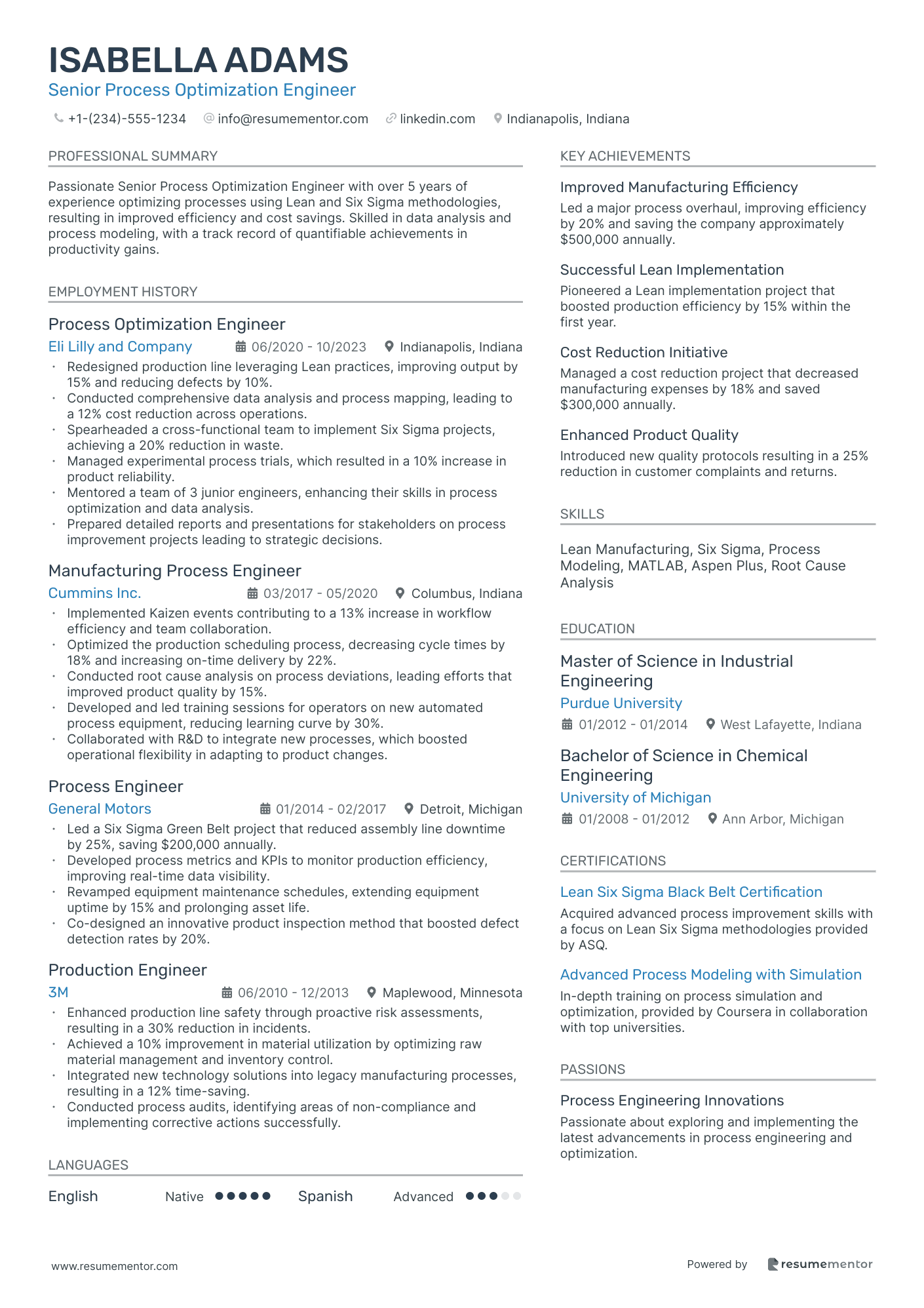

Process Engineer Resume Examples

Jul 18, 2024

|

12 min read

"Streamline your success: a guide to perfecting your process engineer resume. Make your skills flow seamlessly and optimize your chances with these expert tips. Get ready to engineer your dream job one step at a time."

Rated by 348 people

Chemical Process Engineer

Semiconductor Process Engineer

Senior Process Optimization Engineer

Biomedical Process Engineer

Food Process and Safety Engineer

Pharmaceutical Process Engineer

Process Control Systems Engineer

Wastewater Process Engineer

Plastics Manufacturing Process Engineer

Junior Process Design Engineer

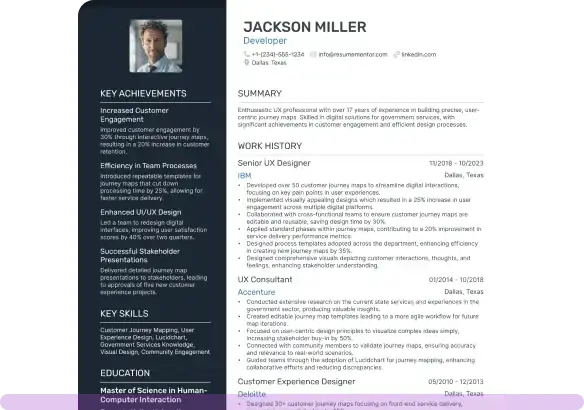

Chemical Process Engineer resume sample

When applying for this position, it's essential to showcase any experience with process optimization or chemical production. Highlight your understanding of safety regulations and compliance, as this is crucial in the industry. If you have completed relevant courses or received certifications like 'Chemical Engineering Principles' or 'Process Safety Management', include these details to demonstrate your expertise. Additionally, provide specific instances where your initiatives led to cost savings or efficiency improvements, using a 'skill-action-result' format to illustrate tangible impacts on previous projects or teams.

- •Designed and optimized chemical processes that improved production efficiency by 15% and reduced costs substantially.

- •Conducted over 30 process simulations annually using Aspen Plus to ensure processes met safety and efficiency standards.

- •Led cross-functional teams to implement workflow improvements, resulting in a 12% increase in overall production capacity.

- •Performed scale-up of processes from lab to production scale, achieving consistency in product quality each time.

- •Developed and maintained over 50 technical documents, including flow diagrams and standard operating procedures.

- •Analyzed process data which led to identifying a bottleneck and improved yield by 8% through subsequent process adjustments.

- •Collaborated with R&D team to streamline processes, leading to a 20% reduction in waste output.

- •Implemented safety audits, ensuring compliance with environmental regulations, resulting in zero incidents over three years.

- •Optimized scaling activities for new processes, significantly reducing downtime by 10% during transition phases.

- •Assisted in the start-up and commissioning of new equipment, ensuring smooth operation within two weeks of installation.

- •Authored technical reports on process optimization strategies, contributing to the regional knowledge base for future reference.

- •Developed process design improvements that reduced operational costs by $250,000 annually through efficiency gains.

- •Managed multiple projects simultaneously, meeting all predetermined deadlines and successfully delivering every project on time.

- •Conducted thorough risk assessments, identifying potential hazards and creating mitigation plans that increased safety standards.

- •Provided technical support and troubleshooting assistance during unexpected process interruptions, minimizing the impact on production.

- •Executed process development projects, which improved laboratory-to-pilot scale conversion by 5%, ensuring product consistency.

- •Conducted detailed experiments and validated new hypotheses, contributing significantly to process innovation.

- •Supported the design and testing of equipment, ensuring alignment with production goals and regulatory standards.

- •Regularly engaged in continuous learning on emerging chemical technologies and process trends, enhancing project results.

