Industrial Engineer Resume Examples

Jul 18, 2024

|

12 min read

Craft your industrial engineer resume: engineer your future with standout skills and precision-tuned formatting tips. Perfectly tailored for your next job search.

Rated by 348 people

Production Process Engineer

Operational Efficiency Engineer

Industrial Quality Assurance Engineer

Automation and Robotics Engineer

Industrial Supply Chain Engineer

Human Factors and Ergonomics Engineer

Plant Safety and Risk Management Engineer

Industrial Lean Process Engineer

Operations Research Engineer

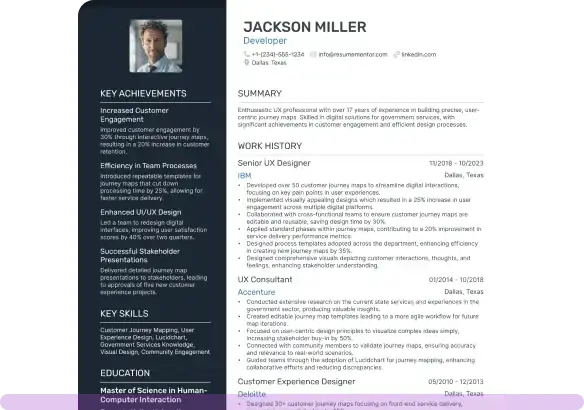

Production Process Engineer resume sample

When applying for this role, it’s important to showcase any hands-on experience in process improvement or quality control. Highlight your familiarity with Lean manufacturing, Six Sigma, or other methodologies that enhance efficiency. Be sure to include any relevant projects or internships where you optimized production workflows. Mention specific tools or software you've used, like CAD or ERP systems, to demonstrate your technical skills. Use a 'skill-action-result' format to illustrate how your contributions led to cost savings or improved production rates in past roles.

- •Led a team to implement Lean manufacturing principles, achieving a 30% reduction in production lead time.

- •Strategized and executed Six Sigma projects that resulted in a 25% increase in throughput.

- •Developed comprehensive process documentation, thereby reducing onboarding time for new hires by 40%.

- •Collaborated with cross-functional teams to identify and resolve a major bottleneck, increasing product output by 15%.

- •Conducted audits ensuring compliance with ISO 9001 standards, reducing non-compliance incidents by 50%.

- •Provided technical training to production staff, resulting in a 20% reduction in process deviation errors.

- •Improved material flow processes, resulting in a 20% reduction in material waste.

- •Led the introduction of new automated systems, increasing production efficiency by 18%.

- •Collaborated on the development of new work instructions, reducing cycle time by 10%.

- •Facilitated cross-departmental process improvement workshops, generating innovative solutions leading to a 15% improvement in process alignment.

- •Analyzed production KPIs and implemented improvements that decreased downtime by 12%.

- •Implemented standard operating procedures that improved product quality by 20%.

- •Supported new product introduction, streamlining the transition process and reducing time-to-market by 15%.

- •Conducted root cause analysis on production failures, implementing corrective actions that reduced defect rates by 25%.

- •Worked closely with the safety team to adopt best practices, resulting in a 30% improvement in safety compliance.

- •Developed new process evaluation techniques, leading to a 10% improvement in operational efficiency.

- •Participated in cross-functional initiatives that reduced manufacturing cycle time by 15%.

- •Implemented continuous improvement plans that sustainably reduced costs by 5%.

- •Provided engineering support for troubleshooting, resulting in a 20% reduction in production disruptions.

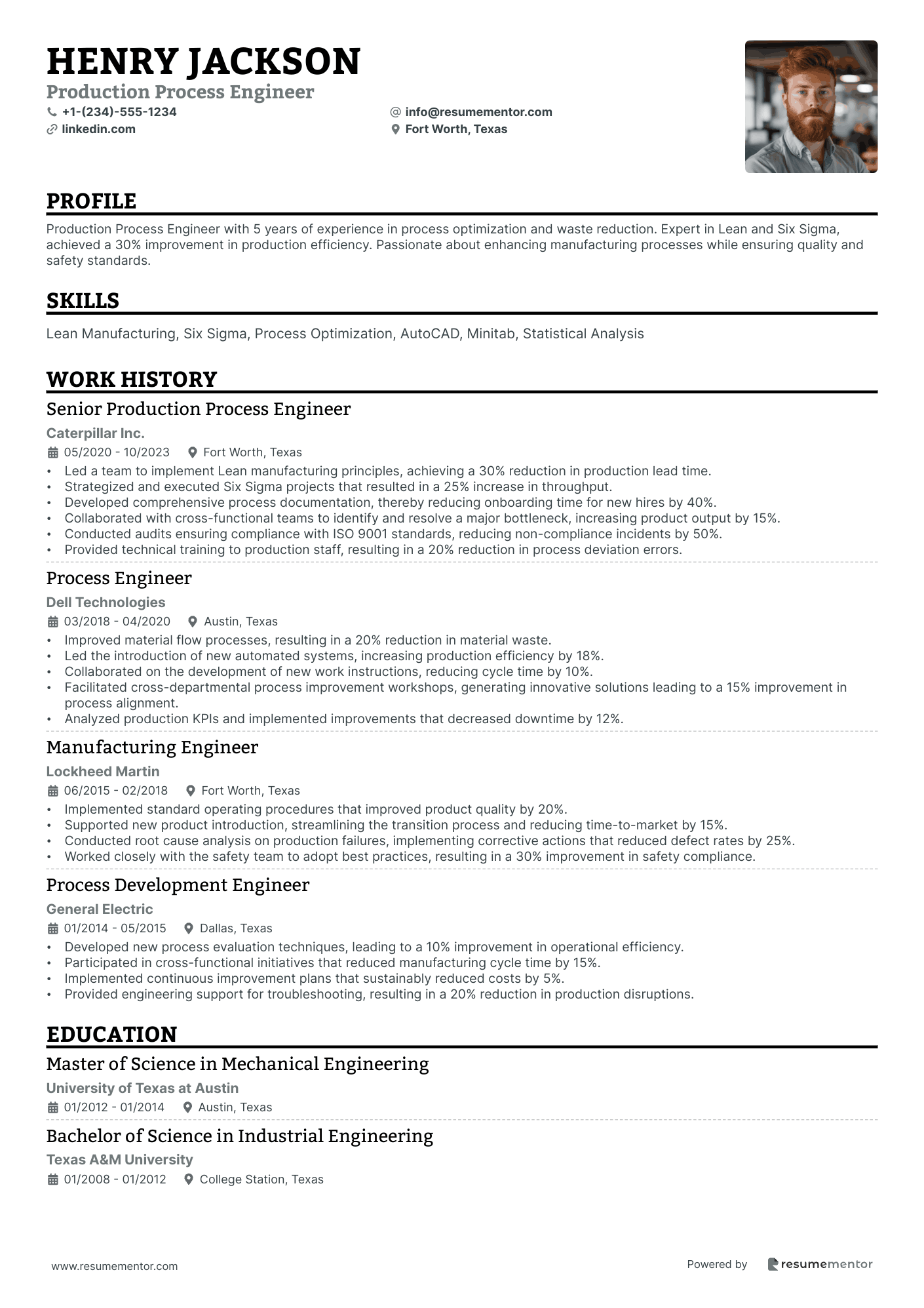

Operational Efficiency Engineer resume sample

When applying for this role, highlight your experience in process improvement and lean methodologies. Include any certifications like 'Lean Six Sigma' or 'Kaizen' to demonstrate your qualifications. It's important to provide examples of how you identified inefficiencies and successfully implemented solutions. Focus on data-driven results to showcase your analytical skills. Use specific metrics, such as reduced cycle times or cost savings, to illustrate your impact. Additionally, emphasize collaboration with cross-functional teams to demonstrate your ability to drive change effectively.

- •Led a project to streamline manufacturing processes, decreasing production time by 15%, resulting in annual savings of $500,000.

- •Implemented Lean methodologies, reducing waste by 22% in the supply chain, significantly improving resource allocation.

- •Conducted data-driven analyses using Power BI, leading to an 18% increase in overall operational efficiency.

- •Spearheaded cross-functional teams to develop SOPs, enhancing team collaboration and performance metrics.

