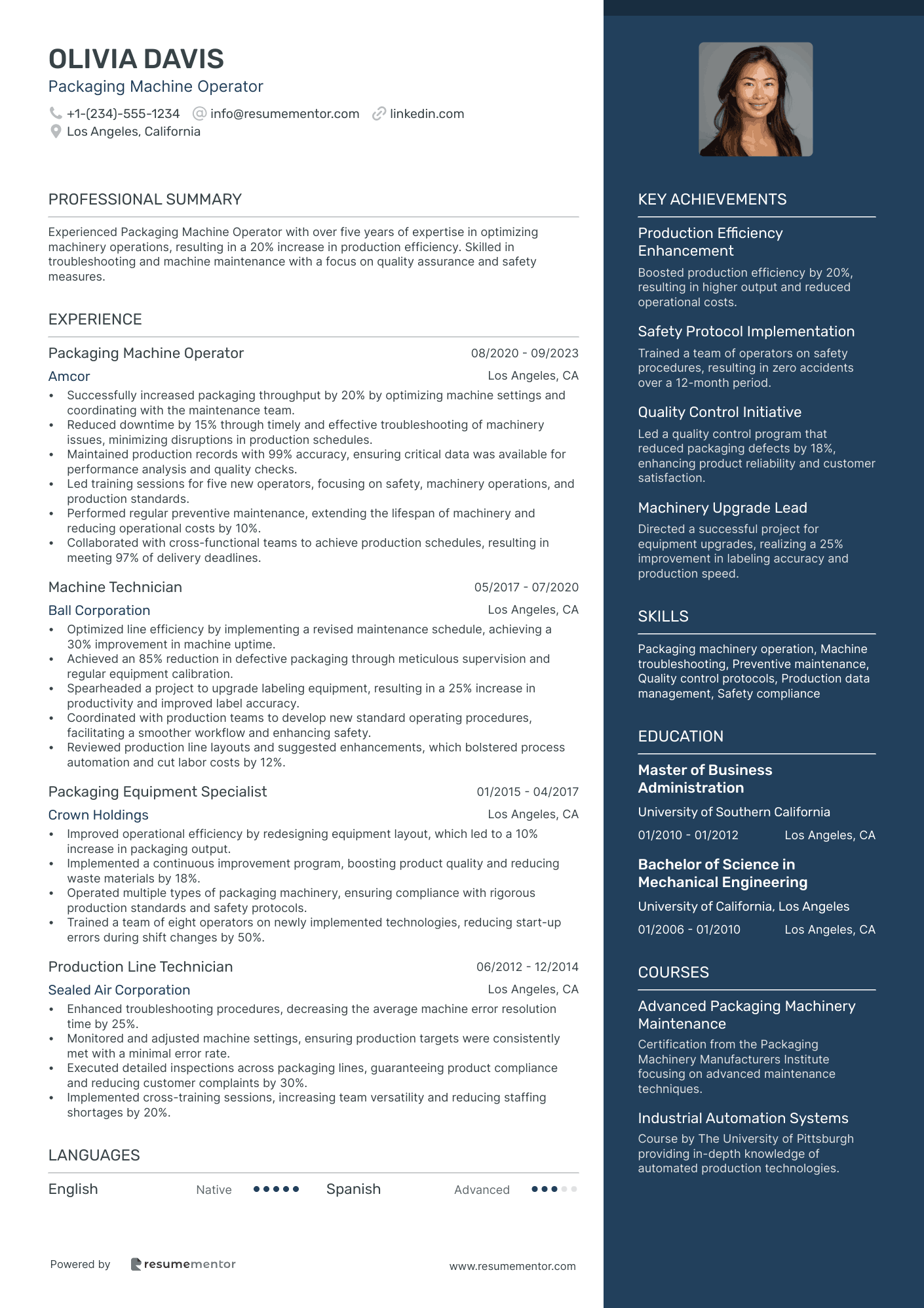

Machine Operator Resume Examples

Mar 31, 2025

|

12 min read

Craft your machine operator resume with precision and skill. Ensure that your application doesn't hit any snags with a smooth layout and a solid display of your qualifications. Make your experience clear-cut and pave the way to your next job!

Rated by 348 people

Heavy Equipment Operator

CNC Machine Operator

Packaging Machine Operator

Textile Machine Operator

Food Processing Machine Operator

Plastic Molding Machine Operator

Computer-Controlled Machine Operator

Construction Machine Operator

Printing Press Operator

Hydraulic Press Operator

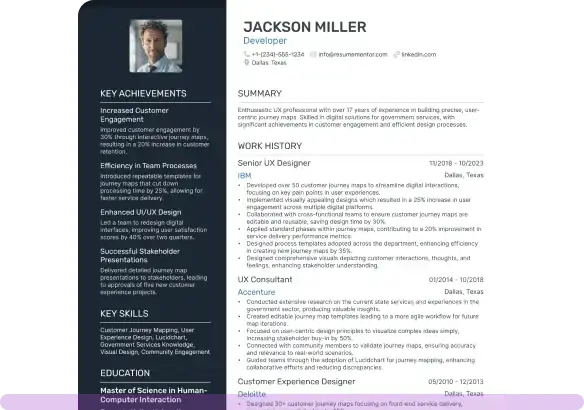

Heavy Equipment Operator resume sample

- •Managed heavy machinery operations to achieve a 32% reduction in project completion time across multiple sites.

- •Led safety audits bi-weekly, resulting in a 45% decrease in reportable incidents on-site, enhancing overall work safety.

- •Collaborated in training programs that resulted in a 25% increase in team competencies in machine handling and safety.

- •Effectively operated bulldozers and excavators, significantly streamlining ground-leveling processes and enhancing site efficiency.

- •Implemented a maintenance checklist that reduced equipment downtime by 35%, aligning tool availability with project schedules.

- •Communicated safety standards across teams, effectively leading to 60% fewer regulatory compliance issues reported.

- •Executed precise operational controls, reducing operational errors by 40%, thus optimizing construction project accuracy.

- •Streamlined equipment inspections, improving maintenance service efficiency by 30% and extending equipment longevity.

- •Optimized materials handling with loaders, increasing material flow efficiency across work sites by 27%.

- •Participated actively in project planning, resulting in 20% improved resource allocation and machinery utilization.

- •Prepared comprehensive daily reports on equipment status, significantly improving data accuracy for project managers.

- •Assisted in developing new SOPs that improved on-time project delivery rates by 15% over two quarters.

- •Utilized backhoes effectively to facilitate a 22% enhancement in foundation excavation operations.

- •Reduced worksite hazards through proactive site assessments, leading to improved safety scores by 18%.

- •Optimized the allocation and usage of heavy machinery, saving project costs by 12% through strategic deployment.

- •Handled diverse heavy equipment on various projects to enhance machinery utilization rate by 25%.

- •Ensured compliance with safety standards, reducing equipment operational risks by 30%.

- •Contributed to the efficient unloading of materials improving speed and safety by 20%.

- •Proactively communicated with teams to maintain clean and organized work areas leading to improved operation efficiency.

