Manufacturing Engineer Resume Examples

Jul 18, 2024

|

12 min read

Crafting your manufacturing engineer resume: tools, tips, and templates to gear up your job search.

Rated by 348 people

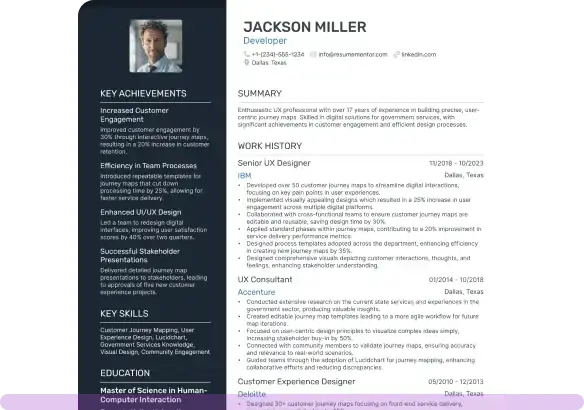

Manufacturing Systems Engineer

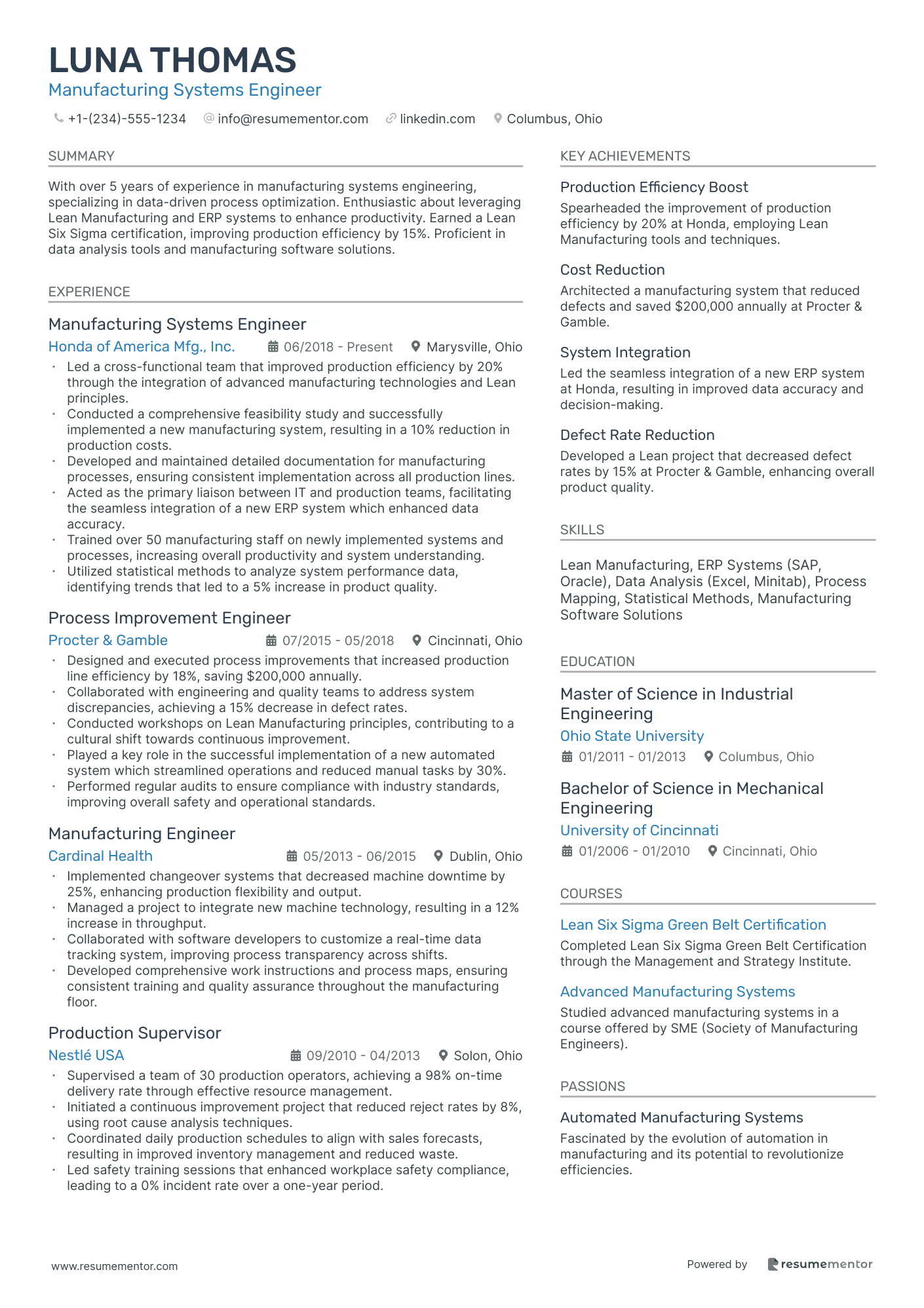

Manufacturing Quality Assurance Engineer

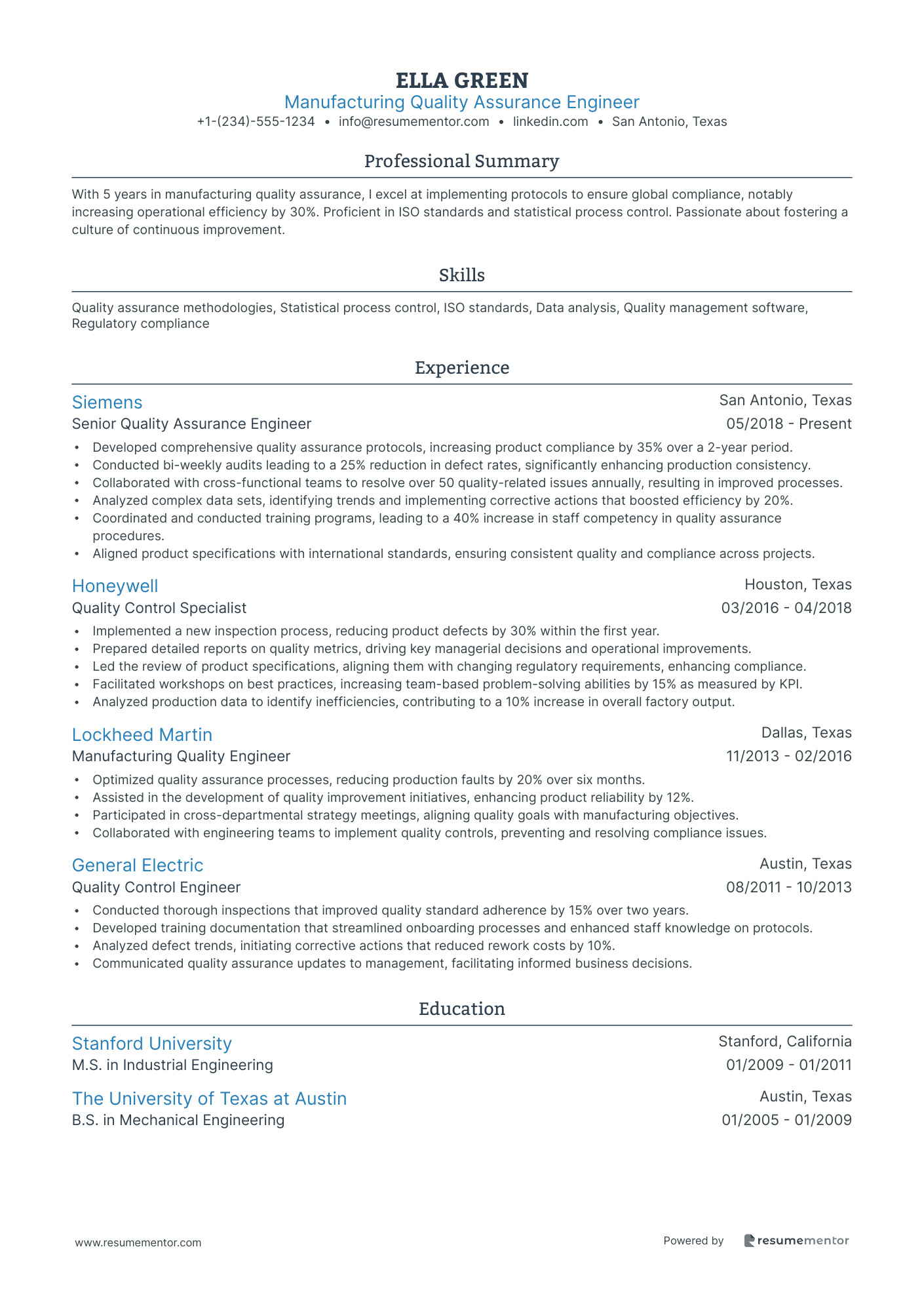

CNC Manufacturing Engineer

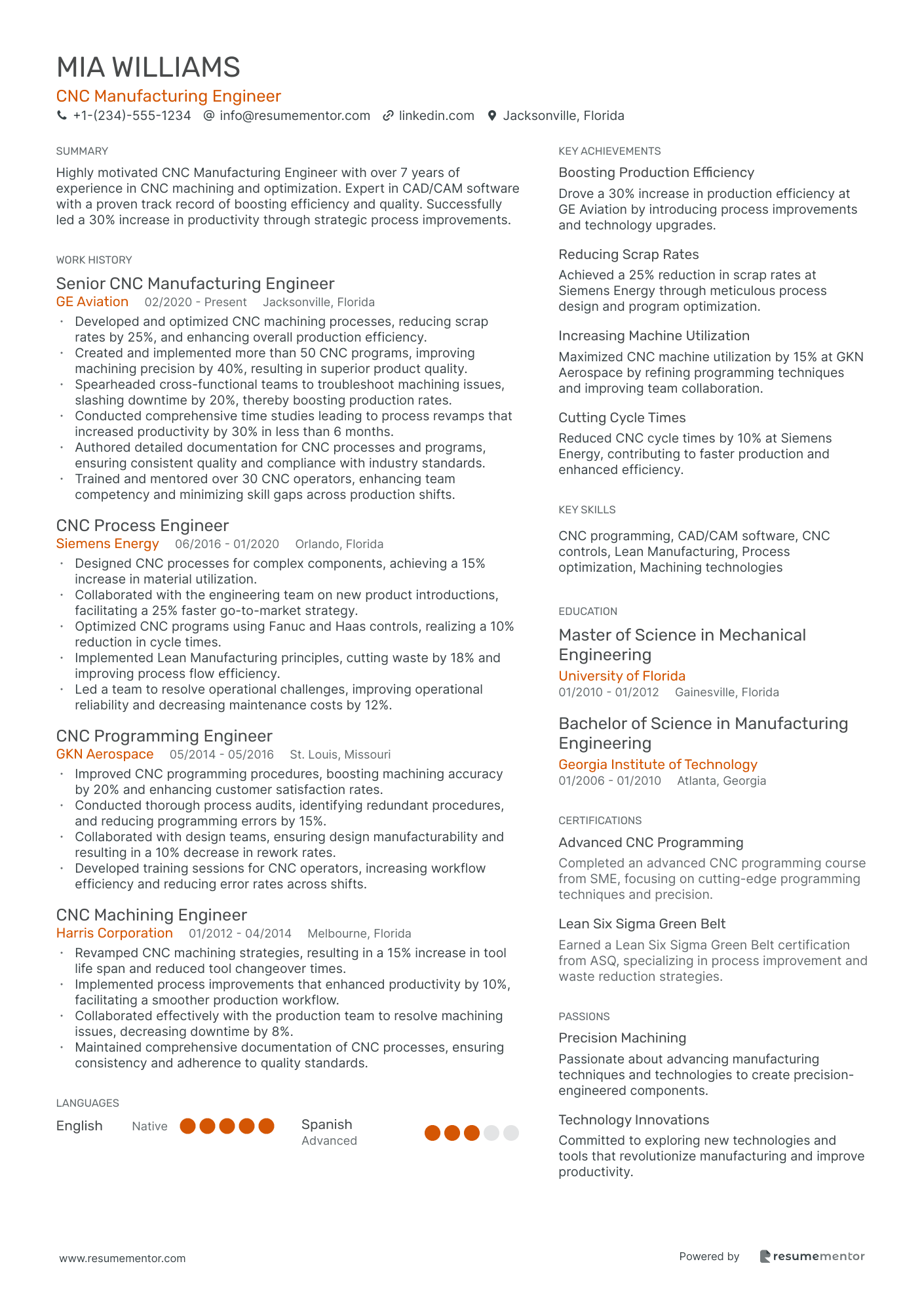

