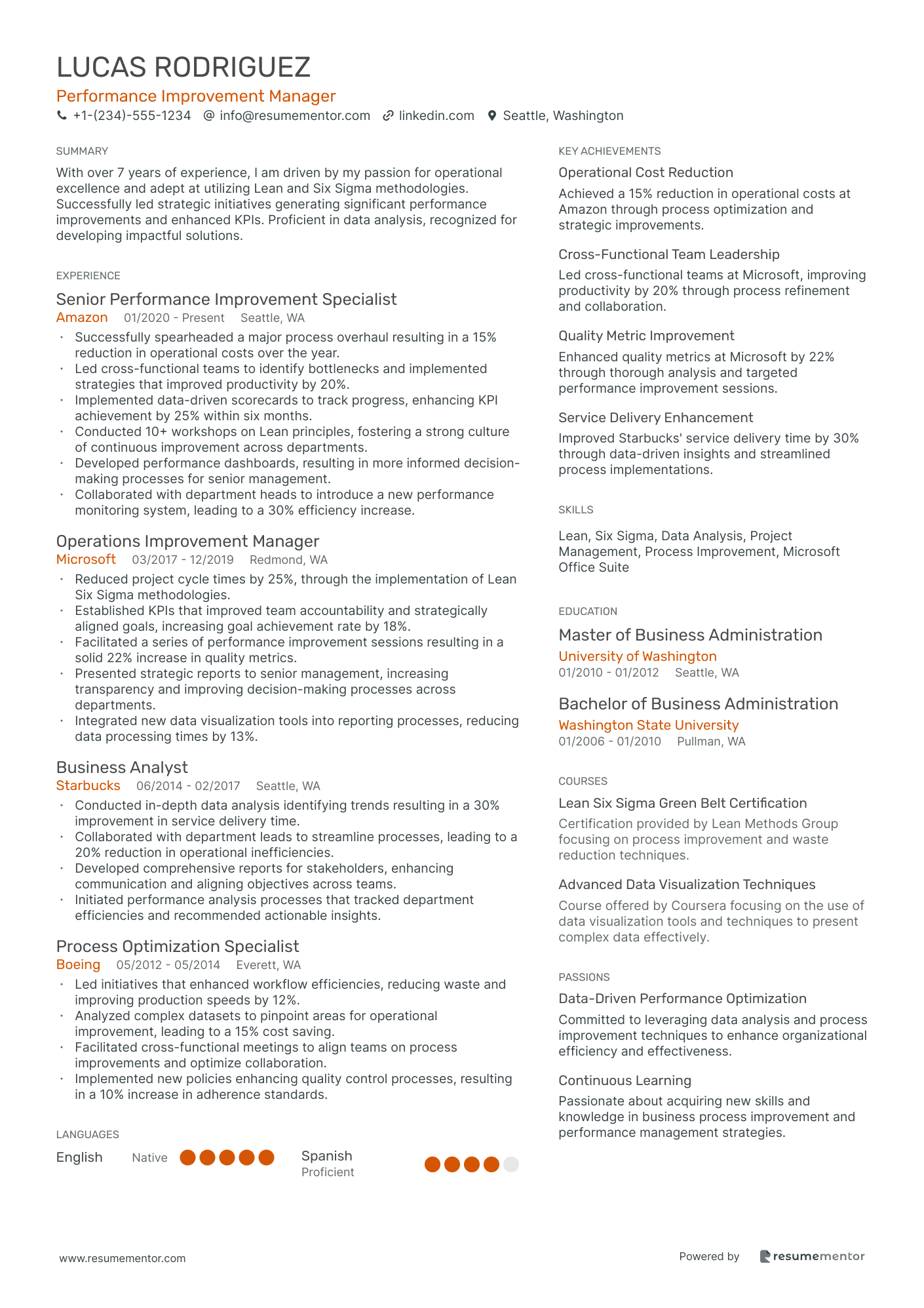

Performance Improvement Manager

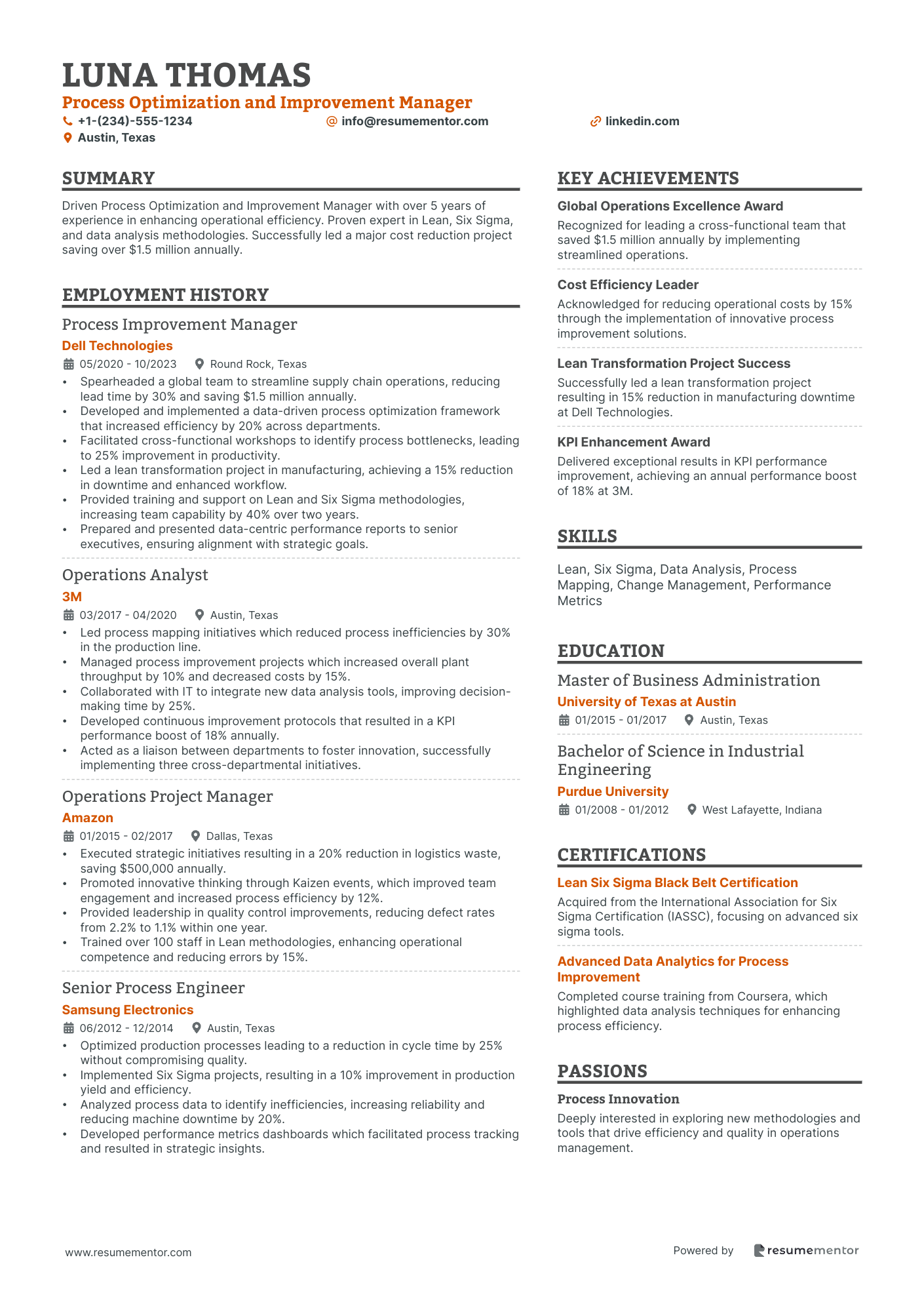

Process Optimization and Improvement Manager

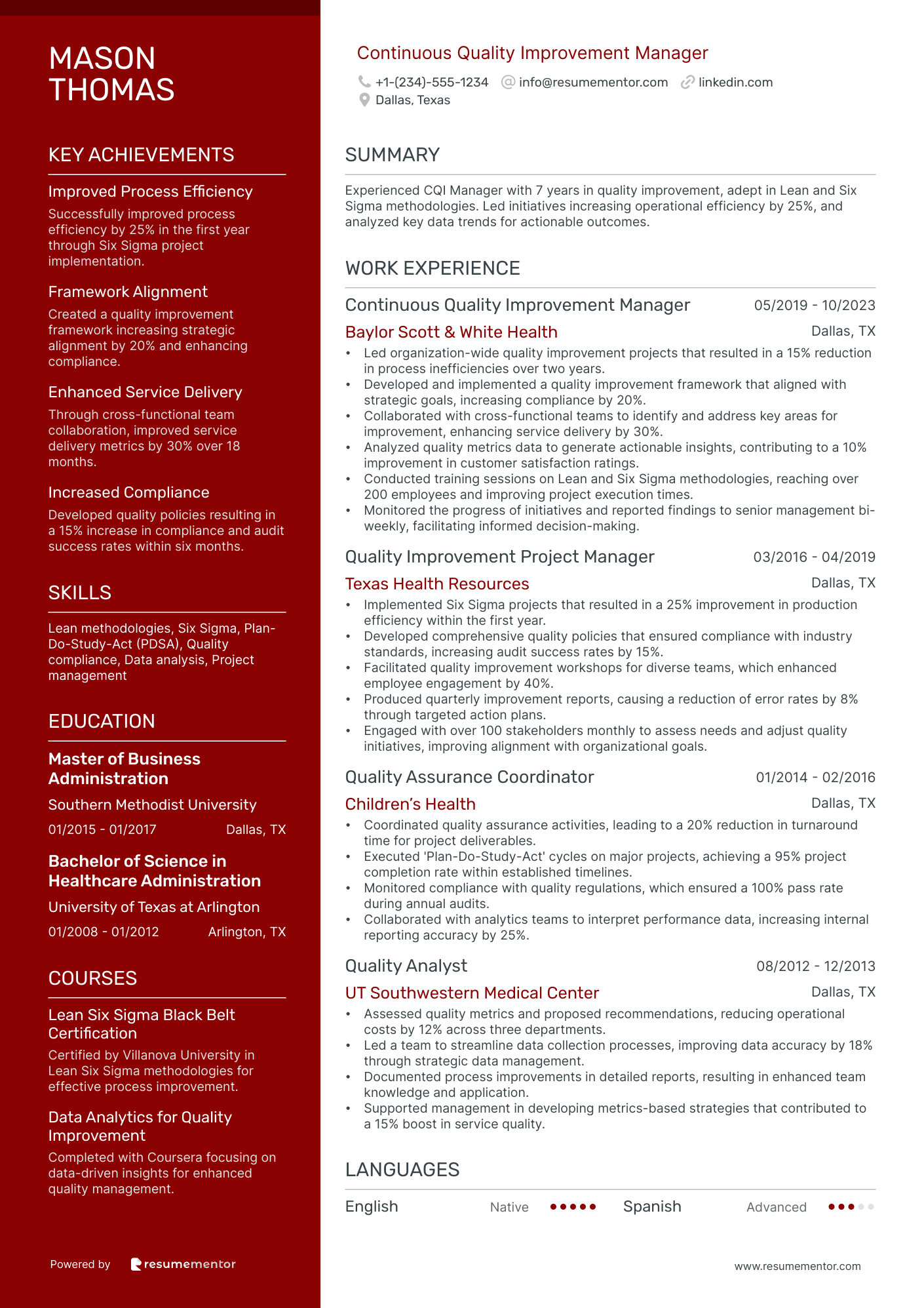

Continuous Quality Improvement Manager

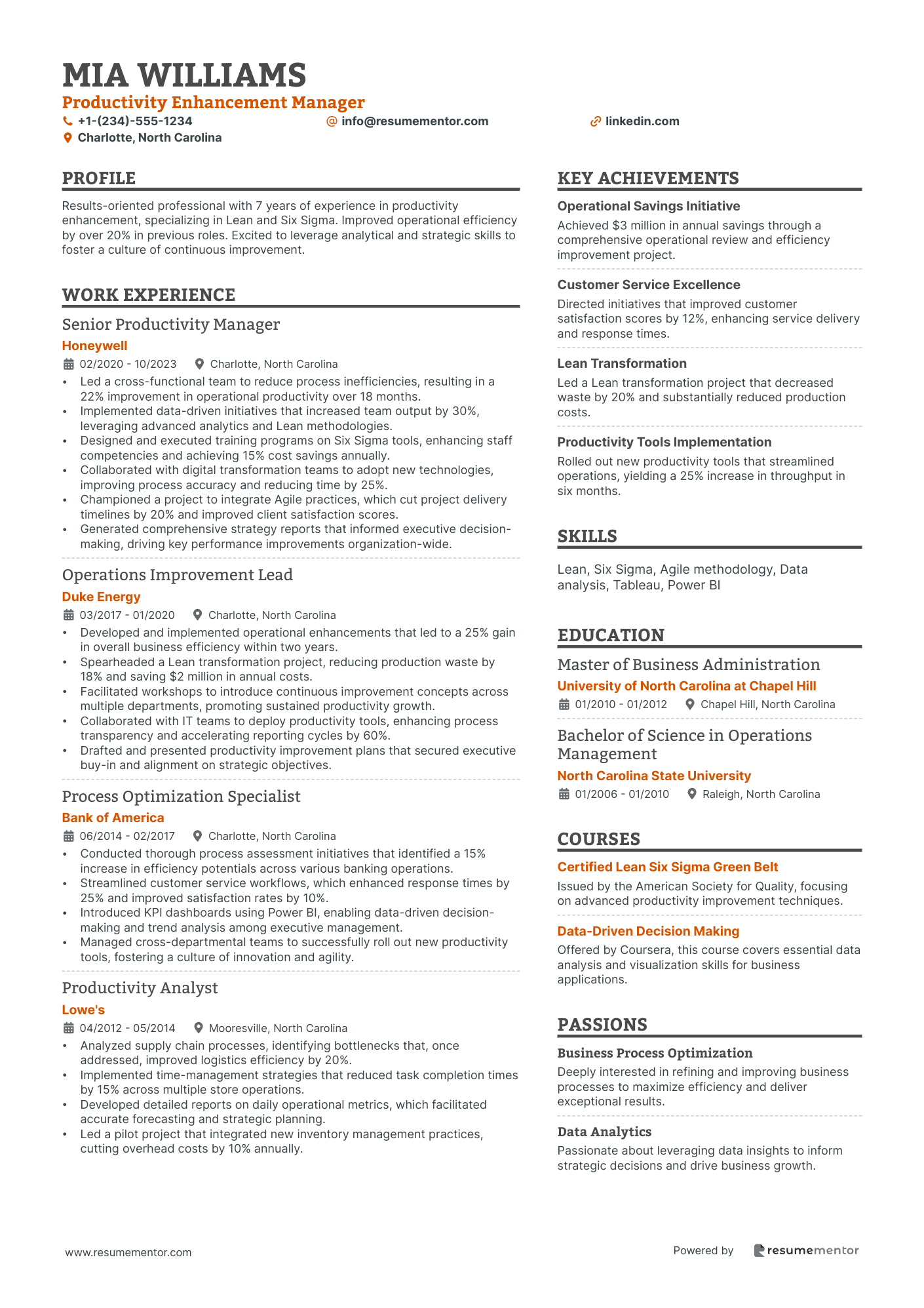

Productivity Enhancement Manager

Supply Chain Continuous Improvement Manager

Lean Continuous Improvement Manager resume sample

- •Led a cross-functional team in a Lean transformation project, increasing production efficiency by 20% over two years.

- •Developed and implemented comprehensive training programs on Lean methodologies, resulting in a 25% improvement in employee engagement in continuous improvement activities.

- •Spearheaded the optimization of quality control processes, leading to a 15% reduction in product defects and consistent compliance with industry standards.

- •Facilitated over 50 Kaizen events, bringing significant cost savings and process standardization across the manufacturing unit.

- •Implemented a data-driven approach to identify improvement opportunities, enhancing resource allocation and streamlining workflows.

- •Collaborated with leadership to align Lean initiatives with strategic business goals, resulting in increased organizational agility and responsiveness.

- •Directed the implementation of Lean principles in service operations, decreasing process lead time by 30%, significantly enhancing customer satisfaction.

- •Negotiated with stakeholders to identify key performance metrics for continuous improvement, leading to a 40% increase in project delivery timelines.

- •Orchestrated Lean Six Sigma training and development workshops, improving team capabilities and reducing operational complexities.

- •Successfully managed a team to conduct root cause analysis, leading to the resolution of recurring operational issues and enhancing process reliability.

- •Conducted regular process assessments, identifying bottlenecks and implementing solutions to achieve a 15% increase in productivity.

- •Led the implementation of 5S methodology in various departments, achieving a 20% improvement in workplace organization and efficiency.

- •Collaborated with department heads to streamline communication channels, resulting in a more cohesive approach to problem-solving and project management.