- •Coordinated training workshops for over 200 employees, improving adherence to new efficiency protocols.

- •Prepared comprehensive reports for senior management, showcasing identified improvements and future opportunities.

- •Optimized assembly line processes, leading to a 10% increase in production output and operational cost reduction.

- •Designed and implemented a new quality assurance procedure, decreasing defects by 24% in product outputs.

- •Developed a data analytics dashboard with Tableau, enabling leadership to make informed decisions quickly.

- •Conducted root cause analyses on recurring supply chain issues and implemented solutions that increased efficiency by 30%.

- •Facilitated cross-departmental workshops to align operations with new and more efficient process standards.

- •Analyzed semiconductor production workflows, implementing changes that improved speed and reduced downtime by 12%.

- •Collaborated with R&D for process improvements, increasing product quality and customer satisfaction by 15%.

- •Implemented Six Sigma tools to identify and mitigate key operational inefficiencies, saving $350,000 annually.

- •Prepared and delivered monthly performance reports, providing actionable insights for management to drive strategic decisions.

- •Reduced operational bottlenecks by reengineering workflows, significantly increasing supply chain throughput.

- •Facilitated a 20-member engineering team’s adoption of Lean principles, enhancing productivity across the board.

- •Authored comprehensive training manuals, ensuring team understanding and adherence to process improvements.

- •Monitored KPIs and facilitated meetings to discuss progress, ensuring projects stayed on track and objectives were met.