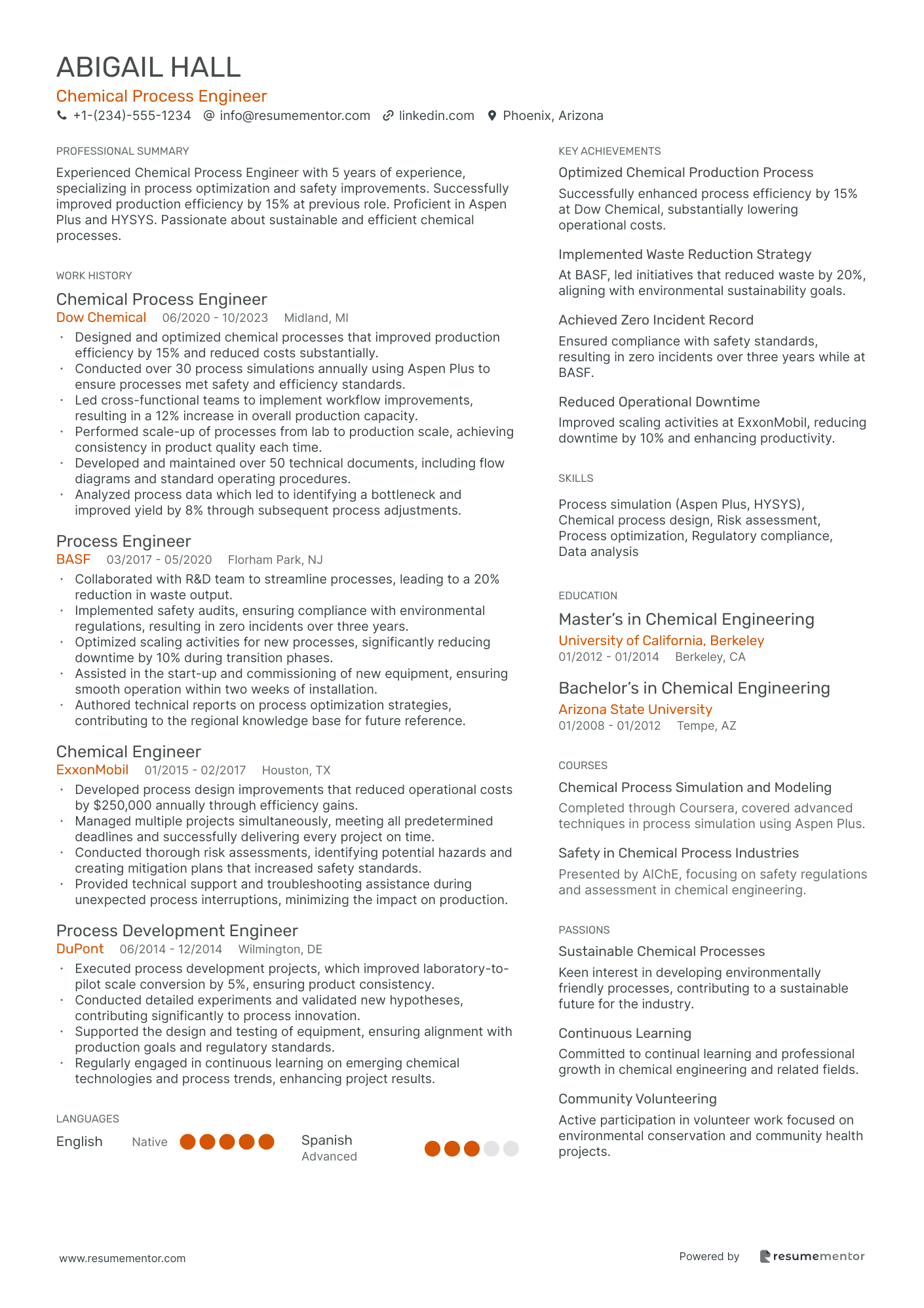

Semiconductor Process Engineer resume sample

When applying for this role, emphasize any hands-on experience with semiconductor fabrication and process optimization. Familiarity with cleanroom protocols and equipment, such as photolithography and etching, is essential. Highlight your teamwork skills, particularly in cross-functional settings, as collaboration with design engineers is often necessary. Include any relevant certifications or training in semiconductor technologies, detailing their impact on your work. Use a 'skill-action-result' format to show how your contributions improved yield rates or reduced cycle times in previous positions.

- •Led a cross-functional team to improve photolithography process, increasing yield by 20% while reducing cycle time by 15%.

- •Implemented SPC methods which helped in reducing defect rates by 40% within the first year of deployment.

- •Collaborated with design teams to integrate new technologies, resulting in successful launch of 5nm node chips ahead of schedule.

- •Conducted root cause analysis for etching anomalies, implementing corrective actions that decreased process variability by 30%.

- •Automated reporting procedures for data collection, improving analysis efficiency by 25% and reducing manual errors.

- •Developed and maintained process documentation, ensuring compliance with ISO standards and enhancing training protocols.

- •Optimized deposition processes, leading to a 15% reduction in material wastage and saving the company $250,000 annually.

- •Collaborated with QA teams to improve packaging processes, enhancing product quality and customer satisfaction metrics by 10%.

- •Utilized DOE to identify critical factors affecting yield, resulting in a 12% improvement in throughput across product lines.

- •Developed a comprehensive cleanroom safety program, reducing safety incidents by 50% within the first year.

- •Provided technical support during production ramp-ups, achieving a 95% success rate in meeting delivery schedules.

- •Conducted experiments to refine etching processes, contributing to a 25% increase in process throughput.

- •Assisted in deploying real-time monitoring tools, facilitating a 30% reduction in equipment downtime.

- •Supported the introduction of SPC methods in the fabrication process, resulting in more consistent product quality.

- •Developed training materials for new hires, streamlining onboarding and reducing ramp-up time by 20%.

- •Analyzed photolithography data to identify trends, improving yield forecasts by 10% and production planning resilience.

- •Introduced new deposition techniques, enhancing process reliability and reducing rework rates by 18%.

- •Coordinated cross-departmental task forces to address quality issues, resulting in a 25% improvement in defect mitigation.

- •Executed packaging optimization project, boosting output by 12% without compromising product integrity.

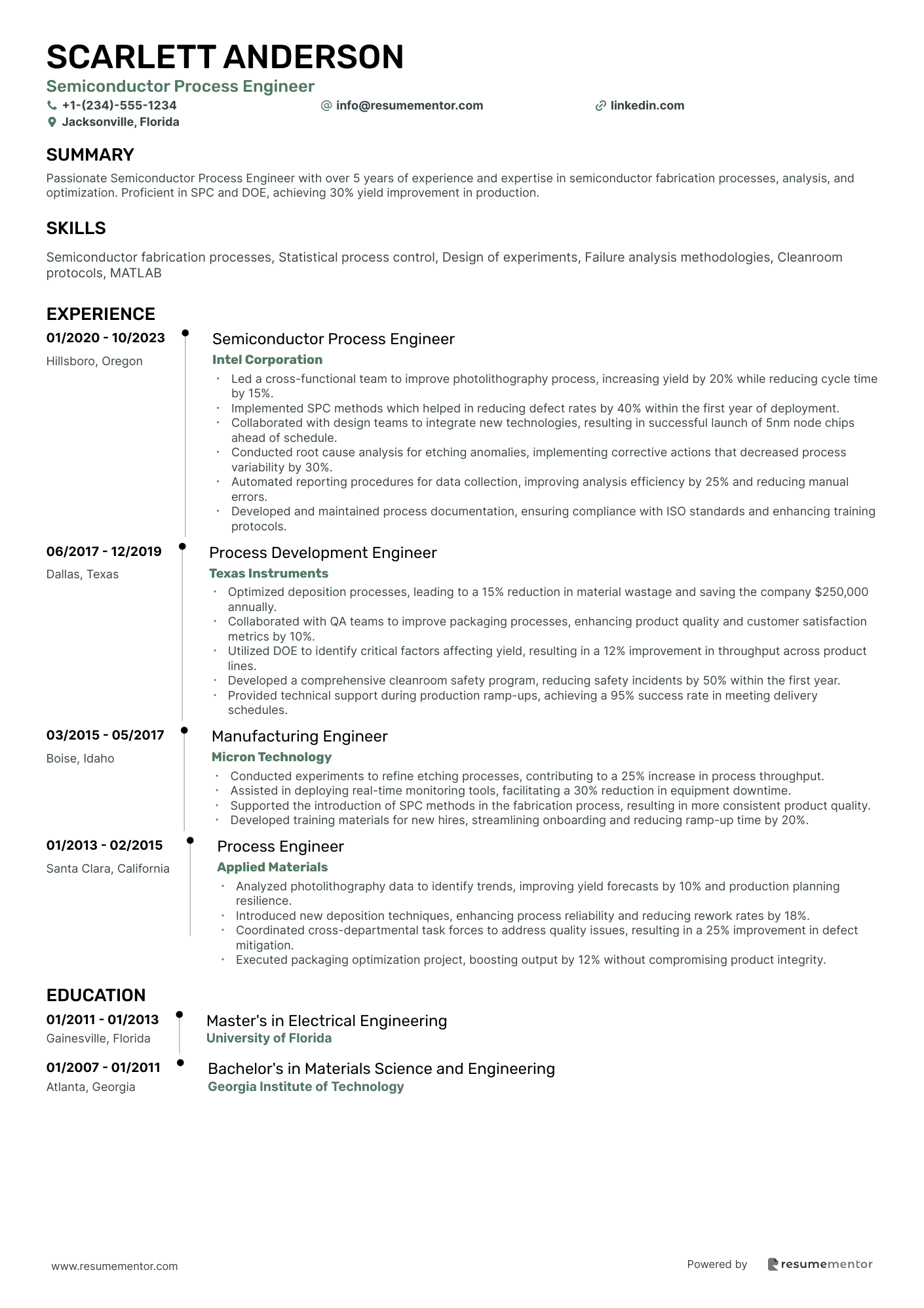

Senior Process Optimization Engineer resume sample

When applying for this role, it's important to showcase your experience with process mapping and value stream analysis. Highlight your familiarity with Lean and Six Sigma methodologies, as well as any certifications you've obtained. Include specific metrics to demonstrate how your initiatives have improved efficiency or reduced costs in previous roles. Provide concrete examples using the 'skill-action-result' format to illustrate your impact. Emphasizing a collaborative spirit and ability to lead cross-functional teams will also strengthen your application.

- •Redesigned production line leveraging Lean practices, improving output by 15% and reducing defects by 10%.

- •Conducted comprehensive data analysis and process mapping, leading to a 12% cost reduction across operations.

- •Spearheaded a cross-functional team to implement Six Sigma projects, achieving a 20% reduction in waste.

- •Managed experimental process trials, which resulted in a 10% increase in product reliability.

- •Mentored a team of 3 junior engineers, enhancing their skills in process optimization and data analysis.

- •Prepared detailed reports and presentations for stakeholders on process improvement projects leading to strategic decisions.

- •Implemented Kaizen events contributing to a 13% increase in workflow efficiency and team collaboration.

- •Optimized the production scheduling process, decreasing cycle times by 18% and increasing on-time delivery by 22%.

- •Conducted root cause analysis on process deviations, leading efforts that improved product quality by 15%.

- •Developed and led training sessions for operators on new automated process equipment, reducing learning curve by 30%.