- •Drove the reduction of waste in production processes, leading to cost savings and better resource utilization across multiple projects.

- •Introduced Value Stream Mapping techniques, facilitating cross-functional collaboration and enhancing overall process visibility and efficiency.

- •Supervised a production team in Lean practices, achieving a 15% increase in throughput while maintaining quality standards.

- •Monitored production KPIs and developed action plans based on data analysis, optimizing operations and improving overall performance.

- •Coached team members on continuous improvement initiatives, fostering an environment open to innovative problem-solving techniques.

- •Coordinated with maintenance to reduce machine downtime by 25%, enhancing production schedules and meeting customer demands efficiently.

Business Process Improvement Manager resume sample

- •Led cross-functional team to streamline inventory processes, achieving a 25% reduction in inventory carrying costs.

- •Implemented Lean methodologies improving workflow efficiency by 30%, resulting in significant time savings per project.

- •Developed a comprehensive metrics system to track key performance indicators, increasing data-driven decision-making by 40%.

- •Collaborated with senior management on strategic initiatives improving operational efficiencies that enhanced customer satisfaction by 15%.

- •Introduced Six Sigma training programs for 50 employees which contributed to productivity improvements across departments.

- •Managed over $1M budget for process improvement initiatives with a fiscal responsibility, ensuring projects were delivered on time and under budget.

- •Spearheaded process refinement projects saving $350K annually by reducing process waste and inefficiencies.

- •Facilitated workshops identifying bottlenecks, improving cross-departmental communication by 20%, enhancing collaboration.

- •Designed and implemented a quality assurance program, reducing errors by 30% in critical projects.

- •Instrumental in the deployment of data analysis tools increasing dynamic reporting capabilities, boosting executive-level insights by 50%.

- •Fostered a culture of continuous improvement through regular training sessions and feedback loops, enhancing team adaptability.

