Ironworker Resume Examples

Mar 18, 2025

|

12 min read

Steel yourself for success: Craft your perfect ironworker resume with ease. This guide provides insights to help you build a solid foundation, showcase your skills, and forge ahead in your career as an ironworker.

Rated by 348 people

Structural Ironworker

Reinforcing Ironworker

Ironworker Foreman

Fabricating Ironworker

Journeyman Ironworker

Ironworker Welder

Ornamental Ironworker

Industrial Maintenance Ironworker

Ironworker Rigger

Ironworker Apprentice

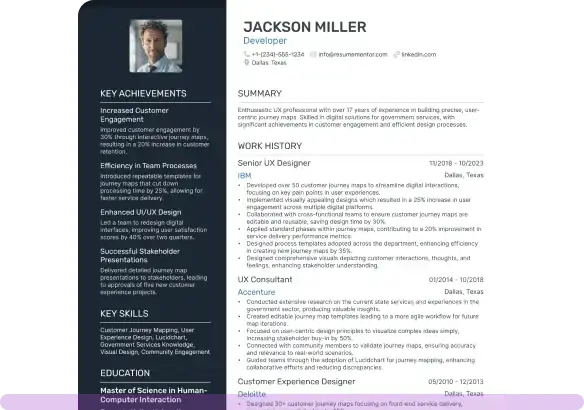

Structural Ironworker resume sample

- •Led a team of 10 ironworkers in the installation of structural steel frameworks, increasing project efficiency by 15%.

- •Implemented a safety inspection protocol adopted company-wide, resulting in a 25% reduction in on-site accidents.

- •Collaborated with engineers and architects to resolve structural issues, achieving 100% project compliance with design specifications.

- •Utilized cranes and hoists to safely position materials at heights of over 100 feet, improving material handling efficiency.

- •Conducted daily team meetings to align on project timelines, often completing tasks 2 days ahead of schedule.

- •Redesigned scaffolding setups for high-rise projects, reducing setup time by 30% and ensuring greater worker safety.

- •Successfully managed the installation of steel beams and trusses, improving structural stability by 20% over previous projects.

- •Facilitated cross-department communication, reducing project miscommunications by 40% and streamlining progress.

- •Assisted in training new hires on safety procedures and tools usage, increasing their performance by 35%.

- •Supervised crane operations during the transportation of materials, significantly reducing material handling time.

- •Played a key role in a high-visibility project, meeting a tight deadline with zero safety incidents.

- •Worked on several commercial buildings, resulting in projects consistently completed 10% under budget.

- •Achieved expert-level proficiency in reading and interpreting complex blueprints and schematics.

- •Participated in regular safety drills, enhancing team response times during emergency situations.

- •Optimized the use of heavy machinery and tools, increasing daily task completion rates by 15%.

- •Assisted in projects valued at over $10 million, consistently maintained project fidelity to architectural requirements.

- •Contributed to over 15 large-scale projects, consistently praised for attention to detail and compliance.

- •Ensured the appropriate alignment and installation of steel columns, increasing structural integrity by 20%.

- •Collaborated on a cross-functional team to meet and exceed client expectations on every project.

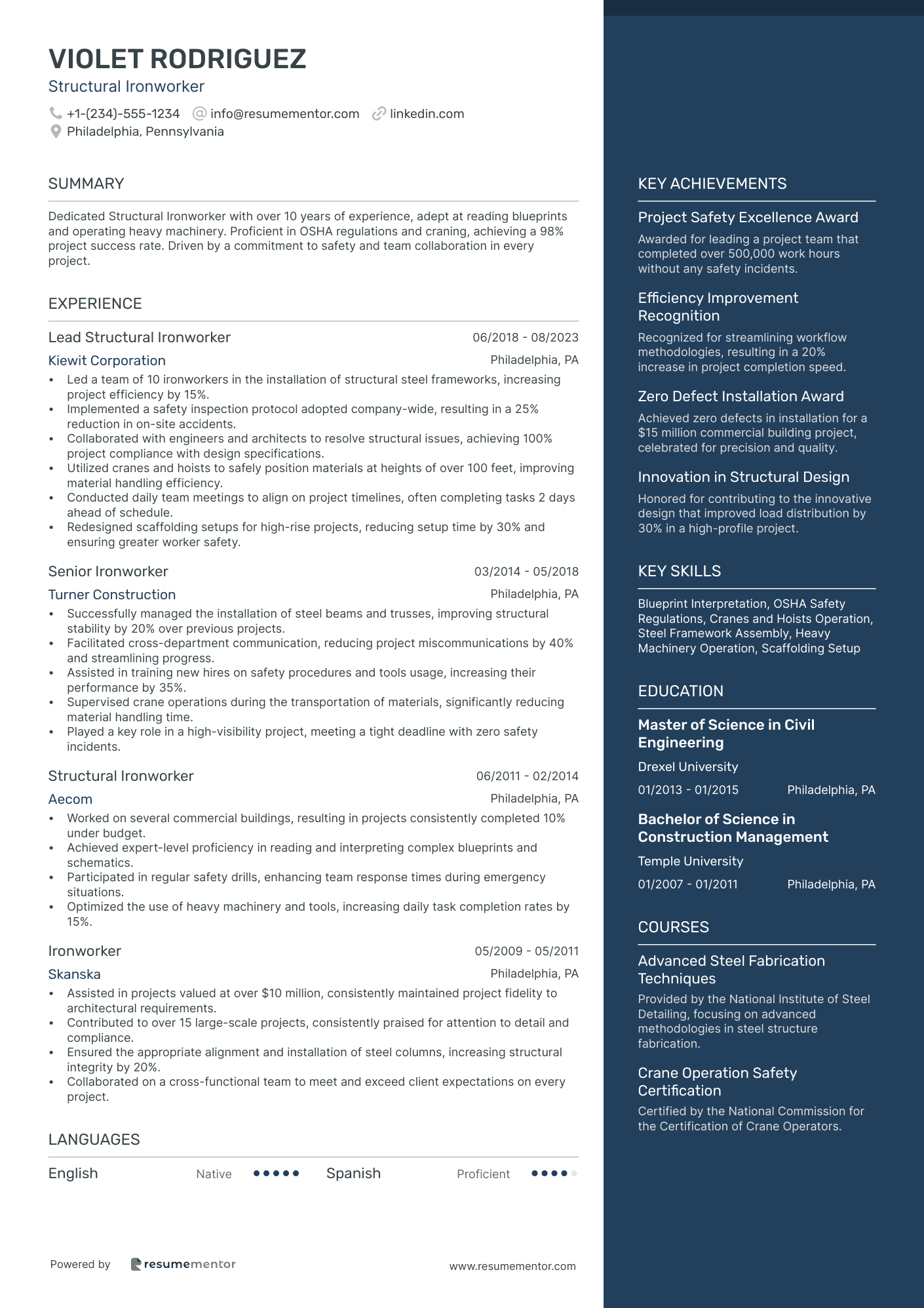

Reinforcing Ironworker resume sample

- •Led the installation of over 1,000 tons of rebar for a 50-story high-rise building, ensuring adherence to safety standards and project timelines.

- •Collaborated with engineers to interpret complex blueprints, resulting in a 15% reduction in material usage through optimized rebar placement.

- •Trained 10 apprentices on rebar installation techniques, increasing team efficiency by 30% within six months.

- •Conducted regular safety audits across sites, which improved team compliance with OSHA regulations by 25%.

- •Liaised with the construction management team to adjust project plans and resolve on-site issues, maintaining project continuity and reducing delays by 20%.

- •Implemented a new rebar tying method that streamlined operations, leading to a 12% increase in overall productivity.

- •Played a key role in the construction of multiple public infrastructure projects, applying rebar to foundations and columns with zero error rate.

- •Contributed to a team that finished a large government contract three weeks ahead of schedule by improving workflow processes.

- •Coordinated with crane operators and other trades on-site, reducing repositioning time of materials by 10% per project.

- •Performed independent rebar inspections, which identified potential 15% cost savings before concrete pouring.

- •Utilized 3D modeling software to enhance blueprint accuracy, minimizing rebar cutting errors by 20% on projects.

- •Supervised a team of 15 ironworkers on a variety of commercial construction projects, ensuring compliance with all safety protocols.

- •Assessed and allocated materials with precision, leading to a notable 10% reduction in waste materials.

- •Demonstrated leadership in high-pressure environments, maintaining crew productivity during tight deadlines through strategic re-planning.

- •Initiated monthly training cycles on the latest safety practices, evidence showing a 35% decrease in workplace incidents.

- •Executed precise installation of rebar grids and cages in tunnels, which enhanced structural integrity by 50% as validated by inspections.

- •Interpreted and adhered to precise structural plans, resulting in a seamless integration with other construction elements.

- •Formulated daily work schedules, optimizing labor hours and minimizing overtime by 15%.

- •Effectively employed hydraulic tools, contributing to a 20% reduction in manual labor hours.