- •Collaborated with R&D to integrate new processes, which boosted operational flexibility in adapting to product changes.

- •Led a Six Sigma Green Belt project that reduced assembly line downtime by 25%, saving $200,000 annually.

- •Developed process metrics and KPIs to monitor production efficiency, improving real-time data visibility.

- •Revamped equipment maintenance schedules, extending equipment uptime by 15% and prolonging asset life.

- •Co-designed an innovative product inspection method that boosted defect detection rates by 20%.

- •Enhanced production line safety through proactive risk assessments, resulting in a 30% reduction in incidents.

- •Achieved a 10% improvement in material utilization by optimizing raw material management and inventory control.

- •Integrated new technology solutions into legacy manufacturing processes, resulting in a 12% time-saving.

- •Conducted process audits, identifying areas of non-compliance and implementing corrective actions successfully.

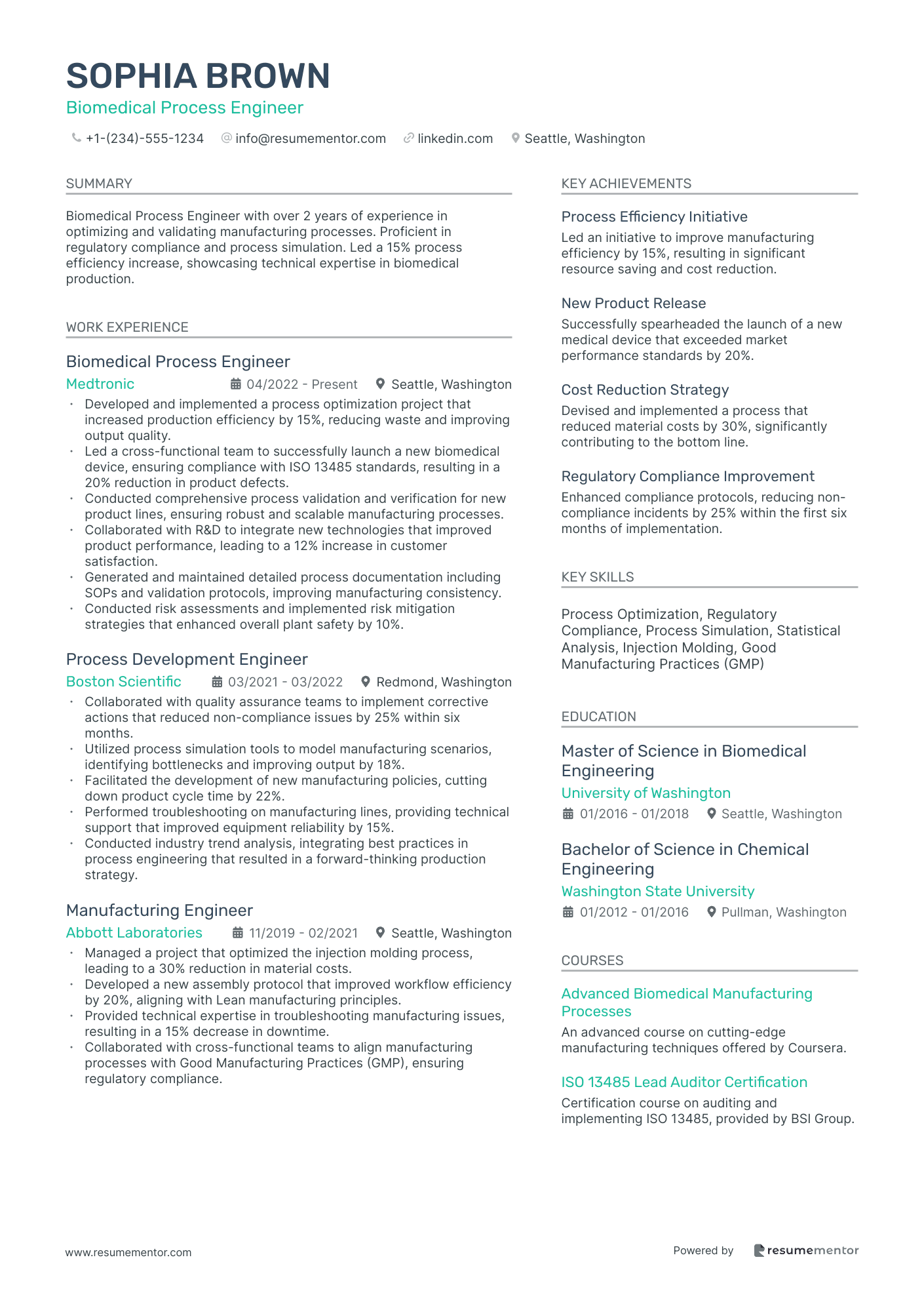

Biomedical Process Engineer resume sample

When applying for this role, it's important to showcase any previous experience with medical devices or laboratory processes. Emphasize technical skills in areas like quality control or regulatory compliance, as these are vital. If you have certifications such as ‘GMP Training’ or relevant coursework in biomanufacturing, be sure to include these details. Use examples that illustrate your problem-solving abilities and how you've improved processes, using the 'skill-action-result' framework to demonstrate your impact and contribution to project success.

- •Developed and implemented a process optimization project that increased production efficiency by 15%, reducing waste and improving output quality.

- •Led a cross-functional team to successfully launch a new biomedical device, ensuring compliance with ISO 13485 standards, resulting in a 20% reduction in product defects.

- •Conducted comprehensive process validation and verification for new product lines, ensuring robust and scalable manufacturing processes.

- •Collaborated with R&D to integrate new technologies that improved product performance, leading to a 12% increase in customer satisfaction.

- •Generated and maintained detailed process documentation including SOPs and validation protocols, improving manufacturing consistency.

- •Conducted risk assessments and implemented risk mitigation strategies that enhanced overall plant safety by 10%.

- •Collaborated with quality assurance teams to implement corrective actions that reduced non-compliance issues by 25% within six months.

- •Utilized process simulation tools to model manufacturing scenarios, identifying bottlenecks and improving output by 18%.

- •Facilitated the development of new manufacturing policies, cutting down product cycle time by 22%.

- •Performed troubleshooting on manufacturing lines, providing technical support that improved equipment reliability by 15%.

- •Conducted industry trend analysis, integrating best practices in process engineering that resulted in a forward-thinking production strategy.

- •Managed a project that optimized the injection molding process, leading to a 30% reduction in material costs.

- •Developed a new assembly protocol that improved workflow efficiency by 20%, aligning with Lean manufacturing principles.

- •Provided technical expertise in troubleshooting manufacturing issues, resulting in a 15% decrease in downtime.

- •Collaborated with cross-functional teams to align manufacturing processes with Good Manufacturing Practices (GMP), ensuring regulatory compliance.

- •Assisted in the development of scalable manufacturing processes for new biomedical devices, meeting and exceeding market demands.

- •Conducted process performance analyses, implementing improvements that enhanced production efficiency by 15%.

- •Created comprehensive work instructions that improved team productivity by 10%.

- •Collaborated with suppliers to ensure material quality, contributing to a 12% increase in final product reliability.