- •Oversaw daily operations, leading a team to maintain/surpass operational benchmarks, achieving 98% compliance.

- •Strategically restructured staffing models, reducing overtime costs by 15% and aligning resources with business needs.

- •Developed new operational protocols increasing throughput by 25% in production lines while maintaining quality standards.

- •Led Lean Six Sigma projects which streamlined maintenance schedules, increasing equipment availability by 18%.

- •Engineered process modifications resulting in a 20% improvement in production efficiency, enhancing product delivery timelines.

- •Collaborated with R&D for innovative solutions that increased process efficiency by 15%, enhancing overall product quality.

- •Utilized Six Sigma methodology for problem-solving, reducing defect rates by 30% in key product lines.

- •Implemented visualization tools for real-time performance tracking, elevating transparency of process flows.

Operational Excellence Manager resume sample

- •Led a cross-functional team to implement Lean processes, reducing operational waste by 20% within the first year.

- •Developed a company-wide training program on Six Sigma methodologies, resulting in a 15% increase in employee participation.

- •Spearheaded an initiative to improve customer service response times, achieving a 30% reduction in average handling time.

- •Managed multiple high-impact projects simultaneously, ensuring delivery on time and under budget, contributing to a 25% increase in efficiency.

- •Created and monitored KPIs, which increased clarity in team objectives and enhanced decision-making processes by 40%.

- •Collaborated with senior leadership to streamline operations based on data-driven insights, which boosted productivity by 18%.

- •Led Six Sigma project to enhance supply chain process, decreasing lead time by 35% and increasing efficiency.

- •Conducted workshops and trainings on Lean methodologies, boosting operational efficiency and cutting costs by 12%.

- •Analyzed data to identify bottlenecks in production process, implementing solutions that increased output by 22%.

- •Oversaw process improvement projects, delivering them ahead of schedule and increasing team collaboration.