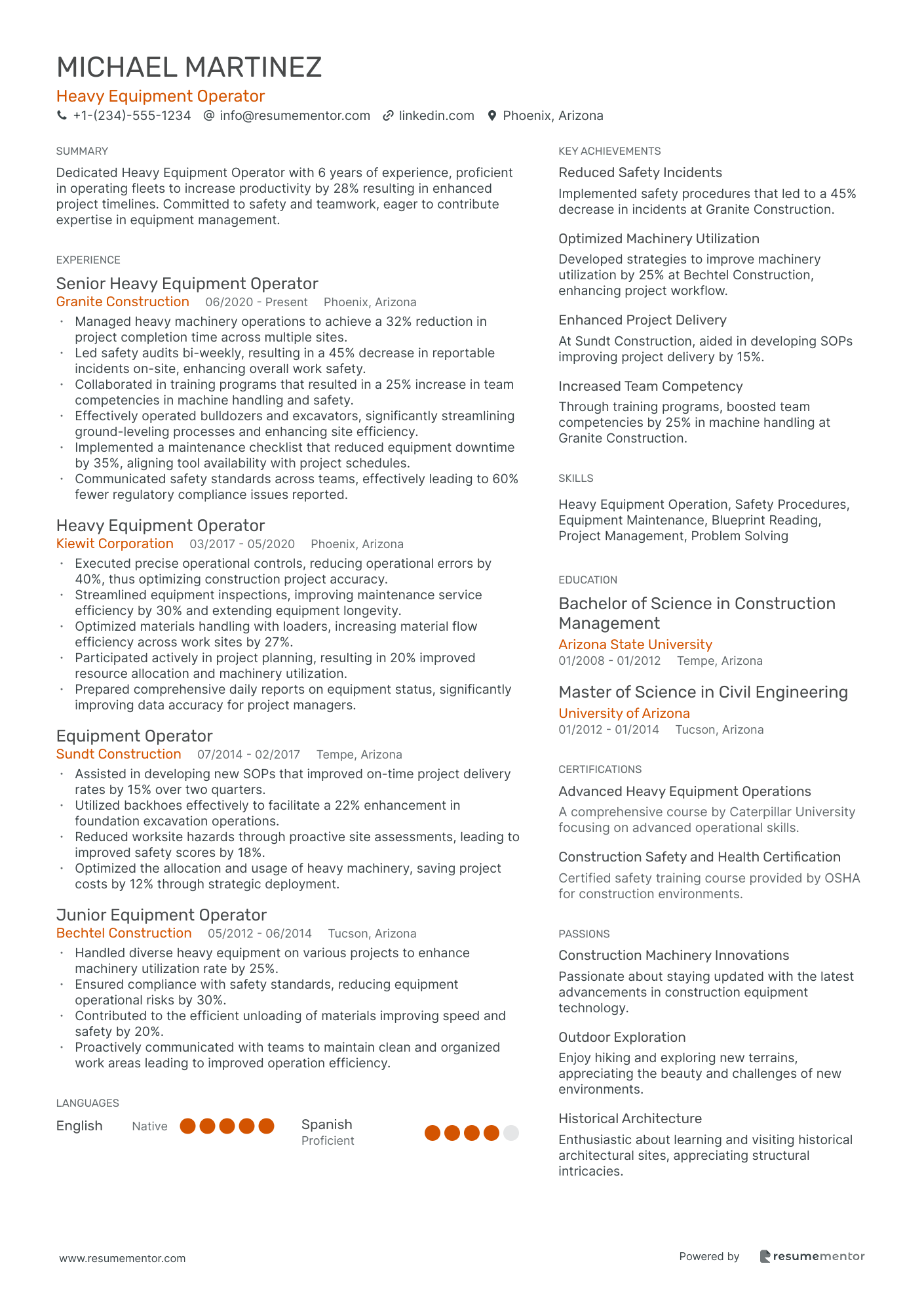

CNC Machine Operator resume sample

- •Operated CNC lathes and routers, increasing production efficiency by 20% through process optimization and reduced setup times.

- •Implemented new quality control procedures, elevating product quality by 15% over six months.

- •Designed and executed custom CNC programs for a variety of projects, leading to a 25% increase in client order deliveries.

- •Led a preventive maintenance program for 10 CNC machines, resulting in a 30% decrease in machine downtime.

- •Managed inventory for tooling and parts, reducing overhead costs by 10% via improved procurement practices.

- •Trained new operators on CNC machine operation and safety protocols, contributing to a 35% reduction in workplace incidents.

- •Developed over 300 efficient G-code programs, leading to a 40% improvement in production time on complex parts.

- •Collaborated with engineering teams to interpret and apply technical drawings accurately for new product designs.

- •Optimized tool path strategies in CNC setups, which boosted production accuracy by 25% and reduced scrap rates.

- •Oversaw a team of five operators, fostering successful teamwork that improved daily output by 15%.

- •Resolved operational issues swiftly, reducing breakdown response time by 20% which minimized production stoppages.

- •Supervised a team of 12 machinists, improving workflow efficiency by 30% through effective communication and task delegation.

- •Inspected finished components to ensure they met stringent military-grade quality standards, reducing rework by 15%.

- •Implemented systematic machine checks that reduced unexpected failures, increasing uptime by 25%.

- •Facilitated training sessions for staff, enhancing team skillset and cross-functional capabilities.

- •Coordinated with suppliers to improve tooling stock, cutting procurement delays by 10%.

- •Interpreted technical blueprints and schematics to set up CNC machinery, ensuring precise production outcomes.

- •Contributed to a team milestone by machining components for a major project three weeks ahead of schedule.

- •Regularly calibrated equipment, maintaining highest levels of precision, which resulted in a 20% reduction in alignment issues.

- •Participated in a continuous improvement program that enhanced overall production processes, increasing output by 10%.

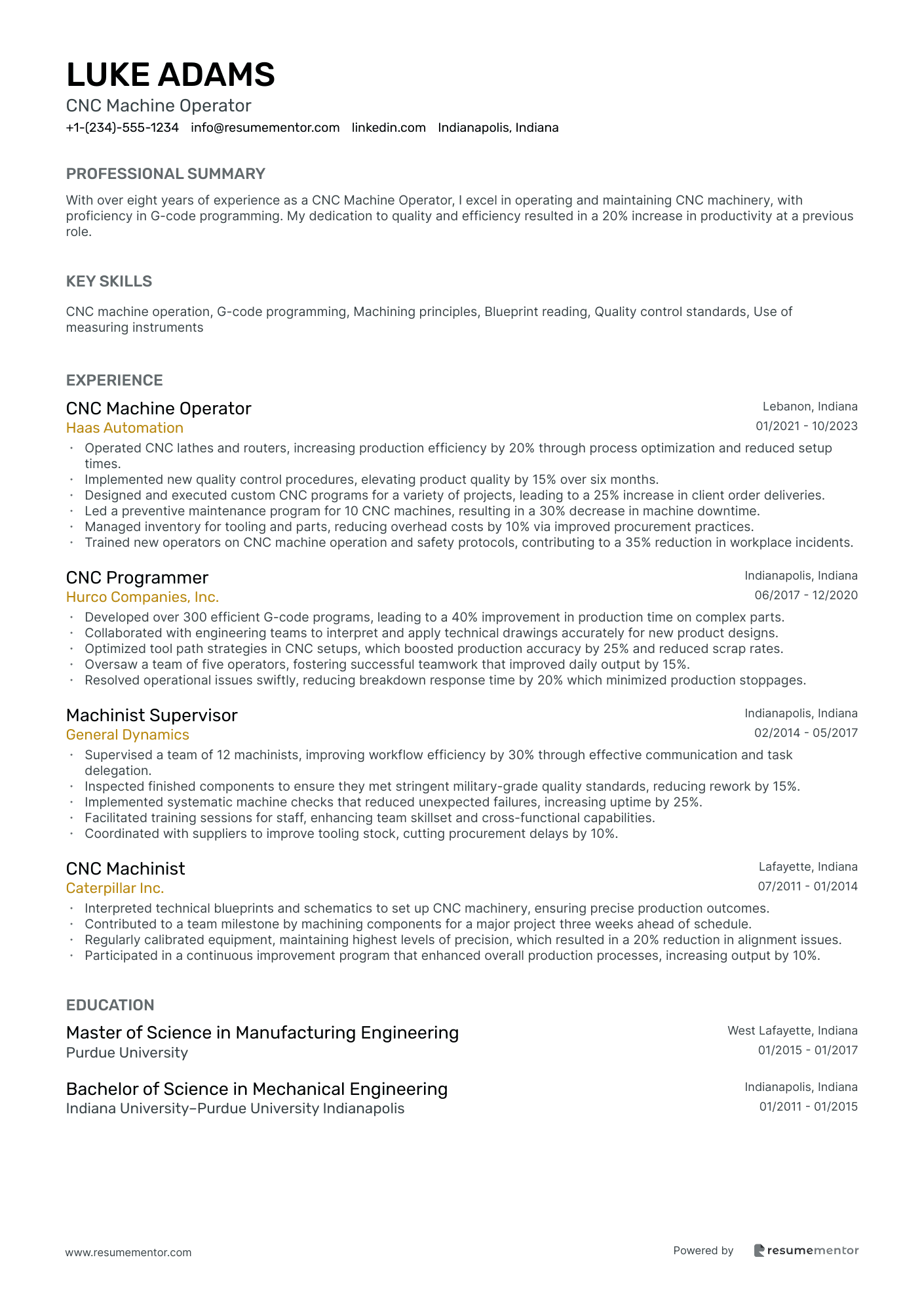

Packaging Machine Operator resume sample

- •Successfully increased packaging throughput by 20% by optimizing machine settings and coordinating with the maintenance team.

- •Reduced downtime by 15% through timely and effective troubleshooting of machinery issues, minimizing disruptions in production schedules.

- •Maintained production records with 99% accuracy, ensuring critical data was available for performance analysis and quality checks.

- •Led training sessions for five new operators, focusing on safety, machinery operations, and production standards.

- •Performed regular preventive maintenance, extending the lifespan of machinery and reducing operational costs by 10%.

- •Collaborated with cross-functional teams to achieve production schedules, resulting in meeting 97% of delivery deadlines.

- •Optimized line efficiency by implementing a revised maintenance schedule, achieving a 30% improvement in machine uptime.

- •Achieved an 85% reduction in defective packaging through meticulous supervision and regular equipment calibration.

- •Spearheaded a project to upgrade labeling equipment, resulting in a 25% increase in productivity and improved label accuracy.

- •Coordinated with production teams to develop new standard operating procedures, facilitating a smoother workflow and enhancing safety.

- •Reviewed production line layouts and suggested enhancements, which bolstered process automation and cut labor costs by 12%.

- •Improved operational efficiency by redesigning equipment layout, which led to a 10% increase in packaging output.