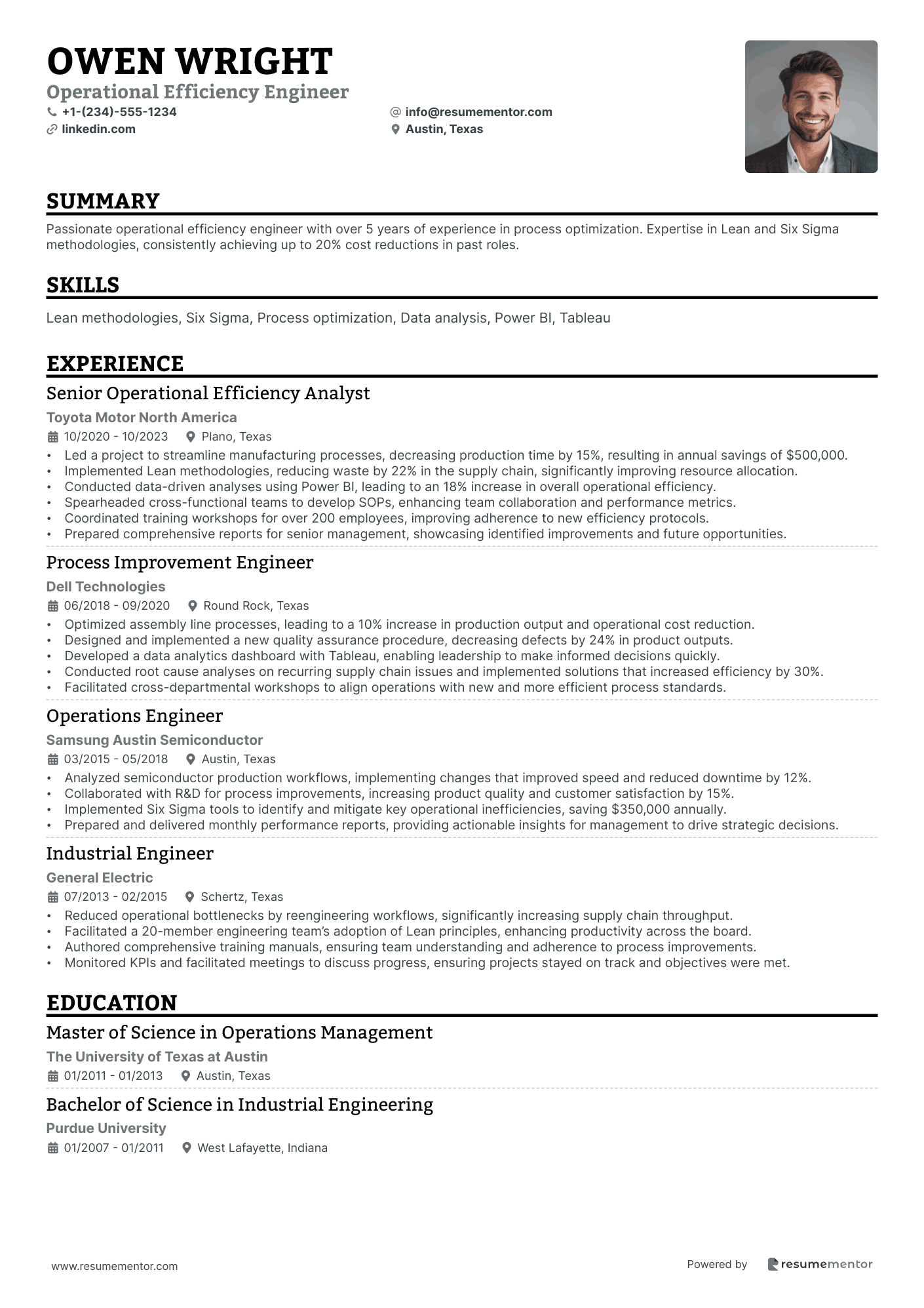

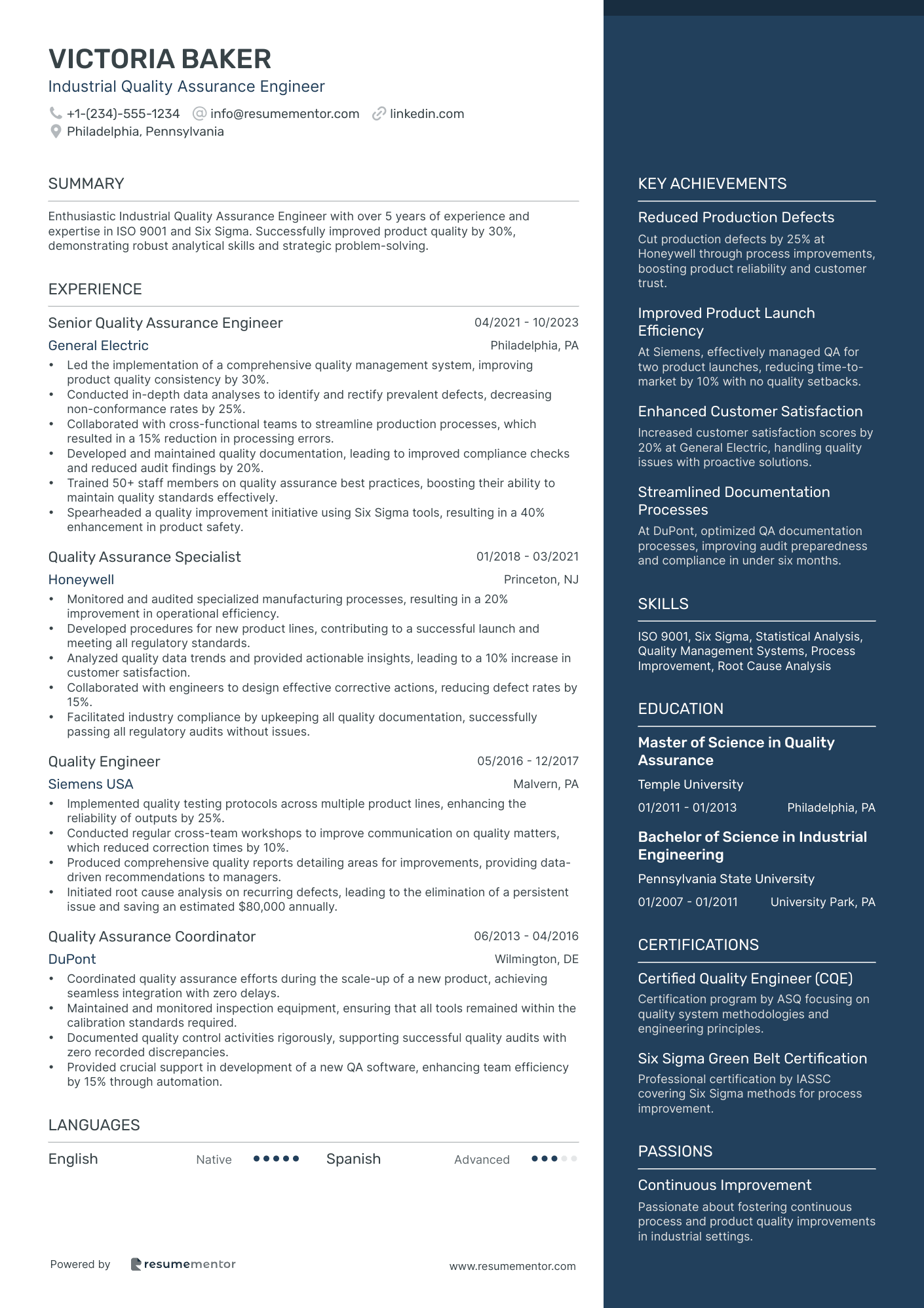

Industrial Quality Assurance Engineer resume sample

When applying for this role, it's essential to highlight any previous experience with quality control processes or audits. Demonstrating familiarity with industry standards such as ISO 9001 or Six Sigma can set you apart. Mention any relevant training or certifications, like 'Quality Management Systems' or 'Failure Mode and Effects Analysis (FMEA)', to show your commitment. Include examples of how you identified defects and implemented corrective actions, using a 'skill-action-result' structure to illustrate the positive impact on product quality or efficiency in your past positions.

- •Led the implementation of a comprehensive quality management system, improving product quality consistency by 30%.

- •Conducted in-depth data analyses to identify and rectify prevalent defects, decreasing non-conformance rates by 25%.

- •Collaborated with cross-functional teams to streamline production processes, which resulted in a 15% reduction in processing errors.

- •Developed and maintained quality documentation, leading to improved compliance checks and reduced audit findings by 20%.

- •Trained 50+ staff members on quality assurance best practices, boosting their ability to maintain quality standards effectively.

- •Spearheaded a quality improvement initiative using Six Sigma tools, resulting in a 40% enhancement in product safety.

- •Monitored and audited specialized manufacturing processes, resulting in a 20% improvement in operational efficiency.

- •Developed procedures for new product lines, contributing to a successful launch and meeting all regulatory standards.

- •Analyzed quality data trends and provided actionable insights, leading to a 10% increase in customer satisfaction.

- •Collaborated with engineers to design effective corrective actions, reducing defect rates by 15%.

- •Facilitated industry compliance by upkeeping all quality documentation, successfully passing all regulatory audits without issues.

- •Implemented quality testing protocols across multiple product lines, enhancing the reliability of outputs by 25%.

- •Conducted regular cross-team workshops to improve communication on quality matters, which reduced correction times by 10%.

- •Produced comprehensive quality reports detailing areas for improvements, providing data-driven recommendations to managers.

- •Initiated root cause analysis on recurring defects, leading to the elimination of a persistent issue and saving an estimated $80,000 annually.

- •Coordinated quality assurance efforts during the scale-up of a new product, achieving seamless integration with zero delays.

- •Maintained and monitored inspection equipment, ensuring that all tools remained within the calibration standards required.

- •Documented quality control activities rigorously, supporting successful quality audits with zero recorded discrepancies.

- •Provided crucial support in development of a new QA software, enhancing team efficiency by 15% through automation.

Automation and Robotics Engineer resume sample

When applying for this role, focus on your hands-on experience with automated systems and robotics programming. Highlight any projects where you've implemented automation solutions, showcasing the tools and technologies you've used, such as PLCs or CAD software. Mention relevant coursework, like 'Robotics Engineering' or 'Control Systems,' detailing the skills acquired. Provide specific examples illustrating how your contributions have optimized processes or reduced costs, using the 'skill-action-result' method to demonstrate your impact and problem-solving abilities.

- •Led a project team to design an automated welding system that increased production efficiency by 30% through innovative integration of robotic arms.

- •Developed custom software to control manufacturing robots using C++ and Python, resulting in a 15% reduction in system downtime.

- •Collaborated with cross-functional teams to identify key automation opportunities that enhanced supply chain operations and reduced costs by 20%.

- •Implemented a new PLC programming protocol that improved system reliability, cutting operational errors by 25%.

- •Authored comprehensive technical documentation for end users and operators, which improved usability and training efficiency, reducing onboarding time by 50%.

- •Stayed current on robotics advancements to ensure deployment of cutting-edge technologies, leading to recognition as a technology ambassador within the team.

- •Designed and implemented a robotic quality control system that decreased inspection time by 35% and improved defect detection rates by 40%.

- •Programming and simulation of robotic systems, contributing to a project that resulted in a 10% increase in manufacturing accuracy.

- •Conducted system integration and validation tests on robotics equipment to ensure compliance with industry safety standards, preventing potential safety incidents.

- •Resolved critical technical issues in automation systems, reducing client-reported downtime by 45% through effective troubleshooting.

- •Worked with suppliers to enhance hardware and software integration for robotics systems, significantly optimizing resource management.

- •Developed a robotic packaging solution that doubled productivity and reduced manual labor requirements by 50%, aligning with company goals for automation.

- •Implemented CAD design solutions for custom automation equipment, facilitating a faster and more agile design process with a 20% design time reduction.

- •Provided training to operators on new automation systems, enhancing in-house operational efficiency by reducing training time by 30%.

- •Monitored and evaluated system performance metrics to anticipate and address potential inefficiencies proactively, improving overall process reliability.

- •Assisted in deploying robotics technology in manufacturing lines, resulting in a production speed increase by 20% while maintaining high-quality standards.

- •Participated in creating detailed automation project plans and timelines, helping ensure projects met deadlines and stayed within budget constraints.

- •Supported the development of new control systems, leading to the successful roll-out of a new product line with a 15% improvement in process efficiency.

- •Contributed to a major upgrade project of the control systems that reduced energy consumption of robotic systems by 10%.