- •Collaborated with the R&D team to streamline new product introduction, reducing time-to-market by 10%.

- •Managed process reengineering projects for Fortune 500 clients, achieving cost savings of over 15%.

- •Implemented Kaizen principles to reorganize workflows and enhance team efficiency, leading to a 20% productivity increase.

- •Conducted performance data analysis to optimize client operations, enhancing service delivery by 25%.

- •Facilitated cross-functional teamwork to develop and execute process optimization strategies, meeting client objectives.

- •Supported operational excellence initiatives resulting in a 10% improvement in back-office processes.

- •Analyzed business data to identify inefficiencies, recommending solutions that cut administrative costs by 8%.

- •Developed reports and presented findings to stakeholders, impacting strategic decisions positively.

- •Collaborated with cross-functional teams to implement business process improvements, reducing error rates by 5%.

Quality Assurance and Improvement Manager resume sample

- •Implemented ISO 9001 standard across the division, reducing non-conformities by 30% over two years.

- •Led a team of 10 in executing quality improvement projects, resulting in a 20% enhancement in process efficiency.

- •Designed and facilitated a training program improving team expertise in Six Sigma, increasing overall skill assessment scores by 40%.

- •Managed quality data analysis and reporting, presenting monthly performance reviews to senior management and achieving improved decision-making speed.

- •Collaborated with R&D and production teams to reduce product defect rate by 15%, enhancing customer satisfaction and product reliability.

- •Implemented corrective actions for identified non-conformities, leading to a 25% reduction in repeat issues.

- •Conducted comprehensive audits and risk assessments, enhancing regulatory compliance and quality control measures.

- •Introduced advanced quality management software tools that increased quality assurance process efficiency by 18%.

- •Developed cross-functional initiatives that standardized quality benchmarks across departments, improving guideline adherence by 22%.

- •Executed root cause analysis for critical incidents, implementing corrective measures that minimized recurrence by 35%.

- •Orchestrated monthly reviews with stakeholders to discuss quality trends, which helped in strategizing improvements.

- •Oversaw quality assurance operations ensuring alignment with company standards, which resulted in certification maintenance.

- •Developed streamlined procedures that enhanced QA staff productivity by 15% through improved workflow strategies.

- •Facilitated cross-training sessions leading to a 30% rise in team versatility and skill interdependency.

- •Constructed data-driven quality reports that facilitated informed decision-making, increasing productivity standards by 10%.

- •Supported the implementation of quality assurance protocols contributing to a 10% improvement in product durability and reliability.

- •Participated in user testing sessions that helped reduce interface errors by 12%, enhancing user experience and satisfaction.

- •Enhanced communication processes that escalated issue resolution times by 30%, improving overall customer satisfaction.

- •Prepared and maintained comprehensive QA documentation, resulting in 100% completion and compliance in external audits.

Continuous Improvement Strategy Manager resume sample

- •Spearheaded strategic initiatives that optimized supply chain efficiency by 25%, resulting in significant cost reduction.

- •Led cross-functional teams to implement Lean principles, achieving a 30% reduction in process waste across departments.

- •Developed comprehensive KPIs for monitoring improvement projects, enhancing decision-making quality by 40%.

- •Facilitated Six Sigma workshops, empowering over 150 employees with advanced continuous improvement tools and skills.

- •Collaborated with senior leadership to design transformation strategies, increasing operational productivity by 20%.

- •Presented detailed reports detailing project progress and insights to executive leadership, enhancing strategic planning.

- •Implemented strategic initiatives that streamlined workflows, reducing production cycle times by 18%.

- •Enhanced cross-functional collaboration to resolve operational bottlenecks, increasing throughput by 25% in less than a year.

- •Conducted in-depth data analysis to identify improvement opportunities, achieving 15% increase in quality control metrics.

- •Delivered training sessions on Lean methodologies to over 120 team members, fostering a culture of continuous improvement.

- •Managed a portfolio of high-impact projects, resulting in operational savings of $2 million over 3 years.

- •Conducted process audits that identified key inefficiencies, leading to a 12% increase in departmental resource utilization.

- •Initiated Six Sigma projects that led to a 20% decline in defects, enhancing product quality and client satisfaction.

- •Collaborated with data analysts to derive actionable insights, steering informed decisions and process optimizations.

- •Improved employee engagement in project execution by facilitating interactive training on performance enhancement tools.

- •Utilized Six Sigma methodologies to enhance quality control processes, leading to a 30% reduction in error rates.

- •Managed projects focused on process transformation, achieving a 10% increase in operational efficiency.

- •Engaged stakeholders during KPI definition, aligning performance assessments to strategic objectives and priorities.

- •Launched successful training initiatives that improved staff skillsets in continuous improvement practices across divisions.

Performance Improvement Manager resume sample

- •Successfully spearheaded a major process overhaul resulting in a 15% reduction in operational costs over the year.

- •Led cross-functional teams to identify bottlenecks and implemented strategies that improved productivity by 20%.

- •Implemented data-driven scorecards to track progress, enhancing KPI achievement by 25% within six months.

- •Conducted 10+ workshops on Lean principles, fostering a strong culture of continuous improvement across departments.

- •Developed performance dashboards, resulting in more informed decision-making processes for senior management.

- •Collaborated with department heads to introduce a new performance monitoring system, leading to a 30% efficiency increase.

- •Reduced project cycle times by 25%, through the implementation of Lean Six Sigma methodologies.

- •Established KPIs that improved team accountability and strategically aligned goals, increasing goal achievement rate by 18%.

- •Facilitated a series of performance improvement sessions resulting in a solid 22% increase in quality metrics.

- •Presented strategic reports to senior management, increasing transparency and improving decision-making processes across departments.

- •Integrated new data visualization tools into reporting processes, reducing data processing times by 13%.

- •Conducted in-depth data analysis identifying trends resulting in a 30% improvement in service delivery time.

- •Collaborated with department leads to streamline processes, leading to a 20% reduction in operational inefficiencies.

- •Developed comprehensive reports for stakeholders, enhancing communication and aligning objectives across teams.

- •Initiated performance analysis processes that tracked department efficiencies and recommended actionable insights.

- •Led initiatives that enhanced workflow efficiencies, reducing waste and improving production speeds by 12%.

- •Analyzed complex datasets to pinpoint areas for operational improvement, leading to a 15% cost saving.

- •Facilitated cross-functional meetings to align teams on process improvements and optimize collaboration.

- •Implemented new policies enhancing quality control processes, resulting in a 10% increase in adherence standards.

Process Optimization and Improvement Manager resume sample

- •Spearheaded a global team to streamline supply chain operations, reducing lead time by 30% and saving $1.5 million annually.

- •Developed and implemented a data-driven process optimization framework that increased efficiency by 20% across departments.

- •Facilitated cross-functional workshops to identify process bottlenecks, leading to 25% improvement in productivity.

- •Led a lean transformation project in manufacturing, achieving a 15% reduction in downtime and enhanced workflow.