Lean Manufacturing Engineer

Robotics Manufacturing Engineer

Automotive Manufacturing Engineer

Industrial Manufacturing Engineer

Aerospace Manufacturing Engineer

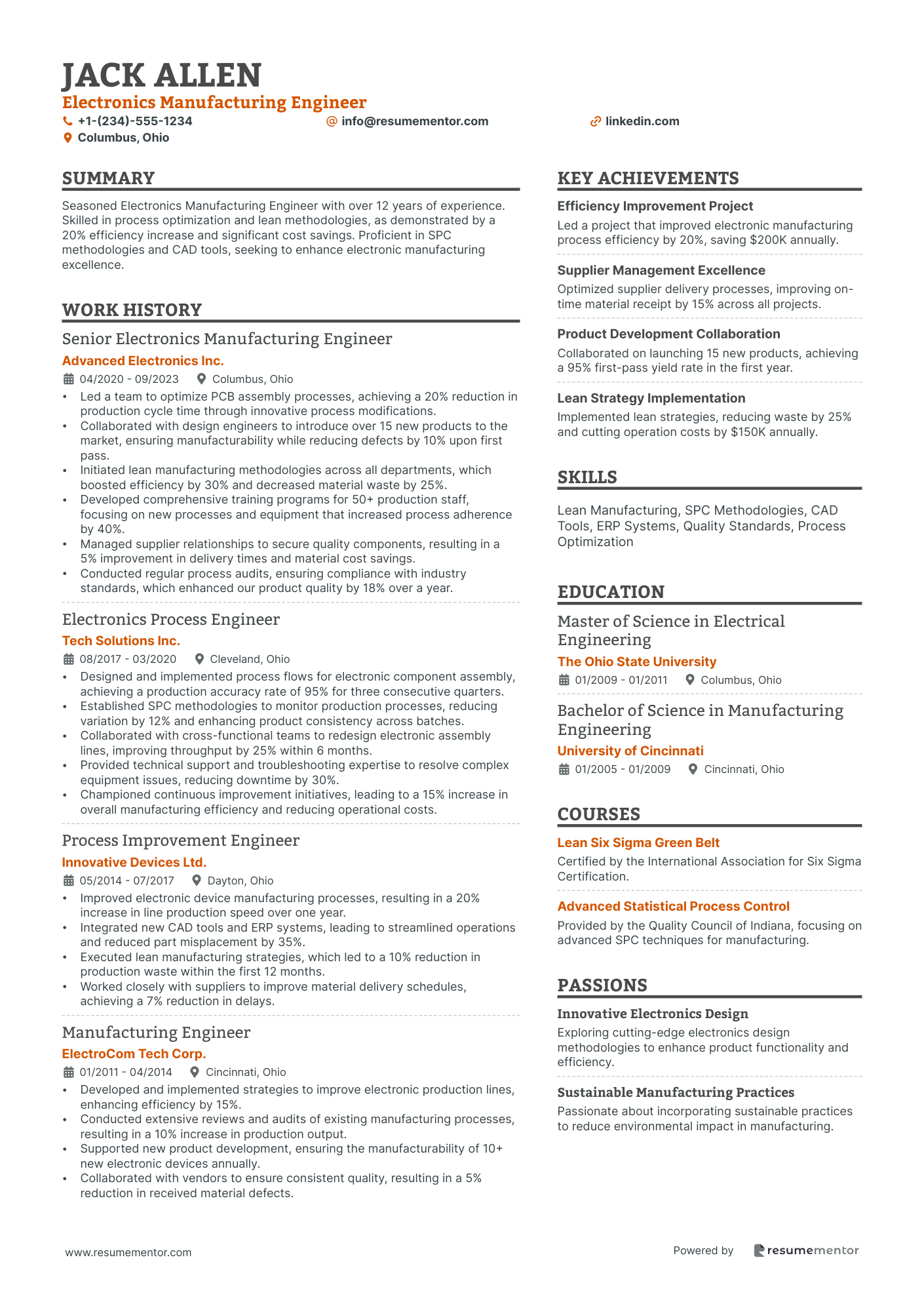

Electronics Manufacturing Engineer

Manufacturing Systems Engineer resume sample

- •Led a cross-functional team that improved production efficiency by 20% through the integration of advanced manufacturing technologies and Lean principles.