- •Implemented a continuous improvement program, boosting product quality and reducing waste materials by 18%.

- •Operated multiple types of packaging machinery, ensuring compliance with rigorous production standards and safety protocols.

- •Trained a team of eight operators on newly implemented technologies, reducing start-up errors during shift changes by 50%.

- •Enhanced troubleshooting procedures, decreasing the average machine error resolution time by 25%.

- •Monitored and adjusted machine settings, ensuring production targets were consistently met with a minimal error rate.

- •Executed detailed inspections across packaging lines, guaranteeing product compliance and reducing customer complaints by 30%.

- •Implemented cross-training sessions, increasing team versatility and reducing staffing shortages by 20%.

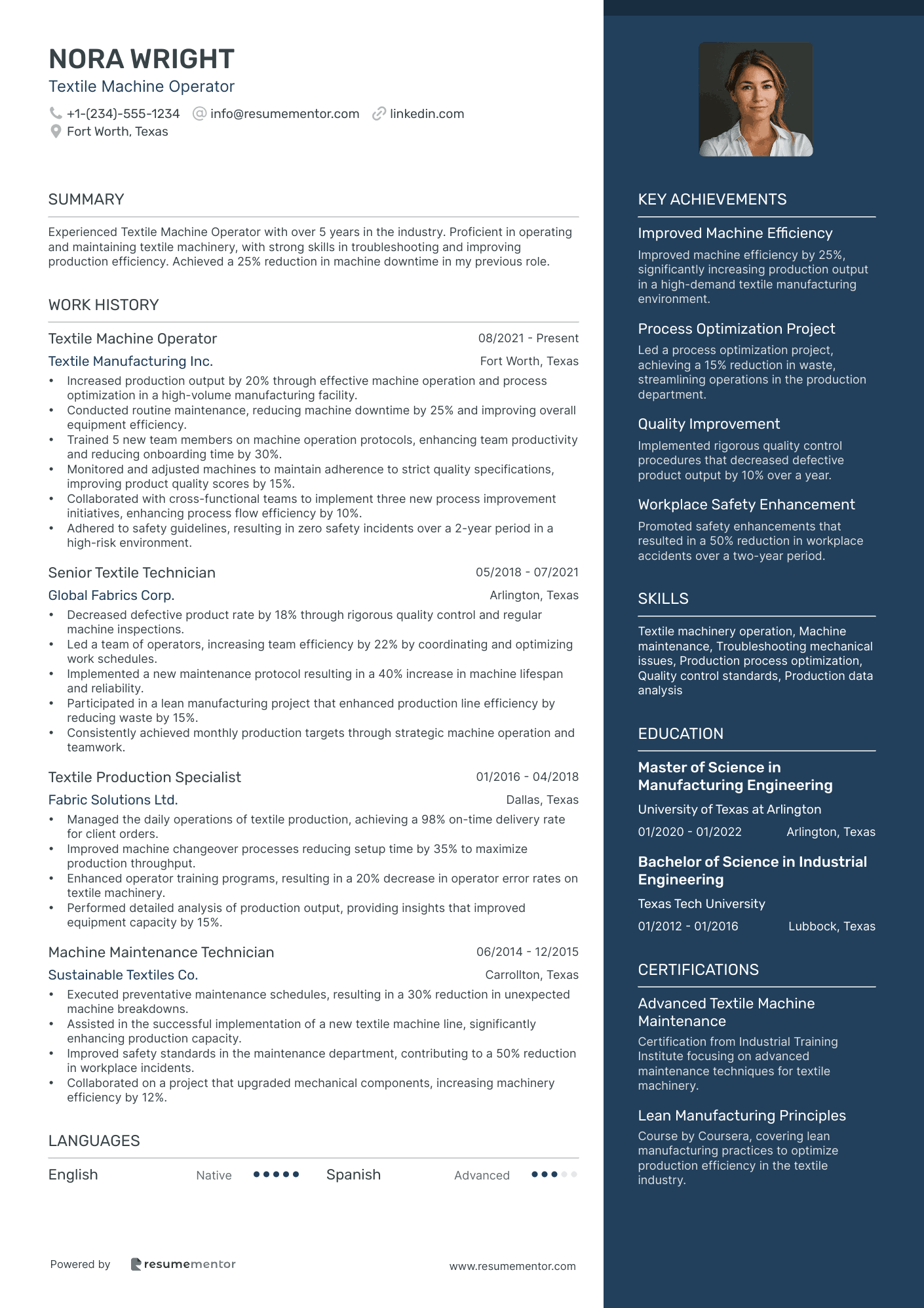

Textile Machine Operator resume sample

- •Increased production output by 20% through effective machine operation and process optimization in a high-volume manufacturing facility.

- •Conducted routine maintenance, reducing machine downtime by 25% and improving overall equipment efficiency.

- •Trained 5 new team members on machine operation protocols, enhancing team productivity and reducing onboarding time by 30%.

- •Monitored and adjusted machines to maintain adherence to strict quality specifications, improving product quality scores by 15%.

- •Collaborated with cross-functional teams to implement three new process improvement initiatives, enhancing process flow efficiency by 10%.

- •Adhered to safety guidelines, resulting in zero safety incidents over a 2-year period in a high-risk environment.

- •Decreased defective product rate by 18% through rigorous quality control and regular machine inspections.

- •Led a team of operators, increasing team efficiency by 22% by coordinating and optimizing work schedules.

- •Implemented a new maintenance protocol resulting in a 40% increase in machine lifespan and reliability.

- •Participated in a lean manufacturing project that enhanced production line efficiency by reducing waste by 15%.

- •Consistently achieved monthly production targets through strategic machine operation and teamwork.

- •Managed the daily operations of textile production, achieving a 98% on-time delivery rate for client orders.

- •Improved machine changeover processes reducing setup time by 35% to maximize production throughput.

- •Enhanced operator training programs, resulting in a 20% decrease in operator error rates on textile machinery.

- •Performed detailed analysis of production output, providing insights that improved equipment capacity by 15%.

- •Executed preventative maintenance schedules, resulting in a 30% reduction in unexpected machine breakdowns.

- •Assisted in the successful implementation of a new textile machine line, significantly enhancing production capacity.

- •Improved safety standards in the maintenance department, contributing to a 50% reduction in workplace incidents.

- •Collaborated on a project that upgraded mechanical components, increasing machinery efficiency by 12%.