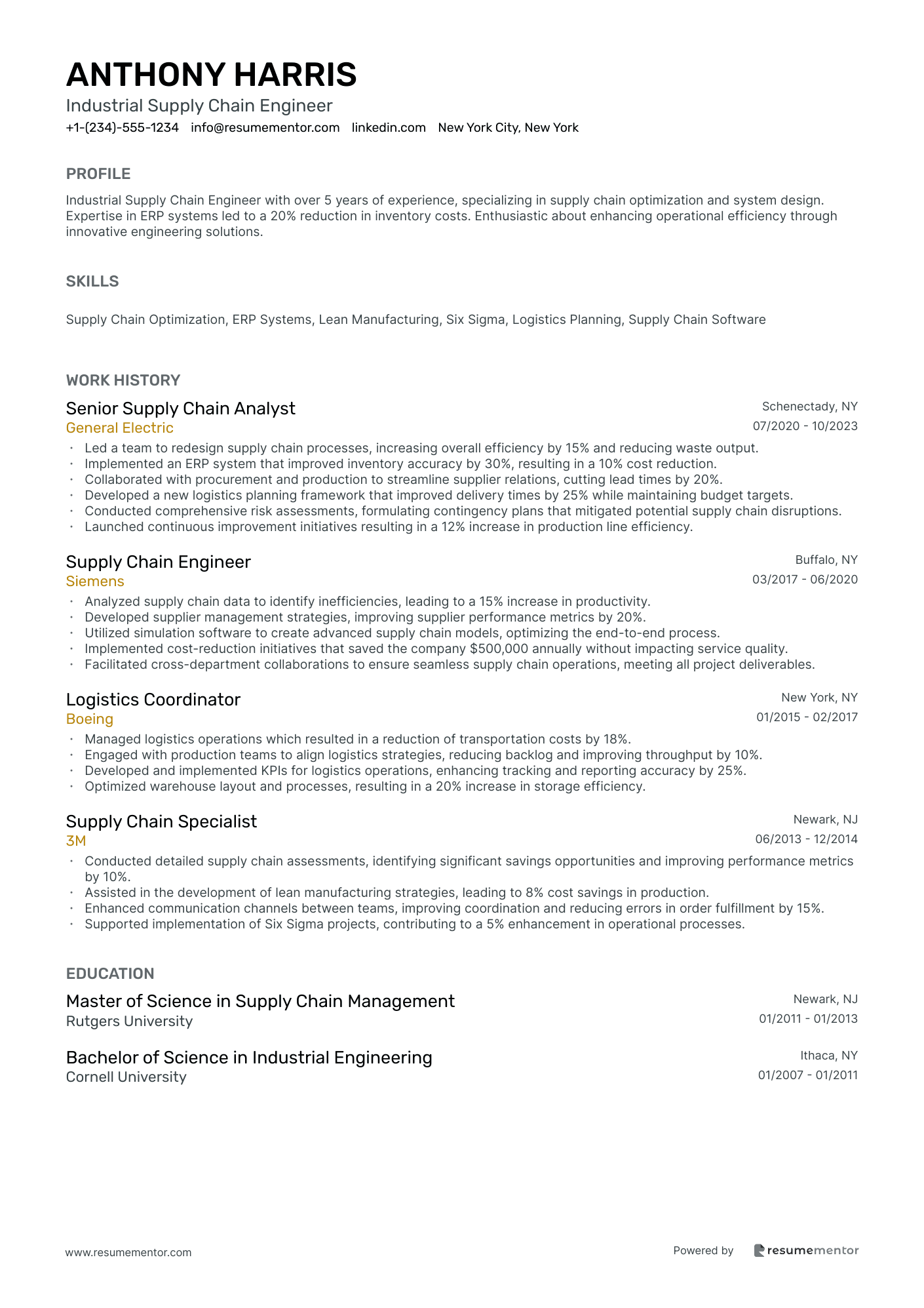

Industrial Supply Chain Engineer resume sample

When applying for this role, it’s important to showcase your experience with supply chain management software and data analysis tools. Highlight any certifications in Lean Manufacturing or Six Sigma, as they demonstrate your commitment to efficiency and quality. Mention specific projects where you optimized processes or reduced costs, using a 'situation-action-outcome' structure. Strong teamwork and problem-solving skills are essential, so provide examples of collaborative efforts that led to successful project completions. Emphasize your ability to adapt to changing environments and drive results.

- •Led a team to redesign supply chain processes, increasing overall efficiency by 15% and reducing waste output.

- •Implemented an ERP system that improved inventory accuracy by 30%, resulting in a 10% cost reduction.

- •Collaborated with procurement and production to streamline supplier relations, cutting lead times by 20%.

- •Developed a new logistics planning framework that improved delivery times by 25% while maintaining budget targets.

- •Conducted comprehensive risk assessments, formulating contingency plans that mitigated potential supply chain disruptions.

- •Launched continuous improvement initiatives resulting in a 12% increase in production line efficiency.

- •Analyzed supply chain data to identify inefficiencies, leading to a 15% increase in productivity.

- •Developed supplier management strategies, improving supplier performance metrics by 20%.

- •Utilized simulation software to create advanced supply chain models, optimizing the end-to-end process.

- •Implemented cost-reduction initiatives that saved the company $500,000 annually without impacting service quality.

- •Facilitated cross-department collaborations to ensure seamless supply chain operations, meeting all project deliverables.

- •Managed logistics operations which resulted in a reduction of transportation costs by 18%.

- •Engaged with production teams to align logistics strategies, reducing backlog and improving throughput by 10%.

- •Developed and implemented KPIs for logistics operations, enhancing tracking and reporting accuracy by 25%.

- •Optimized warehouse layout and processes, resulting in a 20% increase in storage efficiency.

- •Conducted detailed supply chain assessments, identifying significant savings opportunities and improving performance metrics by 10%.

- •Assisted in the development of lean manufacturing strategies, leading to 8% cost savings in production.

- •Enhanced communication channels between teams, improving coordination and reducing errors in order fulfillment by 15%.

- •Supported implementation of Six Sigma projects, contributing to a 5% enhancement in operational processes.

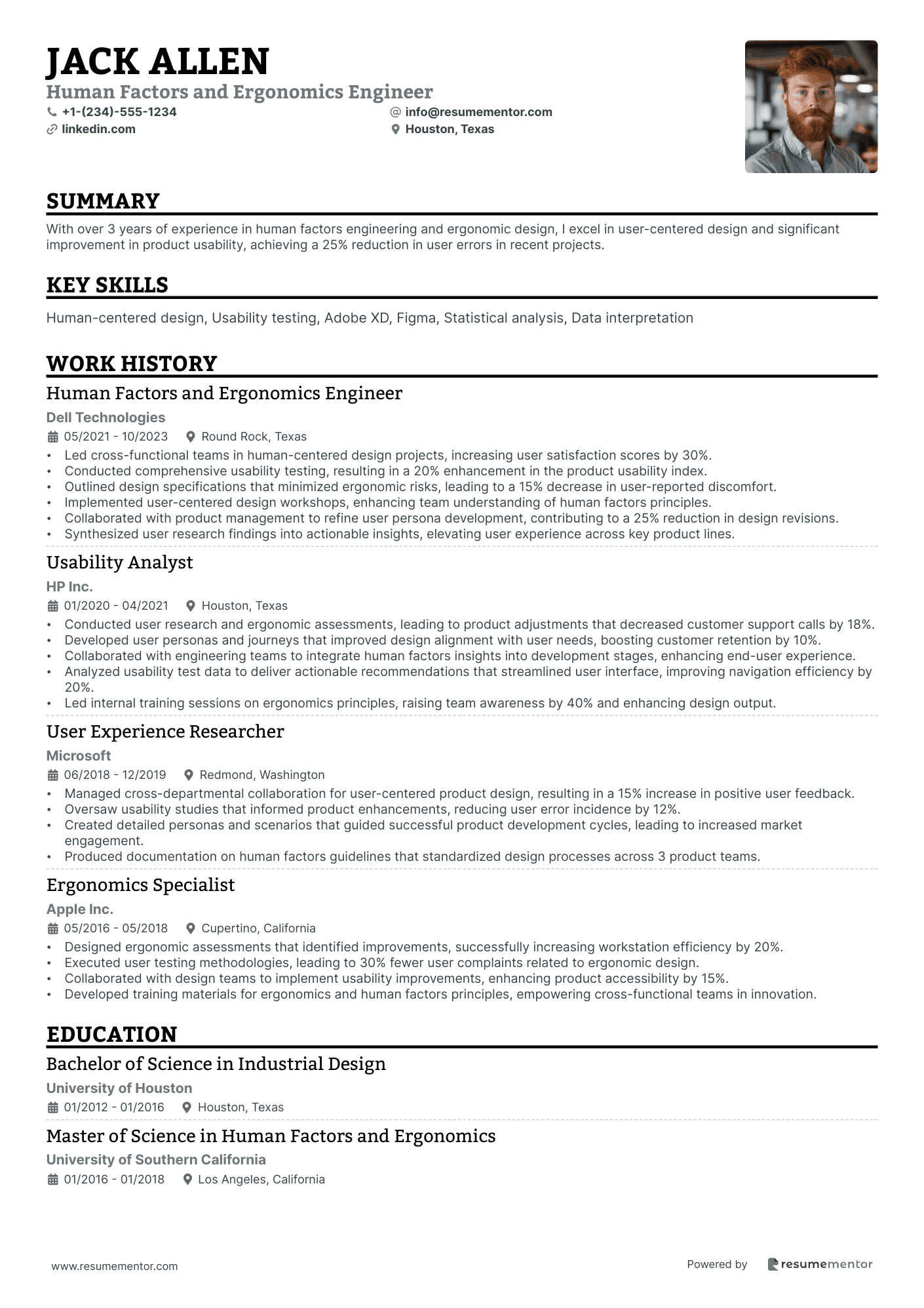

Human Factors and Ergonomics Engineer resume sample

When applying for this role, focus on any experience related to user-centered design or usability testing. Mention your knowledge of ergonomic principles and your ability to apply them in real-world scenarios. If you've completed certifications like 'Human Factors Engineering' or 'Usability Testing Methods', highlight these, including their duration. Share specific instances where your insights have led to improved product designs or user satisfaction. Use the 'skill-action-result' framework to illustrate how your contributions have positively impacted efficiency and safety in previous projects.

- •Led cross-functional teams in human-centered design projects, increasing user satisfaction scores by 30%.

- •Conducted comprehensive usability testing, resulting in a 20% enhancement in the product usability index.