- •Conducted a comprehensive feasibility study and successfully implemented a new manufacturing system, resulting in a 10% reduction in production costs.

- •Developed and maintained detailed documentation for manufacturing processes, ensuring consistent implementation across all production lines.

- •Acted as the primary liaison between IT and production teams, facilitating the seamless integration of a new ERP system which enhanced data accuracy.

- •Trained over 50 manufacturing staff on newly implemented systems and processes, increasing overall productivity and system understanding.

- •Utilized statistical methods to analyze system performance data, identifying trends that led to a 5% increase in product quality.

- •Designed and executed process improvements that increased production line efficiency by 18%, saving $200,000 annually.

- •Collaborated with engineering and quality teams to address system discrepancies, achieving a 15% decrease in defect rates.

- •Conducted workshops on Lean Manufacturing principles, contributing to a cultural shift towards continuous improvement.

- •Played a key role in the successful implementation of a new automated system which streamlined operations and reduced manual tasks by 30%.

- •Performed regular audits to ensure compliance with industry standards, improving overall safety and operational standards.

- •Implemented changeover systems that decreased machine downtime by 25%, enhancing production flexibility and output.

- •Managed a project to integrate new machine technology, resulting in a 12% increase in throughput.

- •Collaborated with software developers to customize a real-time data tracking system, improving process transparency across shifts.

- •Developed comprehensive work instructions and process maps, ensuring consistent training and quality assurance throughout the manufacturing floor.

- •Supervised a team of 30 production operators, achieving a 98% on-time delivery rate through effective resource management.

- •Initiated a continuous improvement project that reduced reject rates by 8%, using root cause analysis techniques.

- •Coordinated daily production schedules to align with sales forecasts, resulting in improved inventory management and reduced waste.

- •Led safety training sessions that enhanced workplace safety compliance, leading to a 0% incident rate over a one-year period.

Manufacturing Quality Assurance Engineer resume sample

- •Developed comprehensive quality assurance protocols, increasing product compliance by 35% over a 2-year period.

- •Conducted bi-weekly audits leading to a 25% reduction in defect rates, significantly enhancing production consistency.

- •Collaborated with cross-functional teams to resolve over 50 quality-related issues annually, resulting in improved processes.

- •Analyzed complex data sets, identifying trends and implementing corrective actions that boosted efficiency by 20%.

- •Coordinated and conducted training programs, leading to a 40% increase in staff competency in quality assurance procedures.

- •Aligned product specifications with international standards, ensuring consistent quality and compliance across projects.

- •Implemented a new inspection process, reducing product defects by 30% within the first year.

- •Prepared detailed reports on quality metrics, driving key managerial decisions and operational improvements.

- •Led the review of product specifications, aligning them with changing regulatory requirements, enhancing compliance.

- •Facilitated workshops on best practices, increasing team-based problem-solving abilities by 15% as measured by KPI.

- •Analyzed production data to identify inefficiencies, contributing to a 10% increase in overall factory output.

- •Optimized quality assurance processes, reducing production faults by 20% over six months.

- •Assisted in the development of quality improvement initiatives, enhancing product reliability by 12%.

- •Participated in cross-departmental strategy meetings, aligning quality goals with manufacturing objectives.

- •Collaborated with engineering teams to implement quality controls, preventing and resolving compliance issues.

- •Conducted thorough inspections that improved quality standard adherence by 15% over two years.

- •Developed training documentation that streamlined onboarding processes and enhanced staff knowledge on protocols.

- •Analyzed defect trends, initiating corrective actions that reduced rework costs by 10%.

- •Communicated quality assurance updates to management, facilitating informed business decisions.

CNC Manufacturing Engineer resume sample

- •Developed and optimized CNC machining processes, reducing scrap rates by 25%, and enhancing overall production efficiency.

- •Created and implemented more than 50 CNC programs, improving machining precision by 40%, resulting in superior product quality.

- •Spearheaded cross-functional teams to troubleshoot machining issues, slashing downtime by 20%, thereby boosting production rates.

- •Conducted comprehensive time studies leading to process revamps that increased productivity by 30% in less than 6 months.

- •Authored detailed documentation for CNC processes and programs, ensuring consistent quality and compliance with industry standards.

- •Trained and mentored over 30 CNC operators, enhancing team competency and minimizing skill gaps across production shifts.

- •Designed CNC processes for complex components, achieving a 15% increase in material utilization.

- •Collaborated with the engineering team on new product introductions, facilitating a 25% faster go-to-market strategy.

- •Optimized CNC programs using Fanuc and Haas controls, realizing a 10% reduction in cycle times.

- •Implemented Lean Manufacturing principles, cutting waste by 18% and improving process flow efficiency.

- •Led a team to resolve operational challenges, improving operational reliability and decreasing maintenance costs by 12%.

- •Improved CNC programming procedures, boosting machining accuracy by 20% and enhancing customer satisfaction rates.

- •Conducted thorough process audits, identifying redundant procedures, and reducing programming errors by 15%.

- •Collaborated with design teams, ensuring design manufacturability and resulting in a 10% decrease in rework rates.

- •Developed training sessions for CNC operators, increasing workflow efficiency and reducing error rates across shifts.

- •Revamped CNC machining strategies, resulting in a 15% increase in tool life span and reduced tool changeover times.

- •Implemented process improvements that enhanced productivity by 10%, facilitating a smoother production workflow.

- •Collaborated effectively with the production team to resolve machining issues, decreasing downtime by 8%.

- •Maintained comprehensive documentation of CNC processes, ensuring consistency and adherence to quality standards.

