Quality Engineer Resume Examples

Jul 18, 2024

|

12 min read

Nail your quality engineer resume with these essential tips. Learn how to showcase your skills, experience, and certifications to ensure your resume stands out and prevents any career misfires.

Rated by 348 people

Automotive Quality Engineer

Quality Control Systems Engineer

Medical Device Quality Engineer

Aerospace Quality Engineer

Pharmaceutical Quality Engineer

Food Safety Quality Engineer

Senior Quality Engineer

Quality Process Improvement Engineer

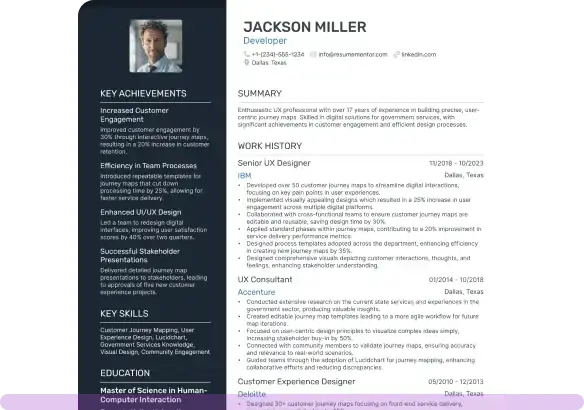

Automotive Quality Engineer resume sample

When applying for this position, it's essential to highlight any experience with automotive manufacturing processes or quality assurance methodologies. Showcase your familiarity with standards like ISO/TS 16949 or IATF 16949. Emphasize your ability to use tools such as FMEA, SPC, and Six Sigma in previous roles. Provide examples of how you identified quality issues and implemented solutions that led to cost savings or improved efficiency. Be sure to mention any related certifications, such as ASQ or CQE, to demonstrate your commitment to the field.

- •Led a team in implementing quality control systems which reduced vehicle defects by 30% over 12 months through strategic process enhancements.

- •Conducted comprehensive audits ensuring compliance with ISO 16949 standards and drove a 15% improvement in audit scores year-over-year.

- •QA process optimizations resulting in a 25% increase in assembly line throughput efficiency, achieving production targets consistently.

- •Developed and delivered training modules on Six Sigma principles to a cross-functional team, raising collective competency by 20%.

- •Pioneered the use of advanced data analytics tools to proactively identify potential quality issues, enhancing early detection rates by 40%.

- •Presented weekly quality performance reports to key stakeholders, ensuring actionable insights directly influenced strategic decision making.

- •Developed and deployed APQP protocols that led to a 20% reduction in product launch times, enhancing market competitiveness.

- •Streamlined FMEA processes across three production facilities, leading to a 15% reduction in unexpected downtime and cost savings.

- •Collaborated with design and production teams to resolve quality issues, improving supplier part performance by 25%.

- •Participated in root cause analysis for defects, implementing corrective actions to prevent reoccurrence, significantly lowering rejection rates.

- •Led cross-departmental initiatives that enhanced quality standards consistency and improved customer satisfaction scores by 12%.

- •Managed quality systems implementation that resulted in a 10% enhancement of product quality consistency across models.

- •Engaged with suppliers to rectify quality discrepancies, achieving a 35% reduction in external defects through improved supplier rapports.

- •Implemented predictive maintenance strategies which extended equipment lifespan, reducing long-term maintenance costs by roughly 18%.

- •Actively supported Six Sigma projects which contributed to a 23% increase in process efficiencies in manufacturing operations.

- •Conducted extensive quality inspections that ensured a 95% compliance rate with regulatory requirements, enhancing product credibility.

- •Played a pivotal role in the re-engineering of quality metrics, redirecting focus on critical benchmarking leading to enlightened strategic initiatives.

- •Collaborated on quality improvement workshops, promoting a proactive quality culture which increased team productivity by 30%.

- •Improved data collection methods that provided quicker and more accurate quality issue resolutions, reducing lead times significantly.

