Sheet Metal Worker Resume Examples

Mar 18, 2025

|

12 min read

Craft a standout sheet metal worker resume with our expert tips. Mold your skills and experience into a powerful application that cuts through the competition and shapes your future career opportunities.

Rated by 348 people

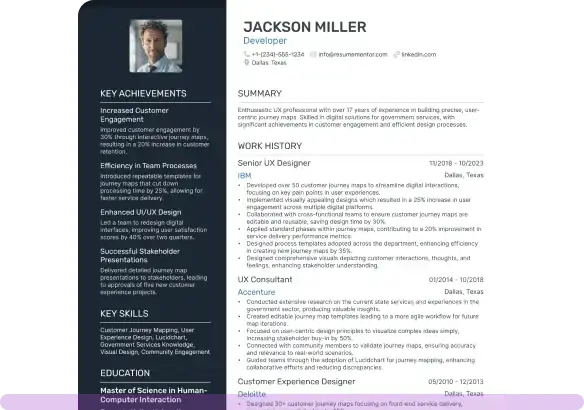

Sheet Metal Fabrication Specialist

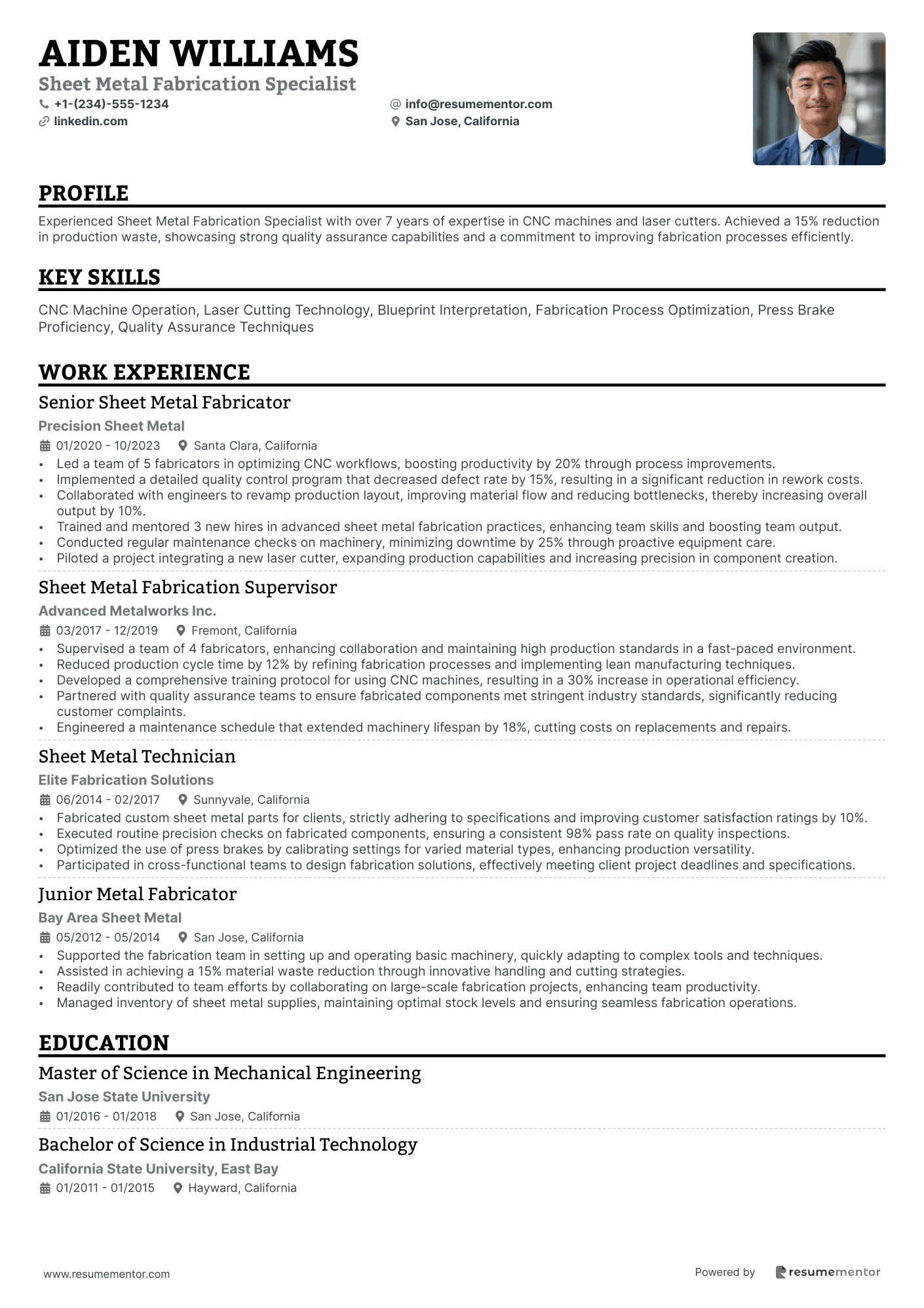

Precision Sheet Metal Fabricator

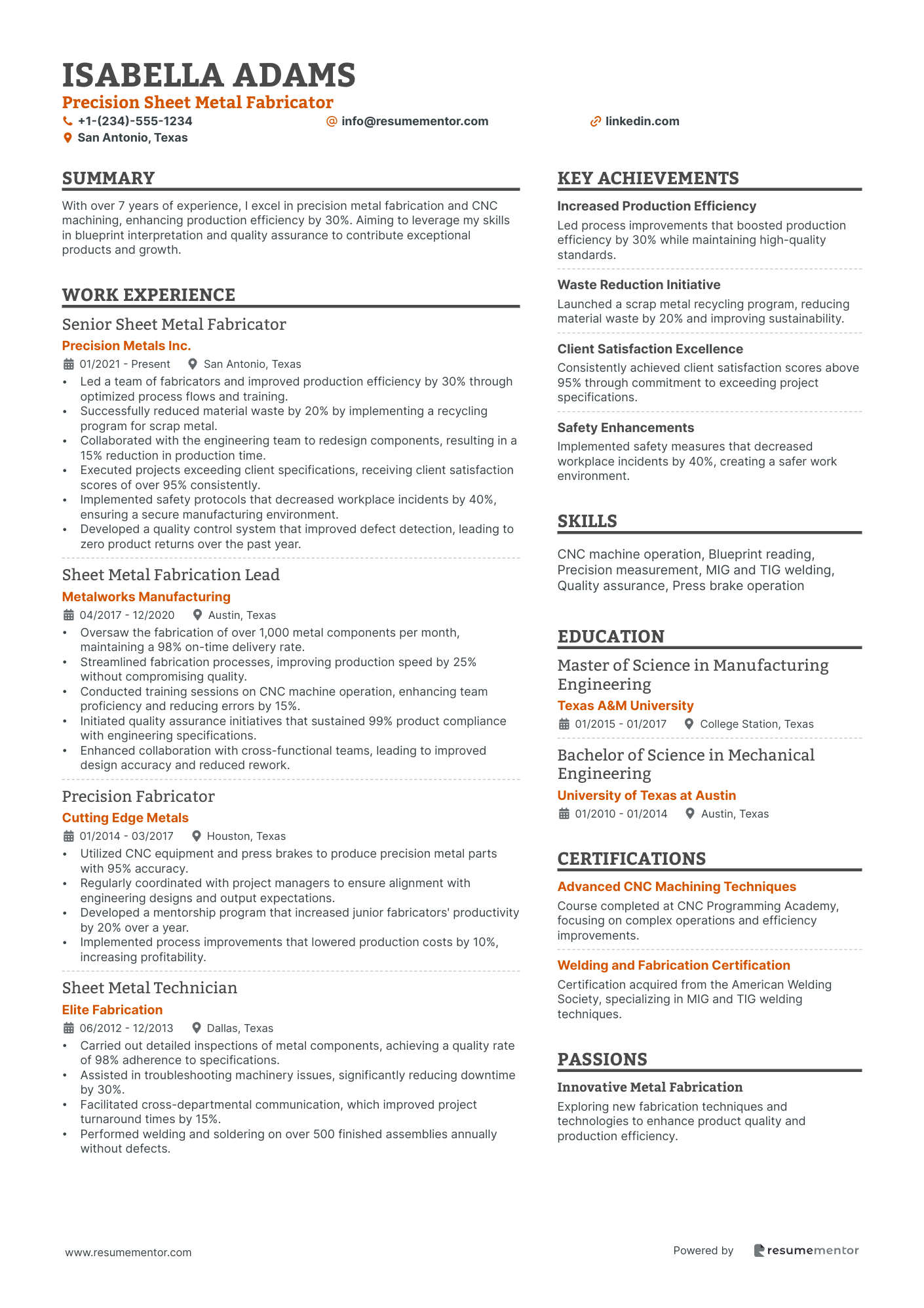

Industrial Sheet Metal Installer

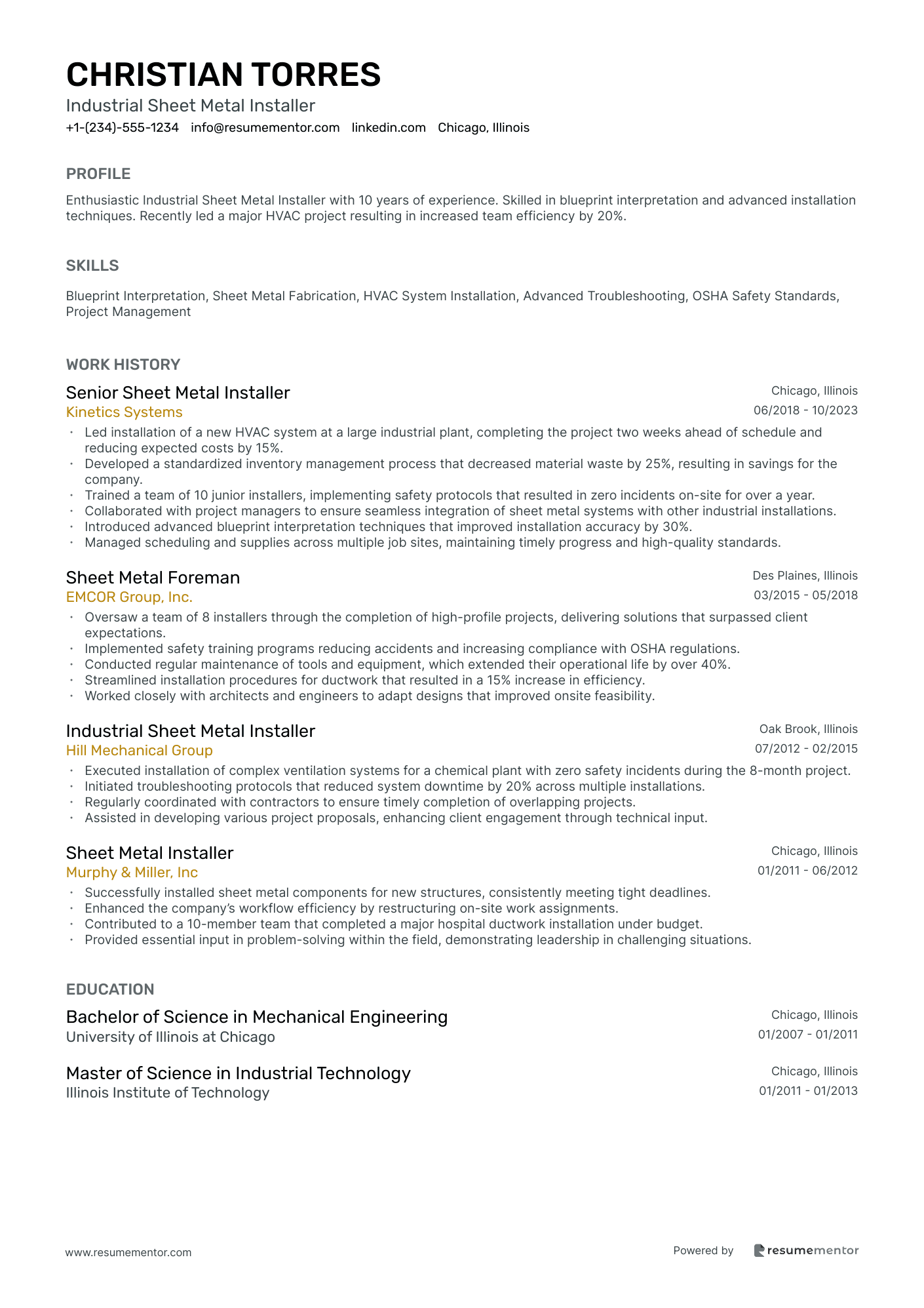

HVAC Sheet Metal Installer

Sheet Metal Pattern Designer

Custom Sheet Metal Craftsman

Architectural Sheet Metal Worker

Sheet Metal Duct Installer

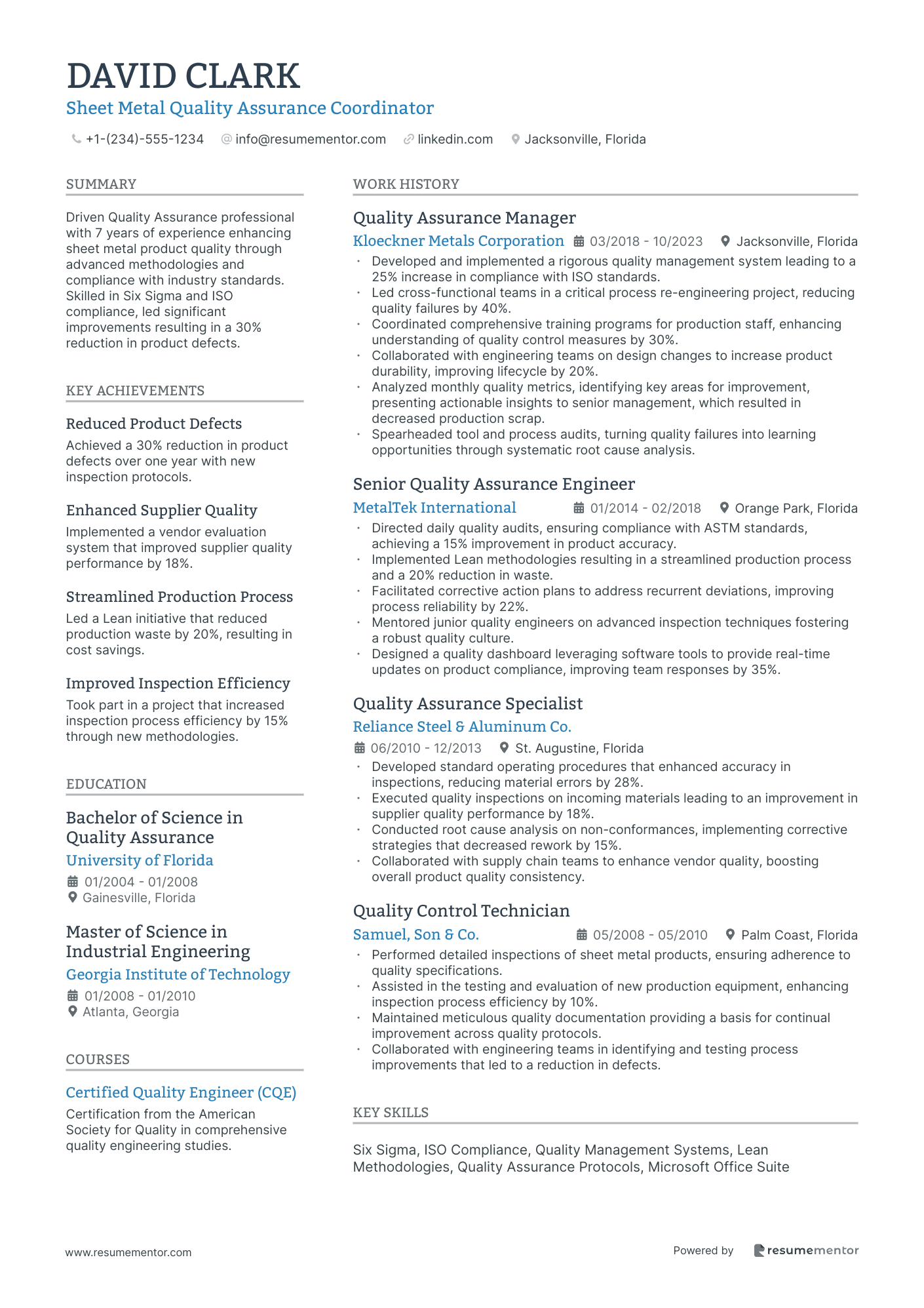

Sheet Metal Quality Assurance Coordinator

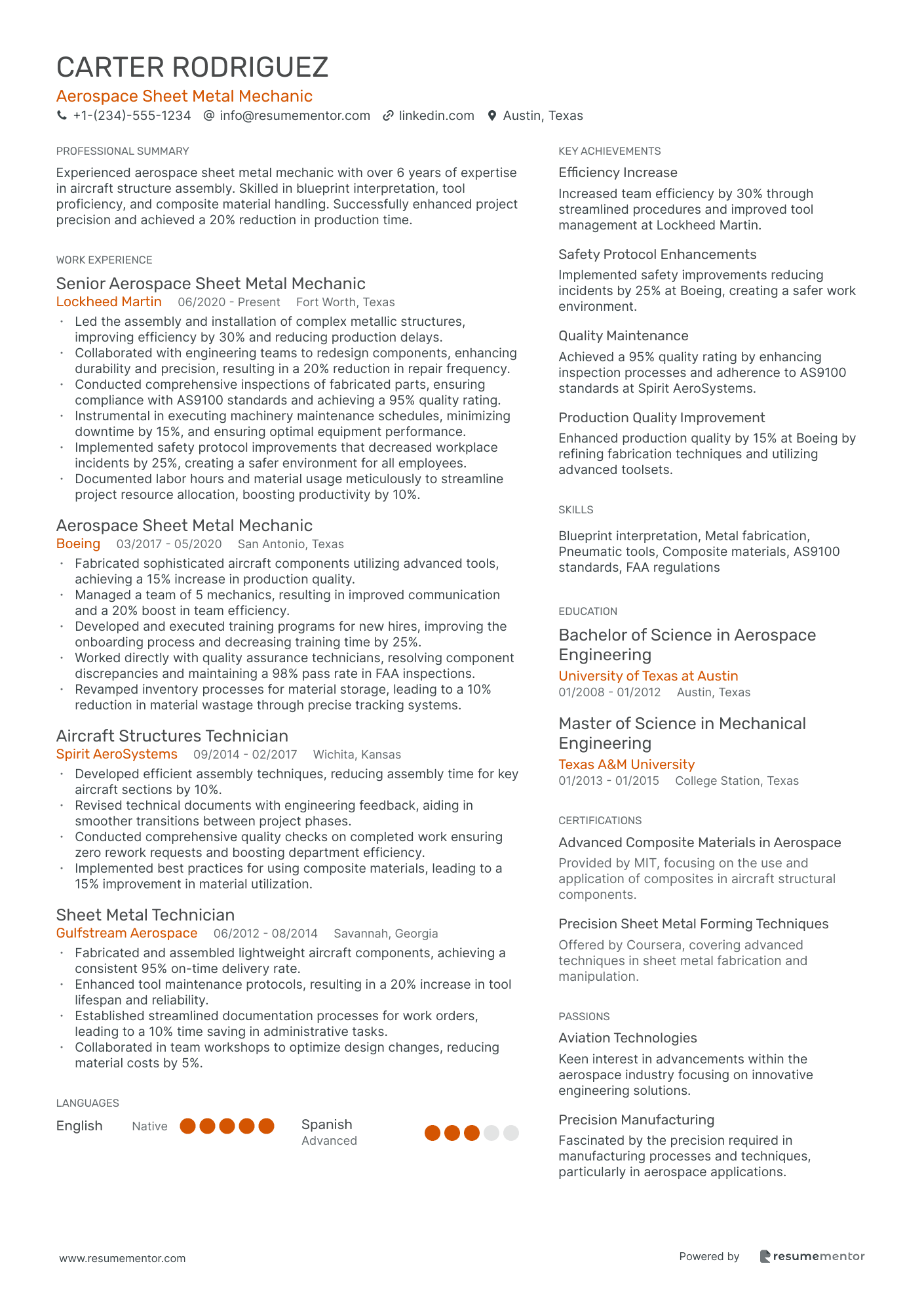

Aerospace Sheet Metal Mechanic

Sheet Metal Fabrication Specialist resume sample

- •Led a team of 5 fabricators in optimizing CNC workflows, boosting productivity by 20% through process improvements.

- •Implemented a detailed quality control program that decreased defect rate by 15%, resulting in a significant reduction in rework costs.

- •Collaborated with engineers to revamp production layout, improving material flow and reducing bottlenecks, thereby increasing overall output by 10%.

- •Trained and mentored 3 new hires in advanced sheet metal fabrication practices, enhancing team skills and boosting team output.

- •Conducted regular maintenance checks on machinery, minimizing downtime by 25% through proactive equipment care.