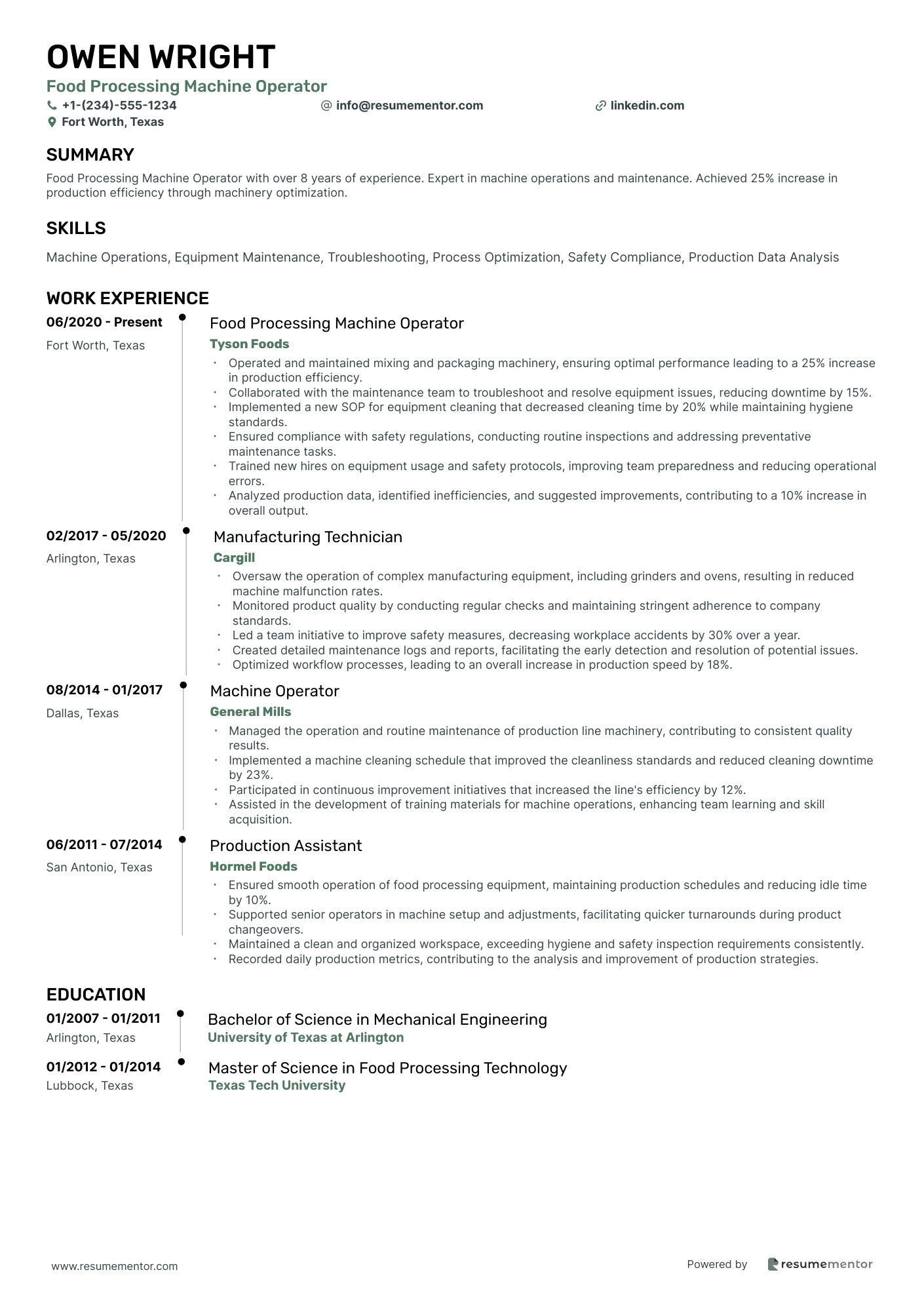

Food Processing Machine Operator resume sample

- •Operated and maintained mixing and packaging machinery, ensuring optimal performance leading to a 25% increase in production efficiency.

- •Collaborated with the maintenance team to troubleshoot and resolve equipment issues, reducing downtime by 15%.

- •Implemented a new SOP for equipment cleaning that decreased cleaning time by 20% while maintaining hygiene standards.

- •Ensured compliance with safety regulations, conducting routine inspections and addressing preventative maintenance tasks.

- •Trained new hires on equipment usage and safety protocols, improving team preparedness and reducing operational errors.

- •Analyzed production data, identified inefficiencies, and suggested improvements, contributing to a 10% increase in overall output.

- •Oversaw the operation of complex manufacturing equipment, including grinders and ovens, resulting in reduced machine malfunction rates.

- •Monitored product quality by conducting regular checks and maintaining stringent adherence to company standards.

- •Led a team initiative to improve safety measures, decreasing workplace accidents by 30% over a year.

- •Created detailed maintenance logs and reports, facilitating the early detection and resolution of potential issues.

- •Optimized workflow processes, leading to an overall increase in production speed by 18%.

- •Managed the operation and routine maintenance of production line machinery, contributing to consistent quality results.

- •Implemented a machine cleaning schedule that improved the cleanliness standards and reduced cleaning downtime by 23%.

- •Participated in continuous improvement initiatives that increased the line's efficiency by 12%.

- •Assisted in the development of training materials for machine operations, enhancing team learning and skill acquisition.

- •Ensured smooth operation of food processing equipment, maintaining production schedules and reducing idle time by 10%.

- •Supported senior operators in machine setup and adjustments, facilitating quicker turnarounds during product changeovers.

- •Maintained a clean and organized workspace, exceeding hygiene and safety inspection requirements consistently.

- •Recorded daily production metrics, contributing to the analysis and improvement of production strategies.

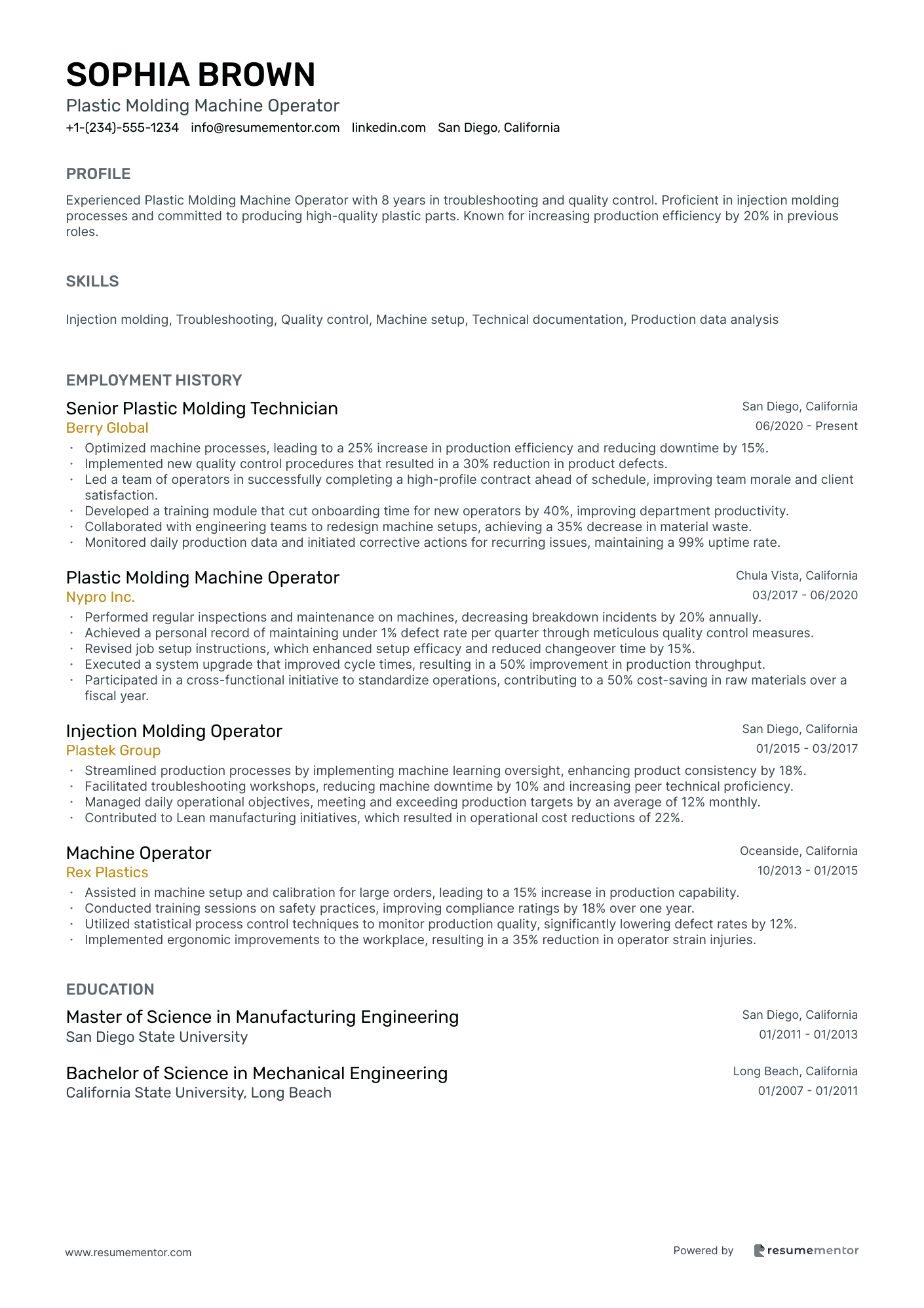

Plastic Molding Machine Operator resume sample

- •Optimized machine processes, leading to a 25% increase in production efficiency and reducing downtime by 15%.

- •Implemented new quality control procedures that resulted in a 30% reduction in product defects.

- •Led a team of operators in successfully completing a high-profile contract ahead of schedule, improving team morale and client satisfaction.

- •Developed a training module that cut onboarding time for new operators by 40%, improving department productivity.

- •Collaborated with engineering teams to redesign machine setups, achieving a 35% decrease in material waste.

- •Monitored daily production data and initiated corrective actions for recurring issues, maintaining a 99% uptime rate.

- •Performed regular inspections and maintenance on machines, decreasing breakdown incidents by 20% annually.

- •Achieved a personal record of maintaining under 1% defect rate per quarter through meticulous quality control measures.

- •Revised job setup instructions, which enhanced setup efficacy and reduced changeover time by 15%.

- •Executed a system upgrade that improved cycle times, resulting in a 50% improvement in production throughput.

- •Participated in a cross-functional initiative to standardize operations, contributing to a 50% cost-saving in raw materials over a fiscal year.

- •Streamlined production processes by implementing machine learning oversight, enhancing product consistency by 18%.

- •Facilitated troubleshooting workshops, reducing machine downtime by 10% and increasing peer technical proficiency.

- •Managed daily operational objectives, meeting and exceeding production targets by an average of 12% monthly.

- •Contributed to Lean manufacturing initiatives, which resulted in operational cost reductions of 22%.

- •Assisted in machine setup and calibration for large orders, leading to a 15% increase in production capability.

- •Conducted training sessions on safety practices, improving compliance ratings by 18% over one year.

- •Utilized statistical process control techniques to monitor production quality, significantly lowering defect rates by 12%.

- •Implemented ergonomic improvements to the workplace, resulting in a 35% reduction in operator strain injuries.