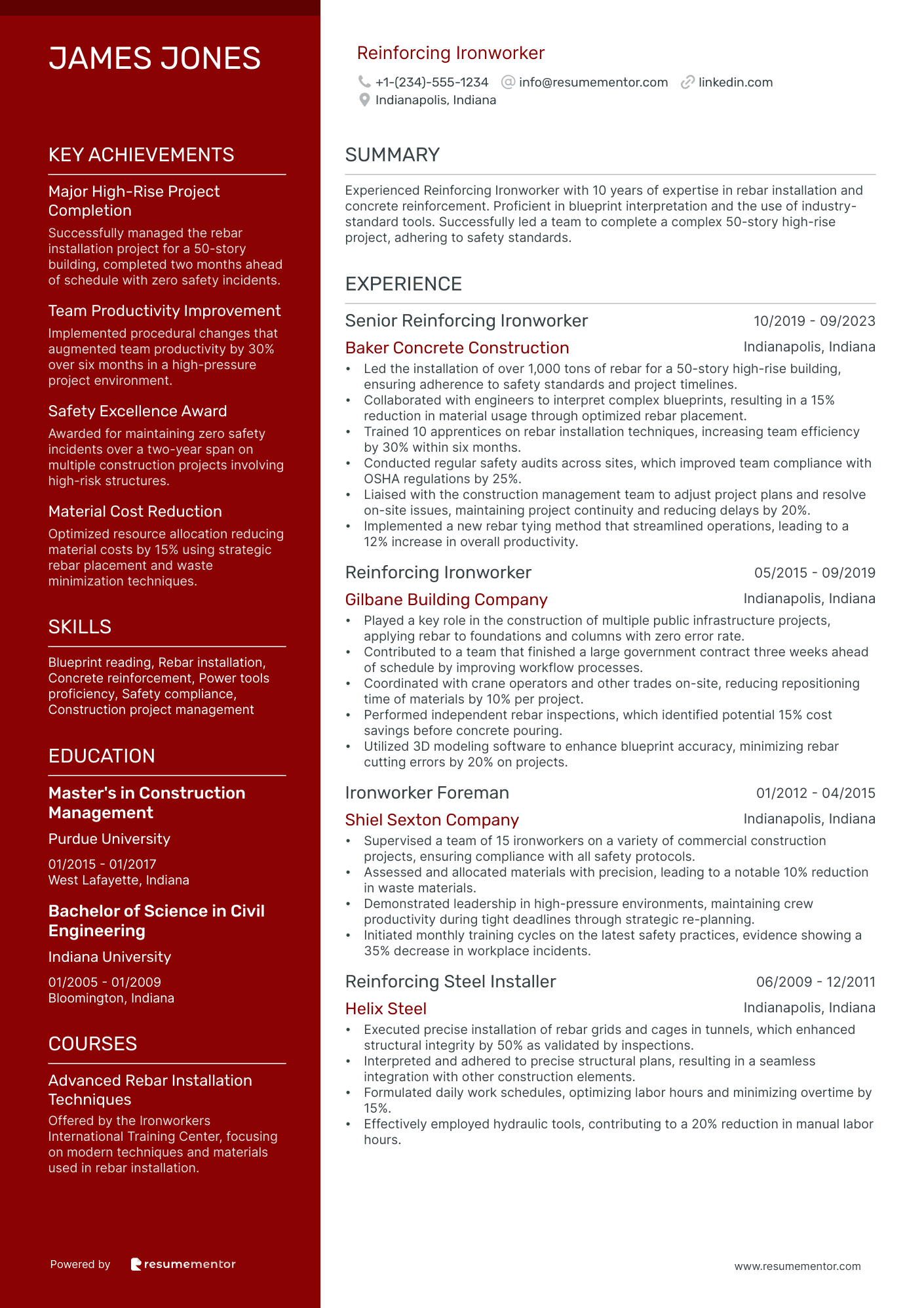

Ironworker Foreman resume sample

- •Led a team of 15 ironworkers in constructing a 150,000 sq ft commercial building, ensuring a 10% reduction in project completion time.

- •Developed and implemented safety protocols that resulted in zero lost-time incidents over a two-year project period.

- •Collaborated with engineers and project managers to enhance project efficiency, leading to a cost saving of 15% annually.

- •Coordinated multiple project schedules simultaneously, improving resource allocation and reducing project cost by 8%.

- •Mentored new team members, focusing on skill enhancement, which increased team productivity by 30% over six months.

- •Conducted site inspections regularly and identified potential compliance issues, leading to 100% adherence to safety regulations.

- •Supervised the installation of 1,000 tons of steel beams in a multi-story complex, leading to completion two weeks ahead of schedule.

- •Managed tool inventory, optimizing usage and reducing equipment downtime by 15% through preventive maintenance plans.

- •Conducted over 50 safety meetings and training sessions, resulting in a 95% decrease in minor onsite accidents.

- •Facilitated the interpretation of complex blueprints with team members, improving accuracy and reducing rework by 10%.

- •Collaborated with subcontractors and vendors effectively, ensuring timely delivery of materials and keeping the project on track.

- •Implemented efficient work methods that increased team productivity by 12%, completing tasks ahead of deadlines.

- •Interpreted blueprints for construction of a 200,000 sq ft manufacturing plant, ensuring precise assembly of structural components.

- •Assisted in the training of 15 junior ironworkers, increasing their skills and contributing to a cohesive team environment.

- •Managed daily work logs and production records, facilitating smooth tracking and documentation for project management.

- •Erected structural frameworks for multiple industrial buildings, ensuring compliance with industry safety standards.

- •Assisted in project work planning, contributing to a 5% reduction in project timeline deviations.

- •Participated in site safety evaluations, offering improvements that reduced workplace incident reports by 20%.

- •Collaborated with other construction trades effectively, leading to improved work site efficiency and cooperation.

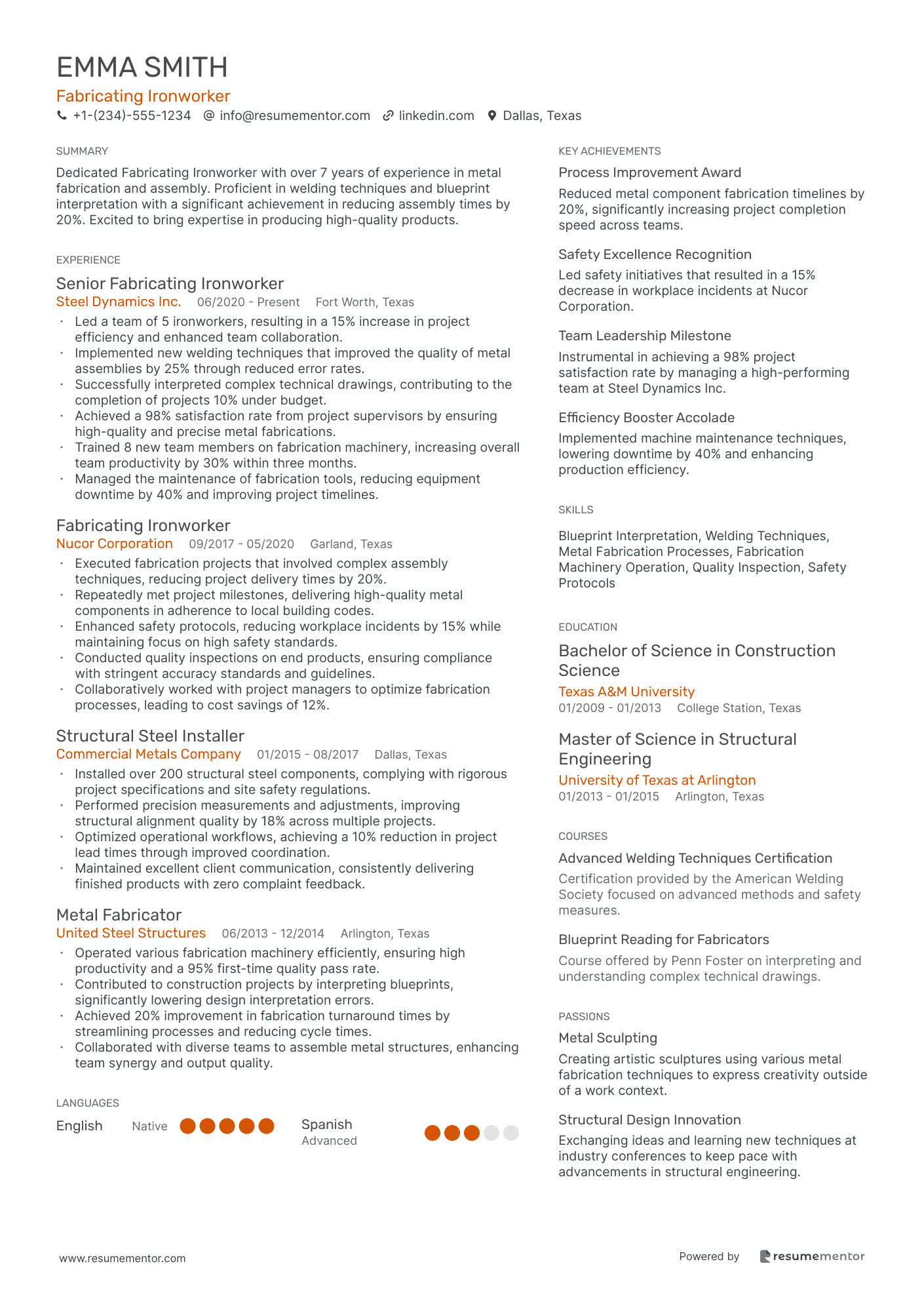

Fabricating Ironworker resume sample

- •Led a team of 5 ironworkers, resulting in a 15% increase in project efficiency and enhanced team collaboration.

- •Implemented new welding techniques that improved the quality of metal assemblies by 25% through reduced error rates.

- •Successfully interpreted complex technical drawings, contributing to the completion of projects 10% under budget.