- •Outlined design specifications that minimized ergonomic risks, leading to a 15% decrease in user-reported discomfort.

- •Implemented user-centered design workshops, enhancing team understanding of human factors principles.

- •Collaborated with product management to refine user persona development, contributing to a 25% reduction in design revisions.

- •Synthesized user research findings into actionable insights, elevating user experience across key product lines.

- •Conducted user research and ergonomic assessments, leading to product adjustments that decreased customer support calls by 18%.

- •Developed user personas and journeys that improved design alignment with user needs, boosting customer retention by 10%.

- •Collaborated with engineering teams to integrate human factors insights into development stages, enhancing end-user experience.

- •Analyzed usability test data to deliver actionable recommendations that streamlined user interface, improving navigation efficiency by 20%.

- •Led internal training sessions on ergonomics principles, raising team awareness by 40% and enhancing design output.

- •Managed cross-departmental collaboration for user-centered product design, resulting in a 15% increase in positive user feedback.

- •Oversaw usability studies that informed product enhancements, reducing user error incidence by 12%.

- •Created detailed personas and scenarios that guided successful product development cycles, leading to increased market engagement.

- •Produced documentation on human factors guidelines that standardized design processes across 3 product teams.

- •Designed ergonomic assessments that identified improvements, successfully increasing workstation efficiency by 20%.

- •Executed user testing methodologies, leading to 30% fewer user complaints related to ergonomic design.

- •Collaborated with design teams to implement usability improvements, enhancing product accessibility by 15%.

- •Developed training materials for ergonomics and human factors principles, empowering cross-functional teams in innovation.

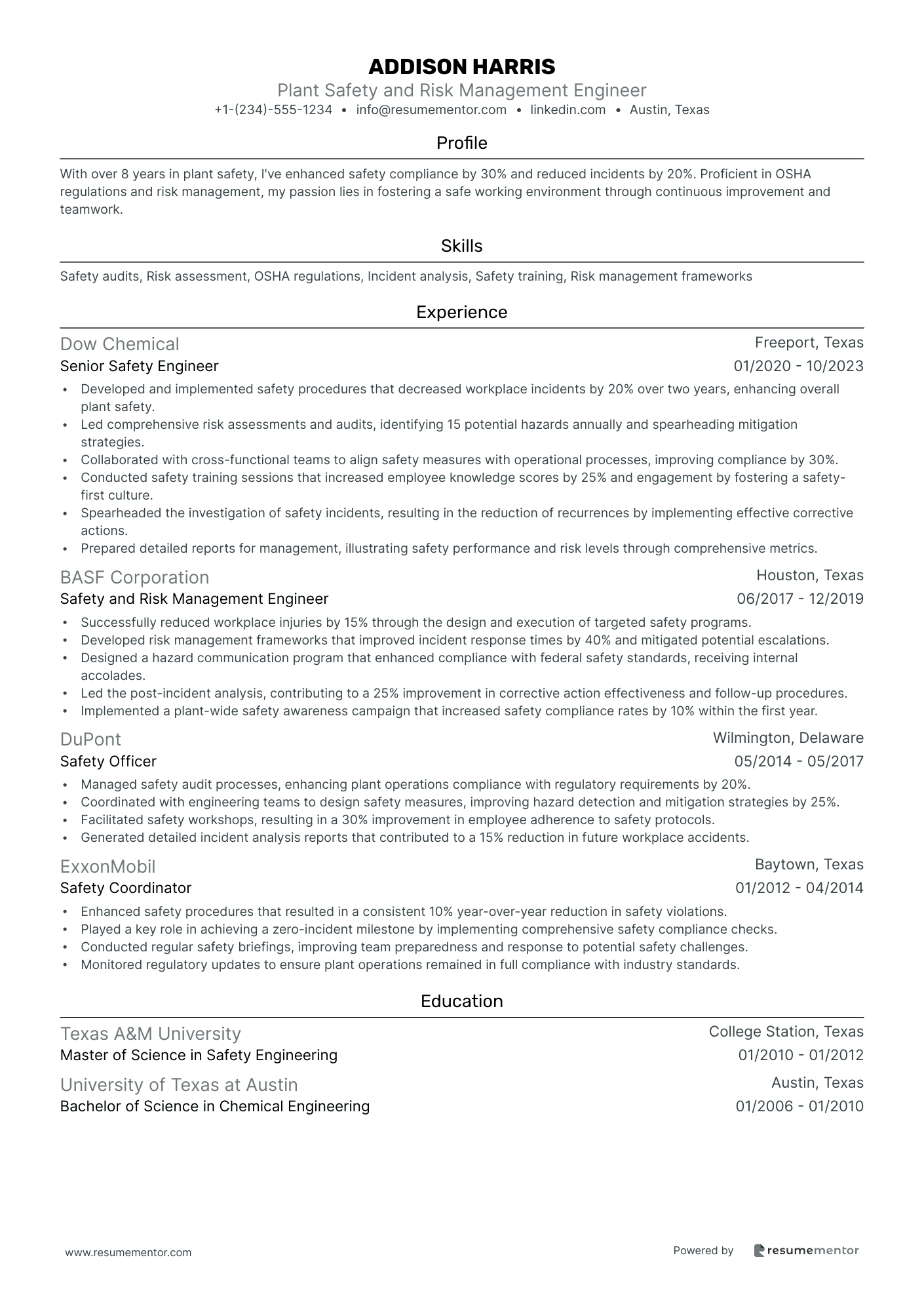

Plant Safety and Risk Management Engineer resume sample

When applying for this role, it’s important to highlight your experience with safety audits and risk assessments. Include any certifications, such as OSHA training or safety management courses, to demonstrate your commitment to maintaining a safe work environment. Discuss your ability to analyze workplace hazards and implement effective safety protocols. Providing examples of how your initiatives led to reduced incidents or improved compliance will strengthen your application. Use metrics to show the impact of your actions, emphasizing the benefits to both employee safety and operational efficiency.

- •Developed and implemented safety procedures that decreased workplace incidents by 20% over two years, enhancing overall plant safety.

- •Led comprehensive risk assessments and audits, identifying 15 potential hazards annually and spearheading mitigation strategies.

- •Collaborated with cross-functional teams to align safety measures with operational processes, improving compliance by 30%.

- •Conducted safety training sessions that increased employee knowledge scores by 25% and engagement by fostering a safety-first culture.

- •Spearheaded the investigation of safety incidents, resulting in the reduction of recurrences by implementing effective corrective actions.

- •Prepared detailed reports for management, illustrating safety performance and risk levels through comprehensive metrics.

- •Successfully reduced workplace injuries by 15% through the design and execution of targeted safety programs.

- •Developed risk management frameworks that improved incident response times by 40% and mitigated potential escalations.

- •Designed a hazard communication program that enhanced compliance with federal safety standards, receiving internal accolades.

- •Led the post-incident analysis, contributing to a 25% improvement in corrective action effectiveness and follow-up procedures.

- •Implemented a plant-wide safety awareness campaign that increased safety compliance rates by 10% within the first year.

- •Managed safety audit processes, enhancing plant operations compliance with regulatory requirements by 20%.

- •Coordinated with engineering teams to design safety measures, improving hazard detection and mitigation strategies by 25%.

- •Facilitated safety workshops, resulting in a 30% improvement in employee adherence to safety protocols.

- •Generated detailed incident analysis reports that contributed to a 15% reduction in future workplace accidents.

- •Enhanced safety procedures that resulted in a consistent 10% year-over-year reduction in safety violations.

- •Played a key role in achieving a zero-incident milestone by implementing comprehensive safety compliance checks.

- •Conducted regular safety briefings, improving team preparedness and response to potential safety challenges.

- •Monitored regulatory updates to ensure plant operations remained in full compliance with industry standards.