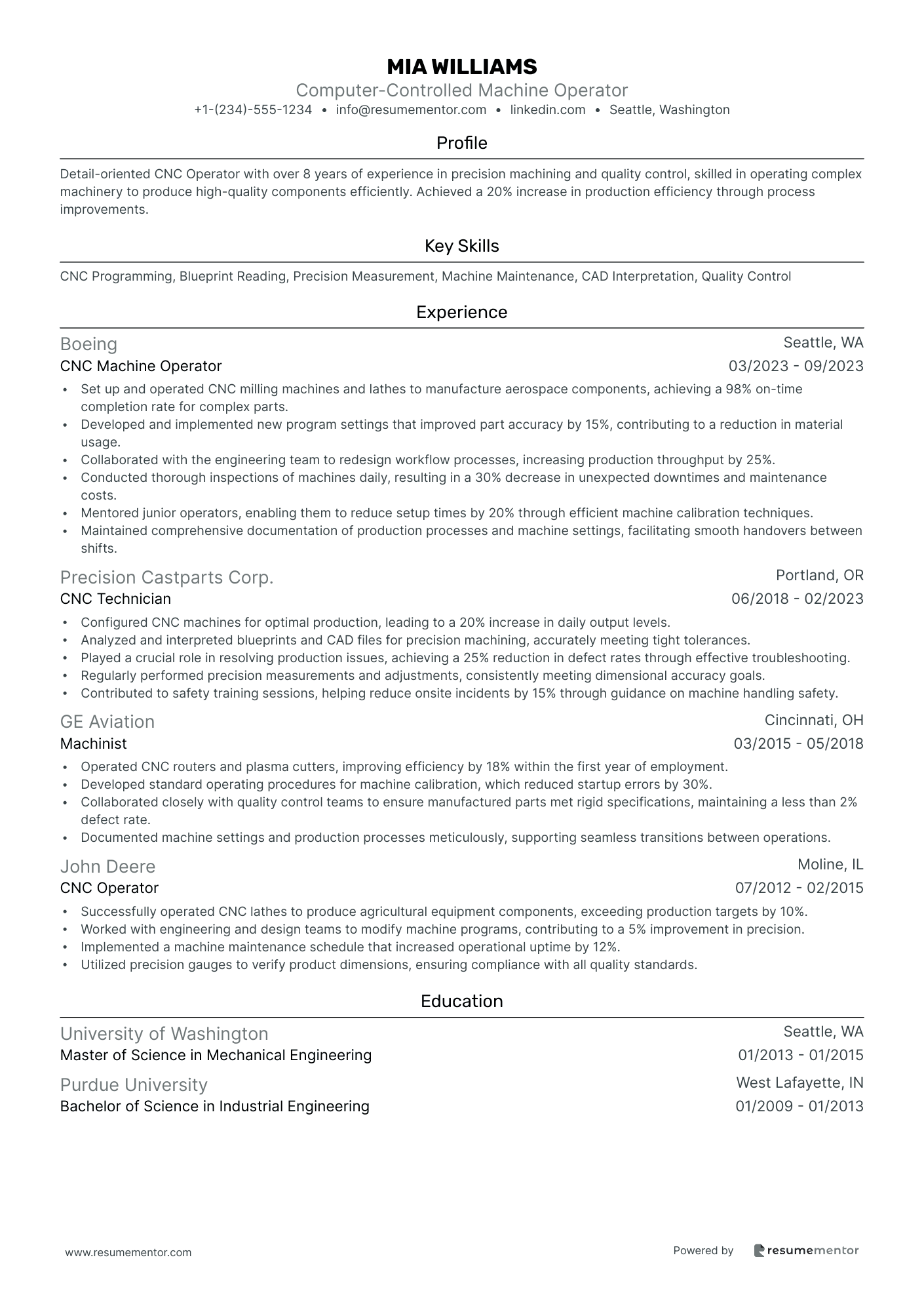

Computer-Controlled Machine Operator resume sample

- •Set up and operated CNC milling machines and lathes to manufacture aerospace components, achieving a 98% on-time completion rate for complex parts.

- •Developed and implemented new program settings that improved part accuracy by 15%, contributing to a reduction in material usage.

- •Collaborated with the engineering team to redesign workflow processes, increasing production throughput by 25%.

- •Conducted thorough inspections of machines daily, resulting in a 30% decrease in unexpected downtimes and maintenance costs.

- •Mentored junior operators, enabling them to reduce setup times by 20% through efficient machine calibration techniques.

- •Maintained comprehensive documentation of production processes and machine settings, facilitating smooth handovers between shifts.

- •Configured CNC machines for optimal production, leading to a 20% increase in daily output levels.

- •Analyzed and interpreted blueprints and CAD files for precision machining, accurately meeting tight tolerances.

- •Played a crucial role in resolving production issues, achieving a 25% reduction in defect rates through effective troubleshooting.

- •Regularly performed precision measurements and adjustments, consistently meeting dimensional accuracy goals.

- •Contributed to safety training sessions, helping reduce onsite incidents by 15% through guidance on machine handling safety.

- •Operated CNC routers and plasma cutters, improving efficiency by 18% within the first year of employment.

- •Developed standard operating procedures for machine calibration, which reduced startup errors by 30%.

- •Collaborated closely with quality control teams to ensure manufactured parts met rigid specifications, maintaining a less than 2% defect rate.

- •Documented machine settings and production processes meticulously, supporting seamless transitions between operations.

- •Successfully operated CNC lathes to produce agricultural equipment components, exceeding production targets by 10%.

- •Worked with engineering and design teams to modify machine programs, contributing to a 5% improvement in precision.

- •Implemented a machine maintenance schedule that increased operational uptime by 12%.

- •Utilized precision gauges to verify product dimensions, ensuring compliance with all quality standards.

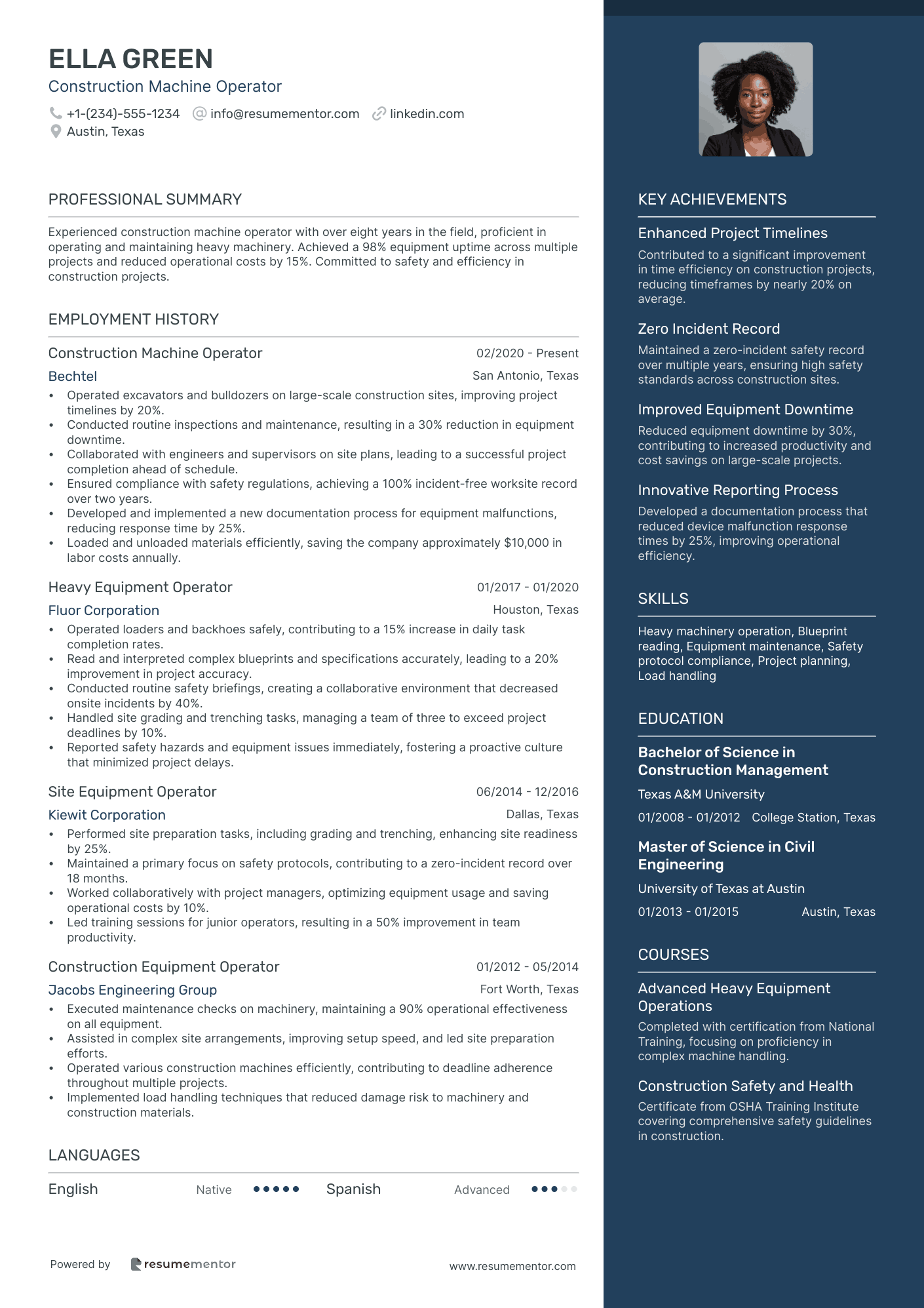

Construction Machine Operator resume sample

- •Operated excavators and bulldozers on large-scale construction sites, improving project timelines by 20%.