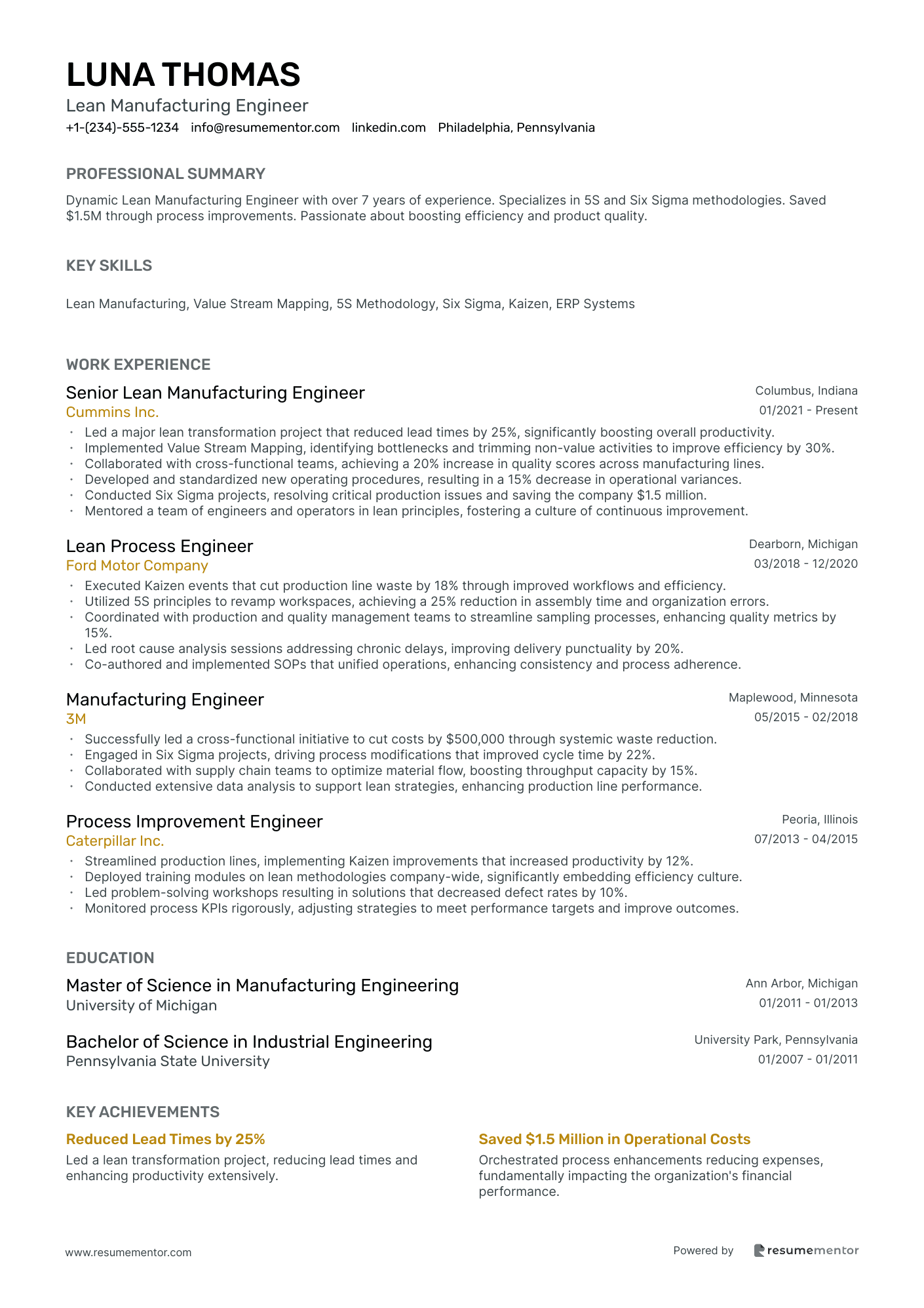

Lean Manufacturing Engineer resume sample

- •Led a major lean transformation project that reduced lead times by 25%, significantly boosting overall productivity.

- •Implemented Value Stream Mapping, identifying bottlenecks and trimming non-value activities to improve efficiency by 30%.

- •Collaborated with cross-functional teams, achieving a 20% increase in quality scores across manufacturing lines.

- •Developed and standardized new operating procedures, resulting in a 15% decrease in operational variances.

- •Conducted Six Sigma projects, resolving critical production issues and saving the company $1.5 million.

- •Mentored a team of engineers and operators in lean principles, fostering a culture of continuous improvement.

- •Executed Kaizen events that cut production line waste by 18% through improved workflows and efficiency.

- •Utilized 5S principles to revamp workspaces, achieving a 25% reduction in assembly time and organization errors.

- •Coordinated with production and quality management teams to streamline sampling processes, enhancing quality metrics by 15%.

- •Led root cause analysis sessions addressing chronic delays, improving delivery punctuality by 20%.

- •Co-authored and implemented SOPs that unified operations, enhancing consistency and process adherence.

- •Successfully led a cross-functional initiative to cut costs by $500,000 through systemic waste reduction.

- •Engaged in Six Sigma projects, driving process modifications that improved cycle time by 22%.

- •Collaborated with supply chain teams to optimize material flow, boosting throughput capacity by 15%.

- •Conducted extensive data analysis to support lean strategies, enhancing production line performance.

- •Streamlined production lines, implementing Kaizen improvements that increased productivity by 12%.

- •Deployed training modules on lean methodologies company-wide, significantly embedding efficiency culture.

- •Led problem-solving workshops resulting in solutions that decreased defect rates by 10%.

- •Monitored process KPIs rigorously, adjusting strategies to meet performance targets and improve outcomes.

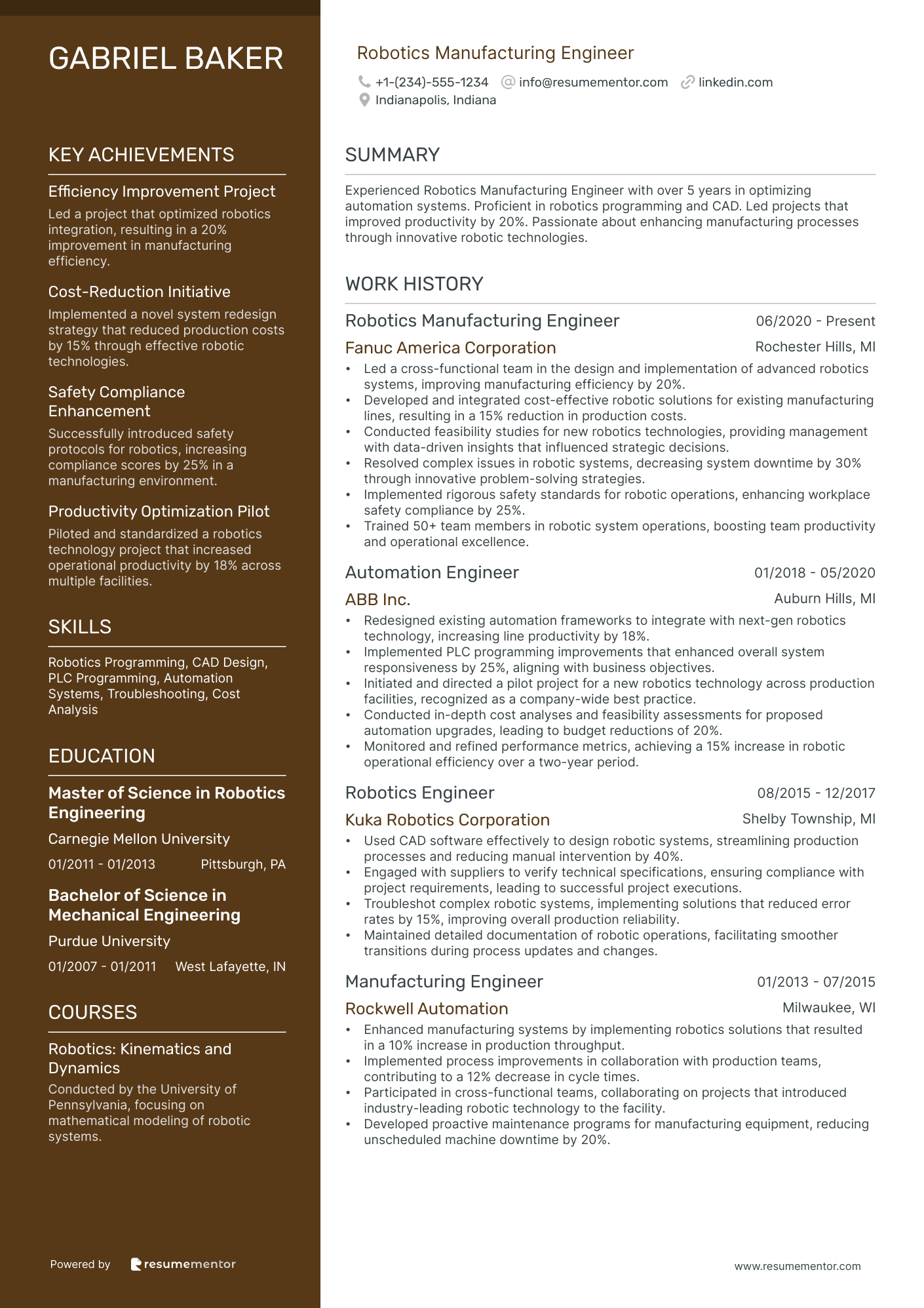

Robotics Manufacturing Engineer resume sample

- •Led a cross-functional team in the design and implementation of advanced robotics systems, improving manufacturing efficiency by 20%.

- •Developed and integrated cost-effective robotic solutions for existing manufacturing lines, resulting in a 15% reduction in production costs.

- •Conducted feasibility studies for new robotics technologies, providing management with data-driven insights that influenced strategic decisions.

- •Resolved complex issues in robotic systems, decreasing system downtime by 30% through innovative problem-solving strategies.

- •Implemented rigorous safety standards for robotic operations, enhancing workplace safety compliance by 25%.

- •Trained 50+ team members in robotic system operations, boosting team productivity and operational excellence.

- •Redesigned existing automation frameworks to integrate with next-gen robotics technology, increasing line productivity by 18%.

- •Implemented PLC programming improvements that enhanced overall system responsiveness by 25%, aligning with business objectives.

- •Initiated and directed a pilot project for a new robotics technology across production facilities, recognized as a company-wide best practice.

- •Conducted in-depth cost analyses and feasibility assessments for proposed automation upgrades, leading to budget reductions of 20%.