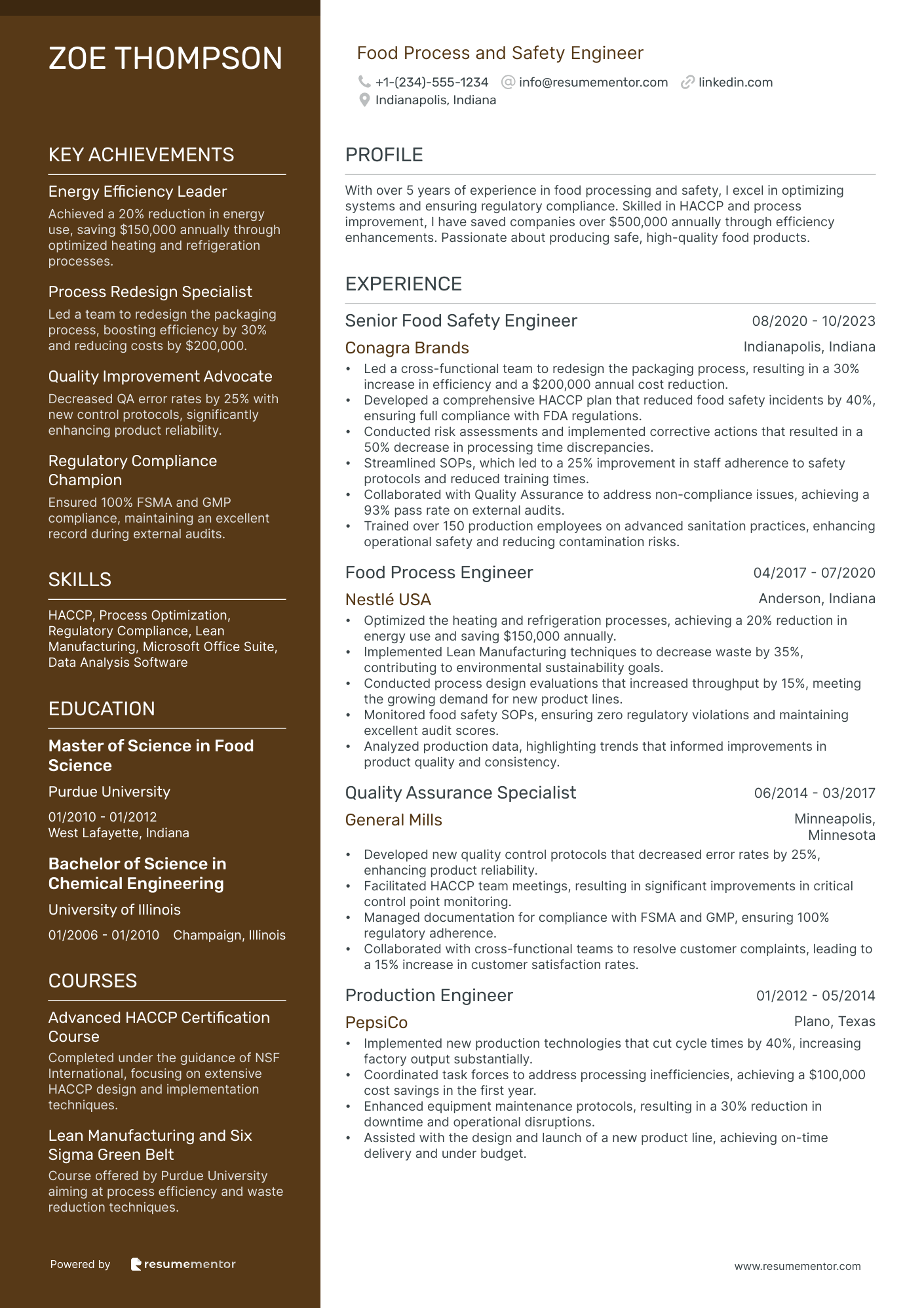

Food Process and Safety Engineer resume sample

When applying for this role, highlight your knowledge of food safety regulations and standards, such as HACCP or FDA guidelines. Emphasize any certifications or training in food safety management systems to show your expertise. Illustrate how you have contributed to improving safety protocols or minimizing risks in previous positions. Use specific examples that follow a 'skill-action-result' format, detailing how your interventions positively impacted food quality or safety. Your ability to collaborate with production teams and conduct effective training sessions is also crucial.

- •Led a cross-functional team to redesign the packaging process, resulting in a 30% increase in efficiency and a $200,000 annual cost reduction.

- •Developed a comprehensive HACCP plan that reduced food safety incidents by 40%, ensuring full compliance with FDA regulations.

- •Conducted risk assessments and implemented corrective actions that resulted in a 50% decrease in processing time discrepancies.

- •Streamlined SOPs, which led to a 25% improvement in staff adherence to safety protocols and reduced training times.

- •Collaborated with Quality Assurance to address non-compliance issues, achieving a 93% pass rate on external audits.

- •Trained over 150 production employees on advanced sanitation practices, enhancing operational safety and reducing contamination risks.

- •Optimized the heating and refrigeration processes, achieving a 20% reduction in energy use and saving $150,000 annually.

- •Implemented Lean Manufacturing techniques to decrease waste by 35%, contributing to environmental sustainability goals.

- •Conducted process design evaluations that increased throughput by 15%, meeting the growing demand for new product lines.

- •Monitored food safety SOPs, ensuring zero regulatory violations and maintaining excellent audit scores.

- •Analyzed production data, highlighting trends that informed improvements in product quality and consistency.

- •Developed new quality control protocols that decreased error rates by 25%, enhancing product reliability.

- •Facilitated HACCP team meetings, resulting in significant improvements in critical control point monitoring.

- •Managed documentation for compliance with FSMA and GMP, ensuring 100% regulatory adherence.

- •Collaborated with cross-functional teams to resolve customer complaints, leading to a 15% increase in customer satisfaction rates.

- •Implemented new production technologies that cut cycle times by 40%, increasing factory output substantially.

- •Coordinated task forces to address processing inefficiencies, achieving a $100,000 cost savings in the first year.

- •Enhanced equipment maintenance protocols, resulting in a 30% reduction in downtime and operational disruptions.

- •Assisted with the design and launch of a new product line, achieving on-time delivery and under budget.

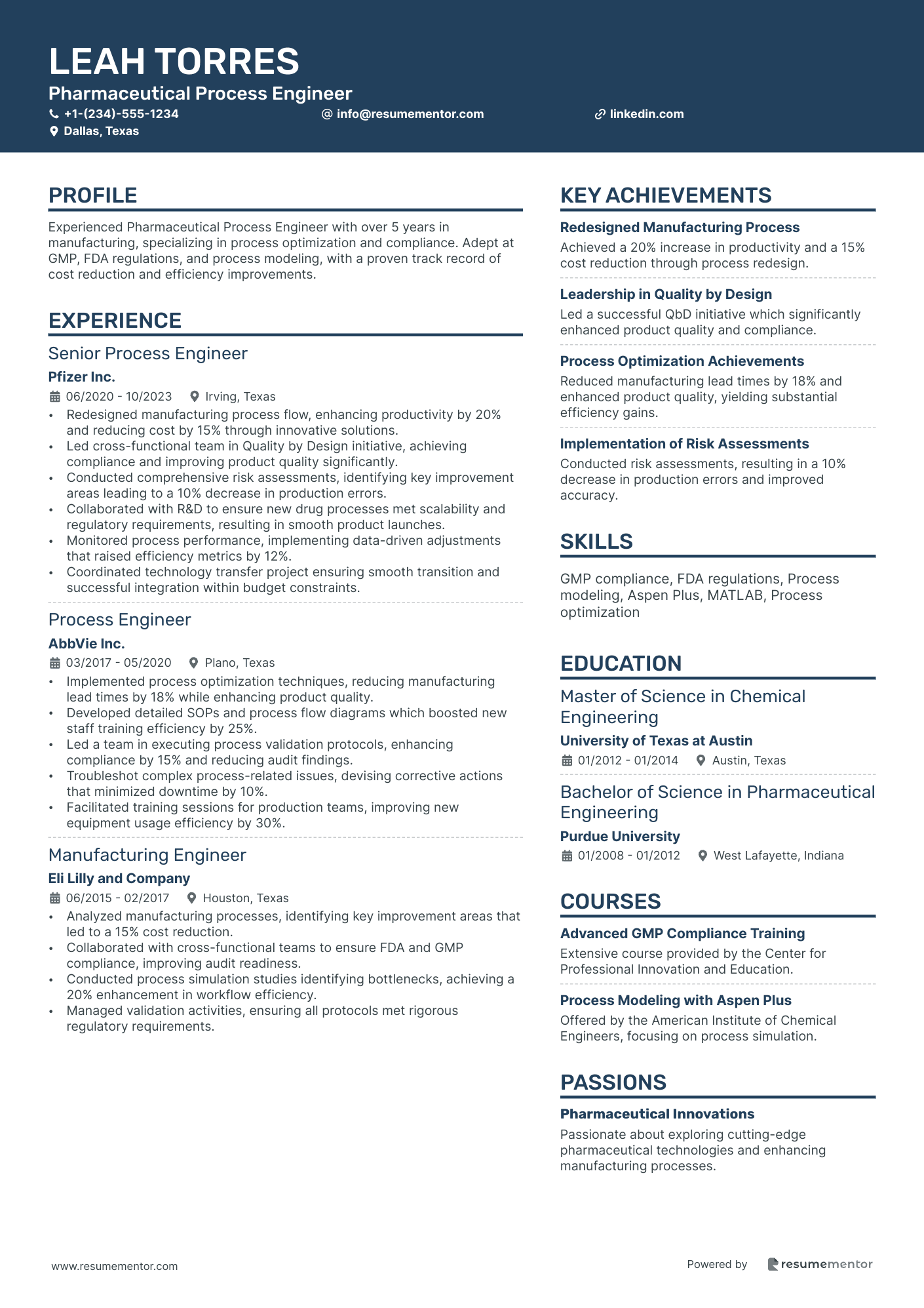

Pharmaceutical Process Engineer resume sample

When applying for this role, it’s important to highlight any experience in biopharmaceutical manufacturing or compliance. Showcase your understanding of regulatory standards, like GMP and FDA guidelines. If you have completed relevant coursework or earned certifications in process validation or quality assurance, include these to demonstrate your expertise. Provide examples of how your process optimization efforts have improved yield or quality, using the 'skill-action-result' format. Focus on teamwork, as collaboration with cross-functional teams is often needed to ensure successful project outcomes.

- •Redesigned manufacturing process flow, enhancing productivity by 20% and reducing cost by 15% through innovative solutions.

- •Led cross-functional team in Quality by Design initiative, achieving compliance and improving product quality significantly.

- •Conducted comprehensive risk assessments, identifying key improvement areas leading to a 10% decrease in production errors.

- •Collaborated with R&D to ensure new drug processes met scalability and regulatory requirements, resulting in smooth product launches.

- •Monitored process performance, implementing data-driven adjustments that raised efficiency metrics by 12%.

- •Coordinated technology transfer project ensuring smooth transition and successful integration within budget constraints.

- •Implemented process optimization techniques, reducing manufacturing lead times by 18% while enhancing product quality.

- •Developed detailed SOPs and process flow diagrams which boosted new staff training efficiency by 25%.

- •Led a team in executing process validation protocols, enhancing compliance by 15% and reducing audit findings.

- •Troubleshot complex process-related issues, devising corrective actions that minimized downtime by 10%.

- •Facilitated training sessions for production teams, improving new equipment usage efficiency by 30%.

- •Analyzed manufacturing processes, identifying key improvement areas that led to a 15% cost reduction.

- •Collaborated with cross-functional teams to ensure FDA and GMP compliance, improving audit readiness.

- •Conducted process simulation studies identifying bottlenecks, achieving a 20% enhancement in workflow efficiency.