- •Conducted routine inspections and maintenance, resulting in a 30% reduction in equipment downtime.

- •Collaborated with engineers and supervisors on site plans, leading to a successful project completion ahead of schedule.

- •Ensured compliance with safety regulations, achieving a 100% incident-free worksite record over two years.

- •Developed and implemented a new documentation process for equipment malfunctions, reducing response time by 25%.

- •Loaded and unloaded materials efficiently, saving the company approximately $10,000 in labor costs annually.

- •Operated loaders and backhoes safely, contributing to a 15% increase in daily task completion rates.

- •Read and interpreted complex blueprints and specifications accurately, leading to a 20% improvement in project accuracy.

- •Conducted routine safety briefings, creating a collaborative environment that decreased onsite incidents by 40%.

- •Handled site grading and trenching tasks, managing a team of three to exceed project deadlines by 10%.

- •Reported safety hazards and equipment issues immediately, fostering a proactive culture that minimized project delays.

- •Performed site preparation tasks, including grading and trenching, enhancing site readiness by 25%.

- •Maintained a primary focus on safety protocols, contributing to a zero-incident record over 18 months.

- •Worked collaboratively with project managers, optimizing equipment usage and saving operational costs by 10%.

- •Led training sessions for junior operators, resulting in a 50% improvement in team productivity.

- •Executed maintenance checks on machinery, maintaining a 90% operational effectiveness on all equipment.

- •Assisted in complex site arrangements, improving setup speed, and led site preparation efforts.

- •Operated various construction machines efficiently, contributing to deadline adherence throughout multiple projects.

- •Implemented load handling techniques that reduced damage risk to machinery and construction materials.

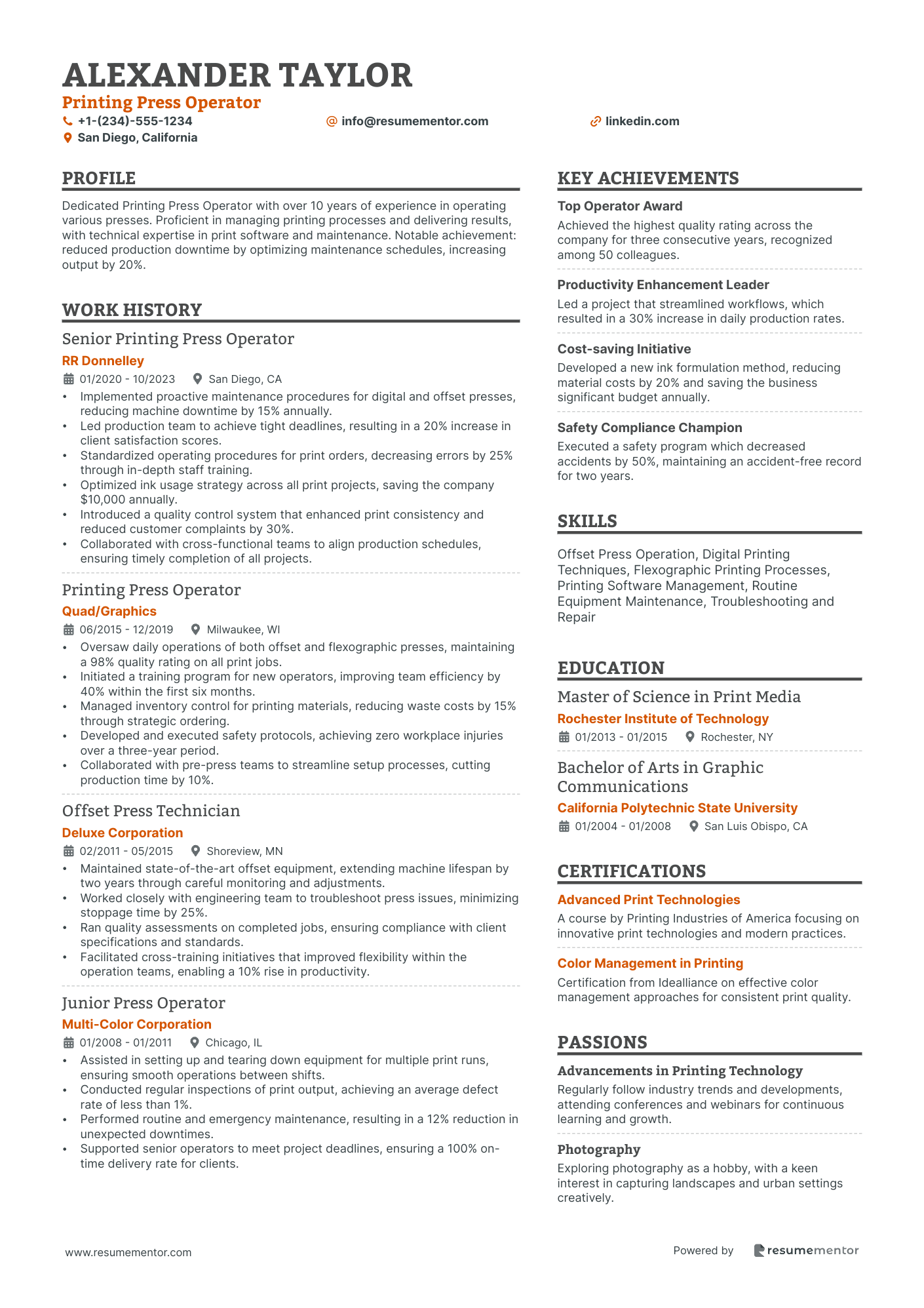

Printing Press Operator resume sample

- •Implemented proactive maintenance procedures for digital and offset presses, reducing machine downtime by 15% annually.

- •Led production team to achieve tight deadlines, resulting in a 20% increase in client satisfaction scores.

- •Standardized operating procedures for print orders, decreasing errors by 25% through in-depth staff training.

- •Optimized ink usage strategy across all print projects, saving the company $10,000 annually.

- •Introduced a quality control system that enhanced print consistency and reduced customer complaints by 30%.

- •Collaborated with cross-functional teams to align production schedules, ensuring timely completion of all projects.

- •Oversaw daily operations of both offset and flexographic presses, maintaining a 98% quality rating on all print jobs.

- •Initiated a training program for new operators, improving team efficiency by 40% within the first six months.

- •Managed inventory control for printing materials, reducing waste costs by 15% through strategic ordering.

- •Developed and executed safety protocols, achieving zero workplace injuries over a three-year period.

- •Collaborated with pre-press teams to streamline setup processes, cutting production time by 10%.

- •Maintained state-of-the-art offset equipment, extending machine lifespan by two years through careful monitoring and adjustments.

- •Worked closely with engineering team to troubleshoot press issues, minimizing stoppage time by 25%.

- •Ran quality assessments on completed jobs, ensuring compliance with client specifications and standards.

- •Facilitated cross-training initiatives that improved flexibility within the operation teams, enabling a 10% rise in productivity.

- •Assisted in setting up and tearing down equipment for multiple print runs, ensuring smooth operations between shifts.

- •Conducted regular inspections of print output, achieving an average defect rate of less than 1%.

- •Performed routine and emergency maintenance, resulting in a 12% reduction in unexpected downtimes.

- •Supported senior operators to meet project deadlines, ensuring a 100% on-time delivery rate for clients.

Hydraulic Press Operator resume sample

- •Implemented new maintenance protocols reducing machine downtime by 15%, increasing production efficiency significantly.

- •Led a team in a crucial project to redesign workflow, successfully increasing output by 20% while maintaining quality standards.

- •Contributed to quality assurance processes, resulting in a 10% improvement in product conformity to specifications.

- •Resolved complex hydraulic systems issues independently, improving machine reliability by 25%.

- •Enhanced safety compliance, leading initiatives that decreased workplace accidents by 30% annually.

- •Mentored junior operators, improving team performance and operational knowledge substantially.

- •Optimized machining parameters reducing cycle time by 10% on critical components.

- •Expanded productivity by leading the introduction of new training protocols for all team members.

- •Achieved a 95% first-pass yield by refining quality control checkpoints and adjustments.

- •Developed troubleshooting guides, resulting in reduced machine downtime by 18%.

- •Maintained comprehensive logs for over 200 operations, enhancing process tracking accuracy.

- •Increased output efficiency by 15% through the refinement of machine settings and tool alignments.