- •Piloted a project integrating a new laser cutter, expanding production capabilities and increasing precision in component creation.

- •Supervised a team of 4 fabricators, enhancing collaboration and maintaining high production standards in a fast-paced environment.

- •Reduced production cycle time by 12% by refining fabrication processes and implementing lean manufacturing techniques.

- •Developed a comprehensive training protocol for using CNC machines, resulting in a 30% increase in operational efficiency.

- •Partnered with quality assurance teams to ensure fabricated components met stringent industry standards, significantly reducing customer complaints.

- •Engineered a maintenance schedule that extended machinery lifespan by 18%, cutting costs on replacements and repairs.

- •Fabricated custom sheet metal parts for clients, strictly adhering to specifications and improving customer satisfaction ratings by 10%.

- •Executed routine precision checks on fabricated components, ensuring a consistent 98% pass rate on quality inspections.

- •Optimized the use of press brakes by calibrating settings for varied material types, enhancing production versatility.

- •Participated in cross-functional teams to design fabrication solutions, effectively meeting client project deadlines and specifications.

- •Supported the fabrication team in setting up and operating basic machinery, quickly adapting to complex tools and techniques.

- •Assisted in achieving a 15% material waste reduction through innovative handling and cutting strategies.

- •Readily contributed to team efforts by collaborating on large-scale fabrication projects, enhancing team productivity.

- •Managed inventory of sheet metal supplies, maintaining optimal stock levels and ensuring seamless fabrication operations.

Precision Sheet Metal Fabricator resume sample

- •Led a team of fabricators and improved production efficiency by 30% through optimized process flows and training.

- •Successfully reduced material waste by 20% by implementing a recycling program for scrap metal.

- •Collaborated with the engineering team to redesign components, resulting in a 15% reduction in production time.

- •Executed projects exceeding client specifications, receiving client satisfaction scores of over 95% consistently.

- •Implemented safety protocols that decreased workplace incidents by 40%, ensuring a secure manufacturing environment.

- •Developed a quality control system that improved defect detection, leading to zero product returns over the past year.

- •Oversaw the fabrication of over 1,000 metal components per month, maintaining a 98% on-time delivery rate.

- •Streamlined fabrication processes, improving production speed by 25% without compromising quality.

- •Conducted training sessions on CNC machine operation, enhancing team proficiency and reducing errors by 15%.

- •Initiated quality assurance initiatives that sustained 99% product compliance with engineering specifications.

- •Enhanced collaboration with cross-functional teams, leading to improved design accuracy and reduced rework.

- •Utilized CNC equipment and press brakes to produce precision metal parts with 95% accuracy.

- •Regularly coordinated with project managers to ensure alignment with engineering designs and output expectations.

- •Developed a mentorship program that increased junior fabricators' productivity by 20% over a year.

- •Implemented process improvements that lowered production costs by 10%, increasing profitability.

- •Carried out detailed inspections of metal components, achieving a quality rate of 98% adherence to specifications.

- •Assisted in troubleshooting machinery issues, significantly reducing downtime by 30%.

- •Facilitated cross-departmental communication, which improved project turnaround times by 15%.

- •Performed welding and soldering on over 500 finished assemblies annually without defects.

Industrial Sheet Metal Installer resume sample

- •Led installation of a new HVAC system at a large industrial plant, completing the project two weeks ahead of schedule and reducing expected costs by 15%.

- •Developed a standardized inventory management process that decreased material waste by 25%, resulting in savings for the company.

- •Trained a team of 10 junior installers, implementing safety protocols that resulted in zero incidents on-site for over a year.

- •Collaborated with project managers to ensure seamless integration of sheet metal systems with other industrial installations.

- •Introduced advanced blueprint interpretation techniques that improved installation accuracy by 30%.