- •Achieved a 98% satisfaction rate from project supervisors by ensuring high-quality and precise metal fabrications.

- •Trained 8 new team members on fabrication machinery, increasing overall team productivity by 30% within three months.

- •Managed the maintenance of fabrication tools, reducing equipment downtime by 40% and improving project timelines.

- •Executed fabrication projects that involved complex assembly techniques, reducing project delivery times by 20%.

- •Repeatedly met project milestones, delivering high-quality metal components in adherence to local building codes.

- •Enhanced safety protocols, reducing workplace incidents by 15% while maintaining focus on high safety standards.

- •Conducted quality inspections on end products, ensuring compliance with stringent accuracy standards and guidelines.

- •Collaboratively worked with project managers to optimize fabrication processes, leading to cost savings of 12%.

- •Installed over 200 structural steel components, complying with rigorous project specifications and site safety regulations.

- •Performed precision measurements and adjustments, improving structural alignment quality by 18% across multiple projects.

- •Optimized operational workflows, achieving a 10% reduction in project lead times through improved coordination.

- •Maintained excellent client communication, consistently delivering finished products with zero complaint feedback.

- •Operated various fabrication machinery efficiently, ensuring high productivity and a 95% first-time quality pass rate.

- •Contributed to construction projects by interpreting blueprints, significantly lowering design interpretation errors.

- •Achieved 20% improvement in fabrication turnaround times by streamlining processes and reducing cycle times.

- •Collaborated with diverse teams to assemble metal structures, enhancing team synergy and output quality.

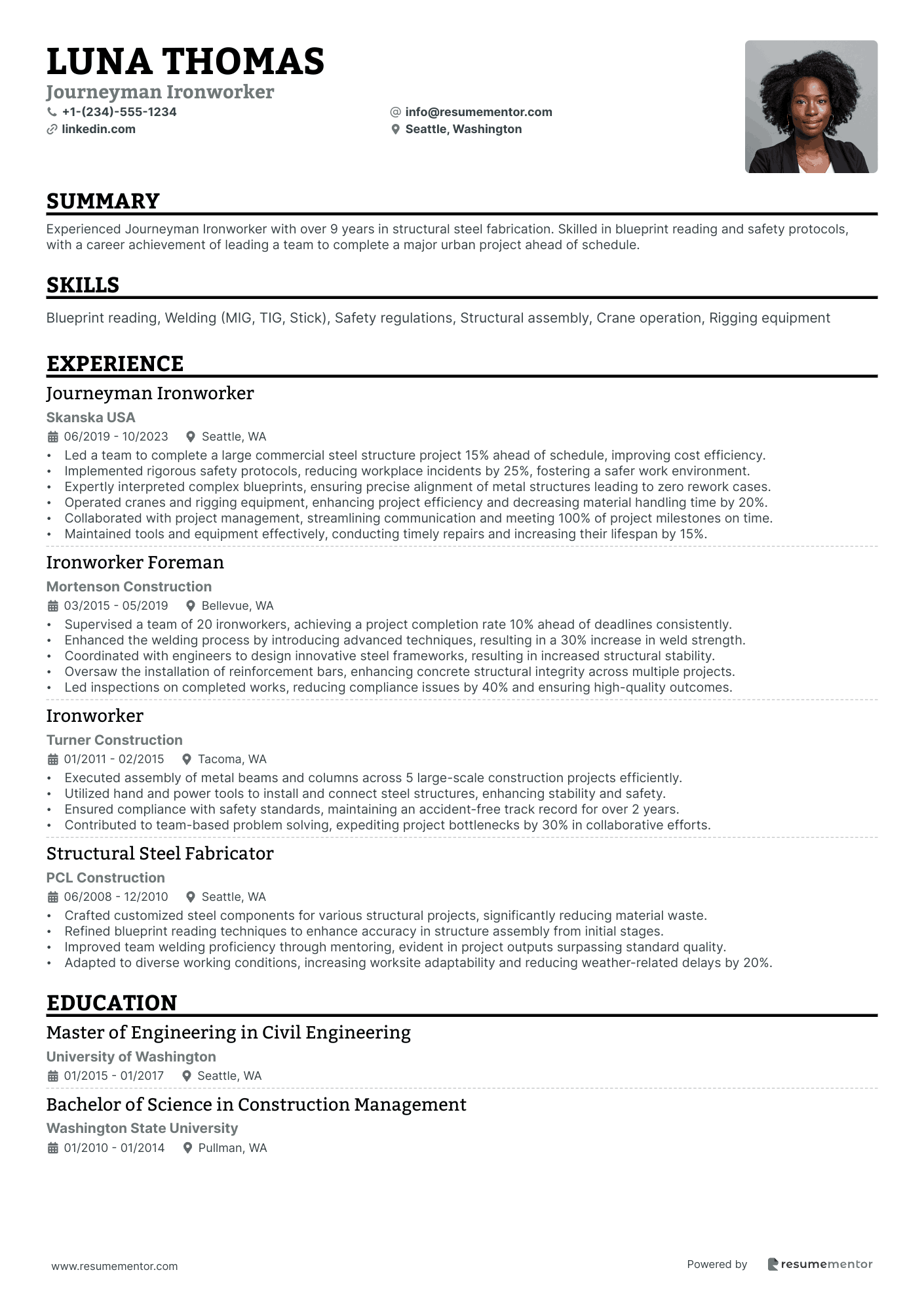

Journeyman Ironworker resume sample

- •Led a team to complete a large commercial steel structure project 15% ahead of schedule, improving cost efficiency.

- •Implemented rigorous safety protocols, reducing workplace incidents by 25%, fostering a safer work environment.

- •Expertly interpreted complex blueprints, ensuring precise alignment of metal structures leading to zero rework cases.

- •Operated cranes and rigging equipment, enhancing project efficiency and decreasing material handling time by 20%.

- •Collaborated with project management, streamlining communication and meeting 100% of project milestones on time.

- •Maintained tools and equipment effectively, conducting timely repairs and increasing their lifespan by 15%.

- •Supervised a team of 20 ironworkers, achieving a project completion rate 10% ahead of deadlines consistently.

- •Enhanced the welding process by introducing advanced techniques, resulting in a 30% increase in weld strength.

- •Coordinated with engineers to design innovative steel frameworks, resulting in increased structural stability.

- •Oversaw the installation of reinforcement bars, enhancing concrete structural integrity across multiple projects.

- •Led inspections on completed works, reducing compliance issues by 40% and ensuring high-quality outcomes.

- •Executed assembly of metal beams and columns across 5 large-scale construction projects efficiently.

- •Utilized hand and power tools to install and connect steel structures, enhancing stability and safety.

- •Ensured compliance with safety standards, maintaining an accident-free track record for over 2 years.

- •Contributed to team-based problem solving, expediting project bottlenecks by 30% in collaborative efforts.

- •Crafted customized steel components for various structural projects, significantly reducing material waste.

- •Refined blueprint reading techniques to enhance accuracy in structure assembly from initial stages.

- •Improved team welding proficiency through mentoring, evident in project outputs surpassing standard quality.

- •Adapted to diverse working conditions, increasing worksite adaptability and reducing weather-related delays by 20%.