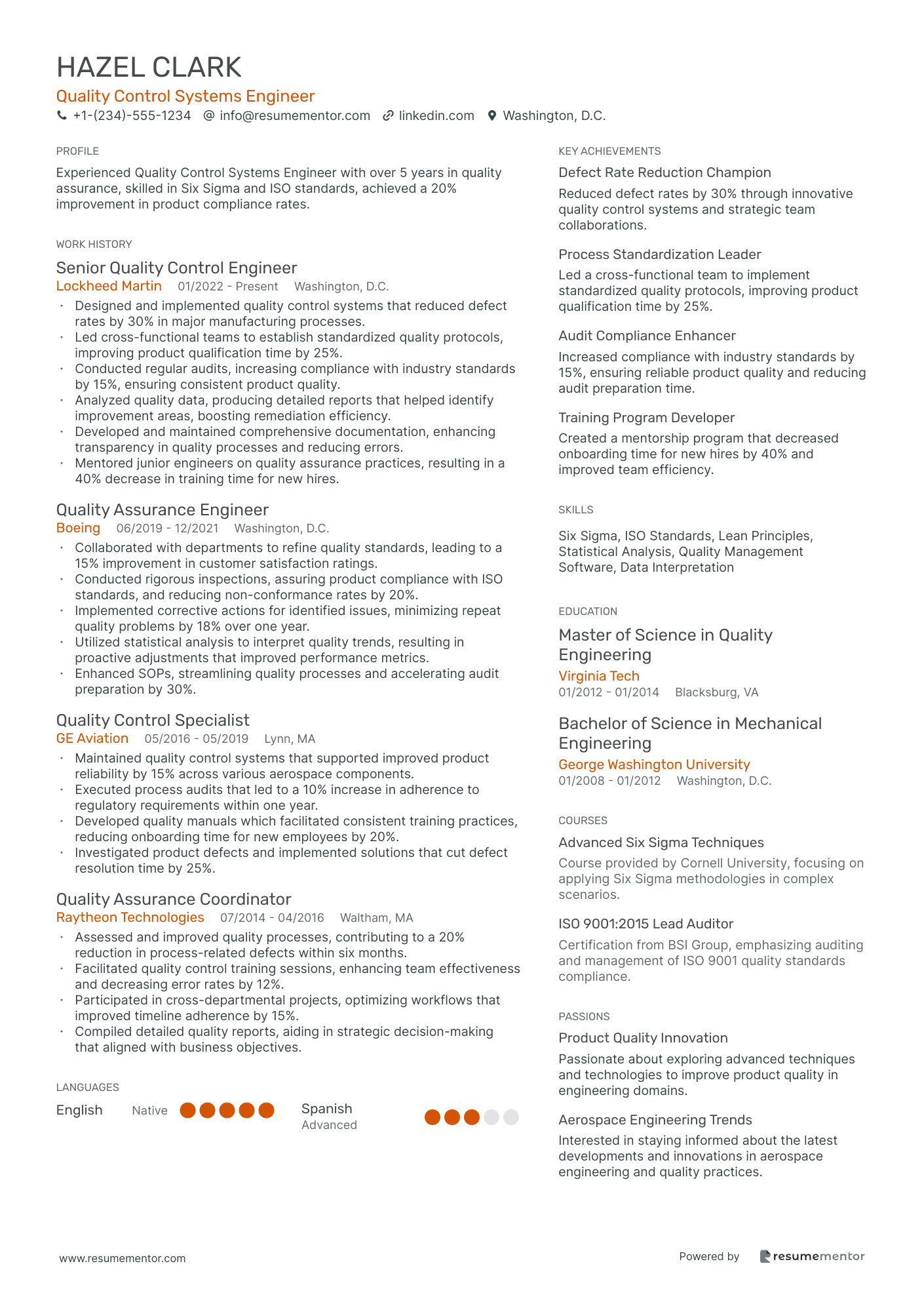

Quality Control Systems Engineer resume sample

When applying for this role, it's important to showcase your experience with quality management systems and compliance standards. Highlight any proficiency in tools like Six Sigma or Lean methodologies, as well as software proficiency in data analysis tools. Include achievements that demonstrate how you streamlined processes or improved efficiency. Mention any relevant certifications, such as ISO 9001, and stress your attention to detail and problem-solving abilities. Use specific examples to illustrate how your contributions enhanced product quality or reduced defects, following a 'skill-action-result' format.

- •Designed and implemented quality control systems that reduced defect rates by 30% in major manufacturing processes.

- •Led cross-functional teams to establish standardized quality protocols, improving product qualification time by 25%.

- •Conducted regular audits, increasing compliance with industry standards by 15%, ensuring consistent product quality.

- •Analyzed quality data, producing detailed reports that helped identify improvement areas, boosting remediation efficiency.

- •Developed and maintained comprehensive documentation, enhancing transparency in quality processes and reducing errors.

- •Mentored junior engineers on quality assurance practices, resulting in a 40% decrease in training time for new hires.

- •Collaborated with departments to refine quality standards, leading to a 15% improvement in customer satisfaction ratings.

- •Conducted rigorous inspections, assuring product compliance with ISO standards, and reducing non-conformance rates by 20%.

- •Implemented corrective actions for identified issues, minimizing repeat quality problems by 18% over one year.

- •Utilized statistical analysis to interpret quality trends, resulting in proactive adjustments that improved performance metrics.

- •Enhanced SOPs, streamlining quality processes and accelerating audit preparation by 30%.

- •Maintained quality control systems that supported improved product reliability by 15% across various aerospace components.

- •Executed process audits that led to a 10% increase in adherence to regulatory requirements within one year.

- •Developed quality manuals which facilitated consistent training practices, reducing onboarding time for new employees by 20%.

- •Investigated product defects and implemented solutions that cut defect resolution time by 25%.

- •Assessed and improved quality processes, contributing to a 20% reduction in process-related defects within six months.

- •Facilitated quality control training sessions, enhancing team effectiveness and decreasing error rates by 12%.

- •Participated in cross-departmental projects, optimizing workflows that improved timeline adherence by 15%.

- •Compiled detailed quality reports, aiding in strategic decision-making that aligned with business objectives.

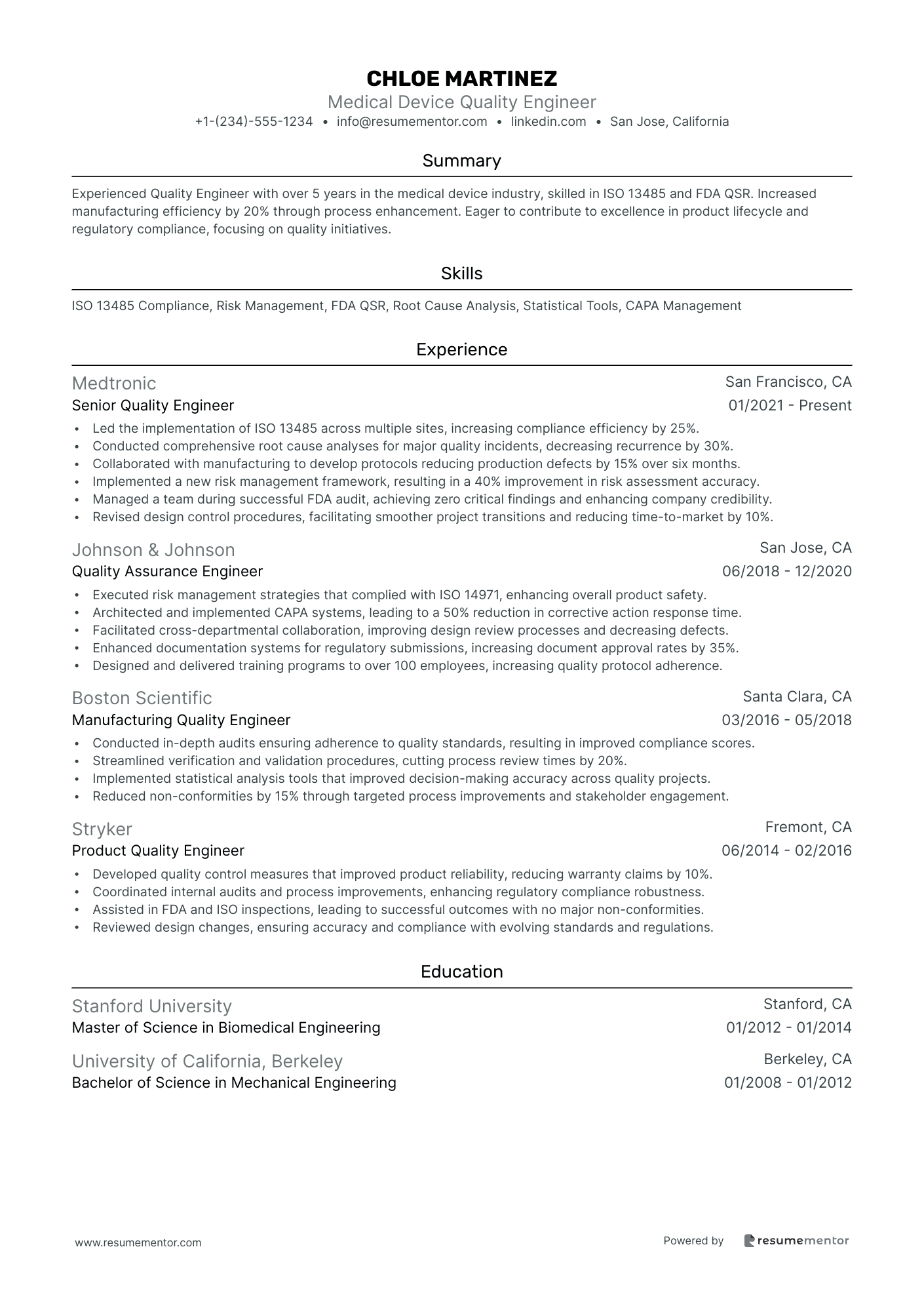

Medical Device Quality Engineer resume sample

Highlight any experience with regulatory compliance, particularly FDA and ISO standards. Detail your proficiency in risk management and quality assurance processes. If you possess certifications like Six Sigma or ASQ Quality Engineer, be sure to mention these as they demonstrate your commitment to quality. Use examples that show how your contributions improved product safety or reduced defects. Follow a 'skill-action-result' format to convey your impact clearly. Emphasize teamwork and collaboration with cross-functional teams to showcase your ability to drive project success effectively.