- •Provided training and support on Lean and Six Sigma methodologies, increasing team capability by 40% over two years.

- •Prepared and presented data-centric performance reports to senior executives, ensuring alignment with strategic goals.

- •Led process mapping initiatives which reduced process inefficiencies by 30% in the production line.

- •Managed process improvement projects which increased overall plant throughput by 10% and decreased costs by 15%.

- •Collaborated with IT to integrate new data analysis tools, improving decision-making time by 25%.

- •Developed continuous improvement protocols that resulted in a KPI performance boost of 18% annually.

- •Acted as a liaison between departments to foster innovation, successfully implementing three cross-departmental initiatives.

- •Executed strategic initiatives resulting in a 20% reduction in logistics waste, saving $500,000 annually.

- •Promoted innovative thinking through Kaizen events, which improved team engagement and increased process efficiency by 12%.

- •Provided leadership in quality control improvements, reducing defect rates from 2.2% to 1.1% within one year.

- •Trained over 100 staff in Lean methodologies, enhancing operational competence and reducing errors by 15%.

- •Optimized production processes leading to a reduction in cycle time by 25% without compromising quality.

- •Implemented Six Sigma projects, resulting in a 10% improvement in production yield and efficiency.

- •Analyzed process data to identify inefficiencies, increasing reliability and reducing machine downtime by 20%.

- •Developed performance metrics dashboards which facilitated process tracking and resulted in strategic insights.

Continuous Quality Improvement Manager resume sample

- •Led organization-wide quality improvement projects that resulted in a 15% reduction in process inefficiencies over two years.

- •Developed and implemented a quality improvement framework that aligned with strategic goals, increasing compliance by 20%.

- •Collaborated with cross-functional teams to identify and address key areas for improvement, enhancing service delivery by 30%.

- •Analyzed quality metrics data to generate actionable insights, contributing to a 10% improvement in customer satisfaction ratings.

- •Conducted training sessions on Lean and Six Sigma methodologies, reaching over 200 employees and improving project execution times.

- •Monitored the progress of initiatives and reported findings to senior management bi-weekly, facilitating informed decision-making.

- •Implemented Six Sigma projects that resulted in a 25% improvement in production efficiency within the first year.

- •Developed comprehensive quality policies that ensured compliance with industry standards, increasing audit success rates by 15%.

- •Facilitated quality improvement workshops for diverse teams, which enhanced employee engagement by 40%.

- •Produced quarterly improvement reports, causing a reduction of error rates by 8% through targeted action plans.

- •Engaged with over 100 stakeholders monthly to assess needs and adjust quality initiatives, improving alignment with organizational goals.

- •Coordinated quality assurance activities, leading to a 20% reduction in turnaround time for project deliverables.

- •Executed 'Plan-Do-Study-Act' cycles on major projects, achieving a 95% project completion rate within established timelines.

- •Monitored compliance with quality regulations, which ensured a 100% pass rate during annual audits.

- •Collaborated with analytics teams to interpret performance data, increasing internal reporting accuracy by 25%.

- •Assessed quality metrics and proposed recommendations, reducing operational costs by 12% across three departments.

- •Led a team to streamline data collection processes, improving data accuracy by 18% through strategic data management.

- •Documented process improvements in detailed reports, resulting in enhanced team knowledge and application.

- •Supported management in developing metrics-based strategies that contributed to a 15% boost in service quality.

Productivity Enhancement Manager resume sample

- •Led a cross-functional team to reduce process inefficiencies, resulting in a 22% improvement in operational productivity over 18 months.

- •Implemented data-driven initiatives that increased team output by 30%, leveraging advanced analytics and Lean methodologies.

- •Designed and executed training programs on Six Sigma tools, enhancing staff competencies and achieving 15% cost savings annually.

- •Collaborated with digital transformation teams to adopt new technologies, improving process accuracy and reducing time by 25%.

- •Championed a project to integrate Agile practices, which cut project delivery timelines by 20% and improved client satisfaction scores.

- •Generated comprehensive strategy reports that informed executive decision-making, driving key performance improvements organization-wide.

- •Developed and implemented operational enhancements that led to a 25% gain in overall business efficiency within two years.

- •Spearheaded a Lean transformation project, reducing production waste by 18% and saving $2 million in annual costs.

- •Facilitated workshops to introduce continuous improvement concepts across multiple departments, promoting sustained productivity growth.

- •Collaborated with IT teams to deploy productivity tools, enhancing process transparency and accelerating reporting cycles by 60%.

- •Drafted and presented productivity improvement plans that secured executive buy-in and alignment on strategic objectives.

- •Conducted thorough process assessment initiatives that identified a 15% increase in efficiency potentials across various banking operations.

- •Streamlined customer service workflows, which enhanced response times by 25% and improved satisfaction rates by 10%.

- •Introduced KPI dashboards using Power BI, enabling data-driven decision-making and trend analysis among executive management.

- •Managed cross-departmental teams to successfully roll out new productivity tools, fostering a culture of innovation and agility.

- •Analyzed supply chain processes, identifying bottlenecks that, once addressed, improved logistics efficiency by 20%.

- •Implemented time-management strategies that reduced task completion times by 15% across multiple store operations.

- •Developed detailed reports on daily operational metrics, which facilitated accurate forecasting and strategic planning.

- •Led a pilot project that integrated new inventory management practices, cutting overhead costs by 10% annually.