- •Managed validation activities, ensuring all protocols met rigorous regulatory requirements.

- •Developed quality metrics reporting system, improving response time to issues by 30% and enhancing product consistency.

- •Conducted thorough risk assessments, leading to a 25% reduction in non-conformance incidents.

- •Collaborated with production teams to refine processes, contributing to a significant reduction in manufacturing costs.

- •Supported technology transfer processes, ensuring seamless transition with no interruptions in production.

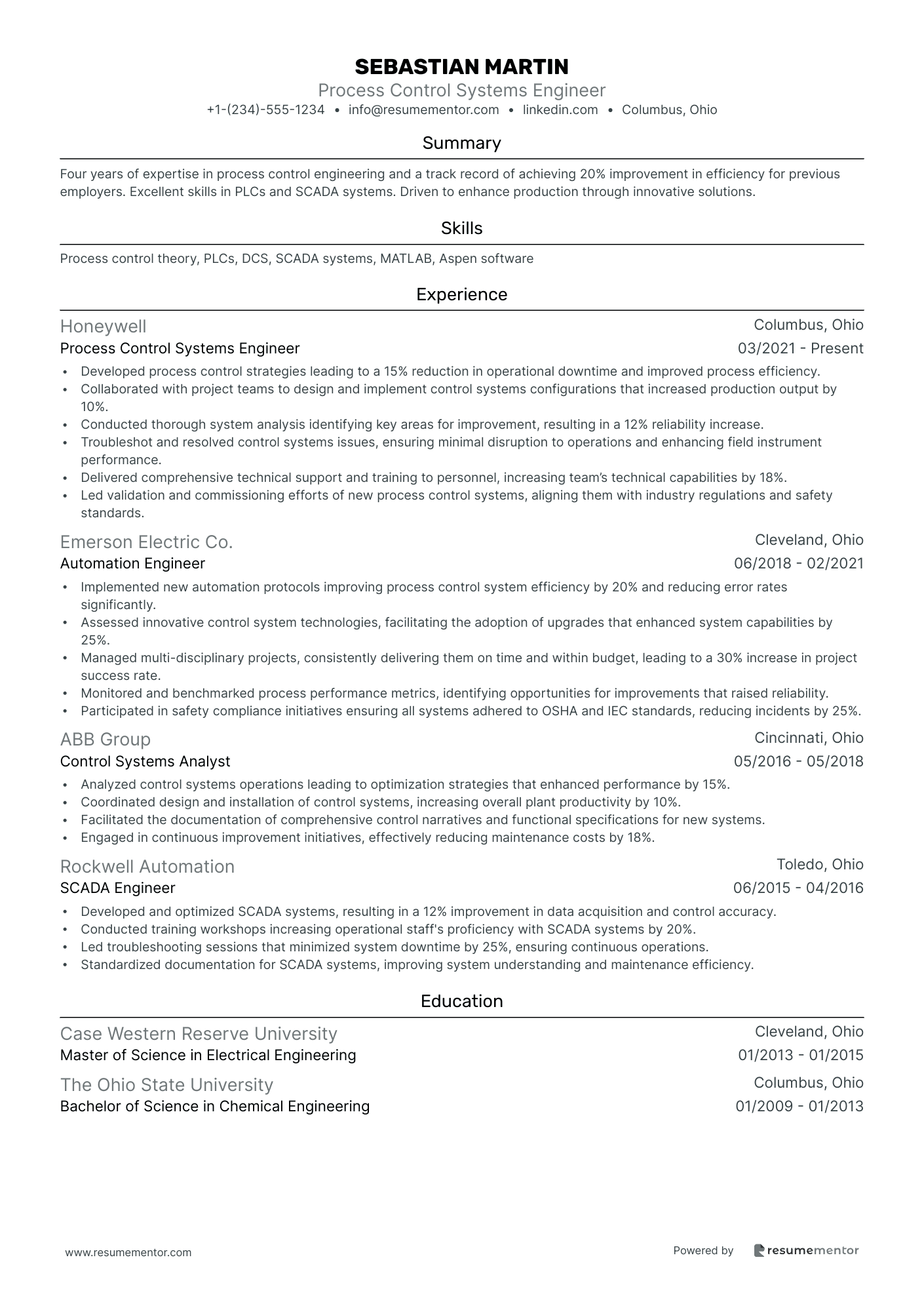

Process Control Systems Engineer resume sample

When applying for this position, it's essential to highlight your experience with control systems and automation technologies. Showcase any familiarity with programming languages like Python or Ladder Logic. Mention any projects where you designed or improved control systems that led to increased efficiency or reduced downtime. Certifications such as 'Certified Automation Professional' can add value. Use specific examples of how your technical skills and problem-solving capabilities have positively impacted past projects. Focus on measurable outcomes to strengthen your application and demonstrate your potential contributions.

- •Developed process control strategies leading to a 15% reduction in operational downtime and improved process efficiency.

- •Collaborated with project teams to design and implement control systems configurations that increased production output by 10%.

- •Conducted thorough system analysis identifying key areas for improvement, resulting in a 12% reliability increase.

- •Troubleshot and resolved control systems issues, ensuring minimal disruption to operations and enhancing field instrument performance.

- •Delivered comprehensive technical support and training to personnel, increasing team’s technical capabilities by 18%.

- •Led validation and commissioning efforts of new process control systems, aligning them with industry regulations and safety standards.

- •Implemented new automation protocols improving process control system efficiency by 20% and reducing error rates significantly.

- •Assessed innovative control system technologies, facilitating the adoption of upgrades that enhanced system capabilities by 25%.

- •Managed multi-disciplinary projects, consistently delivering them on time and within budget, leading to a 30% increase in project success rate.

- •Monitored and benchmarked process performance metrics, identifying opportunities for improvements that raised reliability.

- •Participated in safety compliance initiatives ensuring all systems adhered to OSHA and IEC standards, reducing incidents by 25%.

- •Analyzed control systems operations leading to optimization strategies that enhanced performance by 15%.

- •Coordinated design and installation of control systems, increasing overall plant productivity by 10%.

- •Facilitated the documentation of comprehensive control narratives and functional specifications for new systems.

- •Engaged in continuous improvement initiatives, effectively reducing maintenance costs by 18%.

- •Developed and optimized SCADA systems, resulting in a 12% improvement in data acquisition and control accuracy.

- •Conducted training workshops increasing operational staff's proficiency with SCADA systems by 20%.

- •Led troubleshooting sessions that minimized system downtime by 25%, ensuring continuous operations.

- •Standardized documentation for SCADA systems, improving system understanding and maintenance efficiency.

Wastewater Process Engineer resume sample

When applying for this role, it’s important to highlight any experience with water treatment systems or environmental compliance. Detail your knowledge of wastewater regulations and your ability to conduct process optimization. Certifications in water quality management or relevant engineering design software should be emphasized. Include instances where you improved treatment efficiency or reduced operational costs, using a 'skill-action-result' framework. Showcase teamwork in cross-disciplinary projects and your commitment to sustainable practices to demonstrate how your contributions positively impacted previous employers.

- •Led a team to design and implement process upgrades, resulting in a 25% increase in treatment capacity over a year.

- •Conducted a comprehensive feasibility study, cutting projected costs by 20% while maintaining project scope and compliance.

- •Collaborated effectively with cross-functional teams to introduce innovative waste management solutions, saving $2 million annually.

- •Developed process control strategies that led to a 15% reduction in energy use, aligning with sustainability goals.

- •Prepared detailed technical reports that enhanced stakeholder communication and expedited project approvals by 40%.

- •Monitored and optimized operational efficiency by implementing advanced data analytics, cutting unplanned downtime by 30%.

- •Engineered process improvements at wastewater facilities increasing efficiency by 18% during my tenure.

- •Evaluated emerging treatment technologies, resulting in a pilot project that reduced chemical use by 10%.

- •Directed the construction phase of two major wastewater treatment projects, both completed on time and within budget.

- •Provided technical training, enhancing team capacity and reducing operational errors by 27%.

- •Led a regulatory compliance initiative to update and standardize protocols, leading to a 100% compliance rate.

- •Conducted environmental impact assessments for wastewater facilities, mitigating risks and ensuring alignment with regulations.

- •Designed new treatment processes reducing pollutant output by 12%, significantly enhancing water quality.

- •Collaborated with project managers to evaluate project risks, reducing unforeseen costs by 15%.

- •Developed educational materials and workshops for stakeholders on wastewater management strategies.

- •Assisted in process modeling for new treatment systems, contributing to a 20% increase in efficiency.

- •Supported regulatory reviews and documentation, ensuring compliance and streamlining project timelines by 20%.

- •Engaged in continuous professional development, obtaining certifications that enhanced my technical proficiency in the field.

- •Participated in cross-disciplinary teams, fostering innovation and improving collaborative processes by 30%.