- •Managed scheduling and supplies across multiple job sites, maintaining timely progress and high-quality standards.

- •Oversaw a team of 8 installers through the completion of high-profile projects, delivering solutions that surpassed client expectations.

- •Implemented safety training programs reducing accidents and increasing compliance with OSHA regulations.

- •Conducted regular maintenance of tools and equipment, which extended their operational life by over 40%.

- •Streamlined installation procedures for ductwork that resulted in a 15% increase in efficiency.

- •Worked closely with architects and engineers to adapt designs that improved onsite feasibility.

- •Executed installation of complex ventilation systems for a chemical plant with zero safety incidents during the 8-month project.

- •Initiated troubleshooting protocols that reduced system downtime by 20% across multiple installations.

- •Regularly coordinated with contractors to ensure timely completion of overlapping projects.

- •Assisted in developing various project proposals, enhancing client engagement through technical input.

- •Successfully installed sheet metal components for new structures, consistently meeting tight deadlines.

- •Enhanced the company’s workflow efficiency by restructuring on-site work assignments.

- •Contributed to a 10-member team that completed a major hospital ductwork installation under budget.

- •Provided essential input in problem-solving within the field, demonstrating leadership in challenging situations.

HVAC Sheet Metal Installer resume sample

- •Led the installation of complex HVAC systems in over 50 commercial projects, improving energy efficiency by approximately 15%.

- •Implemented a new sheet metal fabrication technique, reducing waste by 10% and lowering costs by 5%.

- •Streamlined troubleshooting processes, cutting down repair times by 25%, thus increasing client satisfaction by 20%.

- •Collaborated with cross-functional teams, completing projects 10% ahead of schedule, boosting overall team efficiency.

- •Organized regular training sessions for junior installers, enhancing team productivity by 12%.

- •Conducted in-depth inspections of HVAC systems, resulting in a 20% decrease in post-installation issues.

- •Managed installation of over 100 residential HVAC duct systems, ensuring optimal airflow and reducing energy costs by 10%.

- •Collaborated with architects and engineers, enhancing system design accuracy by reviewing blueprints and technical schematics.

- •Spearheaded safety protocol updates that resulted in a 50% reduction in onsite accidents.

- •Streamlined duct installation processes, increasing installation efficiency by 20% through innovative techniques.

- •Optimized the maintenance schedule, extending the lifespan of duct systems by 5 years on average.

- •Installed and maintained HVAC systems, improving air quality and comfort for over 250 clients.

- •Successfully executed technical projects that increased system reliability, reducing failure rates by 15%.

- •Utilized diagnostic tools to troubleshoot and fix air flow issues, reducing service call durations by 30%.

- •Enhanced client satisfaction scores by 40% through diligent follow-ups and engagement.

- •Crafted precise sheet metal components, increasing installation precision by 20% and reducing error rates.

- •Reduced material usage by 15% through accurate measurement and cutting techniques.

- •Assisted in the final assembly of HVAC systems, ensuring adherence to industry standards.

- •Maintained comprehensive records of installations and system performance, contributing to increased accountability.

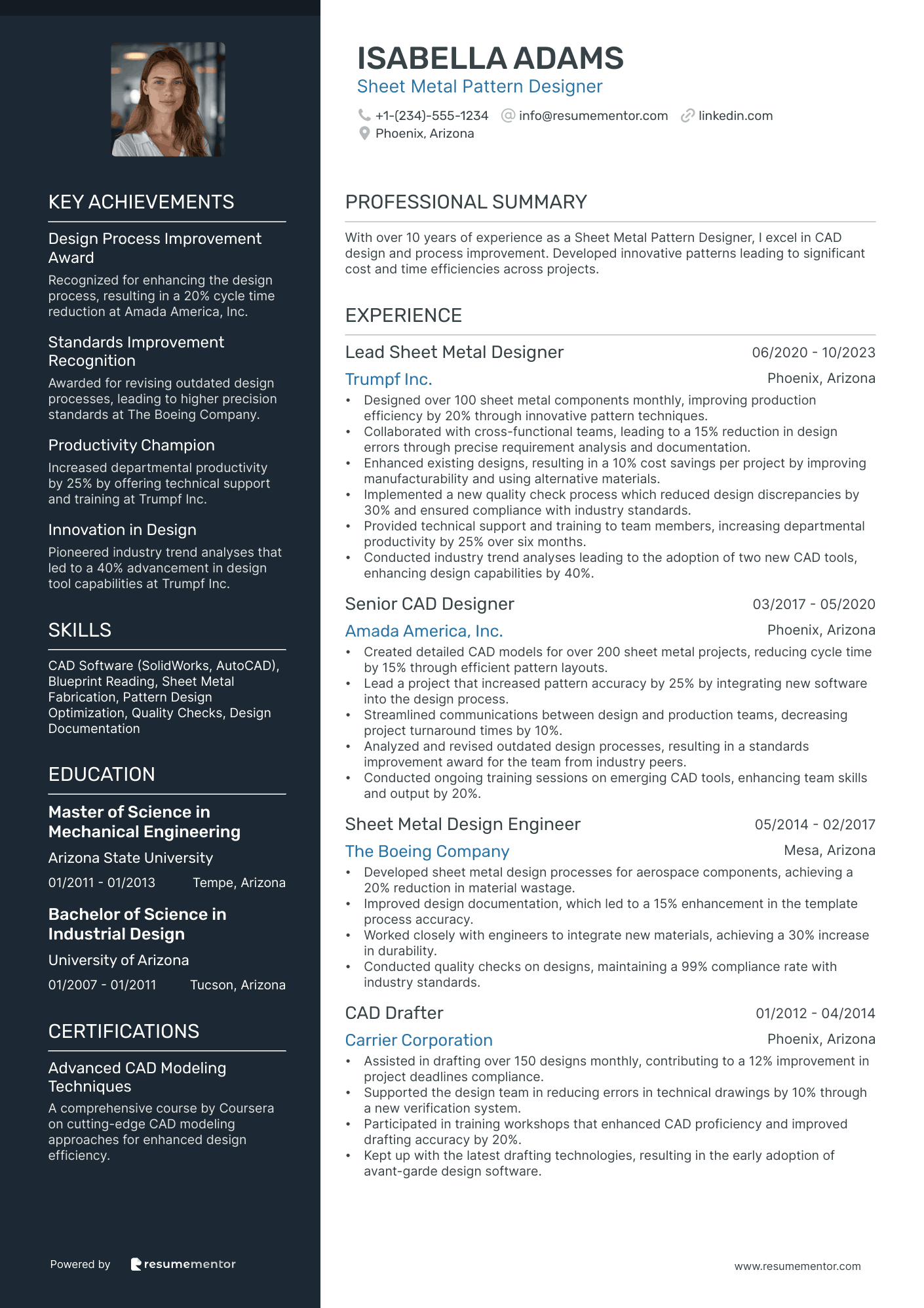

Sheet Metal Pattern Designer resume sample

- •Designed over 100 sheet metal components monthly, improving production efficiency by 20% through innovative pattern techniques.