- •Ensured adherence to safety protocols, contributing to a 40% reduction in incident reports.

- •Designed and executed a quality control checklist boosting compliance with manufacturing specifications.

- •Introduced cost-effective measures, saving the company $20,000 annually on machine maintenance.

- •Successfully interpreted complex blueprints, ensuring a 98% accuracy rate in production outputs.

- •Reduced production errors by 20% through regular calibration of CNC machinery.

- •Contributed to a major project achieving early completion due to improved machine setup times.

- •Proven ability to conduct autonomous equipment inspections, significantly extending machinery lifespan.

In the competitive job market, a strong resume is your key to landing a machine operator position. Your skills are the gears that keep everything running smoothly, and translating those into words can be tough. But don't worry; crafting your resume is like fine-tuning a machine until it operates seamlessly.

Begin by highlighting your experience with various machinery and tools, which directly showcases your technical expertise. A resume template can assist in presenting these skills in a clear and impactful way, ensuring your abilities catch the eye of potential employers. Explore resume templates to find a fit that keeps your achievements organized and polished.

Building on that, emphasize your problem-solving skills and safety awareness—qualities that are crucial in the industry. Mention any certifications or training you have undergone to further underline your capability. Tailoring your resume language to reflect industry standards ensures each section speaks directly to potential employers.

Think of your resume as more than just a list of past roles; it's a snapshot of your potential. By keeping it concise, relevant, and easy to read, you'll craft a resume that's not just paper—it's a well-oiled machine, ready to drive your career forward.

Key Takeaways

- When writing a teacher resume, it is crucial to begin with clear contact information, followed by a strong professional summary that captures your experience and commitment to safety protocols and machine maintenance.

- Your skills section should precisely highlight core competencies related to machine operation and safety compliance, allowing potential employers to gauge your readiness for the job.

- Work experience should be detailed, emphasizing roles related to machine operations and illustrating how you apply your skills to enhance efficiency and safety.

- Education and certifications like OSHA safety courses should be listed to underline your industry preparedness and knowledge of safety standards.

- Utilizing a chronological resume format complemented by modern fonts like Lato or Montserrat can enhance readability and presentation, ensuring your qualifications stand out clearly to hiring managers.

What to focus on when writing your machine operator resume

A machine operator resume should clearly communicate your technical skills, safety knowledge, and problem-solving capabilities to the recruiter. By highlighting your ability to operate and maintain machinery effectively, you establish yourself as a qualified and dependable candidate in the field.

How to structure your machine operator resume

- Contact Information: Your resume should begin with your contact details—full name, phone number, professional email address, and your location. This ensures recruiters can easily get in touch with you for interviews or further discussions about your qualifications.

- Professional Summary: A well-crafted professional summary captures the essence of your experience in just a few sentences—summarize your years in the industry, emphasizing key skills such as machine maintenance, your commitment to safety protocols, and an achievement that showcases your expertise. This section should leave a strong impression that makes recruiters want to learn more about you.

- Skills: Be precise in this section, as it highlights your core competencies—focus on machinery operation, safety compliance, equipment troubleshooting, and precision handling. Mention specific machines or tools you’re adept with, as this adds clarity and relevance, showing your readiness for the job.

- Work Experience: Detail your previous roles, emphasizing those related to machine operations—describe the types of machinery you’ve operated, safety measures you’ve implemented, and any contributions to increasing efficiency. These experiences illustrate how you apply your skills in real-world settings.

- Education: List relevant certifications or training in this section—mention anything like OSHA safety courses or technical school education, which underscores your preparedness and understanding of industry standards.

- Achievements: Quantify your successes wherever possible—highlight how meeting production targets or reducing machine downtime contributed to the business. Demonstrating specific results makes your resume stand out.

By organizing your resume with these sections, you ensure a robust narrative of your qualifications that speaks directly to the needs of a potential employer. Below, we'll cover each section more in-depth to guide you toward a professional and comprehensive machine operator resume.

Which resume format to choose

Crafting a clear and effective machine operator resume is key to making a strong impression. The chronological resume format best highlights the depth of your experience and skills, particularly when your role involves handling complex machinery. This format allows you to showcase your growth and achievements over time, making it easier for potential employers to understand your career progression.

To give your resume a modern and polished appearance, consider fonts like Lato, Montserrat, or Raleway. These fonts provide a clean and professional look, offering a fresh alternative to traditional choices. They maintain readability, which is essential for ensuring your qualifications stand out at a glance.

Once your resume is structured and styled, saving and submitting it as a PDF is crucial. PDFs preserve your formatting, ensuring that your resume looks the same on any device a hiring manager might use. This consistency is important for maintaining a professional presentation.

It's also vital to keep your margins at about one inch on all sides. This standard margin size ensures your resume looks tidy and organized, allowing content to breathe and making it easier for the reader to focus on your qualifications.

By focusing on these elements, you effectively present your qualifications as a machine operator. Emphasizing your expertise and reliability, you create a strong first impression that leaves potential employers eager to learn more about your fit for the role.

How to write a quantifiable resume experience section

For the machine operator experience section on your resume, concentrate on demonstrating your expertise, reliability, and measurable achievements. Begin with the most recent roles, organizing the section in reverse chronological order to showcase your newest experiences first. Span back 10-15 years, or include up to five key job titles to cover your relevant work history. Tailor your experience to align with the job ad by using specific keywords like "operated," "maintained," and "optimized," which directly connect to the role you're applying for. It's important to highlight achievements with numbers, such as boosting production or enhancing safety measures, to clearly show the value you bring to an employer. This section should paint a vivid picture of your skills and dedication, leaving no doubt about your potential contributions.

- •Boosted production efficiency by 25% through better processes and team training.

- •Cut machine downtime by 30% with a proactive maintenance schedule.

- •Enhanced safety, leading to a 40% drop in workplace incidents.

- •Trained a team of 10 operators, raising overall capability and morale.

This experience section stands out by clearly showing how you've made substantial improvements in your previous role, like boosting efficiency and cutting machine downtime. Each bullet point is interconnected through a focus on enhancing operations, from improving safety to lifting team capabilities. By focusing on specific outcomes, you effectively demonstrate how your contributions made a real difference, with concrete results that hiring managers can easily recognize and appreciate. These achievements are directly linked to the skills and qualities that employers are searching for, making your resume significantly more compelling.

Industry-Specific Focus resume experience section

A machine operator-focused resume experience section should effectively showcase your skills and achievements in a cohesive manner that aligns with industry expectations. Start by emphasizing your proficiency in handling machinery and following safety protocols, as these are crucial aspects of the role. Clearly present your key experiences using bullet points, making it easy for employers to grasp your contributions at a glance.

To truly make your resume stand out, ensure your experiences are tailored to the specific job requirements. Illustrate how you've improved operational efficiency, maintained high-quality outputs, or introduced innovative solutions to existing challenges. Providing quantifiable achievements, such as numbers or percentages, is a great way to offer concrete proof of your impact in previous roles. Ultimately, your aim is to seamlessly convey not just what you did, but how your efforts added tangible value to your workplace.

Lead Machine Operator

Precision Tools Manufacturing Co.

Jan 2020 - Present

- Operated and maintained heavy-duty machinery, ensuring 98% uptime across three shifts each day.

- Enhanced safety protocol implementation, leading to a 25% reduction in workplace accidents over a year.

- Trained and supervised a team of 5 junior operators, boosting overall team efficiency by 15%.

- Monitored production outputs and performed minor repairs, reducing equipment downtime by 10%.

Training and Development Focused resume experience section

A Training and Development Focused Machine Operator resume experience section should emphasize your ability to train others and enhance operational efficiency. Start by detailing your responsibilities as a machine operator, emphasizing the training programs you've led or developed to uplift team skills. Provide specific examples of how you've positively impacted team performance or improved safety measures. Use concise bullet points to weave these achievements into a story of continuous growth and contribution.

Moreover, highlight measurable achievements that underscore your impact on the organization. Use numbers to demonstrate boosts in productivity, decreases in downtime, or enhancements in safety compliance. Share any positive feedback or recognition from colleagues or supervisors, as this showcases your effectiveness as a trainer. Ensure that your narrative is cohesive and consistently highlights your skills in training and development, illustrating your ability to elevate team performance.

Machine Operator

ABC Manufacturing Inc.

Jan 2020 - Present

- Led a team of 10 machine operators, improving efficiency by 20%.

- Developed a training manual that reduced onboarding time from 6 weeks to 4 weeks.

- Implemented a safety workshop that resulted in a 30% decrease in equipment-related incidents.

- Received 'Trainer of the Year' award for outstanding contribution to workforce development.

Growth-Focused resume experience section

A growth-focused machine operator resume experience section should highlight how your achievements and skills contribute to the success of a company. Use straightforward language to describe specific actions you took and the positive outcomes that resulted. Focus on improvements like process efficiency, enhanced production results, or reduced waste to showcase your role in boosting operational metrics. Adding numbers, percentages, or timeframes to your achievements can give them more impact and make your resume stand out.