- •Led the implementation of ISO 13485 across multiple sites, increasing compliance efficiency by 25%.

- •Conducted comprehensive root cause analyses for major quality incidents, decreasing recurrence by 30%.

- •Collaborated with manufacturing to develop protocols reducing production defects by 15% over six months.

- •Implemented a new risk management framework, resulting in a 40% improvement in risk assessment accuracy.

- •Managed a team during successful FDA audit, achieving zero critical findings and enhancing company credibility.

- •Revised design control procedures, facilitating smoother project transitions and reducing time-to-market by 10%.

- •Executed risk management strategies that complied with ISO 14971, enhancing overall product safety.

- •Architected and implemented CAPA systems, leading to a 50% reduction in corrective action response time.

- •Facilitated cross-departmental collaboration, improving design review processes and decreasing defects.

- •Enhanced documentation systems for regulatory submissions, increasing document approval rates by 35%.

- •Designed and delivered training programs to over 100 employees, increasing quality protocol adherence.

- •Conducted in-depth audits ensuring adherence to quality standards, resulting in improved compliance scores.

- •Streamlined verification and validation procedures, cutting process review times by 20%.

- •Implemented statistical analysis tools that improved decision-making accuracy across quality projects.

- •Reduced non-conformities by 15% through targeted process improvements and stakeholder engagement.

- •Developed quality control measures that improved product reliability, reducing warranty claims by 10%.

- •Coordinated internal audits and process improvements, enhancing regulatory compliance robustness.

- •Assisted in FDA and ISO inspections, leading to successful outcomes with no major non-conformities.

- •Reviewed design changes, ensuring accuracy and compliance with evolving standards and regulations.

Aerospace Quality Engineer resume sample

When applying for a position in this field, emphasize your experience with aerospace standards like AS9100 and FAA regulations. Highlight any previous roles in quality inspection or assurance that demonstrate your attention to detail. Showcase your familiarity with tools such as Six Sigma or root cause analysis, as well as any relevant certifications. Use specific examples to illustrate how you improved quality processes, decreased defects, or contributed to successful audits. A clear 'skill-action-result' format can effectively showcase your impact in previous roles.

- •Developed and maintained quality assurance protocols, achieving a 15% reduction in non-compliance issues over 12 months.

- •Led a cross-functional team, improving product quality by 22% and enhancing customer satisfaction index by 12%.

- •Implemented Six Sigma methodologies, resulting in a 30% improvement in process efficiency and reducing waste significantly.

- •Conducted thorough inspections on components, raising compliance with AS9100 standards by 25% within two quarters.

- •Trained 20+ staff members on quality best practices, improving team adherence to standards by over 35%.

- •Facilitated internal audits, reducing the number of critical findings by 60%, consequently enhancing operational reliability.

- •Managed quality control processes resulting in improving product defect rates by 45% over a two-year period.

- •Led external quality audits, enhancing supplier compliance to ISO 9001 standards by over 20%.

- •Collaborated with engineering teams on product development, implementing 15 new quality control measures.

- •Analyzed root causes of failures, reducing recurrence rates by 50% within a one-year timeframe.

- •Oversaw training programs for quality assurance, increasing staff competency levels by 25% within six months.

- •Executed comprehensive quality tests, boosting compliance metrics by 30% in less than a year.

- •Streamlined production processes, achieving a reduction in average cycle time by 10%.

- •Supported design and production phases, optimizing quality input and contributing to a 15% cost reduction.

- •Provided quality oversight in 5+ product lines, enhancing operational standards consistently.

- •Conducted material and component inspections, increasing throughput quality by 20%.

- •Assisted in corrective action plans, contributing to a 25% improvement in corrective measures effectiveness.

- •Led root cause analysis initiatives, preventing repeat failures in key product areas.

- •Enhanced communication between cross-functional teams, reducing error rates due to miscommunication by 15%.