- •Monitored and refined performance metrics, achieving a 15% increase in robotic operational efficiency over a two-year period.

- •Used CAD software effectively to design robotic systems, streamlining production processes and reducing manual intervention by 40%.

- •Engaged with suppliers to verify technical specifications, ensuring compliance with project requirements, leading to successful project executions.

- •Troubleshot complex robotic systems, implementing solutions that reduced error rates by 15%, improving overall production reliability.

- •Maintained detailed documentation of robotic operations, facilitating smoother transitions during process updates and changes.

- •Enhanced manufacturing systems by implementing robotics solutions that resulted in a 10% increase in production throughput.

- •Implemented process improvements in collaboration with production teams, contributing to a 12% decrease in cycle times.

- •Participated in cross-functional teams, collaborating on projects that introduced industry-leading robotic technology to the facility.

- •Developed proactive maintenance programs for manufacturing equipment, reducing unscheduled machine downtime by 20%.

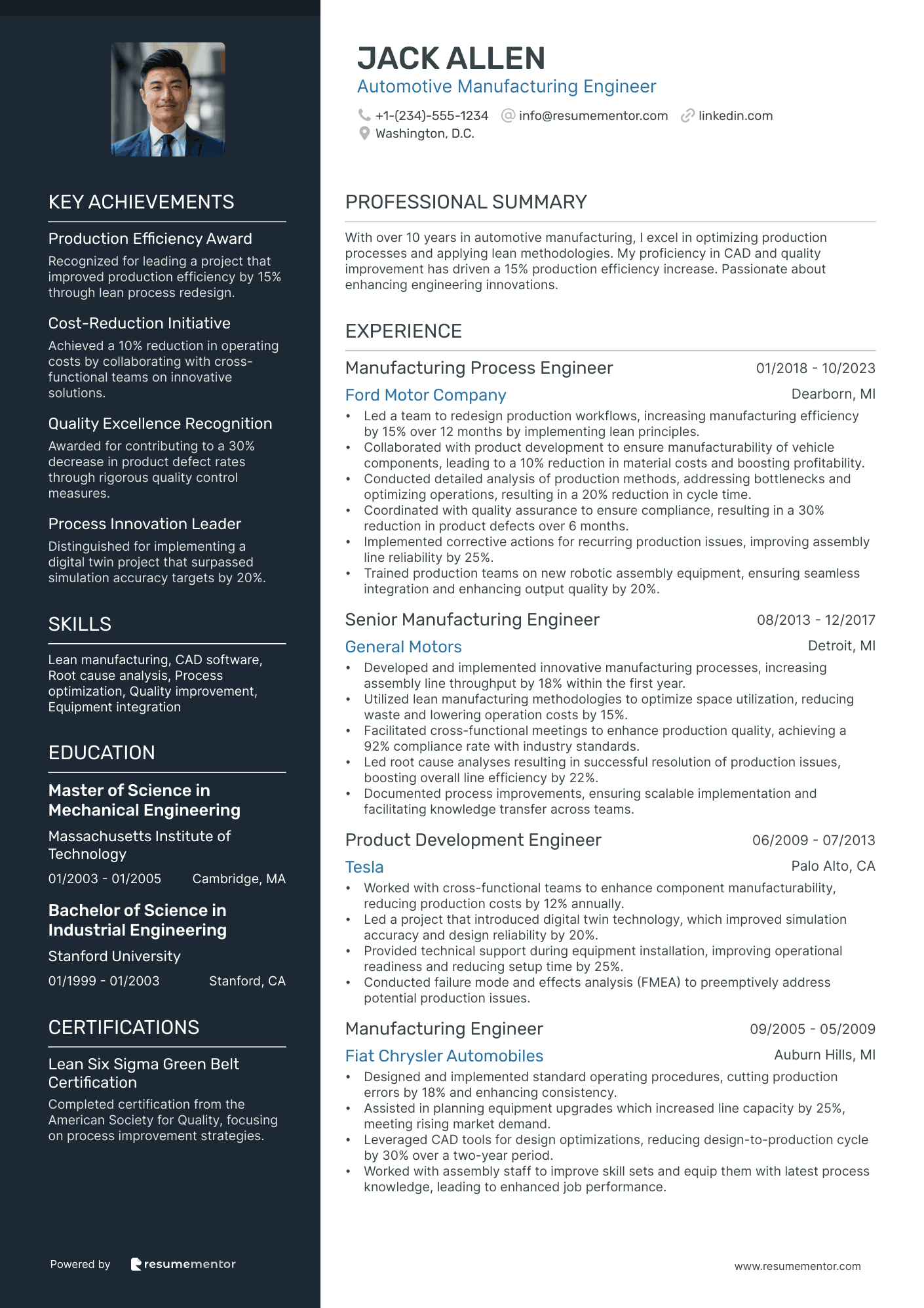

Automotive Manufacturing Engineer resume sample

- •Led a team to redesign production workflows, increasing manufacturing efficiency by 15% over 12 months by implementing lean principles.

- •Collaborated with product development to ensure manufacturability of vehicle components, leading to a 10% reduction in material costs and boosting profitability.

- •Conducted detailed analysis of production methods, addressing bottlenecks and optimizing operations, resulting in a 20% reduction in cycle time.

- •Coordinated with quality assurance to ensure compliance, resulting in a 30% reduction in product defects over 6 months.

- •Implemented corrective actions for recurring production issues, improving assembly line reliability by 25%.

- •Trained production teams on new robotic assembly equipment, ensuring seamless integration and enhancing output quality by 20%.

- •Developed and implemented innovative manufacturing processes, increasing assembly line throughput by 18% within the first year.

- •Utilized lean manufacturing methodologies to optimize space utilization, reducing waste and lowering operation costs by 15%.

- •Facilitated cross-functional meetings to enhance production quality, achieving a 92% compliance rate with industry standards.

- •Led root cause analyses resulting in successful resolution of production issues, boosting overall line efficiency by 22%.

- •Documented process improvements, ensuring scalable implementation and facilitating knowledge transfer across teams.

- •Worked with cross-functional teams to enhance component manufacturability, reducing production costs by 12% annually.

- •Led a project that introduced digital twin technology, which improved simulation accuracy and design reliability by 20%.

- •Provided technical support during equipment installation, improving operational readiness and reducing setup time by 25%.

- •Conducted failure mode and effects analysis (FMEA) to preemptively address potential production issues.

- •Designed and implemented standard operating procedures, cutting production errors by 18% and enhancing consistency.

- •Assisted in planning equipment upgrades which increased line capacity by 25%, meeting rising market demand.

- •Leveraged CAD tools for design optimizations, reducing design-to-production cycle by 30% over a two-year period.

- •Worked with assembly staff to improve skill sets and equip them with latest process knowledge, leading to enhanced job performance.