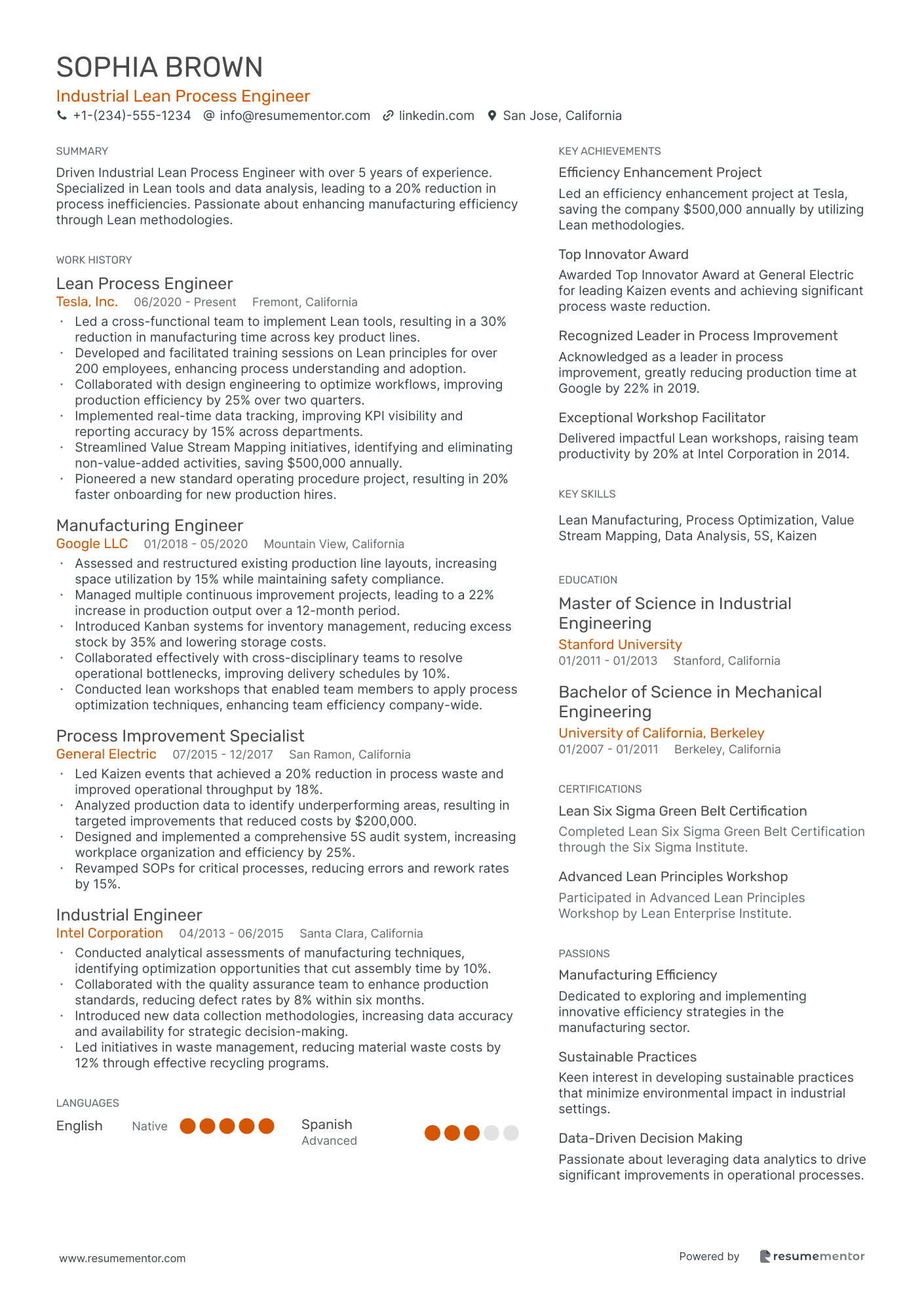

Industrial Lean Process Engineer resume sample

When crafting your cover letter, highlight any experience with process improvement methodologies, such as Lean or Six Sigma. Showcase specific projects where you successfully reduced waste or improved efficiency. Include any certifications in these methodologies to demonstrate your commitment to continuous improvement. Emphasize your analytical skills and your ability to identify bottlenecks within production. Provide concrete examples of how your initiatives led to cost savings or increased output, using metrics to quantify your results. This approach will strengthen your application and show your value to potential employers.

- •Led a cross-functional team to implement Lean tools, resulting in a 30% reduction in manufacturing time across key product lines.

- •Developed and facilitated training sessions on Lean principles for over 200 employees, enhancing process understanding and adoption.

- •Collaborated with design engineering to optimize workflows, improving production efficiency by 25% over two quarters.

- •Implemented real-time data tracking, improving KPI visibility and reporting accuracy by 15% across departments.

- •Streamlined Value Stream Mapping initiatives, identifying and eliminating non-value-added activities, saving $500,000 annually.

- •Pioneered a new standard operating procedure project, resulting in 20% faster onboarding for new production hires.

- •Assessed and restructured existing production line layouts, increasing space utilization by 15% while maintaining safety compliance.

- •Managed multiple continuous improvement projects, leading to a 22% increase in production output over a 12-month period.

- •Introduced Kanban systems for inventory management, reducing excess stock by 35% and lowering storage costs.

- •Collaborated effectively with cross-disciplinary teams to resolve operational bottlenecks, improving delivery schedules by 10%.

- •Conducted lean workshops that enabled team members to apply process optimization techniques, enhancing team efficiency company-wide.

- •Led Kaizen events that achieved a 20% reduction in process waste and improved operational throughput by 18%.

- •Analyzed production data to identify underperforming areas, resulting in targeted improvements that reduced costs by $200,000.

- •Designed and implemented a comprehensive 5S audit system, increasing workplace organization and efficiency by 25%.

- •Revamped SOPs for critical processes, reducing errors and rework rates by 15%.

- •Conducted analytical assessments of manufacturing techniques, identifying optimization opportunities that cut assembly time by 10%.

- •Collaborated with the quality assurance team to enhance production standards, reducing defect rates by 8% within six months.

- •Introduced new data collection methodologies, increasing data accuracy and availability for strategic decision-making.

- •Led initiatives in waste management, reducing material waste costs by 12% through effective recycling programs.

Operations Research Engineer resume sample

When applying for this role, focus on your analytical skills and any relevant projects where you improved processes. Highlight experience with statistical software like MATLAB or Python, and include any coursework in operations research or optimization. Mention certifications in data analysis or process improvement methodologies such as Six Sigma. Share specific examples where your analysis led to cost savings or efficiency gains, using a 'situation-action-result' format. Showing how your work directly benefited your previous employers can make your application stand out.

- •Led a research team to develop an optimization algorithm reducing production cycle time by 30%.

- •Managed a project that improved resource allocation efficiency by 20%, saving $5 million annually.

- •Collaborated with cross-functional teams to implement a forecasting model, increasing demand prediction accuracy by 40%.

- •Conducted statistical analysis that drove a 25% improvement in supply chain reliability.

- •Implemented a data-driven logistic optimization strategy, enhancing service level agreement by 15%.

- •Published findings in a peer-reviewed journal, enhancing organizational expertise and reputation.

- •Developed advanced simulation models that enhanced project delivery speed by 18%.

- •Implemented predictive analytics improving operational accuracy by 22% in strategic areas.

- •Collaborated with IT to integrate data analytics tools, resulting in a $3 million cost-saving.

- •Successfully communicated complex data to non-technical stakeholders, increasing engagement by 50%.

- •Evaluated new analytical methodologies, increasing adoption of best practices by 35%.

- •Engineered a data analysis framework that decreased error rates by 19%.

- •Improved fuel cost efficiency in flight operations through optimized routing, saving $2 million annually.

- •Analyzed customer data to enhance service offerings, increasing retention rates by 15%.

- •Reported insights on competitive positioning, driving a 10% increase in market share.

- •Identified bottlenecks in supply chain processes, reducing lead time by 12%.

- •Utilized data visualization to present analysis results, facilitating strategic decision-making processes.

- •Assessed and refined cost models, increasing profit margins by 18% during key fiscal quarters.

- •Monitored market trends to develop actionable insights, improving competitive strategy.

Crafting a standout industrial engineering resume is like designing a seamless system, where every component fits perfectly to create the best outcome. You tackle complex challenges daily as an industrial engineer, yet condensing your varied skills and experiences into one compelling document can feel overwhelming. This task is not just about showcasing your achievements—it's about choosing the right ones that truly set you apart.

In today's fast-paced job market, your resume acts as your first impression, needing to capture your capabilities quickly and effectively. Think of it as an assembly line, where each section guides the reader smoothly from your educational background to your hands-on experience. Here, a resume template can help streamline this process, ensuring every element finds its right place. Consider these resume templates to make the task easier for you.