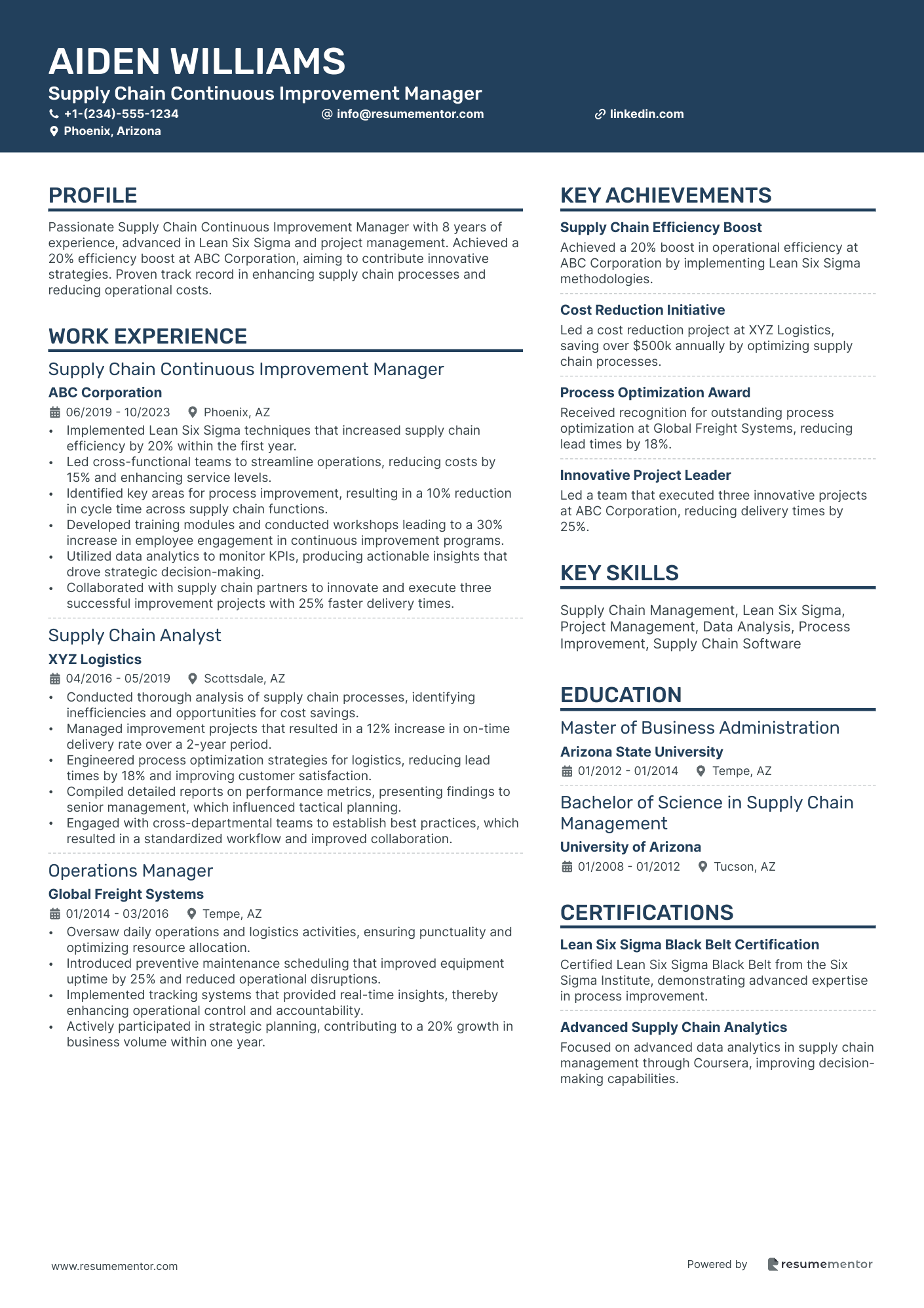

Supply Chain Continuous Improvement Manager resume sample

- •Implemented Lean Six Sigma techniques that increased supply chain efficiency by 20% within the first year.

- •Led cross-functional teams to streamline operations, reducing costs by 15% and enhancing service levels.

- •Identified key areas for process improvement, resulting in a 10% reduction in cycle time across supply chain functions.

- •Developed training modules and conducted workshops leading to a 30% increase in employee engagement in continuous improvement programs.

- •Utilized data analytics to monitor KPIs, producing actionable insights that drove strategic decision-making.

- •Collaborated with supply chain partners to innovate and execute three successful improvement projects with 25% faster delivery times.

- •Conducted thorough analysis of supply chain processes, identifying inefficiencies and opportunities for cost savings.

- •Managed improvement projects that resulted in a 12% increase in on-time delivery rate over a 2-year period.

- •Engineered process optimization strategies for logistics, reducing lead times by 18% and improving customer satisfaction.

- •Compiled detailed reports on performance metrics, presenting findings to senior management, which influenced tactical planning.

- •Engaged with cross-departmental teams to establish best practices, which resulted in a standardized workflow and improved collaboration.

- •Oversaw daily operations and logistics activities, ensuring punctuality and optimizing resource allocation.

- •Introduced preventive maintenance scheduling that improved equipment uptime by 25% and reduced operational disruptions.

- •Implemented tracking systems that provided real-time insights, thereby enhancing operational control and accountability.

- •Actively participated in strategic planning, contributing to a 20% growth in business volume within one year.

- •Coordinated logistics operations for a network of 15 warehouses, streamlining processes and yielding a 10% cost reduction.

- •Assisted in the implementation of inventory management software, contributing to a 20% improvement in inventory accuracy.

- •Conducted supplier negotiations, securing cost-effective contracts and resulting in a 15% reduction in procurement expenses.

- •Developed and maintained relationships with key stakeholders, ensuring consistent and effective communication throughout operations.

Crafting a compelling continuous improvement manager resume can feel like piecing together a complex puzzle, where your skills, achievements, and experience combine into a clear snapshot of your strengths. In your fast-paced world, efficiency and precision aren’t just important—they're essential, much like streamlining processes to capture attention and highlight your value to potential employers swiftly.

Yet, the challenge lies in transforming your analytical strengths and leadership into a form that aligns with industry standards. This means finding engaging ways to showcase your strategic vision and technical expertise that not only describe your past actions but also demonstrate how they led to significant improvements.

One way to simplify this task is by using a resume template. A well-structured template allows you to focus on your unique contributions and impactful results without getting bogged down in format details. Explore resume templates to discover a starting point that effectively showcases your qualifications.

Adopting a tailored resume approach positions you strategically in the job market, bringing your strengths into clear focus. This guide will assist you in crafting a standout resume, transforming potential opportunities into career advancements. Ready to take the first step? Let's ensure your resume captures the essence of the continuous improvement champion you truly are.

Key Takeaways

- Crafting a compelling resume entails showcasing your skills, strategic vision, and technical expertise in a format that aligns with industry standards.

- A well-structured resume template helps focus on your unique contributions without being bogged down in formatting details.

- Adopting a reverse chronological format with a professional font ensures that your expertise and achievements are easily appreciated by potential employers.

- Highlight specific, quantifiable achievements in past roles, utilizing strong action verbs to clearly convey your value and impact.

- Include relevant certifications and a well-tailored education section to emphasize your preparedness and technical foundation for complex problem-solving.

What to focus on when writing your continuous improvement manager resume

A continuous improvement manager resume should effectively convey your ability to drive change and enhance operational efficiency. It's important for recruiters to understand how you've improved processes and led initiatives that foster a culture of growth.

How to structure your continuous improvement manager resume

- Header: Begin with your name, contact information, and LinkedIn profile. This setup ensures that recruiters can easily connect with you—presenting a professional header shows attention to detail from the outset, a crucial trait for a continuous improvement manager.

- Professional Summary: Offer a snapshot of your experience, emphasizing skills like Lean Six Sigma and your dedication to advancing process improvement. This section should reflect your ability to innovate and lead successful improvement initiatives, setting the tone for the rest of your resume.

- Key Skills: Highlight abilities such as process optimization, data analysis, and change management. Include your expertise in methodologies like Kaizen and Lean to show your comprehensive approach—skills that are fundamental in adapting and refining business processes to ensure efficiency.

- Professional Experience: Provide details of your previous roles, focusing on accomplishments like cost reductions and productivity enhancements. Using numbers can clearly demonstrate your impact—illustrating how your efforts directly contribute to an organization's success is vital for this role.