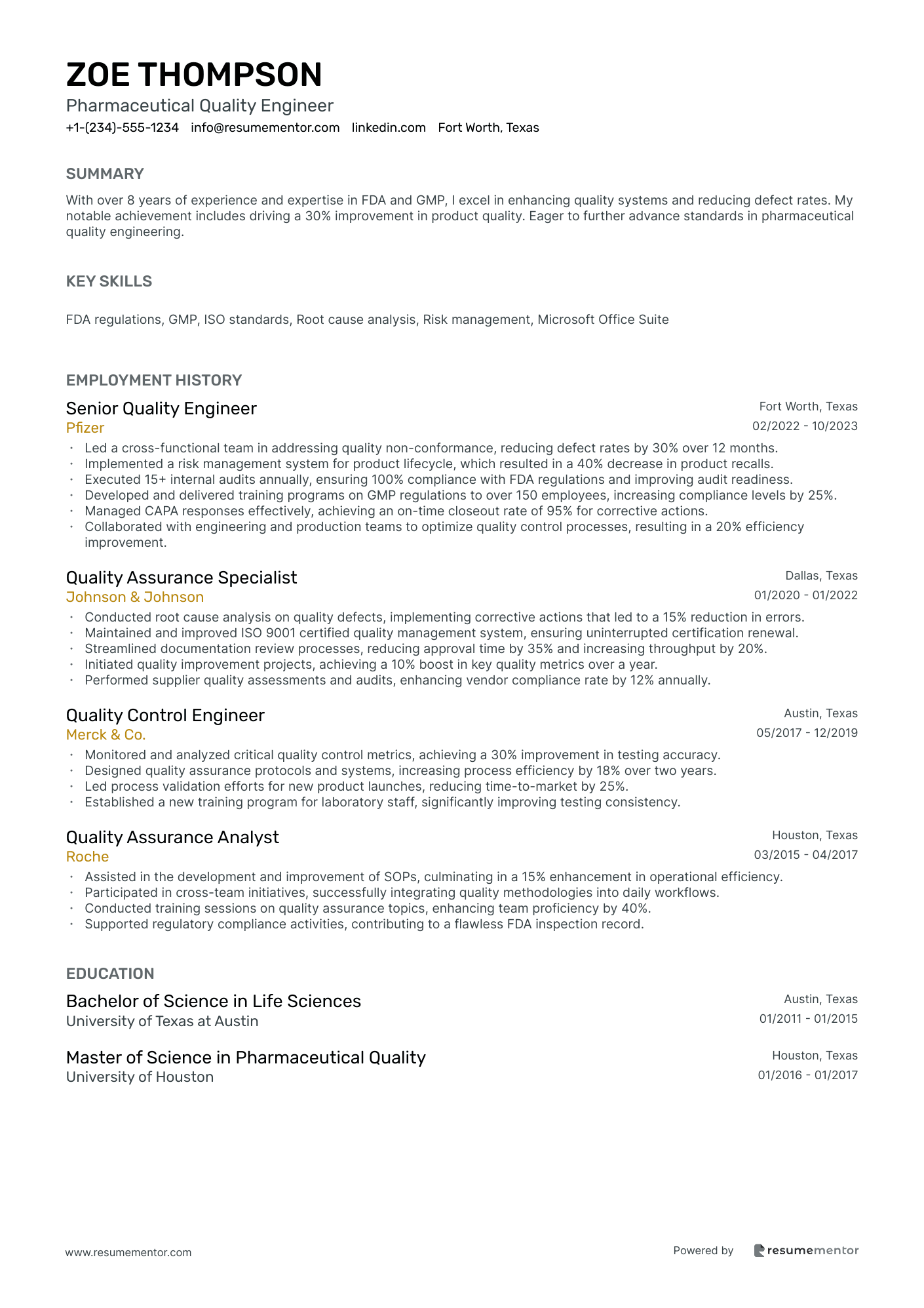

Pharmaceutical Quality Engineer resume sample

When applying for this role, emphasize any experience in regulatory compliance or quality control within the pharmaceutical industry. Highlight your knowledge of Good Manufacturing Practices (GMP) and familiarity with Quality Management Systems (QMS). Certifications like Six Sigma or ISO 13485 can showcase your commitment to quality. Use specific examples to demonstrate how your actions improved processes or ensured product safety and efficacy. Employ the 'skill-action-result' framework to present your accomplishments clearly and effectively, making it easy for the reviewer to see your impact.

- •Led a cross-functional team in addressing quality non-conformance, reducing defect rates by 30% over 12 months.

- •Implemented a risk management system for product lifecycle, which resulted in a 40% decrease in product recalls.

- •Executed 15+ internal audits annually, ensuring 100% compliance with FDA regulations and improving audit readiness.

- •Developed and delivered training programs on GMP regulations to over 150 employees, increasing compliance levels by 25%.

- •Managed CAPA responses effectively, achieving an on-time closeout rate of 95% for corrective actions.

- •Collaborated with engineering and production teams to optimize quality control processes, resulting in a 20% efficiency improvement.

- •Conducted root cause analysis on quality defects, implementing corrective actions that led to a 15% reduction in errors.

- •Maintained and improved ISO 9001 certified quality management system, ensuring uninterrupted certification renewal.

- •Streamlined documentation review processes, reducing approval time by 35% and increasing throughput by 20%.

- •Initiated quality improvement projects, achieving a 10% boost in key quality metrics over a year.

- •Performed supplier quality assessments and audits, enhancing vendor compliance rate by 12% annually.

- •Monitored and analyzed critical quality control metrics, achieving a 30% improvement in testing accuracy.

- •Designed quality assurance protocols and systems, increasing process efficiency by 18% over two years.

- •Led process validation efforts for new product launches, reducing time-to-market by 25%.

- •Established a new training program for laboratory staff, significantly improving testing consistency.

- •Assisted in the development and improvement of SOPs, culminating in a 15% enhancement in operational efficiency.

- •Participated in cross-team initiatives, successfully integrating quality methodologies into daily workflows.

- •Conducted training sessions on quality assurance topics, enhancing team proficiency by 40%.

- •Supported regulatory compliance activities, contributing to a flawless FDA inspection record.

Food Safety Quality Engineer resume sample

When applying for this position, focus on any previous experience with quality control or compliance in food production. Highlight your knowledge of food safety standards like HACCP and FDA regulations. Mention any relevant certifications, such as in food safety management. Provide specific examples of how you've implemented quality measures that improved safety and reduced risks. Use the 'skill-action-result' format to detail how your actions led to safer food handling or better compliance outcomes, showcasing your impact on previous employers.

- •Spearheaded the development and implementation of a new quality assurance program, reducing product defects by 15% within the first year.

- •Led a team of 10 quality professionals to conduct comprehensive internal audits, resulting in a 30% decrease in non-conformances.

- •Collaborated with cross-functional teams to enhance the culture of quality and safety, achieving a 25% improvement in employee adherence to safety protocols.

- •Managed external audits with the USDA and FDA, successfully passing 100% of audits in the last three years.

- •Implemented a corrective action system based on root cause analysis, cutting down response time by 20%.

- •Trained production staff on updated HACCP protocols, increasing compliance rates by 40%.

- •Developed and maintained food safety programs aligned with SQF standards, which improved facility safety ratings by two levels.

- •Conducted over 50 risk assessments annually and implemented corrective actions, improving safety compliance by 18%.

- •Provided consistent staff training on food safety best practices, contributing to a 35% reduction in safety violations.

- •Analyzed quality data trends monthly and formulated strategic improvements, boosting overall product quality metrics by 10%.

- •Led a project team to enhance statistical process control measures, increasing production efficiency by 12%.

- •Coordinated quality control protocols for multiple product lines, enhancing product quality consistency by 20%.

- •Monitored and analyzed quality data, driving the implementation of new continuous improvement initiatives resulting in a 25% reduction in defects.

- •Facilitated internal compliance audits, achieving 100% adherence to industry standards and regulations during tenure.

- •Mentored junior quality officers, fostering their development and increasing department productivity by 15%.

- •Analyzed product samples from production lines, ensuring alignment with company quality standards, resulting in customer satisfaction improvement by 10%.

- •Investigated non-conformance issues and developed corrective action plans, decreasing recurrence rate by 20%.

- •Collaborated on cross-departmental teams to optimize quality procedures, enhancing overall process efficiency by 15%.

- •Assisted with external audits, contributing to the successful attainment of ISO 22000 certification.