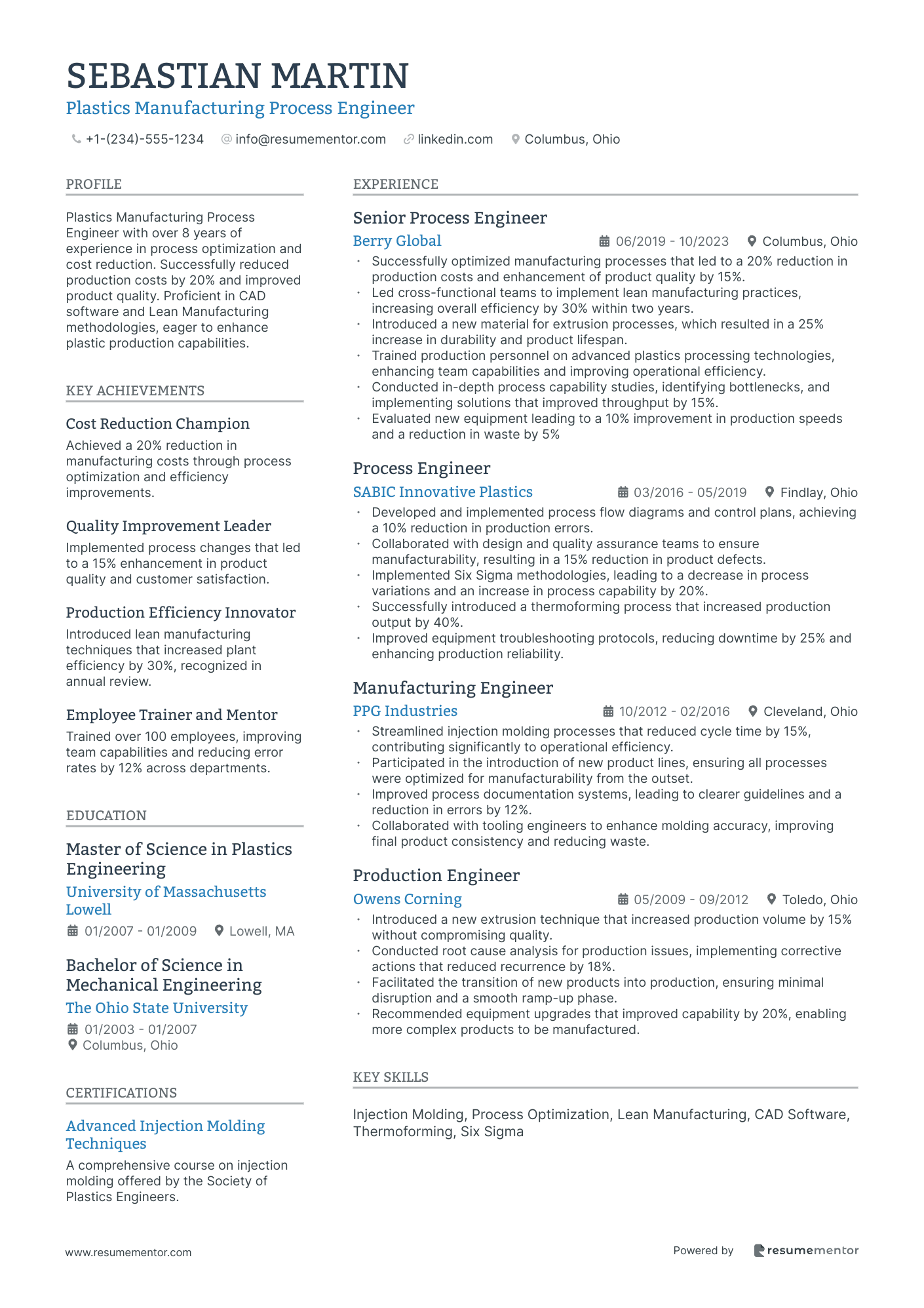

Plastics Manufacturing Process Engineer resume sample

When applying for this role, highlight any experience you have in materials science or plastic processing methods. Detail your familiarity with extrusion, injection molding, or blow molding techniques. Make sure to mention any relevant projects where you optimized production processes or reduced waste. Include certifications or training related to quality assurance or lean manufacturing. Share specific examples of how your contributions led to cost savings or improved product quality. Emphasizing problem-solving skills and a teamwork-oriented approach will strengthen your application.

- •Successfully optimized manufacturing processes that led to a 20% reduction in production costs and enhancement of product quality by 15%.

- •Led cross-functional teams to implement lean manufacturing practices, increasing overall efficiency by 30% within two years.

- •Introduced a new material for extrusion processes, which resulted in a 25% increase in durability and product lifespan.

- •Trained production personnel on advanced plastics processing technologies, enhancing team capabilities and improving operational efficiency.

- •Conducted in-depth process capability studies, identifying bottlenecks, and implementing solutions that improved throughput by 15%.

- •Evaluated new equipment leading to a 10% improvement in production speeds and a reduction in waste by 5%

- •Developed and implemented process flow diagrams and control plans, achieving a 10% reduction in production errors.

- •Collaborated with design and quality assurance teams to ensure manufacturability, resulting in a 15% reduction in product defects.

- •Implemented Six Sigma methodologies, leading to a decrease in process variations and an increase in process capability by 20%.

- •Successfully introduced a thermoforming process that increased production output by 40%.

- •Improved equipment troubleshooting protocols, reducing downtime by 25% and enhancing production reliability.

- •Streamlined injection molding processes that reduced cycle time by 15%, contributing significantly to operational efficiency.

- •Participated in the introduction of new product lines, ensuring all processes were optimized for manufacturability from the outset.

- •Improved process documentation systems, leading to clearer guidelines and a reduction in errors by 12%.

- •Collaborated with tooling engineers to enhance molding accuracy, improving final product consistency and reducing waste.

- •Introduced a new extrusion technique that increased production volume by 15% without compromising quality.

- •Conducted root cause analysis for production issues, implementing corrective actions that reduced recurrence by 18%.

- •Facilitated the transition of new products into production, ensuring minimal disruption and a smooth ramp-up phase.

- •Recommended equipment upgrades that improved capability by 20%, enabling more complex products to be manufactured.

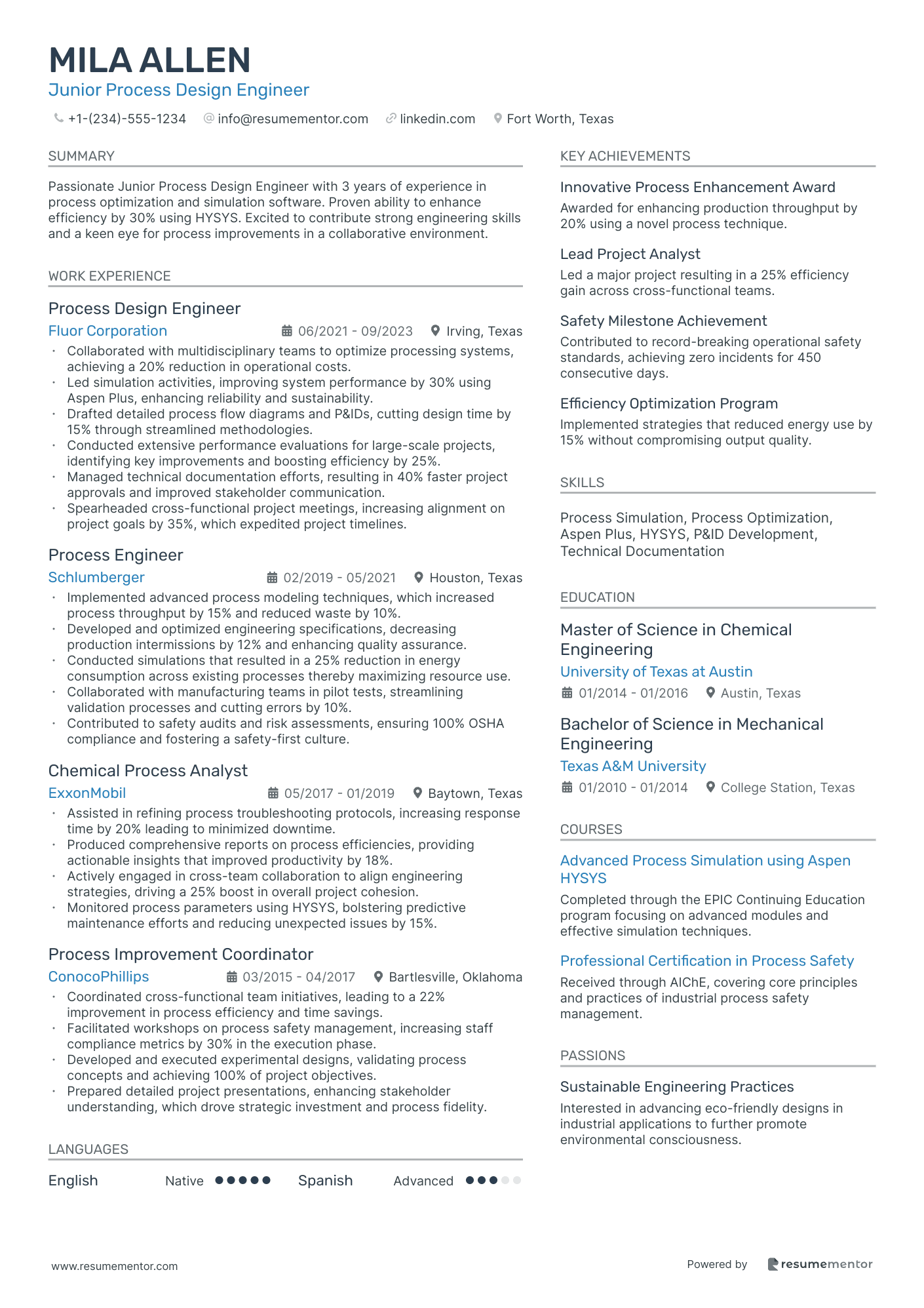

Junior Process Design Engineer resume sample

When applying for this role, highlight any project experience related to process design. Show your ability to use software like AutoCAD or MATLAB. Include coursework in fluid dynamics or thermodynamics, along with any relevant internships. Demonstrate teamwork skills and a willingness to learn from feedback. Use specific examples of how your contributions led to process improvements or cost savings. Focus on how your analytical skills helped solve real-world problems, showcasing your understanding of engineering principles in practical applications.