- Education: List your academic background and crucial certifications like Six Sigma, along with any process improvement training, which ties your educational achievements to your professional skills—educational qualifications solidify your technical foundation and preparedness for complex problem-solving.

Including sections such as Awards, Projects, or Professional Affiliations can further spotlight your leadership and continuous improvement expertise, making your profile even more compelling. In the next section, we'll go deeper into each aspect, providing a clearer view of how to format your resume sections for maximum impact.

Which resume format to choose

As a continuous improvement manager, starting with the right resume format is key to effectively showcasing your expertise. The reverse chronological format is ideal because it highlights your most recent and relevant experiences first, making it easier for employers to follow your career journey and understand your impact within the industry.

Selecting the right font is also crucial for maintaining a professional edge. Opt for Lato, Montserrat, or Raleway, as they offer a clean, modern look that reflects your attention to detail and innovation. These fonts help your text stand out, ensuring your skills and achievements are easy to read and appreciate.

When saving your resume, using a PDF format is the smartest choice. PDFs preserve your formatting and design across all devices, which is important when presenting your strategic planning and continuous improvement projects. This ensures that hiring managers see your resume exactly as you intended, with no risk of accidental alterations that could disrupt your message.

Finally, maintaining a structured and organized appearance with your resume is essential. Using a 1-inch margin on all sides creates a visually appealing document with plenty of white space. This approach makes your resume easier to read and navigate, allowing employers to focus on your accomplishments and the value you can bring to their organization.

How to write a quantifiable resume experience section

The experience section in your continuous improvement manager resume plays a crucial role. It shines a light on your ability to drive improvement and achieve results. Start with your latest position and work backward, spotlighting roles that are relevant. It's important to highlight achievements with clear metrics that demonstrate your influence. Adjust your resume to each job application by customizing job titles, descriptions, and accomplishments to fit the role. Use strong action verbs like "implemented," "optimized," and "streamlined" to emphasize your contributions.

Keep your experience section relevant by including the last 10-15 years. Focus on roles that relate to improvement, such as process optimization or operational excellence, showcasing your successes and the results you delivered. Make sure your language and examples align well with the job you're aiming for.

- •Implemented a lean manufacturing strategy, cutting production costs by 15%.

- •Streamlined operations, reducing production lead times by 20%.

- •Led cross-functional teams in Kaizen events, boosting process efficiency by 25%.

- •Enhanced supply chain logistics, cutting delivery time by 30% and upping customer satisfaction.

This experience section effectively ties your achievements to real, measurable results, capturing the reader's attention. By using strong verbs and clear data, your value is clearly conveyed. Aligning achievements with business goals underscores your ability to instigate meaningful change. The straightforward structure focuses on the most pertinent experiences, ensuring your resume is more than just a job list; it tells a cohesive story of your continuous improvement journey.

Industry-Specific Focus resume experience section

A continuous improvement manager industry-focused resume experience section should highlight your ability to transform operations and boost efficiency. Consider the specific industry you are targeting, like manufacturing, healthcare, or technology, and tailor your experiences to align with their unique needs. By showcasing real examples and using measurable results, you can demonstrate how you've driven change and led teams to success.

Engage readers with action-oriented language that ties your skills and achievements together in a cohesive narrative. Describe the projects you've led, the methodologies or tools employed, and the impactful results you've achieved. Whether you’ve streamlined processes or introduced new systems, weave examples that showcase your problem-solving abilities and leadership skills throughout your experience. Ensure that your accomplishments resonate with the industry's values and challenges, capturing the attention of potential employers.

Continuous Improvement Manager

ABC Manufacturing Co.

June 2018 - Present

- Led a team to redesign workflows, boosting efficiency by 20% in the manufacturing department.

- Applied Six Sigma methods to various projects, achieving a 15% annual cost reduction.

- Created a real-time performance tracking dashboard, cutting reporting time by 30%.

- Trained over 50 employees in lean processes, enhancing their operational skills and performance.

Achievement-Focused resume experience section

A continuous improvement-focused resume experience section should vividly illustrate how your efforts have driven positive change in your past roles. Start by sharing examples of how you've enhanced quality, minimized costs, and streamlined processes. It's crucial to use specific numbers and metrics to highlight the tangible benefits of your work, clearly connecting your initiatives to results that made a difference in the organization.

Using strong action verbs, describe your role in inspiring teams to embrace innovation and increase efficiency. Seamlessly weave in stories of successful projects where your leadership was pivotal. Each accomplishment should reinforce the previous one, showcasing a consistent pattern of value creation and problem-solving that keeps the reader engaged and paints a comprehensive picture of your achievements.

Continuous Improvement Manager

ABC Manufacturing

June 2020 - Present

- Implemented a new lean process methodology, slashing manufacturing costs by 15% in just six months.

- Led a cross-functional team to streamline operations, boosting production efficiency by 20%.

- Developed a staff training program that enhanced skills and cut error rates by 30%.

- Initiated a waste reduction strategy, decreasing scrap material by 25% annually.

Skills-Focused resume experience section

A skills-focused continuous improvement manager resume experience section should emphasize your ability to drive and manage change effectively. Start by highlighting key skills required for your target role, such as process optimization, data analysis, and leadership. Then, align your experiences to showcase these skills clearly. Each bullet point should reflect a specific accomplishment or situation where your expertise mattered, illustrating how you used these skills in a practical setting.

Specificity is crucial; mention the actions you took and quantify the results with numbers, like cost reductions or efficiency improvements. This results-oriented approach makes your resume stand out to employers. To provide a deeper insight into your capabilities, add context to each achievement by discussing challenges you faced and how you resolved them. This demonstrates not only your technical skills but also your problem-solving abilities and adaptability.

Continuous Improvement Manager

Industrial Solutions Corp

January 2020 - Present

- Led a team of 10 in implementing a lean manufacturing process that reduced production waste by 25%.

- Developed and implemented a new quality control system, improving product consistency and reducing defects by 15%.

- Trained staff on Kaizen methods, resulting in a 30% increase in team-led improvement initiatives.

- Analyzed production data to identify bottlenecks, streamlining operations and reducing cycle time by 10%.

Responsibility-Focused resume experience section

A responsibility-focused continuous improvement manager resume experience section should clearly highlight the responsibilities you've taken on and the achievements you've accomplished. Start by listing your job title, the company you worked for, and the dates of employment. As you describe each bullet point, aim to showcase specific accomplishments or key responsibilities that demonstrate your expertise in fostering continuous improvement. Using action verbs will help convey how you initiated change and led improvements, proving your ability to make impactful contributions.

To strengthen your statements, quantify your achievements to illustrate the significant impact of your initiatives. Including metrics such as cost reductions, enhanced efficiency, or improved productivity provides tangible evidence of your work's success. This approach not only adds depth to your resume but also paints a vivid picture of the value you brought to your organization, helping you stand out as a candidate.

Continuous Improvement Manager

Tech Innovations Inc.