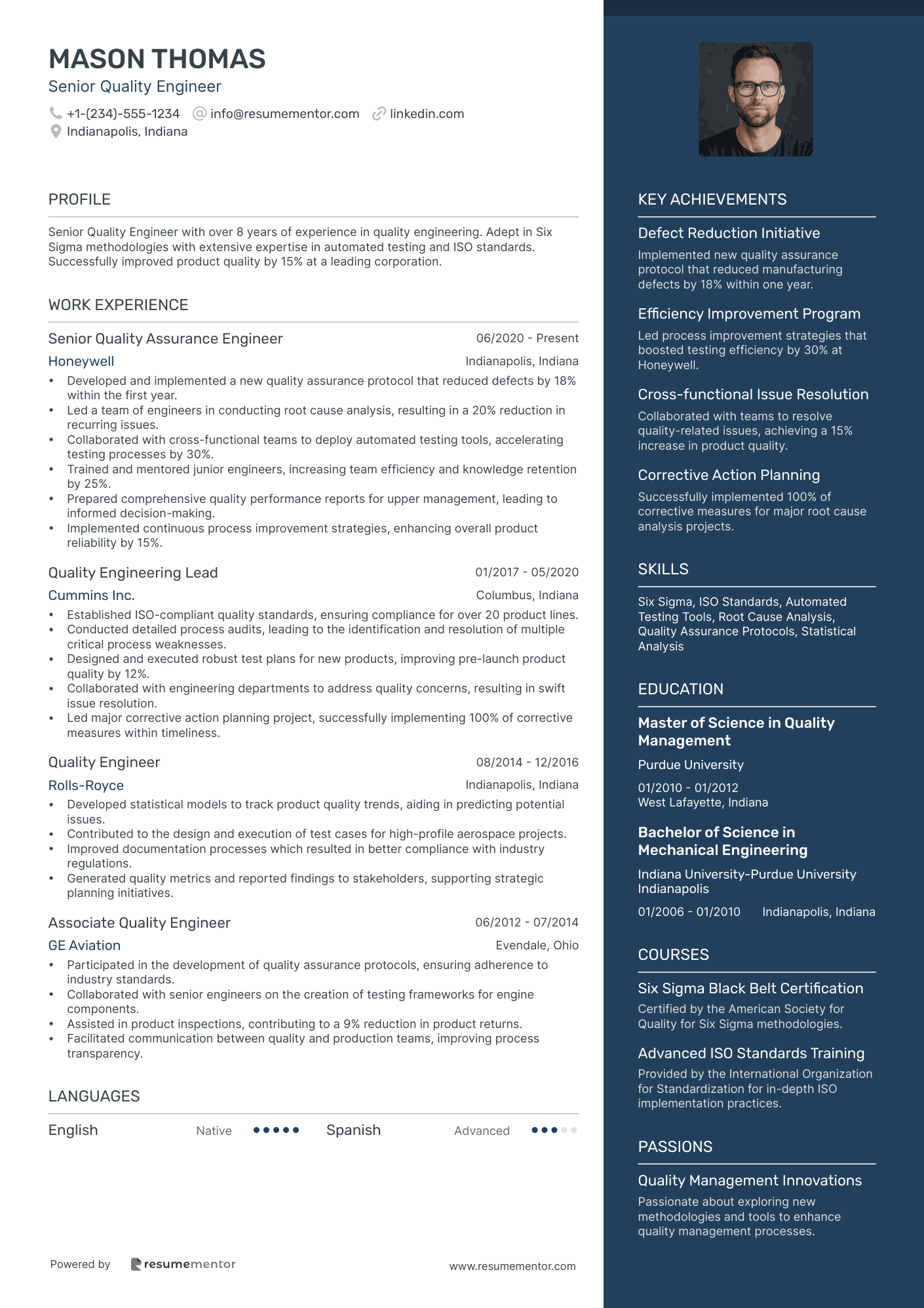

Senior Quality Engineer resume sample

When applying for a Senior Quality Engineer role, focus on showcasing your experience in leading quality improvement projects. Mention any certifications like Six Sigma or ISO standards, and quantify your achievements with specific metrics. Highlight your proficiency with quality management software and data analysis tools. It’s important to demonstrate your ability to mentor junior engineers and lead cross-functional teams effectively. Use the 'skill-action-result' method to present how your initiatives have led to reduced defects or improved processes in previous roles.

- •Developed and implemented a new quality assurance protocol that reduced defects by 18% within the first year.

- •Led a team of engineers in conducting root cause analysis, resulting in a 20% reduction in recurring issues.

- •Collaborated with cross-functional teams to deploy automated testing tools, accelerating testing processes by 30%.

- •Trained and mentored junior engineers, increasing team efficiency and knowledge retention by 25%.

- •Prepared comprehensive quality performance reports for upper management, leading to informed decision-making.

- •Implemented continuous process improvement strategies, enhancing overall product reliability by 15%.

- •Established ISO-compliant quality standards, ensuring compliance for over 20 product lines.

- •Conducted detailed process audits, leading to the identification and resolution of multiple critical process weaknesses.

- •Designed and executed robust test plans for new products, improving pre-launch product quality by 12%.

- •Collaborated with engineering departments to address quality concerns, resulting in swift issue resolution.

- •Led major corrective action planning project, successfully implementing 100% of corrective measures within timeliness.

- •Developed statistical models to track product quality trends, aiding in predicting potential issues.

- •Contributed to the design and execution of test cases for high-profile aerospace projects.

- •Improved documentation processes which resulted in better compliance with industry regulations.

- •Generated quality metrics and reported findings to stakeholders, supporting strategic planning initiatives.

- •Participated in the development of quality assurance protocols, ensuring adherence to industry standards.

- •Collaborated with senior engineers on the creation of testing frameworks for engine components.

- •Assisted in product inspections, contributing to a 9% reduction in product returns.

- •Facilitated communication between quality and production teams, improving process transparency.