- •Collaborated with multidisciplinary teams to optimize processing systems, achieving a 20% reduction in operational costs.

- •Led simulation activities, improving system performance by 30% using Aspen Plus, enhancing reliability and sustainability.

- •Drafted detailed process flow diagrams and P&IDs, cutting design time by 15% through streamlined methodologies.

- •Conducted extensive performance evaluations for large-scale projects, identifying key improvements and boosting efficiency by 25%.

- •Managed technical documentation efforts, resulting in 40% faster project approvals and improved stakeholder communication.

- •Spearheaded cross-functional project meetings, increasing alignment on project goals by 35%, which expedited project timelines.

- •Implemented advanced process modeling techniques, which increased process throughput by 15% and reduced waste by 10%.

- •Developed and optimized engineering specifications, decreasing production intermissions by 12% and enhancing quality assurance.

- •Conducted simulations that resulted in a 25% reduction in energy consumption across existing processes thereby maximizing resource use.

- •Collaborated with manufacturing teams in pilot tests, streamlining validation processes and cutting errors by 10%.

- •Contributed to safety audits and risk assessments, ensuring 100% OSHA compliance and fostering a safety-first culture.

- •Assisted in refining process troubleshooting protocols, increasing response time by 20% leading to minimized downtime.

- •Produced comprehensive reports on process efficiencies, providing actionable insights that improved productivity by 18%.

- •Actively engaged in cross-team collaboration to align engineering strategies, driving a 25% boost in overall project cohesion.

- •Monitored process parameters using HYSYS, bolstering predictive maintenance efforts and reducing unexpected issues by 15%.

- •Coordinated cross-functional team initiatives, leading to a 22% improvement in process efficiency and time savings.

- •Facilitated workshops on process safety management, increasing staff compliance metrics by 30% in the execution phase.

- •Developed and executed experimental designs, validating process concepts and achieving 100% of project objectives.

- •Prepared detailed project presentations, enhancing stakeholder understanding, which drove strategic investment and process fidelity.

Creating a standout resume as a process engineer involves more than just listing your qualifications—it's about telling your professional story in a way that clicks with employers. In your role, you're like the architect of efficiency, always fine-tuning systems for peak performance, yet capturing this expertise on paper can be challenging. It might be tough to distill your intricate projects and technical know-how into something that grabs hiring managers.

When your resume highlights your analytical skills, attention to detail, and knack for enhancing processes, it becomes a true reflection of your capabilities. To make these qualities clear without overwhelming the reader, using a well-designed template is essential. A professional resume template ensures your document is easy on the eyes and flows logically, allowing your information to shine.

By emphasizing key elements like relevant experience, problem-solving skills, and certifications, templates let your unique talents stand out. In the competitive world of engineering, clarity and precision can make all the difference. A strategically crafted resume transforms the complexities of your work into a compelling story, catching the eye of recruiters and paving the way to the next chapter in your career.

Key Takeaways

- Crafting a standout resume involves more than listing qualifications; it's about effectively telling your professional story with a focus on clarity and precision to stand out to employers.

- Highlight analytical skills, attention to detail, problem-solving abilities, relevant experience, and certifications to reflect your capability and make an impact.

- Use professional templates to ensure a stylish, easy-to-read design that logically presents information and showcases your skills.

- Employ a reverse chronological format to clearly show career advancements and impact, using quantifiable achievements to illustrate capability.

- Incorporate both hard and soft skills, tailored education, relevant experience, and certifications to present a comprehensive and appealing profile to hiring managers.

What to focus on when writing your process engineer resume

A process engineer resume should clearly convey your skills in optimizing and designing effective processes. Highlighting your problem-solving abilities and analytical skills shows your experience in process improvement, demonstrating your capability to enhance productivity and quality across various industries.

How to structure your process engineer resume

- Contact Information: Start with your full name, phone number, email address, and LinkedIn profile. Clearly listing this information makes it easy for potential employers to reach you. Ensure your LinkedIn profile is updated to reflect your skills and accomplishments in process engineering, as this creates a cohesive professional image that complements your resume.

- Professional Summary: Use this section to outline your main skills, experiences, and career objectives related to process engineering. By customizing it for the job you want, you can emphasize your focus on areas like process optimization or quality assurance. A compelling summary should also hint at your industry knowledge and readiness to tackle complex engineering challenges, setting the tone for your entire resume.

- Skills: Follow up with a highlight of key skills such as process improvement techniques (like Lean or Six Sigma), data analysis abilities, and equipment troubleshooting, along with your experience using process simulation software. This section builds on your professional summary by detailing the specific abilities you bring to the table. Including both soft skills, like communication and teamwork, alongside technical skills adds depth and demonstrates well-rounded expertise.

- Work Experience: Next, describe your previous roles in process engineering. By focusing on how you’ve improved efficiency or reduced costs, using numbers and strong action verbs, you can illustrate the real-world impact of your skills. Highlight specific projects or initiatives you’ve led, showing how your actions led to tangible improvements in processes or productivity within your team or organization.

- Education: Continue by listing your engineering degrees or related qualifications, including any relevant certifications like a Lean Six Sigma Green Belt. This section supports your professional growth and expertise in the field. Mentioning your participation in ongoing education or training programs can also reveal your commitment to keeping up with industry advancements and standards.

- Technical Proficiencies: Finally, showcase your knowledge of crucial tools and technologies such as AutoCAD, MATLAB, or various process control systems, reinforcing your technical skills and readiness for new challenges. Your familiarity with cutting-edge technology shows employers that you can efficiently implement contemporary solutions to meet their operational needs.

In the next section, we will cover each resume section more in-depth, taking a closer look at how to format each part to maximize impact and ensure your resume stands out.

Which resume format to choose

For a process engineer like you, creating the perfect resume means choosing the right format and details to highlight your skills. Start with a reverse chronological format, which is ideal for showing your progressive expertise and the impact you've made in previous roles. This format lets employers easily track your career advancements and see the tangible outcomes of your engineering projects.

The choice of font plays a role in how your resume is perceived, so consider using a modern option like Rubik, Lato, or Montserrat. These fonts offer a sleek, professional look that reflects the precision and clarity required in engineering roles. They ensure that your resume is not only easy to read but also visually appealing, which can subtly enhance your professionalism.

Always save your resume as a PDF. This file type guards against formatting mishaps that might occur when your resume is opened on various devices or software programs. It keeps the layout consistent, ensuring your carefully crafted document appears exactly as intended.

When setting up your resume, aim for margins between 0.5 and 1 inch. This spacing is crucial for readability, ensuring the document looks organized and inviting rather than cramped. Proper margins help structure your content effectively, allowing important information about your skills and projects to stand out without overwhelming the reader. By integrating these elements, your resume will convey your qualifications as a capable and meticulous process engineer.

How to write a quantifiable resume experience section

The experience section of your process engineer resume should paint a clear picture of your achievements and responsibilities, presenting your impact and expertise effectively. Start with your most recent position, organizing the section in reverse chronological order. Usually, focus on the last 10 to 15 years to ensure relevance, emphasizing roles that match your career goals and the job you're applying for. Tailor your resume by aligning your experiences with the job ad's requirements, using strong action verbs like "developed," "optimized," and "implemented" to highlight your contributions.

Here's a great example:

- •Boosted production efficiency by 25% by implementing lean manufacturing techniques.

- •Cut operational costs by $500,000 each year by optimizing resource allocation and improving supply chain management.

- •Led a cross-functional team to launch a new product line, increasing sales by 15%.

- •Enhanced safety compliance by 30%, achieving zero incidents for three consecutive years with rigorous safety protocols.

This experience section flows smoothly by linking your accomplishments with quantifiable results, making your impact tangible. The use of strong action verbs connects each achievement, emphasizing the significance of your role in driving efficiency and cutting costs. Providing context with a brief description, the bullet points seamlessly highlight distinct achievements, from boosting production efficiency to enhancing safety compliance. This cohesive narrative not only demonstrates your contributions but also effectively connects them to the job requirements you’re targeting, ensuring that your resume resonates with hiring managers.

Innovation-Focused resume experience section

A process engineer innovation-focused resume experience section should highlight your ability to creatively solve problems and improve efficiency. Begin by pinpointing projects where your innovative solutions made a significant impact. Then, clearly describe the challenges faced, the actions you took, and the direct results for your organization. By highlighting your specific achievements, potential employers can easily understand the value you bring to their team.

Use bullet points to organize your achievements, making sure each starts with a strong action verb that conveys change or progress. Straightforward language ensures that your accomplishments are clear to any reader. By emphasizing your skills and achievements, you paint a vivid picture of your capabilities in engineering and innovation.

Senior Process Engineer

Tech Innovations Corp

June 2020 - Present

- Led a team in redesigning a manufacturing process, reducing waste by 25% and increasing efficiency by 30%.

- Developed a cost-saving initiative that saved the company over $100,000 annually.

- Collaborated with cross-functional teams to implement new technology that improved product quality.

- Mentored junior engineers to foster a culture of innovation and continuous improvement.