June 2018 - August 2023

- Reduced operational costs by 15% through streamlined processes and waste reduction initiatives.

- Implemented a new feedback system, increasing team efficiency by 20% over 12 months.

- Collaborated with cross-functional teams to drive initiatives that improved product quality and customer satisfaction.

- Trained staff on Lean Six Sigma principles, resulting in a 30% decrease in process errors.

Write your continuous improvement manager resume summary section

A continuous improvement manager's resume summary should capture your ability to transform processes and drive change within an organization. Highlighting your experience and skills in this section is key to grabbing a potential employer's attention. For example:

This example effectively illustrates your professional strengths by communicating your expertise and achievements in a clear and engaging way. It begins by acknowledging your experience level and transitions into the specific skills that make you stand out, such as leadership and data analytics. By mentioning Lean and Six Sigma methodologies, it signals your specialized knowledge, which is important for this role. Each point flows naturally into the next, making it easy for hiring managers to grasp your capabilities at a glance.

When you describe yourself in a resume summary, it's vital to focus on key strengths and achievements while weaving in unique skills relevant to the job. Action verbs can help project your impact, and customizing the language to align with the job description adds a personal touch that can quickly engage hiring managers.

Compared to a resume summary, a resume objective centers around your career goals and is often more suitable for those with less experience. In contrast, a resume profile might blend career aspirations with skills in a shorter format. Meanwhile, a summary of qualifications provides a straightforward list of achievements and skills. By understanding these distinctions, you can choose the best format to communicate your strengths and experience most effectively to employers.

Listing your continuous improvement manager skills on your resume

A skills-focused continuous improvement manager resume should clearly present your strengths and relevant abilities. Your skills can either have their own section or be integrated into your experience and summary areas. By showcasing your strengths and soft skills, such as leadership and communication abilities, you give employers a glimpse of your personal and interpersonal capabilities. Hard skills, like proficiency in project management tools or knowledge of Lean methodologies, are specific, teachable abilities that demonstrate your technical expertise.

Highlighting the right skills and strengths acts as powerful keywords in your resume, helping it stand out to employers and overcoming Applicant Tracking Systems. Therefore, focus on skills that are relevant to the position, as this effectively showcases your qualifications.

Here's an example of how to present a standalone skills section:

This skills section successfully highlights key abilities relevant to a continuous improvement manager, making them powerful resume keywords due to their industry recognition and relevance.

Best hard skills to feature on your continuous improvement manager resume

Focusing on hard skills in your resume is essential for highlighting your proficiency and reliability. These skills indicate your capability to drive process enhancements and boost productivity. The most in-demand hard skills for this role include:

Hard Skills

- Lean Manufacturing

- Six Sigma

- Project Management

- Data Analysis

- Process Mapping

- Process Optimization

- Quality Assurance

- Change Management

- Performance Metrics

- Kaizen Methodologies

- Root Cause Analysis

- Enterprise Resource Planning (ERP)

- Workflow Automation

- Risk Assessment

- Statistical Process Control (SPC)

Best soft skills to feature on your continuous improvement manager resume

Equally important are soft skills, which demonstrate how well you can work with others and adapt to changes. For a continuous improvement manager, these skills highlight your ability to lead, inspire, and manage successfully. Key soft skills in this field include:

Soft Skills

- Leadership

- Communication

- Problem-Solving

- Critical Thinking

- Adaptability

- Teamwork

- Negotiation

- Relationship Building

- Time Management

- Conflict Resolution

- Decision-Making

- Empathy

- Patience

- Motivation

- Creativity

How to include your education on your resume

An education section is a vital part of a resume, especially for a continuous improvement manager role. Tailoring this section to the job you're applying for increases your chances of grabbing the hiring manager's attention. Exclude any irrelevant educational experiences to maintain focus and relevancy. If you excelled academically, including your GPA can showcase your dedication. When listing it, clearly state both your GPA score and the scale, such as 3.8/4.0. If you graduated with honors, like cum laude, it's a significant achievement worth mentioning alongside your degree. Make sure to list your degree accurately, including the discipline and title, such as "Bachelor of Science in Industrial Engineering."

Here’s a bad example of an education section:

And a better example:

The second example displays a degree that aligns with a continuous improvement manager role. Its focus on industrial engineering demonstrates relevance. A high GPA can highlight diligence and aptitude in the field. Having both the months and years indicates commitment to a complete academic program. Such details are crucial for creating a strong impression.

How to include continuous improvement manager certificates on your resume

Including a certificates section on your resume is essential, especially for a continuous improvement manager. Certificates validate your skills and can set you apart from other candidates. Certificates can also be included in the header to immediately catch the hiring manager's eye.

List the name of each certification clearly. Include the date when you earned the certification. Add the issuing organization to provide authenticity. For instance, “Six Sigma Black Belt” (SSC), “Lean Management” (LEAN), and “Project Management Professional (PMP)” (PMI) are notable certifications for continuous improvement roles.

Here is an effective example:

This example is good because it includes relevant certifications, properly lists the issuing organizations, and provides a straightforward format. These certifications are highly valued in the industry and demonstrate expertise. This clarity makes it easy for hiring managers to understand your qualifications quickly.

Extra sections to include in your continuous improvement manager resume

In the fast-paced world of business, having a keen eye for improving processes is crucial. As a Continuous Improvement Manager, you play a pivotal role in ensuring that operations run smoothly and efficiently. Highlighting your comprehensive skill set on your resume helps you stand out from the crowd.

Language section—Showcase your multilingual abilities to emphasize strong communication skills. Including languages demonstrates your potential to work in diverse environments and with international teams.

Hobbies and interests section—Include relevant hobbies to show your personality and soft skills. Activities like puzzles or coding can hint at your problem-solving prowess, which is essential for this role.

Volunteer work section—Highlight volunteer activities to reflect your commitment to social responsibility. This section helps portray a well-rounded character beyond professional qualifications.

Books section—Mention industry-related books you've read to illustrate your commitment to continuous learning. Referencing influential works can make you seem more knowledgeable and dedicated to your field.

In Conclusion

In conclusion, crafting an effective continuous improvement manager resume involves more than just listing your past jobs and responsibilities. It requires a strategic approach to highlight your skills and achievements that drive change and operational efficiency. By leveraging a structured template, you can focus on presenting your unique contributions and results in a clear and impactful way. Tailoring each resume to fit specific job roles emphasizes your strengths and positions you as a valuable candidate in the job market. Remember to quantify your achievements with metrics and use strong action verbs to showcase your impact. Whether it's reducing costs, boosting efficiency, or leading successful initiatives, your resume should tell a cohesive story of your career journey. Including relevant certifications and a well-thought-out education section bolsters your technical foundation and expertise. Lastly, remember to weave in your soft skills to paint a complete picture of your leadership and teamwork abilities. By paying attention to all these elements, you'll create a resume that not only attracts employers but also unlocks new career opportunities.

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2026. All rights reserved.

Made with love by people who care.