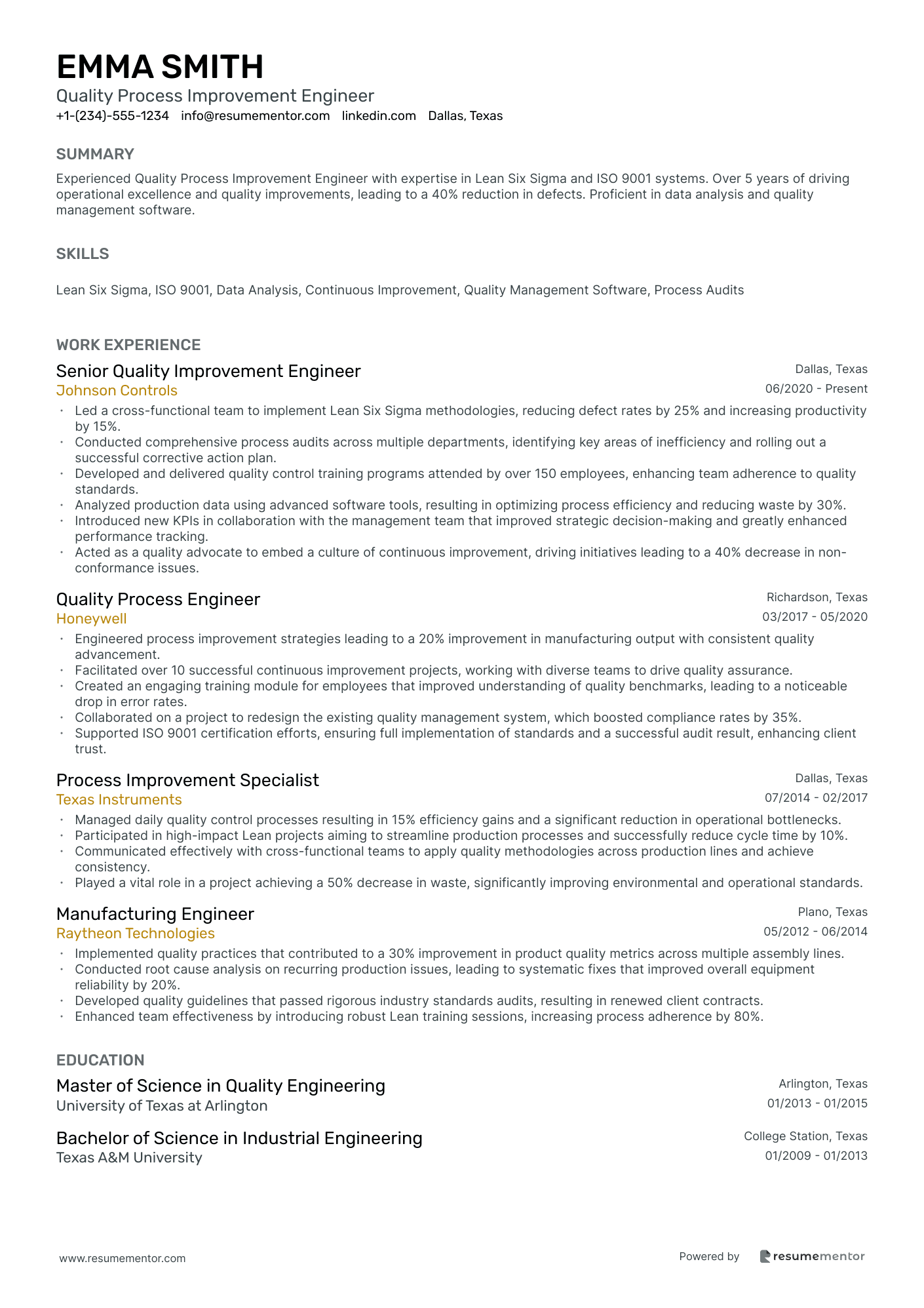

Quality Process Improvement Engineer resume sample

When crafting your cover letter, emphasize your experience with process mapping and root cause analysis. Highlight any certifications like 'Lean Six Sigma' or 'Process Improvement Techniques' to showcase your expertise. Include examples of how you've streamlined workflows or reduced waste in past roles, demonstrating measurable improvements. Use metrics to illustrate your impact, such as percentage reductions in processing times or cost savings. Make your application compelling by showing how your skills can drive efficiency and enhance quality standards within the organization.

- •Led a cross-functional team to implement Lean Six Sigma methodologies, reducing defect rates by 25% and increasing productivity by 15%.

- •Conducted comprehensive process audits across multiple departments, identifying key areas of inefficiency and rolling out a successful corrective action plan.

- •Developed and delivered quality control training programs attended by over 150 employees, enhancing team adherence to quality standards.

- •Analyzed production data using advanced software tools, resulting in optimizing process efficiency and reducing waste by 30%.

- •Introduced new KPIs in collaboration with the management team that improved strategic decision-making and greatly enhanced performance tracking.

- •Acted as a quality advocate to embed a culture of continuous improvement, driving initiatives leading to a 40% decrease in non-conformance issues.

- •Engineered process improvement strategies leading to a 20% improvement in manufacturing output with consistent quality advancement.

- •Facilitated over 10 successful continuous improvement projects, working with diverse teams to drive quality assurance.

- •Created an engaging training module for employees that improved understanding of quality benchmarks, leading to a noticeable drop in error rates.

- •Collaborated on a project to redesign the existing quality management system, which boosted compliance rates by 35%.

- •Supported ISO 9001 certification efforts, ensuring full implementation of standards and a successful audit result, enhancing client trust.

- •Managed daily quality control processes resulting in 15% efficiency gains and a significant reduction in operational bottlenecks.

- •Participated in high-impact Lean projects aiming to streamline production processes and successfully reduce cycle time by 10%.

- •Communicated effectively with cross-functional teams to apply quality methodologies across production lines and achieve consistency.

- •Played a vital role in a project achieving a 50% decrease in waste, significantly improving environmental and operational standards.

- •Implemented quality practices that contributed to a 30% improvement in product quality metrics across multiple assembly lines.

- •Conducted root cause analysis on recurring production issues, leading to systematic fixes that improved overall equipment reliability by 20%.

- •Developed quality guidelines that passed rigorous industry standards audits, resulting in renewed client contracts.

- •Enhanced team effectiveness by introducing robust Lean training sessions, increasing process adherence by 80%.

As a quality engineer, your resume serves as the blueprint for landing your next job. Translating your expertise in QA processes into a compelling document can be daunting, especially given the complexity of the field with its intricate details and industry jargon. This complexity often makes it difficult to clearly express your achievements and skills in a way that resonates with recruiters.

Highlighting your skills without overwhelming the reader is crucial. Recruiters have limited time, and your resume needs to be concise yet impactful. Using a resume template can effectively structure your information, ensuring it remains professional and easy to read. With the right layout, your key achievements and skills can stand out without being overly complicated.

Think of your resume as more than just a job list. It's a problem-solving tool that demonstrates your ability to manage quality and improve processes. Crafting it with precision will help you shine in a competitive job market. Just like in any engineering project, precision is key. Explore these resume templates to guide you in creating a compelling document that highlights your value as a quality engineer. With the right approach, your resume can serve as a powerful advocate for your career.

Key Takeaways

- Your resume as a quality engineer should effectively translate your expertise in QA processes, highlighting skills without overwhelming recruiters due to time constraints.

- A quality engineer resume should act as a problem-solving tool that demonstrates abilities to manage quality and improve processes, crafted with precision for a competitive job market.

- The chronological format is often the most effective choice for a quality engineer resume, highlighting work history, skills progression, and maintaining a professional appearance by saving in PDF format.

- Your work experience section should capture quantifiable impacts, highlight leadership and collaboration, and align with the role by using strong action words and examples.

- Including certificates is essential; clearly listing relevant qualifications helps set you apart and demonstrate continuous professional development in quality engineering.

What to focus on when writing your quality engineer resume

A quality engineer resume should effectively communicate your expertise in quality control and assurance, emphasizing your ability to ensure that products meet high standards while driving process improvements. Highlighting your analytical skills, attention to detail, and problem-solving abilities helps define your capacity to excel in diverse manufacturing or production environments.

How to structure your quality engineer resume

- Professional Summary — This section provides a snapshot of your career, summarizing your most relevant experience in quality assurance. Clearly articulate your key accomplishments and the value you bring to a team. Focus on achievements that underscore your ability to lead quality improvements and sustain high standards. Use this summary to make a strong first impression, setting the stage for the rest of your resume.

- Work Experience — Your work experience should tell the story of your career as a quality engineer. Detail your responsibilities and highlight specific achievements that demonstrate your impact. Quantify your accomplishments to provide measurable proof of your contributions. This section should show a clear progression of skills and responsibilities, letting potential employers see your growth and commitment to quality engineering.

- Education — List your academic credentials, emphasizing any degrees in engineering or related fields. This part of your resume should establish the technical foundation that supports your expertise. Mention any relevant coursework or projects that are particularly applicable to quality engineering roles. This will help underscore your qualifications and readiness for the job.

- Certifications — Including relevant certifications such as Six Sigma, ISO 9001, or CQE reflects your dedication to the field and your continuous professional development. Certifications show that you have the specialized knowledge and skills necessary to maintain and improve quality standards. They also highlight your commitment to staying updated with industry best practices.