- •Collaborated with cross-functional teams, leading to a 15% reduction in design errors through precise requirement analysis and documentation.

- •Enhanced existing designs, resulting in a 10% cost savings per project by improving manufacturability and using alternative materials.

- •Implemented a new quality check process which reduced design discrepancies by 30% and ensured compliance with industry standards.

- •Provided technical support and training to team members, increasing departmental productivity by 25% over six months.

- •Conducted industry trend analyses leading to the adoption of two new CAD tools, enhancing design capabilities by 40%.

- •Created detailed CAD models for over 200 sheet metal projects, reducing cycle time by 15% through efficient pattern layouts.

- •Lead a project that increased pattern accuracy by 25% by integrating new software into the design process.

- •Streamlined communications between design and production teams, decreasing project turnaround times by 10%.

- •Analyzed and revised outdated design processes, resulting in a standards improvement award for the team from industry peers.

- •Conducted ongoing training sessions on emerging CAD tools, enhancing team skills and output by 20%.

- •Developed sheet metal design processes for aerospace components, achieving a 20% reduction in material wastage.

- •Improved design documentation, which led to a 15% enhancement in the template process accuracy.

- •Worked closely with engineers to integrate new materials, achieving a 30% increase in durability.

- •Conducted quality checks on designs, maintaining a 99% compliance rate with industry standards.

- •Assisted in drafting over 150 designs monthly, contributing to a 12% improvement in project deadlines compliance.

- •Supported the design team in reducing errors in technical drawings by 10% through a new verification system.

- •Participated in training workshops that enhanced CAD proficiency and improved drafting accuracy by 20%.

- •Kept up with the latest drafting technologies, resulting in the early adoption of avant-garde design software.

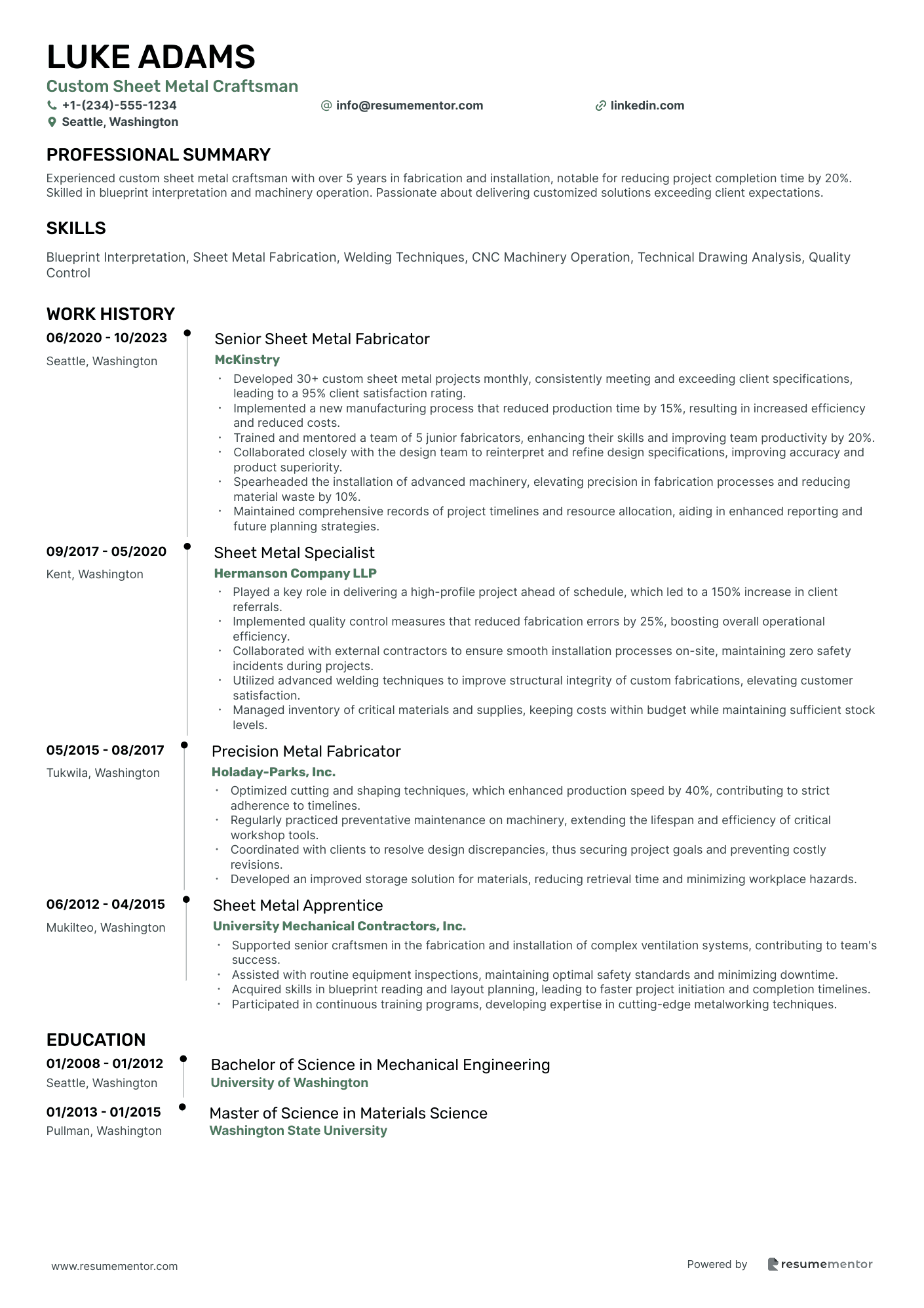

Custom Sheet Metal Craftsman resume sample

- •Developed 30+ custom sheet metal projects monthly, consistently meeting and exceeding client specifications, leading to a 95% client satisfaction rating.