Ensuring your resume balances technical expertise with soft skills is crucial. Employers look for problem-solving abilities as well as your knack for improving processes and collaborating well with others. It’s important that your resume communicates you can manage both people and production efficiently without getting lost in technical jargon.

This guide will help you craft a resume that underscores your engineering strengths. By aligning your skills and tailoring your accomplishments, you'll be able to present a career narrative that resonates with hiring managers. Dive into this opportunity to transform your resume into a powerful tool for your job search.

Key Takeaways

- When creating an industrial engineer resume, focus on highlighting both technical expertise and soft skills to demonstrate problem-solving abilities and efficiency improvements.

- Use a reverse-chronological format to emphasize your most recent roles, achievements, and professional growth; this format aligns with industry standards and prominently showcases your current capabilities.

- Quantify achievements and focus on results in the experience section to clearly illustrate the value you added in previous roles, using action verbs and data-driven examples to make your impact compelling.

- The skills section should balance technical abilities with industry-specific knowledge; this ensures your resume aligns with potential employers' expectations and helps it pass Applicant Tracking Systems (ATS).

- Extra sections, such as certifications, volunteer work, and languages, can enrich your resume and provide a well-rounded view of your expertise and personal interests, distinguishing you from other candidates.

What to focus on when writing your industrial engineer resume

Your industrial engineer resume should effectively highlight your strengths in problem-solving and process optimization. By doing so, recruiters can quickly see your potential to enhance efficiency and elevate productivity within industrial environments.

How to structure your industrial engineer resume

- Contact Information: Start with essential details such as your full name, phone number, email, and LinkedIn profile. Keeping it straightforward ensures ease of contact and sets a professional tone—it's the foundation for making that all-important first impression.

- Professional Summary: Follow with a concise overview that emphasizes your expertise in areas like process improvement, manufacturing systems, and supply chain management. This brief section serves as your introduction, providing a snapshot of your career achievements and setting the stage for showcasing your capabilities in the sections that follow.

- Skills: Next, list relevant skills such as Lean Manufacturing, Six Sigma, and Quality Assurance. Mention your proficiency with tools like AutoCAD or MATLAB, which supports your technical skill set—this section is pivotal in demonstrating your hands-on experience and technical prowess.

- Experience: When detailing your work history, focus on your achievements, like boosting production efficiency or cutting costs. Using action verbs and quantifiable outcomes enriches this section with tangible evidence of your impact—it's where your practical contributions come to life through the results you've delivered.

- Education: Highlight your degree in industrial engineering, including the institution and graduation date. Enhancing this with notable coursework or projects provides additional insight into your academic background—this section connects your education to your future industry role, bridging classroom learning with real-world application.

- Certifications: Wrap up with certifications like Six Sigma Green Belt or PMP, which add value and distinguish you from other candidates. Certifications highlight your commitment to professionalism and lifelong learning, aiding in establishing a competitive edge.

Considering additional sections for awards or publications can further enrich your resume. Recognitions from industry conferences or contributions to professional journals can underline your commitment and expertise—below, we will delve deeper into each of these key sections to ensure your resume format is as impactful as possible.

Which resume format to choose

As an industrial engineer, selecting the right resume format sets a strong foundation for your job application. The reverse-chronological format is particularly effective because it emphasizes your professional journey and growth, capturing the attention of hiring managers focused on expertise and progression. This structure aligns with industry standards by showcasing your most recent roles and accomplishments first, making it easier for employers to see your current skills and capabilities.

Choosing an appropriate font further enhances the readability and professionalism of your resume. Modern fonts such as Lato, Raleway, or Montserrat not only provide a clean and polished look but also convey a sense of innovation and modernity, which are integral to the engineering field. A well-chosen font supports the overall narrative of your resume, subtly underscoring your attention to detail and your ability to keep up with industry trends.

Saving your resume as a PDF is essential to maintaining its format across different devices and platforms. This file type ensures your resume appears exactly as intended, illustrating your understanding of precision and consistency, qualities highly valued in engineering roles. A PDF safeguards your work against formatting shifts that might occur in other file types, presenting a professional and polished document.

Finally, setting your resume margins to 1 inch on all sides contributes to a clean and organized presentation. This standard margin size prevents the page from appearing cluttered, allowing hiring managers to easily navigate through your content. Such attention to layout reflects the methodical and systematic approach valued in engineering processes.

By thoughtfully integrating these elements, you craft a resume that not only highlights your qualifications as an industrial engineer but also resonates with the expectations of the industry and potential employers.

How to write a quantifiable resume experience section

The experience section of an industrial engineer resume is your chance to highlight the impact you've had in past roles. Focus on tangible outcomes and improved efficiencies to show how your skills have benefitted organizations. Start with a clear structure that includes your job title, company name, location, and dates of employment. Use bullet points to emphasize quantifiable achievements. As you list your experiences in reverse chronological order, concentrate on aligning your background with the job you're targeting. Tailor your resume by weaving in keywords from the job ad, ensuring your skills and experiences resonate with the employer’s needs. Use strong action verbs like "optimized," "implemented," and "streamlined" to make sure your contributions are clear and compelling.

- •Boosted production efficiency by 25% with Lean manufacturing techniques.

- •Cut material waste by 15% through better supply chain and inventory management.

- •Led a team to automate processes, reducing labor costs by 30%.

- •Implemented a new quality assurance system, lowering defect rates by 20%.

This experience section excels by focusing on concrete achievements and using numbers to clearly demonstrate your impact. Each bullet point not only highlights improvements but also connects actions to outcomes. Verbs like "boosted," "cut," "led," and "implemented" draw a direct link between your efforts and the success you drove. In connecting your experience with employer needs, the tailored, skill-focused narrative ensures you are seen as a valuable and relevant candidate.

Project-Focused resume experience section

A project-focused industrial engineer resume experience section should clearly highlight your achievements in designing and implementing efficient, cost-effective projects. Center your narrative on specific projects where you've either led or contributed significantly, providing examples that demonstrate your problem-solving skills and expertise. Incorporating measurable outcomes is key to showing your impact, such as increasing production capacity or reducing waste, which highlights your technical skills and leadership abilities.

To create a seamless flow in your resume experience section, use action-oriented bullet points that underscore your direct contributions and accomplishments. Begin each point with a strong action verb, which effectively conveys a sense of accomplishment and responsibility. Make sure your points are clear and concise, connecting your achievements and projects in a way that tells a cohesive story. This approach gives potential employers a comprehensive understanding of your capabilities and the value you can bring to their company.

Industrial Engineer

ABC Manufacturing

January 2020 - Present

- Led a cross-functional team to improve production line efficiency by 25%.

- Implemented lean manufacturing methodologies, reducing waste by 15%.

- Developed a new scheduling system that cut overtime costs by 20%.

- Optimized supply chain processes, resulting in a 10% reduction in material costs.

Result-Focused resume experience section

A result-focused industrial engineer resume experience section should clearly demonstrate the value you've added to your previous roles, emphasizing your achievements and their impact on your company. Use straightforward, active language to paint a picture of how you've driven improvements in productivity, efficiency, and cost reduction. By detailing specific outcomes and showcasing your problem-solving abilities, you create a compelling narrative about your work experience.

Begin with your most relevant positions, listing them in reverse chronological order, and include your job title and the name of the company. If necessary, provide a short description of the company. For each role, use bullet points to highlight your major responsibilities and achievements, focusing on the results you’ve delivered. Incorporate numbers, percentages, and examples to give a clear view of your success, letting potential employers see at a glance the value you bring.

Senior Industrial Engineer

XYZ Manufacturing Co.

January 2019 - March 2023

- Boosted production line efficiency by 15%, cutting downtime and saving $500,000 annually.

- Reduced waste by 20% through streamlined processes, enhancing sustainability.

- Led a team to implement a new inventory system, improving accuracy by 30%.

- Managed project budgets to cut costs by 12% without compromising quality.

Responsibility-Focused resume experience section

A responsibility-focused industrial engineer resume experience section should clearly highlight how you managed key tasks and leveraged your skills to make a positive impact on the company. By using action-oriented language, you can effectively convey the value of your contributions while avoiding complicated jargon. This clarity allows employers to quickly grasp the tangible benefits you provided and places emphasis on the direct results of your efforts.