- Technical Skills — In this section, focus on your proficiency with tools and techniques specific to quality engineering. Highlight your knowledge of quality management systems, statistical analysis software, and root cause analysis tools. Demonstrating technical competence is crucial, as these skills are essential for tackling daily challenges and ensuring high product standards.

- Projects — Highlight key projects to showcase your hands-on experience and the impact of your work. Describe your role and how you contributed to the project’s success in terms of quality improvements and efficiency gains. This section should link your practical experience with your stated skills, providing a real-world context to your capabilities.

Understanding these sections lays the groundwork for a strong quality engineer resume. Next, we will explore each section more in-depth, providing you with the details needed to craft an effective resume or improve your existing one.

Which resume format to choose

As a quality engineer, crafting the ideal resume starts with selecting the right format. A chronological format is often the most effective choice for your industry. This format not only underscores your work history but also highlights the progression of your skills and roles, presenting a clear narrative of your expertise in quality management. Employers value seeing how your experience has developed over time, giving them confidence in your ability to handle quality assurance effectively.

In terms of font selection, opting for modern and professional styles like Rubik, Lato, or Montserrat can make a substantial difference. These fonts offer a clean aesthetic that enhances readability while projecting a contemporary and polished image. This choice aligns with the professional standards of industries that emphasize precision and attention to detail, just like quality engineering.

Saving your resume as a PDF is a technical decision that impacts how your document is perceived. A PDF ensures that your carefully chosen format and fonts remain intact, preserving the professional appearance you’ve crafted. This consistency is crucial, as it demonstrates your attention to detail and provides a seamless viewing experience for potential employers, regardless of the device or software they use.

Lastly, setting your margins to one inch on all sides might seem like a minor detail, but it plays a significant role in your resume’s presentation. This standard margin size creates a sense of balance and organization, preventing your information from appearing cluttered. In a field where precision and clarity are paramount, a well-organized resume reflects your commitment to excellence.

By focusing on these elements, you will create a resume that not only highlights your qualifications but also demonstrates the professionalism and meticulousness expected in the field of quality engineering. Employers will recognize the thought and effort you’ve put into your application, setting you apart as a candidate who values precision and detail.

How to write a quantifiable resume experience section

Your quality engineer resume should capture the impact and results of your work by highlighting how you've added value in previous roles. Start by organizing your experience section in reverse chronological order, which draws attention to your most recent and relevant experiences. Focus on the last 10-15 years to ensure your resume stays relevant and concise. To make your resume shine, tailor it to each job by smoothly incorporating specific keywords and phrases from the job ad. Use strong action words like "implemented," "improved," or "reduced" to clearly convey your accomplishments. Here’s a compelling way to structure this section:

- •Implemented a new quality control system, decreasing product defects by 30% within six months.

- •Led a cross-functional team that improved production efficiency by 25%.

- •Developed and executed QA training for 50+ employees, reducing errors by 20%.

- •Analyzed data from daily QA checks, leading to a 15% reduction in rework.

This quality engineer experience section connects your achievements by demonstrating a clear progression of skills and successes. Each bullet point ties back to your ability to create real impact through measurable results. Strong, specific language communicates your strengths while addressing the needs of prospective employers. By tailoring the resume to the job ad, you clearly show that you understand and are prepared to meet the specific challenges of the role. Highlighting quantifiable improvements makes it evident that you can drive change and deliver substantial results, which is a key attribute of a successful quality engineer.

Collaboration-Focused resume experience section

A collaboration-focused quality engineer resume experience section should emphasize how your teamwork abilities have driven process improvements. Begin by highlighting specific projects where collaboration was essential, using clear action verbs and measurable outcomes to showcase your achievements. Describe how your role in a team led to better processes, cost savings, or enhanced product quality, helping employers see the tangible impacts of your collaborative efforts.

Start your experience section by stating your job title and the dates you held the position. Use bullet points to detail your accomplishments and your role in cross-functional teams. Emphasize contributions that made workflows smoother, leveraged your expertise, or fostered a positive team environment. This approach effectively communicates not only your technical expertise but also your ability to engage with others to achieve significant improvements.

Quality Engineer

TechnoWidgets Inc.

2018 - 2022

- Led a cross-functional team to cut product defects by 25%, which significantly boosted customer satisfaction over two years.

- Collaborated with the R&D team to develop new testing protocols, resulting in a 15% reduction in production delays.

- Facilitated weekly meetings to ensure quality goals aligned with manufacturing, enhancing communication and teamwork across departments.

- Trained team members in root cause analysis methods, empowering them to resolve quality issues independently.

Industry-Specific Focus resume experience section

A quality-focused engineer resume experience section should spotlight achievements that align with the role you're targeting. Begin by being specific about the tasks you handled and the outcomes you achieved, painting a clear picture of your contributions. Use strong action verbs and detailed examples to emphasize your skills and competencies. Make sure to tailor your descriptions to the job you're applying for, showing your ability to address problems and enhance processes effectively.

Start by listing your job title, the workplace, and the employment dates to set the stage. For each position, use bullet points to highlight key achievements, such as reducing error rates, implementing new methodologies, or working collaboratively with teams. It's beneficial to mention any certifications or training that boost your industry expertise. Keep your entries concise yet rich in detail to maintain the reader's interest and create a lasting impression.

Quality Engineer

Tech Innovations Co.

March 2018 - July 2023

- Reduced product defects by 20% through effective root cause analysis.

- Led a project team that improved production line efficiency by 15%.

- Implemented new quality assurance protocols, enhancing compliance by 30%.

- Collaborated with cross-functional teams to streamline processes and cut costs.

Achievement-Focused resume experience section

A quality-focused quality engineer resume experience section should highlight your achievements and the impact you've made in your roles. Start by showcasing significant accomplishments that reflect your ability to enhance product quality and streamline processes. Connect these experiences by explaining how you effectively worked with cross-functional teams to drive improvements. This approach will not only demonstrate your technical skills but also your ability to collaborate and lead.

When detailing your achievements, use specific examples and metrics to create a cohesive narrative. Describe the challenges you faced, the actions you took, and the positive results that followed, tying each element together to emphasize your commitment to continuous improvement and innovation. This method will convey your proactive nature and dedication to quality, making your resume more appealing to potential employers.

Senior Quality Engineer

Tech Solutions Inc.

January 2020 - Present

- Led a team of 10 engineers, cutting production defects by 30% through improved inspections and testing.

- Implemented a data-driven quality system, which boosted defect detection rate by 25% for enhanced product reliability.

- Streamlined manufacturing processes across departments, resulting in a 15% increase in overall efficiency.

- Ran training sessions that significantly increased team skills, contributing to higher morale and better team performance.

Problem-Solving Focused resume experience section

A problem-solving-focused quality engineer resume experience section should highlight your expertise in pinpointing and resolving quality issues, demonstrating your analytical skills and collaborative teamwork. Begin by showcasing your leadership in quality improvement projects that enhanced product performance. Highlight how your skills made a positive impact on the organization, ensuring the reader understands your value.