- •Implemented a new manufacturing process that reduced production time by 15%, resulting in increased efficiency and reduced costs.

- •Trained and mentored a team of 5 junior fabricators, enhancing their skills and improving team productivity by 20%.

- •Collaborated closely with the design team to reinterpret and refine design specifications, improving accuracy and product superiority.

- •Spearheaded the installation of advanced machinery, elevating precision in fabrication processes and reducing material waste by 10%.

- •Maintained comprehensive records of project timelines and resource allocation, aiding in enhanced reporting and future planning strategies.

- •Played a key role in delivering a high-profile project ahead of schedule, which led to a 150% increase in client referrals.

- •Implemented quality control measures that reduced fabrication errors by 25%, boosting overall operational efficiency.

- •Collaborated with external contractors to ensure smooth installation processes on-site, maintaining zero safety incidents during projects.

- •Utilized advanced welding techniques to improve structural integrity of custom fabrications, elevating customer satisfaction.

- •Managed inventory of critical materials and supplies, keeping costs within budget while maintaining sufficient stock levels.

- •Optimized cutting and shaping techniques, which enhanced production speed by 40%, contributing to strict adherence to timelines.

- •Regularly practiced preventative maintenance on machinery, extending the lifespan and efficiency of critical workshop tools.

- •Coordinated with clients to resolve design discrepancies, thus securing project goals and preventing costly revisions.

- •Developed an improved storage solution for materials, reducing retrieval time and minimizing workplace hazards.

- •Supported senior craftsmen in the fabrication and installation of complex ventilation systems, contributing to team's success.

- •Assisted with routine equipment inspections, maintaining optimal safety standards and minimizing downtime.

- •Acquired skills in blueprint reading and layout planning, leading to faster project initiation and completion timelines.

- •Participated in continuous training programs, developing expertise in cutting-edge metalworking techniques.

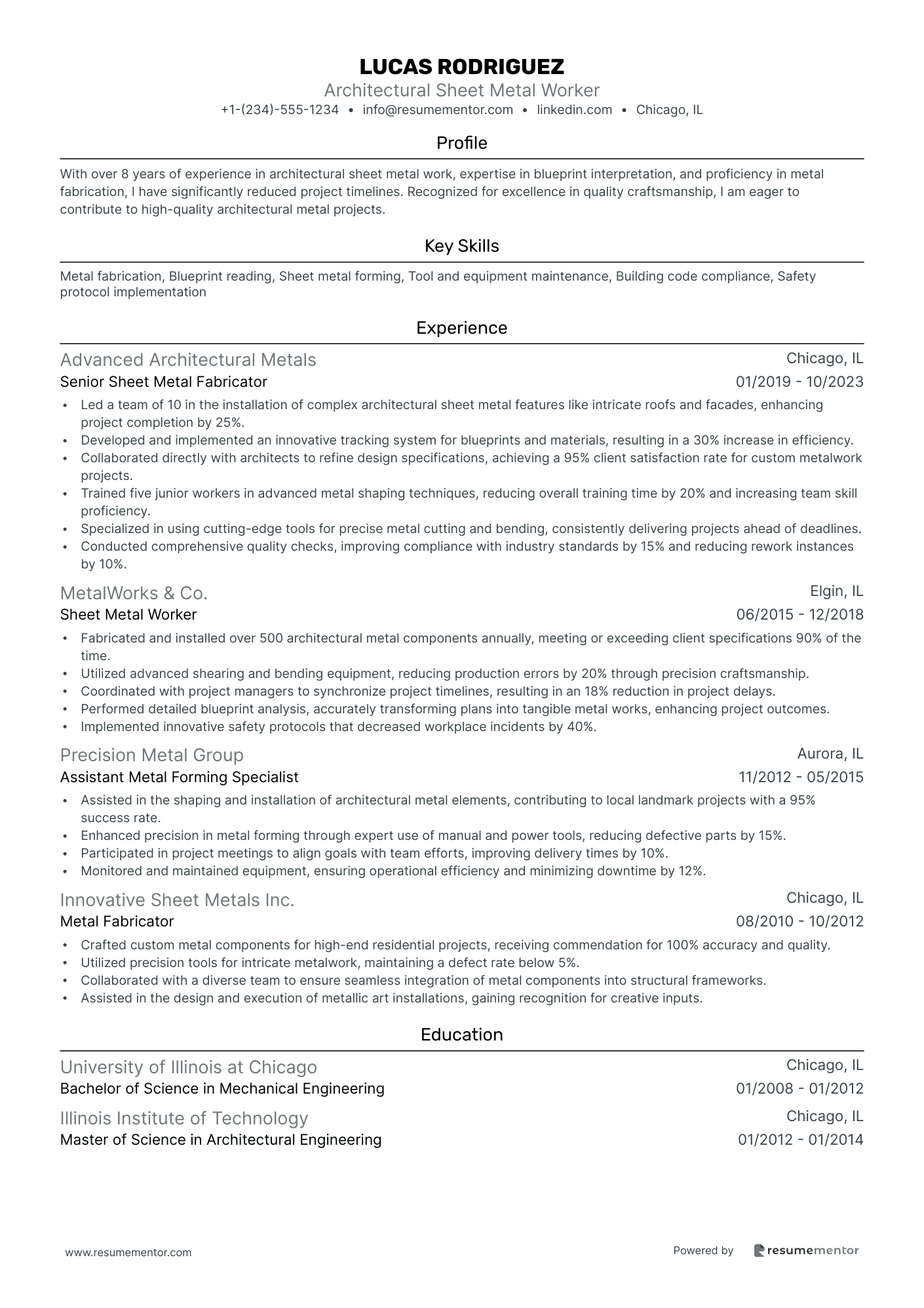

Architectural Sheet Metal Worker resume sample

- •Led a team of 10 in the installation of complex architectural sheet metal features like intricate roofs and facades, enhancing project completion by 25%.

- •Developed and implemented an innovative tracking system for blueprints and materials, resulting in a 30% increase in efficiency.