Start by identifying the key responsibilities or accomplishments in your work history that demonstrate your ability to drive improvement and innovation. Use action-oriented language in each bullet point to show your proactive approach to challenges. For instance, you might mention how you introduced a method to increase productivity or made changes that led to cost savings. By highlighting your problem-solving skills and your readiness to learn and adapt, you can make yourself an attractive candidate for employers aiming to grow their teams.

Machine Operator

ABC Manufacturing Co.

January 2020 - Present

- Improved machine efficiency by 15% through regular maintenance and system optimization.

- Led a team of 5 in implementing a new procedure that reduced downtime by 20%.

- Trained new operators which led to a 30% decrease in mistakes and operational delays.

- Implemented waste reduction strategies saving the company $10,000 annually.

Collaboration-Focused resume experience section

A collaboration-focused machine operator resume experience section should highlight how you work effectively with others to enhance processes and achieve objectives. Begin by selecting roles where teamwork was crucial, and describe how you coordinated with colleagues and other departments to drive positive changes. Emphasize situations where your collaborative efforts led to tangible improvements or successes, ensuring to use simple language to illustrate your contributions. Highlight how your skills in working with people directly impacted the group's achievements.

To make your resume stand out, tailor your bullet points to underscore collaboration. Speak to initiatives where teamwork was vital, joint problem-solving tasks, or any contributions you made to team projects that resulted in greater efficiency or quality. It's important to provide specific examples instead of generic statements, as these will make your resume more engaging. If possible, include quantifiable outcomes, such as helping your team improve efficiency by a certain percentage, to reinforce the impact of your achievements.

Machine Operator

ABC Manufacturing Co.

May 2018 - June 2021

- Worked closely with a team of five to improve production line efficiency by 20%.

- Collaborated with maintenance team to address machine downtime, reducing it by 15%.

- Participated in cross-functional meetings to streamline communication and workflow between departments.

- Assisted in training new operators, fostering a team-oriented work environment.

Write your machine operator resume summary section

A skills-focused machine operator resume summary should effectively highlight your expertise and accomplishments in the field. If you have solid experience, this section can clearly demonstrate both your capabilities and the impact you've made in past roles. Consider an example such as:

This example succeeds by presenting a concise depiction of your skills and achievements. By specifying abilities like "operating and maintaining heavy machinery" and quantifying success with "increasing productivity by 20%," it becomes more impactful. This focus on safety and quality further supports your fit for the role.

Crafting a resume summary allows you to connect your experience with the potential employer’s needs, using clear language and strong examples. This is essential in coaxing the hiring manager to explore your resume further. Distinguishing between a summary and other sections helps optimize your resume. While a summary spotlights your expertise, a resume objective is better for newcomers eager to set their career goals, with phrases like "Looking to join a fast-paced company to grow my skills." In contrast, a resume profile provides a more expansive view of your professional journey. A summary of qualifications, through bullet points, highlights critical skills and achievements for those with more extensive experience. Each type serves a different purpose depending on your background and the aspects you wish to highlight to potential employers.

Listing your machine operator skills on your resume

A skills-focused machine operator resume should strategically showcase your technical abilities and personal strengths. When crafting the skills section, you can either set it apart or integrate it into other sections like experience and summary. Highlighting both your strengths and soft skills reveals your personal attributes, while hard skills demonstrate your technical proficiency gained through training and experience. These skill types serve as keywords that employers and resume screening software actively look for.

Effectively weaving these skills throughout your resume ensures alignment with job descriptions. Whether they stand alone or are integrated into your work experiences or summary, these keywords can capture the attention of recruiters and automated systems alike. By focusing on relevant skills, you showcase your capabilities and compatibility for the role you seek.

This skills section is impressive because it swiftly lists essential, industry-specific hard skills for a machine operator. Each skill directly relates to the responsibilities typical for the role, showcasing your expertise in areas that employers value. By avoiding generic phrases and focusing on pertinent skills, you strengthen this part of your resume.

Best hard skills to feature on your machine operator resume

Communicate your technical capabilities with hard skills that underscore your ability to perform complex tasks and handle machinery proficiently. They highlight your capacity to maintain, troubleshoot, and manage equipment, providing a competitive edge over other candidates.

Hard Skills

- Machine operation

- CNC programming

- Equipment calibration

- Technical troubleshooting

- Quality control

- Preventive maintenance

- Welding

- Safety compliance

- Precision measurement

- Automated machinery operation

- Product assembly

- PLC programming

- Blueprint reading

- Material handling

- Lean manufacturing techniques

Best soft skills to feature on your machine operator resume

Emphasize your interpersonal skills and work ethic through your soft skills. These skills demonstrate your ability to work well with others, follow instructions, and maintain productivity, ensuring you can excel in a team environment while managing tasks efficiently.

Soft Skills

- Communication

- Teamwork

- Problem-solving

- Attention to detail

- Time management

- Adaptability

- Reliability

- Organization

- Patience

- Initiative

- Stress management

- Conflict resolution

- Critical thinking

- Leadership

- Decision-making

How to include your education on your resume

The education section is an important part of your resume as it provides potential employers with a snapshot of your academic background. It's crucial to tailor this section to the job you are applying for, which means including only relevant education experiences. Irrelevant education can clutter your resume and distract from more crucial information. When listing your degree, clearly state your field of study and the name of the institution. If your GPA is impressive, such as 3.5 or higher, you should include it. You can format it as "GPA: 3.8/4.0" to give a clear picture. For honors like cum laude, list them right after your degree to highlight your achievements. Here’s a look at examples for better clarity.

Here's an incorrect example:

Now, here's an effective education section example for a machine operator:

The second example is effective because it focuses on an industrial technology degree, which is relevant to the machine operator role. Showcasing a solid GPA of 3.6 signals to employers your competency in the field. Highlighting your academic achievements, such as an Associate of Applied Science, reinforces your practical skills and knowledge in industrial settings, which is appealing to recruiters in this sector.

How to include machine operator certificates on your resume

Including a certificates section in your machine operator resume is crucial because it highlights your qualifications and expertise. List the name of each certification clearly to ensure it stands out. Include the date you received or will receive the certification to show currency. Add the issuing organization to provide legitimacy and context for your achievements. You can also feature key certifications in the header to immediately capture attention. For example, you might write: "Certified CNC Operator | OSHA Forklift Certified" directly under your name.

A well-structured certificate section can significantly enhance your resume. Here's how an effective example can look, illustrating what makes it strong. It includes certifications relevant to a machine operator role, such as safety and specialized machinery certifications. This specificity demonstrates your direct competency for the job, making you a more appealing candidate.

This example is effective because the certifications are specific to the skills needed as a machine operator, such as operating machinery safely and proficiently. Including recognized issuing organizations adds credibility and assures potential employers of your competence. This approach can make your resume stand out by clearly showing that you have the necessary skills and dedication for the role.

Extra sections to include on your machine operator resume

In creating a resume for a machine operator position, it's essential to highlight various sections that showcase your diverse skills and experiences. Adding distinct sections not only enriches your resume but also makes it more relatable and appealing to potential employers.

Language section — Highlight multiple language proficiencies to demonstrate cultural adaptability and communication skills. Employers value language proficiency because it enhances teamwork in diverse environments.

Hobbies and interests section — Showcase unique hobbies to reveal personal traits that align with the job. Employers may gain insights into your creativity, problem-solving, and teamwork abilities through this section.

Volunteer work section — Include volunteer experiences to illustrate your commitment to community and teamwork. Volunteering can reflect leadership and dedication, useful qualities in a machine operation role.

Books section — List books you've read that are relevant to your industry to show ongoing learning and curiosity. Reading books related to machinery or engineering demonstrates a proactive attitude towards professional growth.

In Conclusion

In conclusion, crafting a well-rounded machine operator resume involves a thoughtful approach to highlighting both your technical competencies and personal attributes. By clearly showcasing your experience with machinery and tools, your resume becomes a compelling narrative of your expertise. It's important to format your resume in a way that easily conveys your skills, achievements, and growth over time, making use of chronological order to display your career progression. Introducing quantifiable data enhances your resume's impact by providing tangible evidence of your contributions to past employers. Additionally, remember to include any certifications that underscore your qualifications, as they establish your credibility in operating specialized equipment safely and efficiently.

Beyond the basics, consider integrating sections that show off your adaptability, ongoing learning, and engagement with the broader community. Whether it's through language skills, hobbies, volunteer work, or even relevant books you've read, these aspects offer employers insight into your interpersonal skills and character. Moreover, maintaining a modern and professional resume appearance with appropriate fonts and clean layout contributes to a strong first impression. Ultimately, your resume should not only reflect your ability to operate machines effectively but also highlight your soft skills, fostering an image of a balanced and capable team player. By paying attention to detail and aligning your resume with industry standards, you'll position yourself as a standout candidate ready to advance in your machine operator career.

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2026. All rights reserved.

Made with love by people who care.