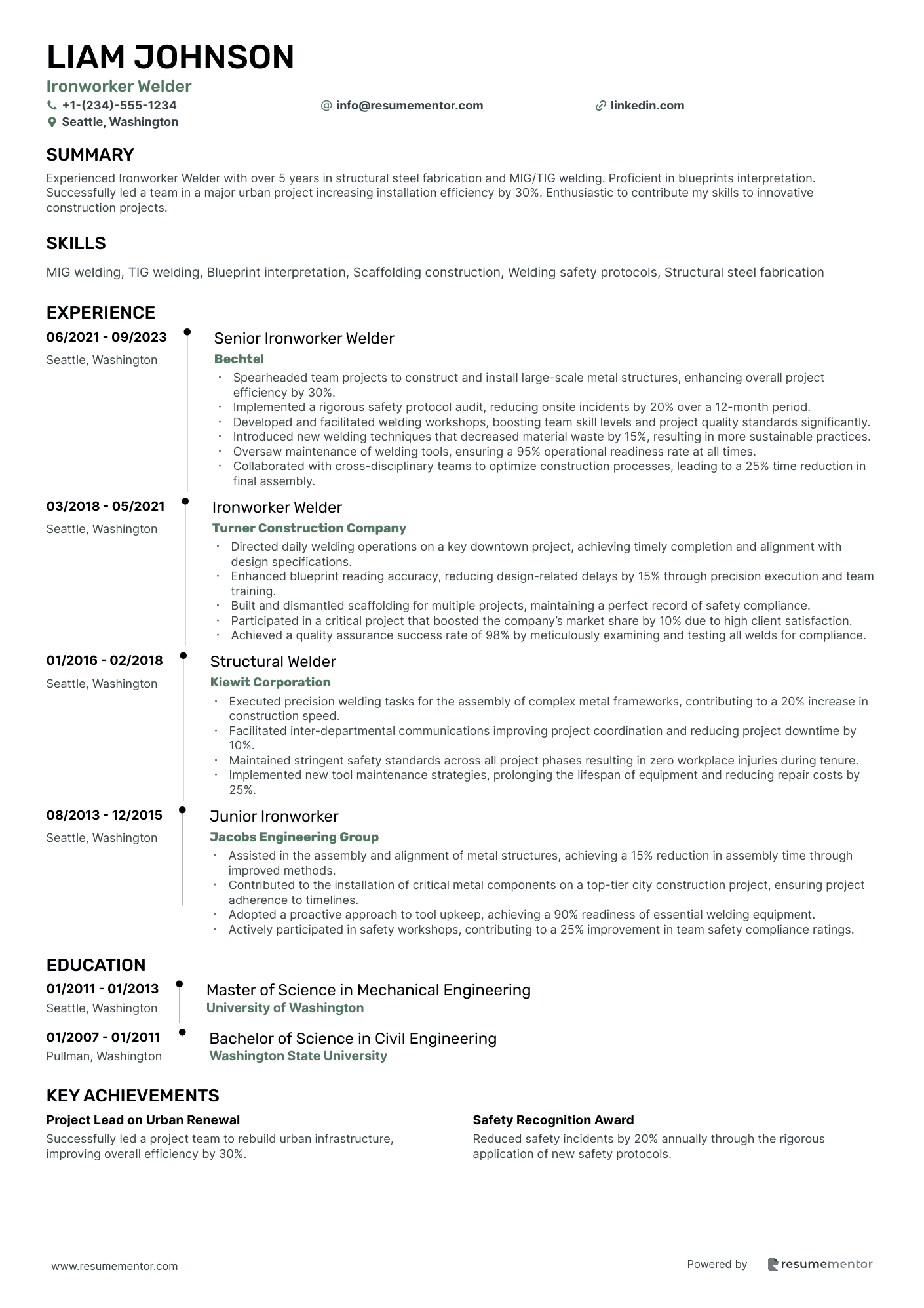

Ironworker Welder resume sample

- •Spearheaded team projects to construct and install large-scale metal structures, enhancing overall project efficiency by 30%.

- •Implemented a rigorous safety protocol audit, reducing onsite incidents by 20% over a 12-month period.

- •Developed and facilitated welding workshops, boosting team skill levels and project quality standards significantly.

- •Introduced new welding techniques that decreased material waste by 15%, resulting in more sustainable practices.

- •Oversaw maintenance of welding tools, ensuring a 95% operational readiness rate at all times.

- •Collaborated with cross-disciplinary teams to optimize construction processes, leading to a 25% time reduction in final assembly.

- •Directed daily welding operations on a key downtown project, achieving timely completion and alignment with design specifications.

- •Enhanced blueprint reading accuracy, reducing design-related delays by 15% through precision execution and team training.

- •Built and dismantled scaffolding for multiple projects, maintaining a perfect record of safety compliance.

- •Participated in a critical project that boosted the company’s market share by 10% due to high client satisfaction.

- •Achieved a quality assurance success rate of 98% by meticulously examining and testing all welds for compliance.

- •Executed precision welding tasks for the assembly of complex metal frameworks, contributing to a 20% increase in construction speed.

- •Facilitated inter-departmental communications improving project coordination and reducing project downtime by 10%.

- •Maintained stringent safety standards across all project phases resulting in zero workplace injuries during tenure.

- •Implemented new tool maintenance strategies, prolonging the lifespan of equipment and reducing repair costs by 25%.

- •Assisted in the assembly and alignment of metal structures, achieving a 15% reduction in assembly time through improved methods.

- •Contributed to the installation of critical metal components on a top-tier city construction project, ensuring project adherence to timelines.

- •Adopted a proactive approach to tool upkeep, achieving a 90% readiness of essential welding equipment.

- •Actively participated in safety workshops, contributing to a 25% improvement in team safety compliance ratings.

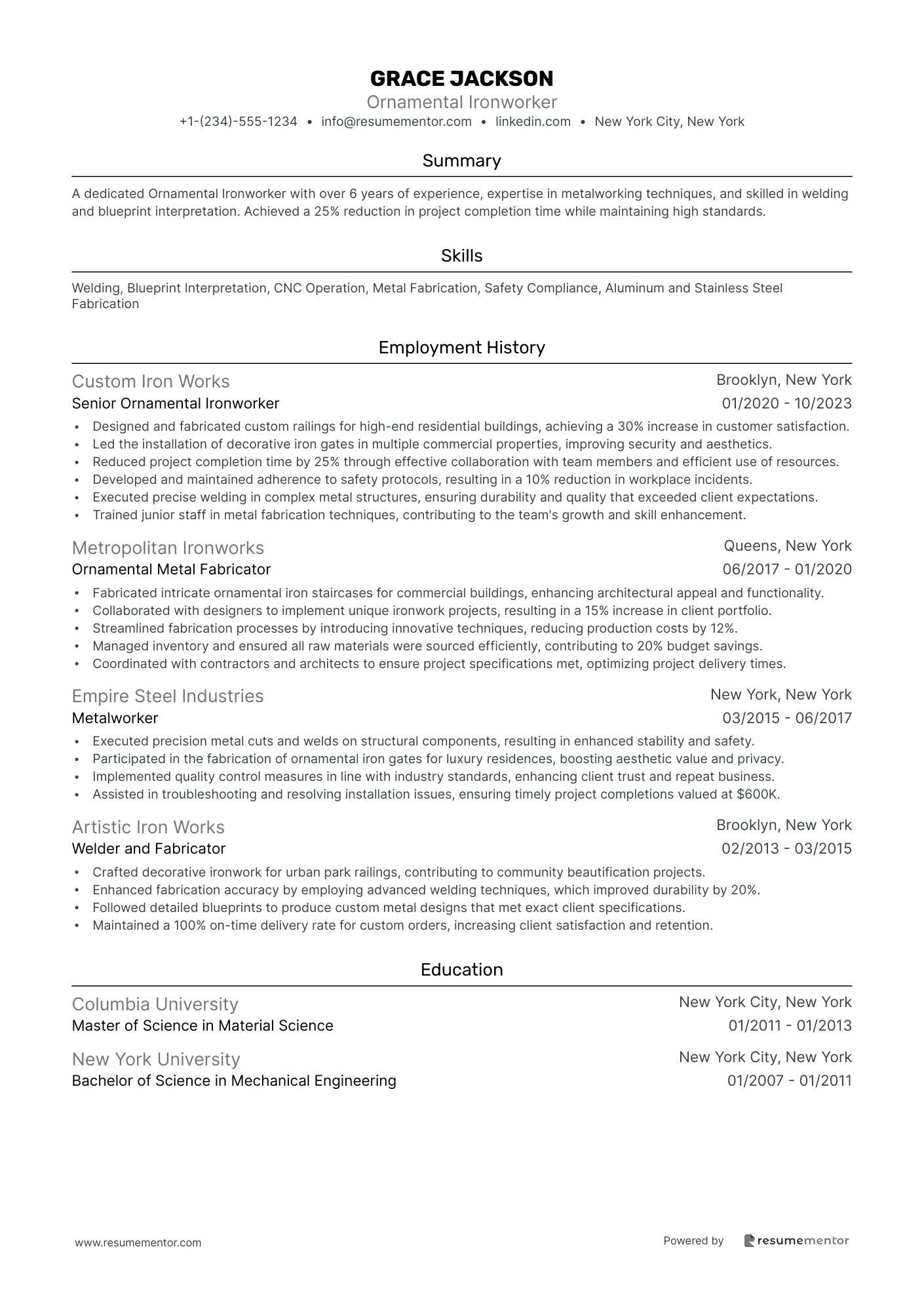

Ornamental Ironworker resume sample

- •Designed and fabricated custom railings for high-end residential buildings, achieving a 30% increase in customer satisfaction.

- •Led the installation of decorative iron gates in multiple commercial properties, improving security and aesthetics.

- •Reduced project completion time by 25% through effective collaboration with team members and efficient use of resources.

- •Developed and maintained adherence to safety protocols, resulting in a 10% reduction in workplace incidents.

- •Executed precise welding in complex metal structures, ensuring durability and quality that exceeded client expectations.

- •Trained junior staff in metal fabrication techniques, contributing to the team's growth and skill enhancement.

- •Fabricated intricate ornamental iron staircases for commercial buildings, enhancing architectural appeal and functionality.

- •Collaborated with designers to implement unique ironwork projects, resulting in a 15% increase in client portfolio.

- •Streamlined fabrication processes by introducing innovative techniques, reducing production costs by 12%.

- •Managed inventory and ensured all raw materials were sourced efficiently, contributing to 20% budget savings.

- •Coordinated with contractors and architects to ensure project specifications met, optimizing project delivery times.

- •Executed precision metal cuts and welds on structural components, resulting in enhanced stability and safety.

- •Participated in the fabrication of ornamental iron gates for luxury residences, boosting aesthetic value and privacy.

- •Implemented quality control measures in line with industry standards, enhancing client trust and repeat business.

- •Assisted in troubleshooting and resolving installation issues, ensuring timely project completions valued at $600K.

- •Crafted decorative ironwork for urban park railings, contributing to community beautification projects.

- •Enhanced fabrication accuracy by employing advanced welding techniques, which improved durability by 20%.

- •Followed detailed blueprints to produce custom metal designs that met exact client specifications.

- •Maintained a 100% on-time delivery rate for custom orders, increasing client satisfaction and retention.