Your bullet points should connect seamlessly, starting with strong action verbs that detail your direct contributions. Explain the problems faced and how your solutions led to measurable results. For example, lead a team to address a significant quality issue, then perform a root-cause analysis using Six Sigma methods to significantly cut defect rates. Continue by describing your work with suppliers to improve material quality and detail training you provided to peers that enhanced inspection efficiency. This connected narrative will clearly convey how you upheld and improved quality standards in your past roles.

Senior Quality Engineer

TechSolutions Corporation

June 2020 - July 2023

- Led a team to tackle a major quality issue that led to a 10% defect rate in production.

- Applied Six Sigma methods to perform a root-cause analysis, cutting defects by 30%.

- Worked closely with suppliers to boost material quality, enhancing product durability by 15%.

- Trained peers on top quality control practices, raising inspection efficiency by 25%.

Write your quality engineer resume summary section

A quality-focused Quality Engineer resume summary should effectively capture your key skills and achievements to stand out to potential employers. In just a few well-crafted sentences, you can vividly illustrate your professional story. Consider this example:

This summary is effective because it communicates your impact through quantifiable achievements. By including numbers, you not only highlight your past successes but also demonstrate your potential to contribute significantly to future employers. A resume summary like this is more fitting for someone with considerable experience, as it offers a succinct preview of your expertise and skills. Unlike a resume objective, which tends to state career aspirations, a summary provides a concrete glimpse into what you bring to the table. While similar to a resume summary, a profile might be broader and occasionally include personal traits. Alternatively, a summary of qualifications presents a bullet-point list of skills and accomplishments, suitable for those with a lengthy career history. With a clear focus on your unique strengths and notable achievements, your summary creates a memorable and impactful first impression.

Listing your quality engineer skills on your resume

A skills-focused quality engineer resume should clearly highlight your expertise and abilities. Start by deciding whether to include a standalone skills section or integrate your skills into other sections like experience and summary. Strengths often reflect your natural abilities and critical soft skills, such as communication and leadership, while hard skills are more specific teachable abilities like statistical analysis or software proficiency.

Think of your skills and strengths as keywords—they can catch the eye of hiring managers and applicant tracking systems, improving your chances of getting noticed. By effectively balancing hard and soft skills, you demonstrate both your technical expertise and interpersonal capabilities.

Here is an example of a standalone skills section in JSON format:

This section clearly lists the key skills that are essential for a quality engineer. It allows employers to quickly grasp your qualifications at a glance.

Best hard skills to feature on your quality engineer resume

Quality engineers rely on hard skills to demonstrate their technical prowess and ability to enhance product quality. These skills should reflect your competence in handling quality systems, analyzing data, and implementing improvements.

Hard Skills

- Quality Management Systems

- Statistical Process Control (SPC)

- Root Cause Analysis

- ISO Standards

- Six Sigma Methodologies

- Lean Manufacturing

- Failure Mode Effects Analysis (FMEA)

- Auditing Techniques

- Risk Management

- Process Improvement

- Product Lifecycle Management (PLM)

- Calibration Techniques

- Computer Aided Design (CAD)

- Quality Assurance Testing

- Reliability Engineering

Best soft skills to feature on your quality engineer resume

Soft skills are equally crucial in a quality engineer's toolkit, revealing how you interact with teams and manage projects. They spotlight your ability to communicate effectively, lead initiatives, and think critically.

Soft Skills

- Problem-Solving

- Critical Thinking

- Communication

- Attention to Detail

- Project Management

- Leadership

- Adaptability

- Team Collaboration

- Time Management

- Initiative

- Conflict Resolution

- Decision-Making

- Creativity

- Organizational Skills

- Customer Focus

How to include your education on your resume

The education section of your resume is vital to show off your qualifications for a quality engineer position. Ensuring the education you list is relevant to the job you're applying for is crucial. Irrelevant education can clutter your resume and distract from your relevant skills and experiences.

If your GPA is strong, consider including it, preferably above 3.5, to demonstrate your academic achievements. If you graduated with honors, like cum laude, list it to highlight your accomplishments. When listing degrees, clearly state the degree type, your major, and the institution from which you graduated.

Incorrect example:

Correct example:

- •Graduated cum laude

The second example is ideal because it focuses on a relevant degree in mechanical engineering from a reputable university, perfect for a quality engineer role. Including a strong GPA and honors like cum laude showcases your capabilities and dedication.

How to include quality engineer certificates on your resume

Including a certificates section in your quality engineer resume is essential. It highlights your qualifications and sets you apart from other candidates. List the name of the certificate, include the date you obtained it, and add the issuing organization. Certificates can also be included in the header for quick visibility. For instance, you can write "Certified Quality Engineer (CQE) | Lean Six Sigma Green Belt" right next to your name.

Here is an example of a good standalone certificates section:

This example is effective because it lists relevant certifications that a quality engineer would need. Each entry includes the title of the certificate and the organization that issued it, adding credibility. Keeping this section clear and concise ensures that hiring managers can quickly recognize your qualifications.

Extra sections to include in your quality engineer resume

As a quality engineer, your resume needs to reflect a balance of technical skills, certifications, and unique personal attributes that set you apart. Including diverse sections in your resume can enrich your profile and provide a closer glimpse into who you are.

- Language section — List languages you speak, especially those relevant to global companies, to show your multicultural background and communication skills.

- Hobbies and interests section — Share hobbies that reflect skills or traits valuable for engineering, such as attention to detail or problem-solving.

- Volunteer work section — Highlight volunteer experiences to demonstrate your commitment to community and teamwork, showcasing your sense of responsibility.

- Books section — Mention books you’ve read related to engineering or personal development, showing your commitment to ongoing learning and improvement.

These sections make your resume not just a list of qualifications and experiences, but a reflection of your personality and values. They help you stand out to potential employers who value both technical expertise and well-rounded individuals. Including these details can also spark interesting conversations during interviews, helping you leave a memorable impression.

In Conclusion

In conclusion, your resume is a representation of you and your professional journey. As a quality engineer, it's vital to translate your expertise in quality management, process improvement, and technical skills into a document that speaks volumes to potential employers. A well-crafted resume is not merely a list of previous jobs—it's a tool to show your problem-solving skills, commitment to quality, and readiness to meet future challenges. Focusing on clarity and precision will guide recruiters through your career achievements and abilities effectively. Opt for a format that highlights the progression of your experience, using a modern font and a clean layout to maintain professionalism. Incorporate quantifiable results and strong action verbs to illustrate the impact of your work and capture attention. Remember to tailor your resume for each application, demonstrating an understanding of the specific role and industry needs. By balancing hard and soft skills and including relevant certifications, you bolster your profile as a comprehensive, skilled candidate. Additionally, enriching your resume with sections about languages, hobbies, or volunteer work adds personal depth, showcasing you as a well-rounded individual. Your resume should leave a lasting impression by capturing who you are not only as a professional but as a person.

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2025. All rights reserved.

Made with love by people who care.