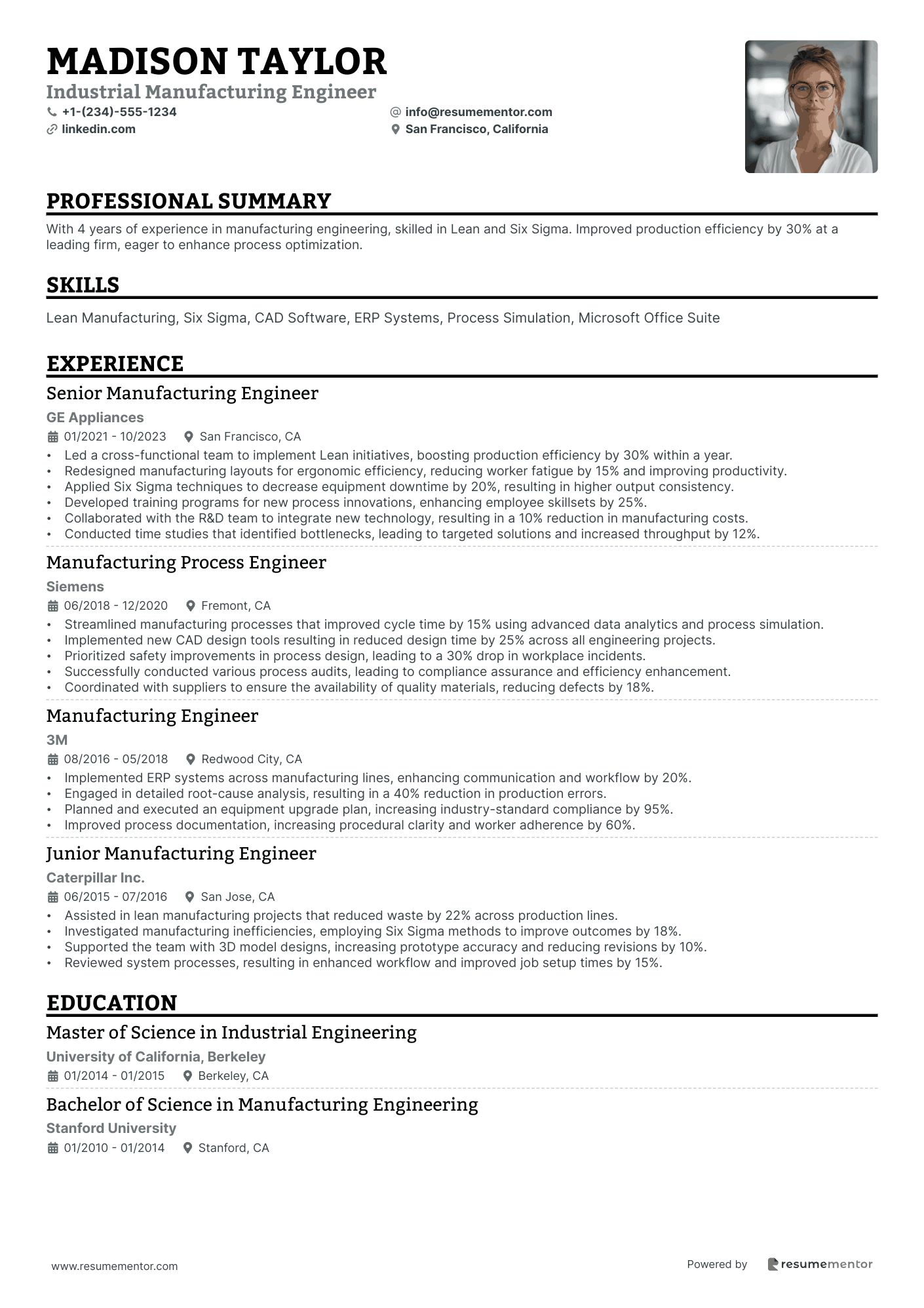

Industrial Manufacturing Engineer resume sample

- •Led a cross-functional team to implement Lean initiatives, boosting production efficiency by 30% within a year.

- •Redesigned manufacturing layouts for ergonomic efficiency, reducing worker fatigue by 15% and improving productivity.

- •Applied Six Sigma techniques to decrease equipment downtime by 20%, resulting in higher output consistency.

- •Developed training programs for new process innovations, enhancing employee skillsets by 25%.

- •Collaborated with the R&D team to integrate new technology, resulting in a 10% reduction in manufacturing costs.

- •Conducted time studies that identified bottlenecks, leading to targeted solutions and increased throughput by 12%.

- •Streamlined manufacturing processes that improved cycle time by 15% using advanced data analytics and process simulation.

- •Implemented new CAD design tools resulting in reduced design time by 25% across all engineering projects.

- •Prioritized safety improvements in process design, leading to a 30% drop in workplace incidents.

- •Successfully conducted various process audits, leading to compliance assurance and efficiency enhancement.

- •Coordinated with suppliers to ensure the availability of quality materials, reducing defects by 18%.

- •Implemented ERP systems across manufacturing lines, enhancing communication and workflow by 20%.

- •Engaged in detailed root-cause analysis, resulting in a 40% reduction in production errors.

- •Planned and executed an equipment upgrade plan, increasing industry-standard compliance by 95%.

- •Improved process documentation, increasing procedural clarity and worker adherence by 60%.

- •Assisted in lean manufacturing projects that reduced waste by 22% across production lines.

- •Investigated manufacturing inefficiencies, employing Six Sigma methods to improve outcomes by 18%.

- •Supported the team with 3D model designs, increasing prototype accuracy and reducing revisions by 10%.

- •Reviewed system processes, resulting in enhanced workflow and improved job setup times by 15%.

Aerospace Manufacturing Engineer resume sample

- •Designed and optimized manufacturing processes for complex aerospace components, achieving a 12% reduction in production time.

- •Led cross-functional teams in root cause analysis and corrective actions which improved product quality by 25%.

- •Implemented SPC techniques to monitor manufacturing performances, increasing process efficiency by 10%.

- •Developed comprehensive process documentation and SOPs, enhancing operational consistency and training efficiency.

- •Conducted tooling design reviews, ensuring manufacturability and reducing tooling errors by 8%.

- •Participated in Lean Manufacturing projects, increasing productivity by 15% without additional labor costs.

- •Collaborated with design engineers to develop efficient manufacturing methods, cutting costs by 10% annually.

- •Executed corrective actions on production line issues, resulting in a 20% reduction in downtime.

- •Trained production staff on best practices, enhancing operational efficiency and minimizing errors by 15%.

- •Led Six Sigma projects focused on quality improvement, achieving a 95% on-time delivery rate.

- •Evaluated new manufacturing technologies, facilitating the adoption of a new CAD system that reduced design time by 25%.

- •Utilized CAD software to design innovative manufacturing solutions, improving assembly speed by 10%.

- •Conducted extensive root cause analyses, reducing defect rates by 18% over a year's period.

- •Developed process plans for new aerospace products, ensuring compliance with AS9100 standards.

- •Participated in continuous improvement workshops, identifying key areas for a 5% reduction in waste.

- •Assisted in designing manufacturing processes for military aerospace components, enhancing product lifespan by 20%.

- •Conducted in-depth analyses to streamline processes, achieving a 7% increase in manufacturing efficiency.

- •Collaborated on cross-functional teams to resolve production challenges, ensuring quick turnaround solutions.

- •Reviewed and improved tooling designs, facilitating a 12% reduction in operational downtime.

Electronics Manufacturing Engineer resume sample

- •Led a team to optimize PCB assembly processes, achieving a 20% reduction in production cycle time through innovative process modifications.

- •Collaborated with design engineers to introduce over 15 new products to the market, ensuring manufacturability while reducing defects by 10% upon first pass.

- •Initiated lean manufacturing methodologies across all departments, which boosted efficiency by 30% and decreased material waste by 25%.

- •Developed comprehensive training programs for 50+ production staff, focusing on new processes and equipment that increased process adherence by 40%.

- •Managed supplier relationships to secure quality components, resulting in a 5% improvement in delivery times and material cost savings.

- •Conducted regular process audits, ensuring compliance with industry standards, which enhanced our product quality by 18% over a year.

- •Designed and implemented process flows for electronic component assembly, achieving a production accuracy rate of 95% for three consecutive quarters.

- •Established SPC methodologies to monitor production processes, reducing variation by 12% and enhancing product consistency across batches.

- •Collaborated with cross-functional teams to redesign electronic assembly lines, improving throughput by 25% within 6 months.

- •Provided technical support and troubleshooting expertise to resolve complex equipment issues, reducing downtime by 30%.

- •Championed continuous improvement initiatives, leading to a 15% increase in overall manufacturing efficiency and reducing operational costs.

- •Improved electronic device manufacturing processes, resulting in a 20% increase in line production speed over one year.

- •Integrated new CAD tools and ERP systems, leading to streamlined operations and reduced part misplacement by 35%.

- •Executed lean manufacturing strategies, which led to a 10% reduction in production waste within the first 12 months.

- •Worked closely with suppliers to improve material delivery schedules, achieving a 7% reduction in delays.

- •Developed and implemented strategies to improve electronic production lines, enhancing efficiency by 15%.

- •Conducted extensive reviews and audits of existing manufacturing processes, resulting in a 10% increase in production output.

- •Supported new product development, ensuring the manufacturability of 10+ new electronic devices annually.

- •Collaborated with vendors to ensure consistent quality, resulting in a 5% reduction in received material defects.

As a manufacturing engineer, you're the architect of innovation, turning raw materials into intricate masterpieces. Yet, condensing your technical know-how and achievements into a concise resume can feel like a challenge. Each detail about your skills and experience needs to shine, but finding a way to make it all fit in a crowded job market is tough.