Project-Focused resume experience section

A project-focused process engineer resume experience section should effectively showcase your ability to enhance processes and solve complex problems. Start by highlighting your most impactful projects, focusing on those that led to significant improvements in efficiency, cost savings, or quality. Choose action words to clearly describe your role and use data to quantify the positive outcomes, making your contributions tangible and compelling.

Ensure your sentences flow smoothly, painting a clear picture of both your achievements and their benefits to the company. Begin each entry by noting the time frame of your involvement, followed by a descriptive project title. Use bullet points to outline key responsibilities and accomplishments, ensuring that each point builds on the last to emphasize your results-driven approach. By demonstrating the positive changes that resulted from your efforts, you'll effectively convey your value as a process engineer.

Process Engineer

Manufacturing Co.

January 2020 - December 2021

- Reduced production cycle time by 15% through process redesign.

- Implemented new quality control procedures, decreasing defects by 20%.

- Led cross-functional team of 8 in project execution, ensuring on-time completion.

- Achieved $150,000 annual savings after system upgrades.

Responsibility-Focused resume experience section

A responsibility-focused process engineer resume experience section should center on your role in achieving significant improvements and enhancements. This involves showcasing how you took charge, worked collaboratively, and managed projects that led to positive outcomes. It's important to demonstrate your expertise in optimizing processes and reducing costs, highlighting your accountability in these efforts. Each bullet point should clearly reflect your responsibilities and the tangible results that were achieved because of your actions.

To make your resume impactful, use clear language and specific examples to illustrate your contributions and start bullet points with action words. When you quantify your achievements, it helps to convey the impact of your work. Being specific about your role clarifies your contributions, whether you led teams, developed solutions, or streamlined operations. By providing these details, you create a coherent narrative that emphasizes your expertise and highlights the significant impact of your work.

Process Engineer

Tech Industries

Jan 2018 - Dec 2020

- Led a team to redesign production processes, reducing production time by 20%.

- Implemented a new quality control system, resulting in a 15% decrease in defects.

- Collaborated with suppliers to improve raw material sourcing, cutting costs by 10%.

- Developed and executed training programs for staff, enhancing skill sets and teamwork.

Skills-Focused resume experience section

A skills-focused process engineer resume experience section should effectively highlight specific achievements and relevant skills in your field. Start by showcasing how your accomplishments have driven improvements in processes, efficiency, and quality. Rather than merely listing duties, craft a narrative that incorporates metrics, tools, and skills that you used to solve particular challenges. This demonstrates not only your capabilities but also your proficiency in applying them effectively.

When detailing your roles, emphasize results with bullet points that clearly illustrate your achievements and their impact on the organization. Focus on quantifiable successes, like increasing output by a significant percentage or reducing waste considerably. Additionally, emphasize skills like process optimization, workflow improvements, or any relevant software proficiency that further underline your expertise. Throughout each role, highlight how your contributions added value to the company, underscoring your talent for driving improvements and enhancing efficiencies.

Process Engineer

ABC Manufacturing Ltd.

January 2019 - Present

- Implemented a new process across production, enhancing output by 20%.

- Reduced material waste by 15% through the introduction of Lean practices.

- Led a team in upgrading systems to improve workflow, cutting downtime by 30%.

- Developed a training program for staff on new procedures, boosting compliance.

Write your process engineer resume summary section

A process engineer-focused resume summary should effectively showcase your unique skills and accomplishments while tying together the various elements of your experience. Drawing attention to the impact you've made in your previous roles is crucial. To keep it compelling, aim for about four concise sentences that truly capture your professional essence. Think of it as an elevator pitch for your career. Consider this example:

This summary seamlessly expresses expertise and achievements, underscoring a commitment to continuous improvement. For those just starting their careers, a resume objective might be more appropriate. By focusing on your aspirations, the objective sets a forward-looking tone. It highlights your eagerness to apply new skills, such as in a statement like, "Aspiring process engineer eager to apply academic knowledge in a dynamic work environment."

The way you position yourself depends significantly on understanding the differences between various resume styles. A resume summary highlights past accomplishments and skills, while an objective focuses on future career goals. A resume profile blends these elements, presenting a balanced view of past and future. On the other hand, a summary of qualifications offers a bullet-point list of key skills and achievements. Choosing the right format tailored to your experience level and career goals not only makes your resume more personalized but also more appealing to hiring managers. By weaving these elements together, you ensure they quickly grasp the value you bring to their team.

Listing your process engineer skills on your resume

A skills-focused process engineer resume should clearly present your abilities in a way that stands out to employers and applicant tracking systems. When deciding how to showcase your skills, consider whether to make it a distinct section or integrate them into your experience or summary areas. Highlighting your strengths and soft skills is crucial, as they display your ability to collaborate with others and effectively manage tasks. Hard skills, on the other hand, represent the technical expertise required for specific engineering tasks, such as leveraging specialized software or deciphering complex systems. Together, these skills and strengths can serve as keywords that boost the visibility of your resume.

Here's an example of a skills section in JSON format:

This skills section is effective because it succinctly lists relevant abilities using industry-standard terms that employers value, and it also helps your resume pass automated systems.

Best hard skills to feature on your process engineer resume

For process engineers, hard skills are essential because they demonstrate your technical prowess and capability to handle complex systems. These skills signal your competence in performing technical tasks and using essential industry tools. Here are the top hard skills to highlight:

Hard Skills

- Process Optimization

- Lean Manufacturing

- Six Sigma

- Chemical Engineering

- Project Management

- AutoCAD

- Data Analysis

- Quality Control

- Process Design

- System Integration

- Statistical Process Control

- Manufacturing Processes

- Root Cause Analysis

- Production Planning

- Risk Management

Best soft skills to feature on your process engineer resume

Equally important are soft skills, which signal your ability to contribute positively in team environments and manage projects effectively. Soft skills showcase your capacity to lead initiatives and communicate well with colleagues. Here are the key soft skills for process engineers to feature:

Soft Skills

- Communication

- Problem-solving

- Teamwork

- Adaptability

- Leadership

- Time Management

- Critical Thinking

- Attention to Detail

- Creativity

- Decision Making

- Conflict Resolution

- Initiative

- Persistence

- Negotiation

- Emotional Intelligence

How to include your education on your resume

The education section of your resume is a key part, showcasing your academic achievements. Tailor your education to the job you're applying for, avoiding irrelevant details. When listing a degree, include the name of the degree and the institution where you earned it. If your GPA is strong, say above 3.5, include it to stand out. Cum laude honors can elevate your profile, so mention them if you graduated with such distinction. Here's a wrong and a right way to format your education section.

Wrong example:

Right example:

The second example effectively highlights relevant education for a process engineer position. It specifies a degree in Chemical Engineering from a well-regarded institution. Inclusion of the "cum laude" honor and a high GPA indicates strong academic performance, aligning well with the demands of process engineering roles. This kind of precise, relevant information helps employers understand your suitability for the position.

How to include process engineer certificates on your resume

Including a certificates section in your process engineer resume is crucial. List the name of the certificate clearly. Include the date when you obtained it. Add the issuing organization’s name to verify its authenticity. Displaying relevant certificates in your header can make them stand out instantly. For example, "Certified Six Sigma Green Belt, 2022 - ASQ" at the top grabs attention.

Here’s how to write a strong certificates section. Start by grouping all relevant certificates together. Make sure each entry is accurate and easy to read. Include certificates that are specifically relevant to process engineering, such as Lean Manufacturing or Six Sigma certifications.

This example is strong because it focuses on certifications that directly apply to the process engineering field. The certificates are recent and from respected organizations. The section is easy to read and understand, ensuring that your qualifications are immediately recognized. Including the issuing body adds credibility and weight to your expertise.

Extra sections to include in your process engineer resume

As a process engineer, your resume is a vital tool in showcasing your skills and experiences to potential employers. Highlighting specific sections such as languages, hobbies and interests, volunteer work, and books can help paint a more comprehensive picture of you as a candidate.

- Language section—Demonstrate your fluency in multiple languages to show your communication versatility and ability to work in diverse environments.

- Hobbies and interests section—Include hobbies and interests to provide insights into your personality and highlight your soft skills, such as teamwork or creativity.

- Volunteer work section—Showcase your volunteer work to reveal your commitment to community and willingness to go the extra mile outside of professional duties.

- Books section—Mentioning relevant books you've read can indicate ongoing self-education and a deep interest in your field or personal growth.

Incorporating these sections into your resume can set you apart by highlighting your well-rounded character and dedication. They bring a human element to your application, making it easier for hiring managers to see you as a whole person, not just a list of skills and experiences. This approach can not only help you stand out but also resonate with potential employers on a more personal level.

In Conclusion

In conclusion, creating an outstanding resume as a process engineer is more than just displaying qualifications—it's about crafting a narrative that captivates hiring managers. Your resume should highlight your role as the architect of efficiency, showcasing your skills in optimizing processes, problem-solving, and project management. A well-designed template and clear structure help convey these qualities without overwhelming readers. When you focus on presenting relevant experience, certifications, and technical proficiencies, you position yourself as a highly qualified candidate in a competitive field. Remember to include both hard and soft skills, as this combination demonstrates a balanced expertise essential for engineering roles. Additionally, consider adding sections that showcase your personality and interests, which can provide a well-rounded view of your professional persona. Using modern fonts and maintaining consistent formatting with PDF saves ensure that your resume appears polished and professional across all devices. By crafting each section thoughtfully, your resume will not only stand out to employers but also reflect your genuine dedication and capability as a process engineer.

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2025. All rights reserved.

Made with love by people who care.