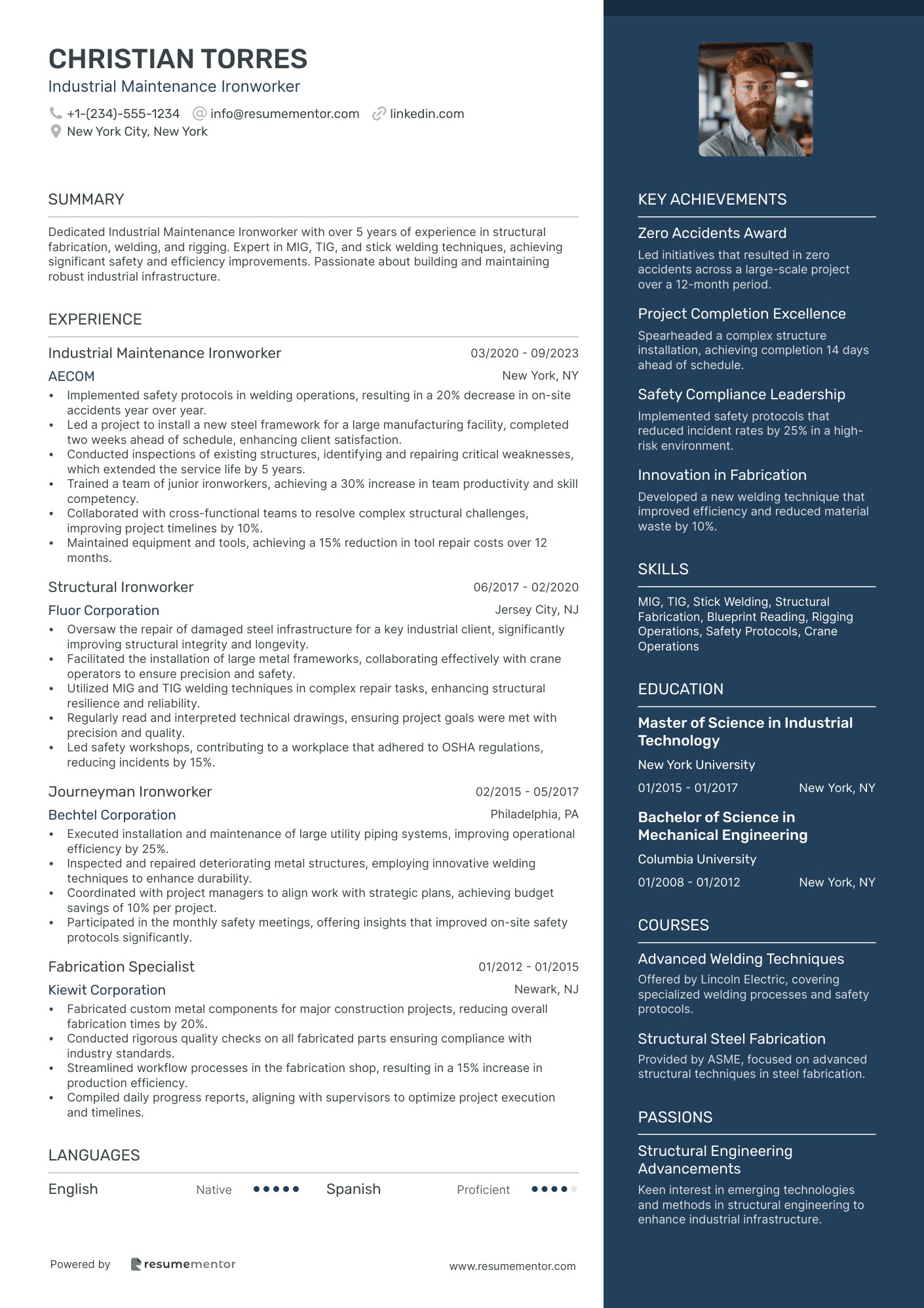

Industrial Maintenance Ironworker resume sample

- •Implemented safety protocols in welding operations, resulting in a 20% decrease in on-site accidents year over year.

- •Led a project to install a new steel framework for a large manufacturing facility, completed two weeks ahead of schedule, enhancing client satisfaction.

- •Conducted inspections of existing structures, identifying and repairing critical weaknesses, which extended the service life by 5 years.

- •Trained a team of junior ironworkers, achieving a 30% increase in team productivity and skill competency.

- •Collaborated with cross-functional teams to resolve complex structural challenges, improving project timelines by 10%.

- •Maintained equipment and tools, achieving a 15% reduction in tool repair costs over 12 months.

- •Oversaw the repair of damaged steel infrastructure for a key industrial client, significantly improving structural integrity and longevity.

- •Facilitated the installation of large metal frameworks, collaborating effectively with crane operators to ensure precision and safety.

- •Utilized MIG and TIG welding techniques in complex repair tasks, enhancing structural resilience and reliability.

- •Regularly read and interpreted technical drawings, ensuring project goals were met with precision and quality.

- •Led safety workshops, contributing to a workplace that adhered to OSHA regulations, reducing incidents by 15%.

- •Executed installation and maintenance of large utility piping systems, improving operational efficiency by 25%.

- •Inspected and repaired deteriorating metal structures, employing innovative welding techniques to enhance durability.

- •Coordinated with project managers to align work with strategic plans, achieving budget savings of 10% per project.

- •Participated in the monthly safety meetings, offering insights that improved on-site safety protocols significantly.

- •Fabricated custom metal components for major construction projects, reducing overall fabrication times by 20%.

- •Conducted rigorous quality checks on all fabricated parts ensuring compliance with industry standards.

- •Streamlined workflow processes in the fabrication shop, resulting in a 15% increase in production efficiency.

- •Compiled daily progress reports, aligning with supervisors to optimize project execution and timelines.

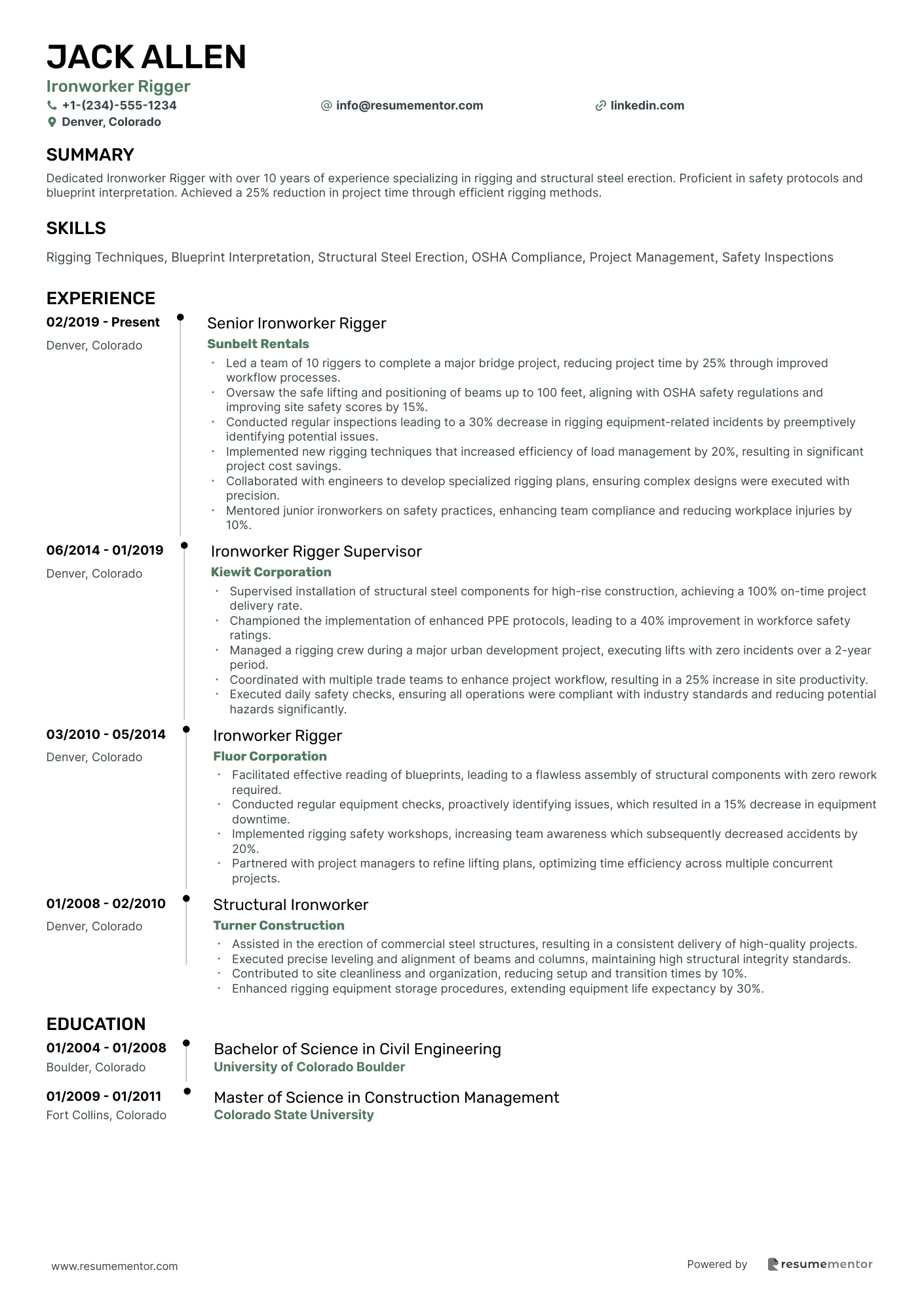

Ironworker Rigger resume sample

- •Led a team of 10 riggers to complete a major bridge project, reducing project time by 25% through improved workflow processes.