Structuring this information into bullet points improves readability, and each point should start with a strong verb to make a powerful impression. When detailing your achievements, specify the processes or techniques used and link them to measurable improvements. Tailoring your points to align with the job you're applying for ensures your resume speaks directly to the potential employer’s needs, emphasizing responsibilities and achievements that matter most to them.

Industrial Engineer

ABC Manufacturing Co.

Jan 2020 - Present

- Led a team of 5 to streamline the assembly line process, reducing production time by 20%.

- Implemented a new inventory management system, which decreased stock shortages by 15%.

- Developed and documented a training manual for new engineers, enhancing training efficiency by 30%.

- Conducted regular efficiency studies, using findings to optimize resource allocation and improve productivity.

Innovation-Focused resume experience section

An innovation-focused industrial engineer resume experience section should effectively highlight your contributions that drive progress within an organization. Start by pinpointing the key innovations you've implemented or supported in past roles and reflect on changes you've made that enhanced processes, boosted productivity, or advanced product development. By using specific numbers or metrics, you can clearly demonstrate your impact and tailor your narratives to display your problem-solving abilities and creative thinking. Ensuring that each point remains succinct and centered on results is essential for clarity and impact.

As you craft your bullet points, focus on various aspects of innovation—such as developing new processes, improving systems, or leading projects that resulted in significant advancements. Show a diverse range of skills and experiences to highlight your adaptability. Action verbs can help convey dynamism and leadership, making your achievements stand out. Since employers are looking for proof of your ability to enhance efficiency and effectiveness, link your accomplishments to tangible outcomes like cost reductions, increased efficiency, or improved safety standards to capture their attention.

Industrial Engineer

Tech Innovations Inc.

June 2020 - Present

- Led a team to develop a new assembly line process, reducing production time by 30%.

- Implemented a data-driven inventory system, resulting in a 20% cost reduction.

- Designed a predictive maintenance framework, cutting machine downtime by 15%.

- Conducted workflow analysis that eliminated non-value-added steps, increasing daily output by 25%.

Write your industrial engineer resume summary section

A well-focused industrial engineer resume summary should succinctly convey your professional strengths. Use just a couple of sentences to highlight your most important skills, experiences, and achievements. Take, for example, this resume summary:

This summary flows well because it lists achievements with concrete numbers and terms relevant to industrial engineering, which helps prospective employers see your value quickly. Tailor your summary by aligning it with the job description, focusing on the skills and accomplishments that matter most for the position.

Describing yourself effectively involves using action verbs and specific examples to bring your skills to life. Understanding the difference between a resume summary and a resume objective is also crucial; a resume objective discusses your career goals and how they connect with the job. A resume profile is similar to a summary and outlines your skills and experience. Meanwhile, a summary of qualifications often features bullet points highlighting key skills and experiences. Choosing the right format based on your background and objectives can significantly improve your resume's impact.

Listing your industrial engineer skills on your resume

An industrial engineer resume's skills section should effectively highlight your professional capabilities. This section might be a standalone part of your resume or seamlessly woven into your experience and summary sections. Emphasizing strengths and soft skills is key, as they demonstrate your knack for collaboration, problem-solving, and adaptability. Meanwhile, hard skills provide tangible evidence of your proficiency in specific software or tools crucial to your field.

Incorporating these skills into your resume not only highlights your abilities but also acts as critical keywords that potential employers search for. Doing so boosts your chances of passing the Applicant Tracking Systems (ATS) many companies use. A well-structured skills section succinctly communicates your expertise.

The example provided stands out because it skillfully balances technical abilities with industry-specific knowledge. Each skill aligns with the requirements of an industrial engineering role, underscoring your professional capabilities.

Best hard skills to feature on your industrial engineer resume

Including hard skills is essential to demonstrate your technical and analytical expertise. For an industrial engineer, these skills should convey your ability to optimize processes and manage complex systems efficiently.

Hard Skills

- Process Optimization

- Lean Manufacturing

- Six Sigma

- Data Analysis

- Computer-Aided Design (CAD) Software

- Supply Chain Management

- Ergonomics

- Quality Control

- Systems Engineering

- Statistical Analysis

- Production Planning

- Inventory Management

- Microsoft Excel

- Root Cause Analysis

- Simulation Software

Best soft skills to feature on your industrial engineer resume

Soft skills are vital because they reveal your interpersonal abilities and how you manage challenges. An industrial engineer should excel in communication and teamwork to coordinate effectively with diverse teams.

Soft Skills

- Communication

- Teamwork

- Problem Solving

- Adaptability

- Time Management

- Critical Thinking

- Leadership

- Conflict Resolution

- Decision Making

- Attention to Detail

- Creativity

- Emotional Intelligence

- Collaboration

- Negotiation

- Active Listening

How to include your education on your resume

The education section is an important part of your industrial engineer resume. It should be tailored specifically to the job you're applying for, only including relevant education that enhances your qualifications for that role. When listing your degree, specify the exact title to demonstrate expertise, such as "Bachelor of Science in Industrial Engineering." Including your GPA is optional, but it can be beneficial if it's 3.0 or higher. To feature GPA, list it with the scale (e.g., "GPA: 3.5/4.0"). If you've graduated with honors, mention distinctions like "cum laude" immediately following your degree. This showcases your academic excellence.

Here’s an example of a poorly structured education section:

Now, let's see a well-crafted example relevant to an industrial engineer position:

The second example is effective because it provides a degree directly relevant to the industrial engineering field. It lists a high GPA that’s beneficial for the role and omits unnecessary location details, keeping the focus on your education and academic performance. Tailoring your education details for the target job can greatly enhance your resume.

How to include industrial engineer certificates on your resume

Including a certificates section in your resume is crucial for showcasing your professional development and expertise. List the name of the certificate first to grab attention. Include the date you earned the certificate to give context to its relevance. Add the issuing organization to lend credibility to the certification. You can also position these certificates in your resume header for immediate visibility.

Here's how it can look in JSON format:

This example is strong because it highlights certifications directly relevant to the role of an industrial engineer. It includes well-regarded issuing organizations, giving credibility. Additionally, stating the full title of the certificates ensures clarity. The combination of these factors makes your resume more impactful and succinct.

Extra sections to include in your industrial engineer resume

Crafting the perfect resume is key to securing your dream job as an industrial engineer. Highlighting the right sections can set you apart from other candidates and show employers your diverse range of skills and experiences.

- Language section — Demonstrate your ability to communicate in multiple languages to make you a more versatile hire. List languages you speak fluently, such as English, Spanish, or Mandarin.

- Hobbies and interests section — Showcase your rounded personality and transferable skills you gain from hobbies. Mention activities such as robotics clubs, hiking, or playing chess.

- Volunteer work section — Provide evidence of your willingness to contribute and your teamwork skills. Highlight positions such as organizing community clean-ups or mentoring students in STEM subjects.

- Books section — Illustrate your commitment to continuous learning by sharing titles relevant to your field. Include books like "The Toyota Way" by Jeffrey Liker or "Lean Thinking" by James P. Womack and Daniel T. Jones.

Carefully curating these sections can give employers a fuller picture of who you are. Tailor your resume to include these elements to stand out and make a lasting impression.

In Conclusion

In conclusion, creating a compelling industrial engineering resume requires strategic thought and meticulous organization. Your resume should be as efficient and precise as the engineering systems you design. Focus on structuring it to effectively convey both your technical capabilities and your soft skills. Use a clear format, such as the reverse-chronological style, which highlights your experience and growth within the field. By selecting the right combination of technical skills like Lean Manufacturing or Six Sigma, and soft skills like communication and problem-solving, you display a well-rounded professional image. Include tangible achievements in your experience section to demonstrate your impact, using strong action verbs and specific metrics to illustrate your contributions. Don’t forget the education and certification sections, where you can showcase relevant studies and any ongoing professional development. Consider including additional sections like languages or volunteer work to give hiring managers a fuller view of your skills and interests. By aligning each component to the role you are pursuing, you build a resume that stands out. Effectively presenting your qualifications will help you make a lasting impression in a competitive job market, transforming your resume into a powerful tool for career advancement.

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2025. All rights reserved.

Made with love by people who care.