This is where a resume becomes your essential blueprint for success. To catch the eye of hiring managers, you need to translate your hands-on experience and technical skills into a structured format. A clear foundation is crucial, and using a resume template can provide this organized framework for showcasing your credentials effectively.

These ready-made templates not only save you time but also ensure your resume looks polished and professional. By highlighting your strengths in a well-organized way, employers can easily see your potential and understand what you bring to their team.

Key Takeaways

- The manufacturing engineer resume should emphasize skills in problem-solving, process optimization, and boosting product efficiency to attract potential employers.

- A clear and structured format, aided by resume templates, is crucial for effectively showcasing hands-on experience, technical skills, and professional credentials.

- Including concrete metrics in the work experience section, such as efficiency improvements and productivity gains, helps demonstrate direct contributions to organizational success.

- Selecting a chronological resume format and using modern fonts maintain the resume's professional appearance and ensure easy readability.

- Highlighting both hard skills, like CAD software proficiency, and soft skills, such as communication, ensures the resume captures a comprehensive view of the candidate's abilities.

What to focus on when writing your manufacturing engineer resume

Your manufacturing engineer resume should clearly convey your abilities in problem-solving, process optimization, and boosting product efficiency. These skills are crucial as employers seek professionals who can design systems to enhance productivity and maintain quality.

How to structure your manufacturing engineer resume

- Contact Information — Make it easy for recruiters to connect with you by providing your name, phone number, professional email, and LinkedIn profile. Ensure all details are correctly formatted and current, reflecting a professional and accessible image to potential employers. An updated LinkedIn profile can also provide a deeper insight into your professional journey, reinforcing your resume.

- Professional Summary — This section is your elevator pitch. Emphasize your years of experience, particularly in lean manufacturing, and highlight key achievements that illustrate your impact on manufacturing processes. This is where you succinctly capture the essence of your career, sparking interest for the recruiter to dive deeper into your application.

- Skills — Highlight the skills that matter most in manufacturing, such as process improvement, CAD software proficiency, and expertise in Six Sigma or Lean methodologies. These abilities are directly linked to driving operational success. Using industry-specific terminology here can showcase your familiarity with the field and demonstrate that you possess the necessary technical acumen.

- Work Experience — Detail your hands-on experience with concrete metrics, like "improved efficiency by 15% through process automation," to demonstrate your direct contributions to productivity gains. Tailor your experience to reflect the responsibilities and achievements most relevant to the job description, which can help align your past successes with potential future expectations.

- Education — Your educational background should support your experience. List your degree, major, and university, along with relevant coursework or certifications, such as Six Sigma or PMP, to show your dedication to continuous improvement. These elements can demonstrate your foundation in essential engineering principles and best practices in manufacturing.

- Projects — Include projects that highlight your capacity to innovate or tackle complex challenges, underscoring your ability to make a significant impact in the field. Describing your role and achievements in specific projects can help communicate your unique contributions and the tangible benefits you've driven within your team or organization.

We will now transition into discussing the ideal resume format and delve more deeply into each section to fully support your career objectives and align with the specific demands of a manufacturing engineer position.

Which resume format to choose

For a manufacturing engineer, selecting the right resume format sets the stage for effectively showcasing your skills and accomplishments. A chronological layout is your go-to option if you have a consistent work history, as it highlights your career trajectory and technical expertise over time. This format aligns well with the structured nature of engineering, making your experience easy to follow for potential employers.

When it comes to choosing a font, modern options like Raleway, Lato, or Montserrat offer a clean and professional aesthetic. These fonts keep your resume looking contemporary and ensure that your information is legible, mirroring the precision and clarity essential in engineering tasks.

Saving your resume as a PDF is crucial because it preserves the layout and design, ensuring that what you see is what potential employers will see, regardless of the device they use. This reflects your commitment to quality and reliability, traits that are highly valued in the manufacturing industry.

Maintaining one-inch margins on all sides provides a balanced and tidy appearance, making your resume easy to read. This attention to detail helps convey your organizational skills and meticulous nature, both of which are important in efficiently managing engineering projects.

Overall, these elements come together to create a resume that not only presents your qualifications but also embodies the precision and professionalism that define a successful manufacturing engineer.

How to write a quantifiable resume experience section

Your experience section is the heart of your resume, especially crucial for a manufacturing engineer. It stands out by spotlighting tangible achievements and your direct contributions, creating a strong impact. Start with your most recent job and tailor your entries to match the job ad, highlighting the skills and successes they seek. Use strong action verbs like "optimized," "implemented," and "reduced" to paint a clear picture of your impact. By focusing on the last 10-15 years, you keep your experience relevant and show a solid career trajectory. Tailoring aligns your experiences with the job description, illustrating why you're the ideal candidate.

- •Cut production downtime by 30% with predictive maintenance practices.

- •Guided a team of 15 in redesigning workflow for a 25% throughput increase.

- •Rolled out lean manufacturing techniques, slashing material waste by 20% annually.

- •Worked with cross-functional teams to boost product quality, hitting a 98% customer satisfaction rate.

This experience section seamlessly blends your achievements into a coherent narrative, making each point naturally lead to the next. You're not just listing accomplishments; you're building a story of continuous improvement and impact. By focusing on quantifiable results, each bullet connects to the overarching theme of efficiency and quality enhancement. The strong action words effectively tie your actions to the outcomes. Tailoring your experience to the job ad ensures that each detail is relevant and meaningful, clearly demonstrating your fit for the role in a cohesive and compelling way.

Collaboration-Focused resume experience section

A collaboration-focused manufacturing engineer resume experience section should demonstrate your ability to effectively work with various teams and stakeholders. Start by sharing examples where your teamwork enabled successful project outcomes or enhanced operational efficiency. Highlight your role in these projects, underscoring how you integrated different perspectives and contributed to company-wide benefits. Use specific examples that vividly illustrate these collaborative endeavors in action.

In the bullet points, clearly present your contributions and the results achieved through teamwork. Mention the projects you participated in, your collaborators, and the technical and interpersonal skills you applied. Also, discuss any creative solutions you helped develop or significant improvements initiated while partnering with others. Each entry should not only cover the tasks completed but also highlight how collaboration played a crucial role in achieving these goals.

Manufacturing Engineer

ABC Manufacturing Corp

June 2020 - Present

- Teamed up with cross-functional groups to design and implement a new assembly line process, successfully cutting production time by 15%.

- Steered a team of five engineers in developing a cost-reduction strategy, achieving a 10% decrease in material costs.

- Worked closely with the R&D department to refine prototypes, which enhanced both product quality and customer satisfaction.

- Facilitated weekly meetings that brought maintenance and operations teams together to address and resolve production bottlenecks, boosting efficiency by 20%.

Efficiency-Focused resume experience section

An efficiency-focused manufacturing engineer resume experience section should clearly demonstrate your strengths in improving processes and enhancing productivity. Start by describing your role in boosting efficiency, cutting waste, or speeding up production, ensuring you highlight specific methods or tools that led to measurable results. By detailing key projects you've led or contributed to, you can illustrate how these initiatives have positively impacted the company's performance. Use action words like "implemented," "optimized," and "streamlined" throughout to emphasize your active role in these achievements.

To present your work experience effectively, organize it in a straightforward manner. Begin with the dates, followed by your job title and the company's name. Use bullet points to list your achievements, ensuring each starts with a dynamic action word and offers enough context about your successes. Incorporate numbers or percentages to clearly demonstrate your impact, helping potential employers quickly grasp the extent of your skills and results-driven approach.

Manufacturing Engineer

TechPro Industries

June 2021 - Present

- Implemented a new lean manufacturing process, increasing production efficiency by 20%.

- Optimized assembly line workflow, reducing production cycle time by 15%.

- Developed and led training sessions for team members on process improvements.

- Collaborated with cross-functional teams to reduce material waste by 10%.

Training and Development Focused resume experience section

A training and development-focused manufacturing engineer resume experience section should highlight your accomplishments in creating and managing employee training programs. Start by noting the dates, your job title, and the workplace where you held the role. Discuss your successes with clear examples, linking them with measurable results like increased productivity or the number of employees trained, emphasizing the impact of your work.