- •Oversaw the safe lifting and positioning of beams up to 100 feet, aligning with OSHA safety regulations and improving site safety scores by 15%.

- •Conducted regular inspections leading to a 30% decrease in rigging equipment-related incidents by preemptively identifying potential issues.

- •Implemented new rigging techniques that increased efficiency of load management by 20%, resulting in significant project cost savings.

- •Collaborated with engineers to develop specialized rigging plans, ensuring complex designs were executed with precision.

- •Mentored junior ironworkers on safety practices, enhancing team compliance and reducing workplace injuries by 10%.

- •Supervised installation of structural steel components for high-rise construction, achieving a 100% on-time project delivery rate.

- •Championed the implementation of enhanced PPE protocols, leading to a 40% improvement in workforce safety ratings.

- •Managed a rigging crew during a major urban development project, executing lifts with zero incidents over a 2-year period.

- •Coordinated with multiple trade teams to enhance project workflow, resulting in a 25% increase in site productivity.

- •Executed daily safety checks, ensuring all operations were compliant with industry standards and reducing potential hazards significantly.

- •Facilitated effective reading of blueprints, leading to a flawless assembly of structural components with zero rework required.

- •Conducted regular equipment checks, proactively identifying issues, which resulted in a 15% decrease in equipment downtime.

- •Implemented rigging safety workshops, increasing team awareness which subsequently decreased accidents by 20%.

- •Partnered with project managers to refine lifting plans, optimizing time efficiency across multiple concurrent projects.

- •Assisted in the erection of commercial steel structures, resulting in a consistent delivery of high-quality projects.

- •Executed precise leveling and alignment of beams and columns, maintaining high structural integrity standards.

- •Contributed to site cleanliness and organization, reducing setup and transition times by 10%.

- •Enhanced rigging equipment storage procedures, extending equipment life expectancy by 30%.

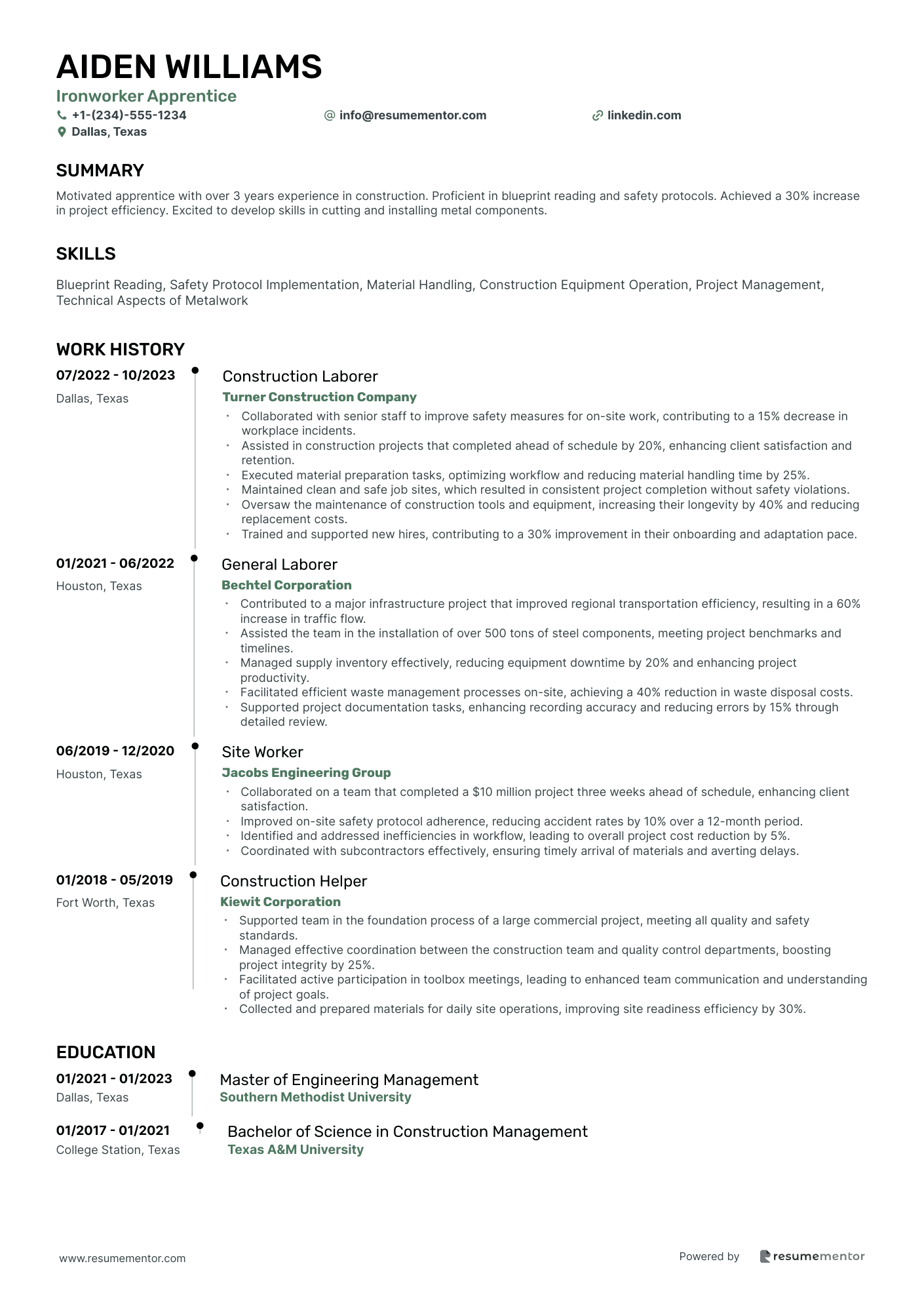

Ironworker Apprentice resume sample

- •Collaborated with senior staff to improve safety measures for on-site work, contributing to a 15% decrease in workplace incidents.

- •Assisted in construction projects that completed ahead of schedule by 20%, enhancing client satisfaction and retention.

- •Executed material preparation tasks, optimizing workflow and reducing material handling time by 25%.

- •Maintained clean and safe job sites, which resulted in consistent project completion without safety violations.

- •Oversaw the maintenance of construction tools and equipment, increasing their longevity by 40% and reducing replacement costs.

- •Trained and supported new hires, contributing to a 30% improvement in their onboarding and adaptation pace.

- •Contributed to a major infrastructure project that improved regional transportation efficiency, resulting in a 60% increase in traffic flow.

- •Assisted the team in the installation of over 500 tons of steel components, meeting project benchmarks and timelines.

- •Managed supply inventory effectively, reducing equipment downtime by 20% and enhancing project productivity.

- •Facilitated efficient waste management processes on-site, achieving a 40% reduction in waste disposal costs.

- •Supported project documentation tasks, enhancing recording accuracy and reducing errors by 15% through detailed review.

- •Collaborated on a team that completed a $10 million project three weeks ahead of schedule, enhancing client satisfaction.

- •Improved on-site safety protocol adherence, reducing accident rates by 10% over a 12-month period.

- •Identified and addressed inefficiencies in workflow, leading to overall project cost reduction by 5%.

- •Coordinated with subcontractors effectively, ensuring timely arrival of materials and averting delays.

- •Supported team in the foundation process of a large commercial project, meeting all quality and safety standards.

- •Managed effective coordination between the construction team and quality control departments, boosting project integrity by 25%.

- •Facilitated active participation in toolbox meetings, leading to enhanced team communication and understanding of project goals.

- •Collected and prepared materials for daily site operations, improving site readiness efficiency by 30%.

As an ironworker, you're used to creating solid structures that hold everything together, but crafting your resume can feel like building without a plan. It often seems tough to translate your hands-on skills into words, as your technical know-how in balancing precision with strength easily gets lost on paper.

When you're on the job hunt, this challenge can be frustrating. It’s not just about listing every weld and rivet but turning them into a story that grabs attention. Tailoring your resume to highlight your skills and safety record is key—it should clearly reflect your reliability and attention to detail.

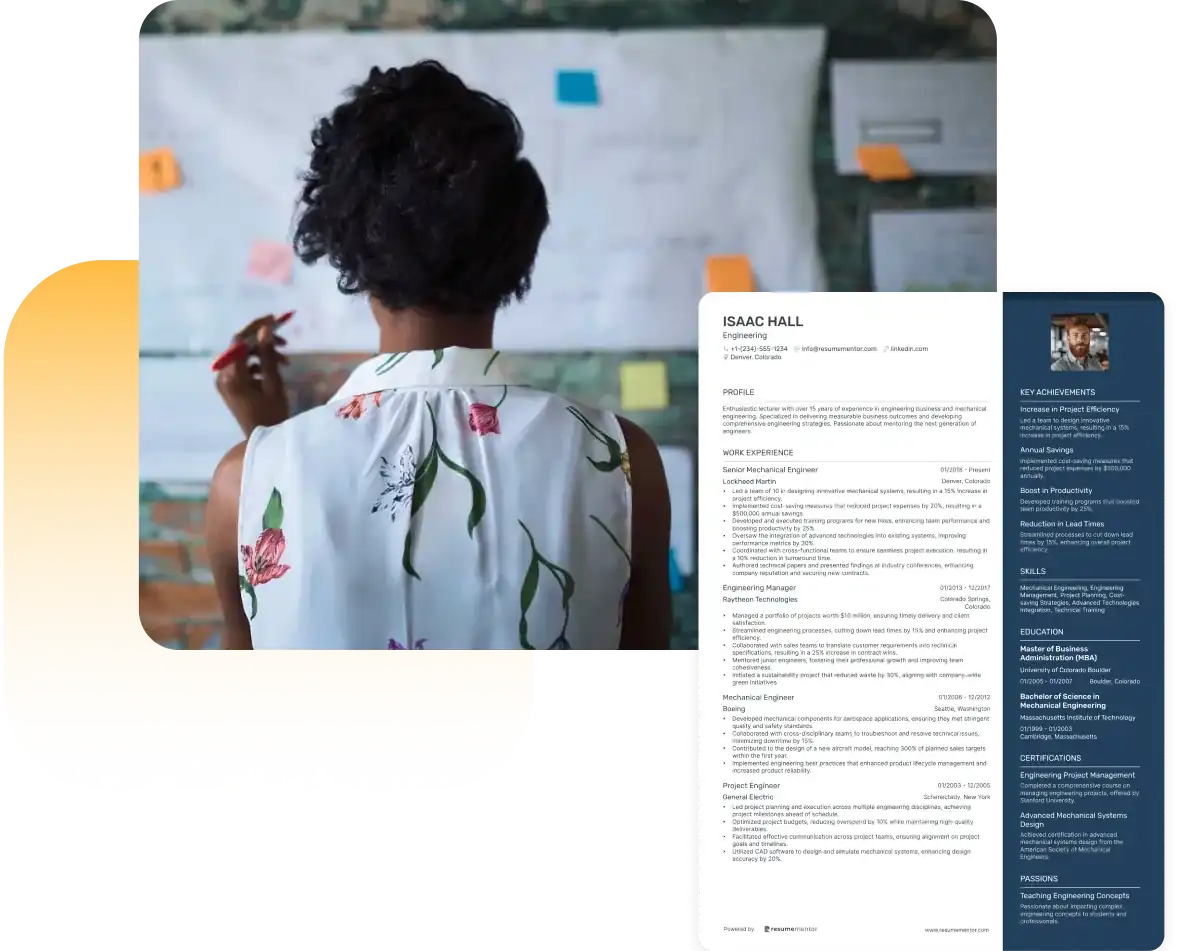

This is where a good resume template becomes invaluable. Such templates provide structure, guiding you to present your skills and experience clearly. They transform your resume into an organized and professional document, making it easy for hiring managers to quickly see your value.

With the right tools and guidance, building an impressive resume becomes a manageable task. By following this guide, you’ll learn to turn your on-the-job achievements into a polished resume. You'll be ready to secure the next great job on your career path.

Key Takeaways

- Highlight your skills and safety record by tailoring your resume to reflect your reliability and attention to detail.

- Use resume templates to provide structure and guide you in presenting your skills and experience clearly.

- Choose the reverse chronological resume format to showcase the most recent and relevant work experiences.

- Craft a quantifiable experience section that highlights specific achievements and employs strong action verbs.

- Include certifications and licenses to set yourself apart by demonstrating your commitment to safety and professionalism.

What to focus on when writing your ironworker resume

An ironworker resume should convey to recruiters that you have the essential skills, experience, and reliability for the job. It needs to show your proficiency in managing physically demanding tasks, maintaining safety at heights, and constructing and installing steel frameworks—critical aspects that affirm your readiness and enthusiasm for the role.

How to structure your ironworker resume

- Contact Information: Your full name, phone number, email address, and location are the primary details here. These ensure that recruiters can easily connect with you when considering you for the position. Accuracy in these details reflects professionalism and attention to detail, qualities you should display throughout your resume.

- Professional Summary: This should be a strong, concise paragraph capturing your ironworking experience, with key highlights of your safety certifications and any particular specialties such as welding or rigging. A well-crafted summary not only showcases your core competencies but also provides insight into your career objectives, setting the tone for the rest of the resume as a testament to your expertise in the field.

- Work Experience: When listing your jobs in reverse order, focus on roles involving fabricating metal structures, reading blueprints, and erecting steel beams. These experiences highlight your hands-on expertise. Use this section to emphasize accomplishments and specific contributions, providing a narrative of your career progression and value delivered in past roles.

- Skills: Include abilities such as blueprint reading, welding, crane operation, and understanding safety procedures. Clearly defined skills align your capabilities with the job requirements, demonstrating your technical proficiency and preparedness to tackle the challenges of the role head-on.

- Certifications and Licenses: Detailing certifications like OSHA safety training, welding certification, or rigging certification demonstrates your commitment to safety and professionalism in the field. Credentials set you apart from others, showing dedication to maintaining a high standard in your craft.

- Education: Enhancing this section with information on your educational background, such as a high school diploma or trade school certifications, rounds out your qualifications. It complements other sections of your resume, supporting your expertise with foundational knowledge that adds credibility to your practical skills.

Preparing each section with attention to detail will support your goal of crafting a compelling resume—below, we will delve into each section more thoroughly, ensuring you convey your best potential to recruiters.

Which resume format to choose

Selecting the right resume format for your ironworker career is crucial for making a strong impact on potential employers. The reverse chronological format is typically the most effective choice. This structure highlights your most recent work experiences right at the top, providing a clear view of how your skills have evolved over time. This is particularly important in construction, where staying updated with the latest tools and techniques is essential.

When it comes to fonts, consider modern options like Lato, Montserrat, or Raleway. These fonts give your resume a clean and contemporary look without sacrificing readability. A clear font choice reflects the precision and attention to detail that are important in the ironworking profession. Always save your resume as a PDF to keep its formatting intact. A PDF ensures your document looks the same on any device, preventing any unintended changes in layout or structure that could occur with other file types.

Setting one-inch margins on all sides creates a balanced and professional appearance. This spacing ensures your content is easy to read and makes your resume appear organized, which is vital in a field driven by accuracy and clarity. By focusing on these elements, you’ll create a resume that effectively communicates your value as an ironworker and leaves a lasting impression.

How to write a quantifiable resume experience section

The experience section of your ironworker resume is key to showcasing your hands-on skills and demonstrating the tangible results you've delivered on the job. By concentrating on specific tasks you've completed and highlighting measurable achievements, you create a powerful narrative. Start with your most recent position and work backward, covering the past 10-15 years. This chronological structure not only shows your career progression but also paints a clear picture of your growing expertise. Including relevant job titles such as Ironworker, Welder, or Construction Worker ensures alignment with the role you're applying for. Tailor your resume to each job ad, emphasizing experiences that align with the employer’s specific needs. Using strong action words like "fabricated," "collaborated," "achieved," and "installed" helps convey your contributions effectively and keeps the reader engaged.

Here's how you can structure it:

- •Directed a team of 10 ironworkers to install over 500 tons of structural steel on time and within budget, boosting project efficiency by 15%.

- •Cut workplace incidents by 20% through enhanced safety protocols and regular training sessions.

- •Worked with project engineers to tweak blueprints, saving $200,000 in materials and labor costs.

- •Fabricated and assembled intricate structures, resulting in a 98% client satisfaction rate due to quality workmanship.

This experience section stands out by weaving together quantifiable achievements that highlight your impact across different projects. Starting with your most recent position demonstrates your ability to handle increasing responsibilities over time. By using strong action verbs and citing concrete results like tons of steel installed and cost savings achieved, you vividly illustrate your capability and effectiveness. Tailoring the resume to focus on safety improvements and cost reductions addresses potential employer priorities. The clear, direct language keeps your message concise, reflecting your ability to communicate effectively in dynamic construction settings.

Technology-Focused resume experience section

A technology-focused ironworker resume experience section should emphasize the tech skills and achievements that set you apart. Begin by identifying the specific technologies and machinery you've mastered, demonstrating how these tools have been essential in your work. Highlight how you have used technology to enhance safety protocols and successfully complete projects. By presenting a clear and impactful overview of your experience, you can capture the attention of prospective employers.

Ensure your descriptions are direct and focus on the value you brought to past roles. Start with the dates of employment and your job title, but make sure to connect each point to show a progression in your responsibilities and impact. Utilize action verbs like "operated," "implemented," and "managed" to inject energy into your achievements. Each bullet should highlight how your tech skills benefitted the workplace, creating a cohesive narrative of growth and expertise. Highlight your roles in innovative projects and any relevant training or certifications to round out your story.

Lead Ironworker

Steel Structures, Inc.

January 2018 - Present

- Operated CNC machinery, ensuring precise cutting and welding for complex structures.

- Leveraged digital blueprint technology to improve installation accuracy by 30%.

- Utilized automated software for real-time project adjustments and resource tracking.

- Enhanced team precision by training members in using advanced laser alignment tools.

Growth-Focused resume experience section

A growth-focused ironworker resume experience section should highlight your technical skills and achievements that underline your contributions to the company's success. By focusing on accomplishments, you illustrate your expertise and the positive impact you've had on projects. Connecting reliability, safety commitment, and task efficiency within your roles demonstrates your value. Using numbers to quantify achievements, like indicating project sizes or citing percentage improvements, provides clear, tangible evidence of your impact.

To make this section compelling, craft bullet points that emphasize aspects aligning with growth, such as leading projects, enhancing efficiency, or advancing team success. It’s important to use active language that highlights actions and results, ensuring each point clearly portrays your role and impact. Specifying the types of projects and the tools or techniques you’ve mastered helps provide a comprehensive picture of your skill set to employers. This focused approach paints you as a proactive ironworker dedicated to quality and efficiency, enhancing your appeal as a valuable part of any construction team.