In the bullet points, seamlessly transition between your skills in identifying training needs, developing materials, and evaluating their effectiveness. Connect how your collaboration with various departments led to comprehensive training strategies, and showcase your use of technology to improve learning experiences. This approach not only demonstrates your expertise but also your commitment to cultivating a culture of ongoing improvement and skill enhancement in a manufacturing setting.

Training and Development Manager

Acme Manufacturing

June 2019 - Present

- Developed and implemented a training program for 150 employees, resulting in a 20% increase in production efficiency.

- Collaborated with cross-functional teams to tailor training materials for specific manufacturing processes.

- Led workshops and seminars, achieving a 95% satisfaction rate from participants.

- Utilized digital platforms to create interactive learning modules, reducing training time by 30%.

Industry-Specific Focus resume experience section

A manufacturing-focused engineer resume experience section should clearly highlight achievements that demonstrate your problem-solving skills, expertise in optimizing processes, and ability to work well in teams. Start each entry with your job title, followed by the company name and your years of employment. In the bullet points, focus on projects or improvements you led or contributed to, using numbers to show tangible results such as cost reductions, efficiency improvements, or output increases. By clearly illustrating how your contributions made a positive impact on manufacturing processes and company goals, you provide a compelling picture of your capabilities.

Use action-oriented language to describe your roles, showing the proactive nature of your work. Include innovative solutions and their benefits to emphasize your critical thinking and positive influence. This approach captures your role in developing new processes or refining existing ones, ensuring your experience section effectively conveys your skills and achievements in the industry.

Manufacturing Engineer

Tech Dynamics Ltd.

Jan 2018 - Dec 2022

- Led a cross-functional team to redesign manufacturing processes, reducing cycle time by 20%.

- Implemented a cost-saving initiative that lowered raw material waste by 15%, saving $200K annually.

- Developed a statistical process control system to boost production consistency and lower defects by 30%.

- Collaborated with quality assurance to enhance product testing, cutting return rates by 8%.

Write your manufacturing engineer resume summary section

A manufacturing-focused resume summary or objective section should clearly convey your achievements and goals as a manufacturing engineer. If you have substantial experience, a concise summary can effectively showcase your strengths and expertise. For example:

In this summary, specific accomplishments and skills are highlighted, painting a clear picture of your capabilities. The focus on years of experience and concrete results makes it compelling for potential employers. On the other hand, if your experience is limited, a resume objective sets the stage for your career aspirations and contributions. Consider this approach:

[here was the JSON object 2]

This objective paints a picture of your ambition and the unique skills you bring to the table. Connecting these elements is the understanding that each format serves a different function. A summary describes your past achievements, while an objective forecasts your career intentions. A resume profile merges these elements, providing a brief reflection of your career and skills. Meanwhile, a summary of qualifications lists practical skills and experiences directly. Choosing the right format involves aligning it with the job and the employer’s needs while maintaining clarity and relevance. A well-crafted section ensures your resume resonates with those who read it.

Listing your manufacturing engineer skills on your resume

A skills-focused manufacturing engineer resume should effectively highlight what makes you stand out to employers. The skills section is crucial, as it can stand alone, offering a clear view of your expertise, or be woven into sections like experience and summary to show how you've applied these skills. Your strengths and soft skills, like collaboration and communication, demonstrate traits that enhance workplace interactions. Hard skills are different; they are specific, teachable abilities crucial for the job, like proficiency in CAD software or understanding Lean manufacturing principles.

Including both skills and strengths in your resume also means you're adding important keywords. Employers and their software scan for these keywords to determine your fit for the job. This makes a well-crafted skills section essential. Here's an example of a standalone skills section for a manufacturing engineer:

This section is effective because it is direct and easy to understand, covering essential skills for manufacturing engineers. These skills highlight your expertise that potential employers find valuable.

Best hard skills to feature on your manufacturing engineer resume

As a manufacturing engineer, your hard skills demonstrate your technical knowledge and specialized abilities. They show you can handle specific industry tasks with efficiency and expertise.

Hard Skills

- CAD software proficiency

- Lean manufacturing principles

- Process improvement

- AutoCAD expertise

- Quality assurance

- Troubleshooting

- Six Sigma certification

- Process simulation

- Production planning

- CNC programming

- Robotics integration

- Value stream mapping

- Materials science knowledge

- Supply chain management

- Technical documentation skills

Best soft skills to feature on your manufacturing engineer resume

As a manufacturing engineer, soft skills reflect your ability to work well with others and handle various challenges. They highlight your interpersonal and problem-solving skills.

Soft Skills

- Communication

- Teamwork

- Problem solving

- Adaptability

- Leadership

- Time management

- Conflict resolution

- Creativity

- Attention to detail

- Decision making

- Multitasking

- Critical thinking

- Patience

- Negotiation

- Interpersonal skills

How to include your education on your resume

The education section of your resume is a critical component, especially for a manufacturing engineer position. It presents your academic qualifications and aligns them with the job you're targeting. Tailoring this section to fit the role is key; irrelevant education should not be included as it clutters your resume. If your GPA is noteworthy, include it, like this: "GPA: 3.8/4.0." If you graduated with honors, such as "cum laude," it should follow your degree title, e.g., "Bachelor of Science in Mechanical Engineering, cum laude." Your degree should be clearly listed with the title, institution, and dates. Avoid common mistakes by maintaining relevance and clarity.

Here is how not to do it:

- •Studied general courses

Here is a well-crafted example:

This second example excels by highlighting a relevant degree that fits the job title of manufacturing engineer. By mentioning "cum laude," it showcases your academic excellence, and specifying the GPA underscores your capability. Only necessary information is included, making the section concise and focused.

How to include manufacturing engineer certificates on your resume

A certificates section is a key part of your manufacturing engineer resume. List the name of the certification clearly. Include the date you earned it. Add the issuing organization to show its authenticity. Certificates can be included in the header to make them stand out. For example:

A good example of a standalone certificates section includes:

[here was the JSON object 2]

This example is strong because it lists relevant certificates for a manufacturing engineer. Both certificates are industry-recognized, showing your commitment to the field. They also illustrate your specialized skills in manufacturing processes and quality improvement. By including the issuing organizations, you enhance the credibility of your certifications. This information helps in grabbing the recruiter's attention quickly. Such details can give you an edge in the hiring process.

Extra sections to include in your manufacturing engineer resume

As a manufacturing engineer, your resume should clearly reflect your skills, experience, and unique qualities that make you an ideal candidate for the job. Including specific sections can help your accomplishments and personality shine through to potential employers.

Language section — Demonstrate your language skills to highlight your ability to work in multi-lingual environments. Fluency or proficiency in different languages can set you apart in the global marketplace.

Hobbies and interests section — Share your hobbies to give a fuller picture of who you are outside of work. This can build common ground and make you memorable to hiring managers.

Volunteer work section — Show your commitment to community service and highlight transferrable skills. Employers value well-rounded candidates who demonstrate leadership and teamwork.

Books section — List books you have read that relate to engineering or professional development to showcase your commitment to continuous learning. This can also serve as a conversation starter during interviews.

Including these sections makes your resume more personal and engaging while demonstrating your diverse capabilities. This well-rounded approach helps you stand out in a competitive job market.

In Conclusion

In conclusion, crafting an effective manufacturing engineer resume is a thoughtful process that combines technical skills with personal achievements. It’s not just about listing your job history; it's about carefully organizing your experience to highlight your problem-solving abilities, process improvements, and teamwork contributions. Utilizing a resume template can streamline this effort, ensuring your strengths shine in a professional format that resonates with employers. Tailor each section to match the job description, using action words and quantifiable results to demonstrate your impact. Highlighting certifications, such as Lean Six Sigma, can further set you apart, emphasizing your commitment to industry standards. Your education and skills sections should complement your work experience, reinforcing your capabilities in a cohesive narrative. Don’t shy away from including personal touches like languages, hobbies, or volunteer work to offer a fuller picture of who you are. These elements create a well-rounded resume that not only captures your qualifications but also reflects your personality and enthusiasm for growth. By focusing on clarity and relevance, you ensure your resume is a powerful tool in landing your desired manufacturing engineering role. Your ultimate goal is to make a lasting impression, showcasing your journey of continuous improvement and your potential to drive future successes.

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2026. All rights reserved.

Made with love by people who care.