Structural Ironworker

ABC Construction Company

March 2018 - Present

- Increased project completion rates by 20% through effective team collaboration and time management.

- Implemented new safety guidelines resulting in a 30% decrease in on-site accidents.

- Led a team of 5 in the successful installation of steel frameworks for multiple high-rise buildings.

- Enhanced welding techniques to improve structural stability and meet all quality standards.

Achievement-Focused resume experience section

A well-crafted achievement-focused ironworker resume experience section should effectively highlight the impressive results you've achieved in your past roles. Begin by pinpointing standout tasks and accomplishments that showcase your skills and demonstrate your value. Consider what sets you apart, such as your ability to finish projects faster than expected or implement safety practices that successfully reduce incidents. Employ action-oriented language and incorporate specific numbers whenever possible to underline the concrete effects of your work. In this way, you can showcase major contributions to large-scale projects or highlight your effective teamwork with other trades, illustrating your collaborative abilities.

When crafting bullet points, ensure each one highlights a distinct achievement or responsibility, avoiding vague descriptions to help weave a cohesive story of your career progress. Clearly differentiating between roles, especially if your experience covers multiple projects, will aid in building a logical career narrative. By focusing on clarity and specificity, you allow your achievements to naturally reflect your skills and dedication to the trade. The goal is to present a concise and complete narrative that positions you as a skilled and reliable ironworker, whose professional journey speaks volumes through accomplishments.

Ironworker

Skyline Construction Co.

June 2020 - August 2023

- Installed over 200 steel beams for a skyscraper project, completing the work 10% ahead of schedule.

- Followed strict safety protocols and reduced on-site incidents by 30%.

- Collaborated with a team of 15 workers to successfully assemble a bridge structure.

- Trained 5 apprentices on welding techniques, increasing team efficiency by 20%.

Leadership-Focused resume experience section

A leadership-focused ironworker resume experience section should highlight your accomplishments while demonstrating your ability to lead. Start by identifying the leadership skills you've honed throughout your career, focusing on examples that best showcase these strengths. Use action words to begin each bullet point, conveying a sense of initiative and achievement. Numbers and statistics can be a powerful way to provide a clear and tangible picture of your capabilities.

Emphasizing your contributions to team successes and projects you've led can illustrate the positive impact you've made in your previous roles. Include examples of how you've implemented safety measures that improved working conditions or strategies that boosted productivity and team efficiency. It's important to create a narrative that shows how your leadership has directly influenced outcomes. By sharing instances of challenges you've overcome, you provide a comprehensive view of your leadership prowess and ability to tackle difficult situations.

Lead Ironworker

Skyline Constructions

June 2018 – August 2023

- Led a team of 15 in completing a high-rise building project three months ahead of schedule.

- Implemented a new safety protocol that reduced on-site accidents by 20%.

- Facilitated weekly team meetings, enhancing communication and increasing team productivity by 30%.

- Mentored junior ironworkers, resulting in a 25% skill improvement within six months.

Write your ironworker resume summary section

A skills-focused ironworker resume summary should showcase your strengths, experience, and what you offer to the role. If you're an experienced ironworker, highlighting your years in the trade, safety record, and specialized skills is essential. Consider this example:

This summary gives potential employers a clear view of your reliability and commitment to safety, crucial traits for an ironworker. If you're newer to the field or pivoting careers, crafting a resume objective might be more advantageous. This approach can communicate your goals and enthusiasm for the position, making it an ideal choice for those just starting or transitioning.

[here was the JSON object 2]

Building upon this, a resume profile combines elements of both summaries and objectives. It offers a brief yet balanced snapshot of what makes you unique. In contrast, a summary of qualifications is a list highlighting your most impressive skills and achievements, perfect for industry veterans with substantial experience to showcase.

By understanding the differences among a resume summary, objective, profile, and qualifications, you can tailor your resume to reflect your experience and aspirations effectively, ensuring it makes a strong impression.

Listing your ironworker skills on your resume

A skills-focused ironworker resume should clearly highlight the abilities that set you apart. Start with a standalone skills section to draw attention to your expertise, or integrate your skills into your experience or summary for added depth. Highlighting strengths and soft skills is essential. These are your personal assets, like teamwork and problem-solving, that enhance any work environment. Meanwhile, hard skills represent the technical, teachable abilities crucial to your role, such as welding or reading blueprints.

Incorporating these skills and strengths as resume keywords is essential for catching the eye of recruiters and applicant tracking systems. Placing them strategically increases your chance of matching job requirements and makes you stand out.

Example of a standalone skills section:

This example is effective because it lists critical ironworking abilities like blueprint reading and welding, which are essential to the role. By presenting these skills concisely, employers can easily assess how your qualifications meet their needs.

Best hard skills to feature on your ironworker resume

When listing hard skills, focus on those highlighting your expertise in working with metal and structures. These should communicate your technical knowledge and practical experience, demonstrating your competence and reliability.

Hard Skills

- Structural Blueprint Reading

- Steel Fabrication

- Welding Techniques

- Rigging

- Heavy Equipment Operation

- Safety Compliance

- Scaffolding Inspection and Assembly

- Material Handling

- Torch Cutting

- Construction Mathematics

- Reinforcement Installation

- Laser Alignment

- Metal Grinding

- Riveting

- Load Analysis

Best soft skills to feature on your ironworker resume

As an ironworker, showcasing soft skills that embody collaboration and adaptability is vital. These skills enable effective communication and problem-solving, showing your capability to excel in varied situations.

Soft Skills

- Team Collaboration

- Problem Solving

- Attention to Detail

- Time Management

- Communication

- Adaptability

- Critical Thinking

- Multitasking

- Leadership

- Reliability

- Conflict Resolution

- Patience

- Physical Stamina

- Resourcefulness

- Stress Management

How to include your education on your resume

The education section of your resume is a crucial part. It provides a snapshot of your learning journey and sets the foundation for your career as an ironworker. Tailoring this section to the job is essential—make sure you leave out any irrelevant education. List each degree clearly, mentioning the institution and timeframe. If you've earned honors like cum laude, include this next to your degree. When your GPA is strong and recent, you may list it to show academic excellence. Place it in parentheses after your degree, stating both your GPA and the maximum GPA if you want it to be clear.

For example, a resume displaying unfocused education information would look like this:

In contrast, a well-crafted section focused on relevant qualifications would appear like this:

This second example is effective because it showcases qualifications relevant to an ironworker's role. The inclusion of cum laude highlights your dedication and skills. Listing courses such as welding and blueprint reading aligns with the ironworker's duties. Your excellent GPA is mentioned, reflecting academic strength.

How to include ironworker certificates on your resume

Including a certificates section on your ironworker resume is crucial to showcase your qualifications and skills. This section can be added to the header or as a standalone section within your resume. Start by listing the name of each certificate you have earned. Include the date you received each certificate to demonstrate your ongoing commitment to the profession. Add the issuing organization to verify the legitimacy of your certification. Here's how you can structure your certificates section by placing it in the header:

- Certified Ironworker | Ironworkers International Union | 2021

This concise format keeps essential information upfront and relevant. Alternatively, here is an example of a standalone certificates section using JSON format:

This example is good because the certificates are directly related to ironworking. The "Certified Ironworker" title establishes your professional credibility, and the "OSHA 30-Hour Construction Safety" certificate highlights your knowledge of workplace safety, which is essential in the construction industry. The format is clear, making it easy for employers to quickly gauge your qualifications.

Extra sections to include on your ironworker resume

Creating a stand-out resume is crucial for showcasing your skills and experiences, especially in a hands-on field like ironworking. An effective resume highlights not just your technical skills but also your well-rounded personality and commitment to both professional and personal growth.

Language section — List any additional languages you speak fluently, as they can make you an asset on diverse job sites. Speaking another language can facilitate better communication with a wider range of team members and clients.

Hobbies and interests section — Use this section to show skills or traits that relate to ironworking, like metal crafts or construction projects. Offering insight into your passions can make you more relatable and memorable to employers.

Volunteer work section — Highlight any volunteer experiences related to construction or community improvement projects. Demonstrating volunteer work shows leadership and willingness to contribute beyond the paycheck.

Books section — Mention books that have influenced your work ethic or technical skills, such as industry-related textbooks or biographies of famous engineers. Sharing your reading habits can indicate a commitment to lifelong learning and staying informed in your field.

Including these sections can complement your resume by providing a fuller picture of you as a candidate and may give you an edge in standing out to potential employers.

In Conclusion

In conclusion, crafting a resume as an ironworker requires careful attention to detail, much like the precise work you perform on job sites. A strong resume not only details your hands-on skills but also captures the essence of your professional journey. By using a well-organized structure and focusing on relevant roles and achievements, you reflect your technical prowess and reliability. It's crucial to tailor each aspect of your resume to highlight your safety record and certifications, which underscore your commitment to the industry's standards. Including quantifiable accomplishments in your experience section can vividly showcase the impact of your efforts. Don’t forget to present a comprehensive skill set, blending both hard technical skills and soft interpersonal abilities. Choose a resume format that best highlights your career progression, making it easy for employers to see your growth and potential. Remember, each section, from your summary to additional sections, should contribute to an engaging narrative about your expertise and dedication. By integrating feedback and refining your resume, you stand poised to capture the attention of potential employers, advancing your career in this demanding and rewarding field. Your resume isn't just a list; it's a story of your career and potential, ready to unfold in your next role.

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2026. All rights reserved.

Made with love by people who care.