- •Collaborated directly with architects to refine design specifications, achieving a 95% client satisfaction rate for custom metalwork projects.

- •Trained five junior workers in advanced metal shaping techniques, reducing overall training time by 20% and increasing team skill proficiency.

- •Specialized in using cutting-edge tools for precise metal cutting and bending, consistently delivering projects ahead of deadlines.

- •Conducted comprehensive quality checks, improving compliance with industry standards by 15% and reducing rework instances by 10%.

- •Fabricated and installed over 500 architectural metal components annually, meeting or exceeding client specifications 90% of the time.

- •Utilized advanced shearing and bending equipment, reducing production errors by 20% through precision craftsmanship.

- •Coordinated with project managers to synchronize project timelines, resulting in an 18% reduction in project delays.

- •Performed detailed blueprint analysis, accurately transforming plans into tangible metal works, enhancing project outcomes.

- •Implemented innovative safety protocols that decreased workplace incidents by 40%.

- •Assisted in the shaping and installation of architectural metal elements, contributing to local landmark projects with a 95% success rate.

- •Enhanced precision in metal forming through expert use of manual and power tools, reducing defective parts by 15%.

- •Participated in project meetings to align goals with team efforts, improving delivery times by 10%.

- •Monitored and maintained equipment, ensuring operational efficiency and minimizing downtime by 12%.

- •Crafted custom metal components for high-end residential projects, receiving commendation for 100% accuracy and quality.

- •Utilized precision tools for intricate metalwork, maintaining a defect rate below 5%.

- •Collaborated with a diverse team to ensure seamless integration of metal components into structural frameworks.

- •Assisted in the design and execution of metallic art installations, gaining recognition for creative inputs.

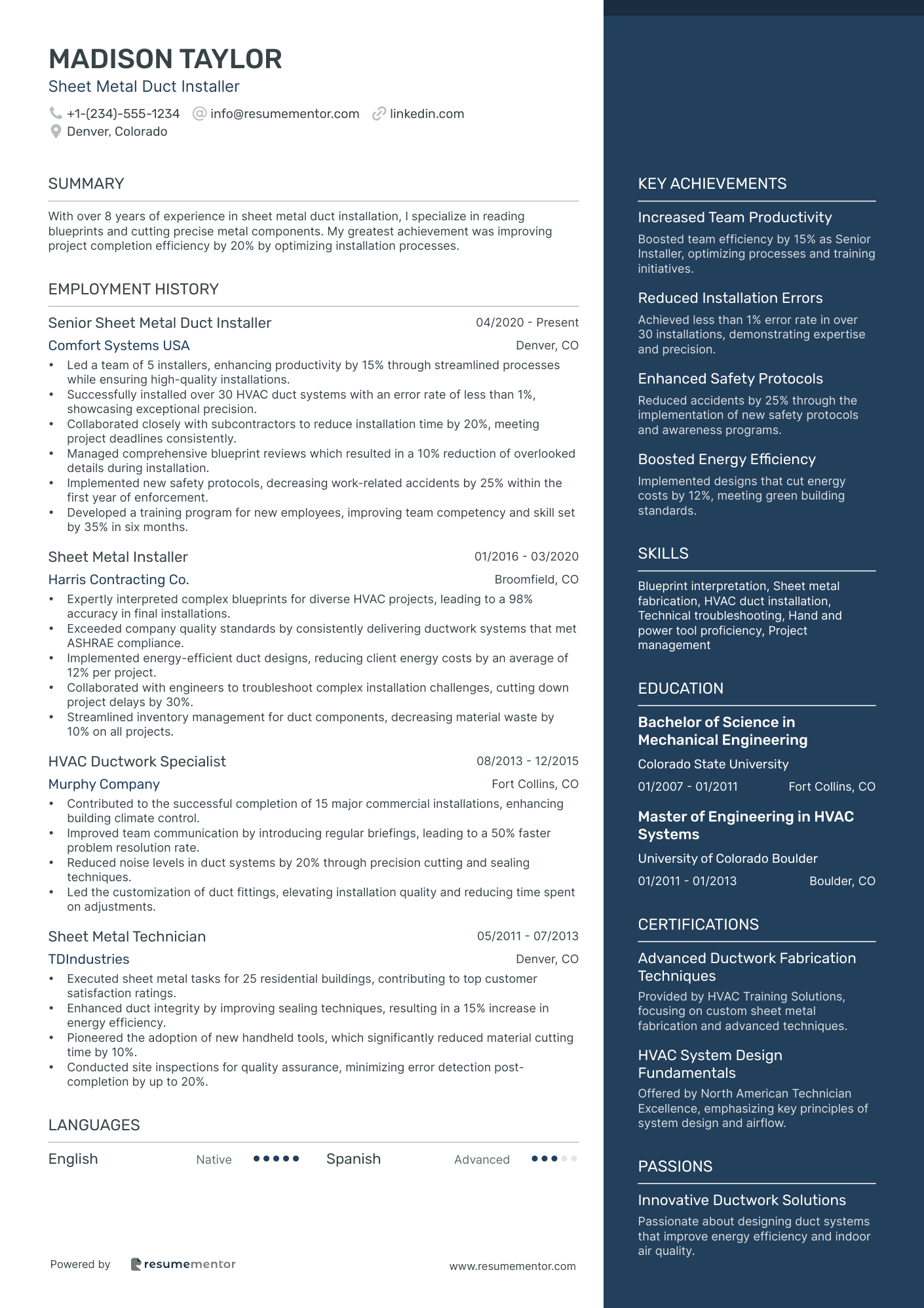

Sheet Metal Duct Installer resume sample

- •Led a team of 5 installers, enhancing productivity by 15% through streamlined processes while ensuring high-quality installations.

- •Successfully installed over 30 HVAC duct systems with an error rate of less than 1%, showcasing exceptional precision.

- •Collaborated closely with subcontractors to reduce installation time by 20%, meeting project deadlines consistently.

- •Managed comprehensive blueprint reviews which resulted in a 10% reduction of overlooked details during installation.

- •Implemented new safety protocols, decreasing work-related accidents by 25% within the first year of enforcement.

- •Developed a training program for new employees, improving team competency and skill set by 35% in six months.

- •Expertly interpreted complex blueprints for diverse HVAC projects, leading to a 98% accuracy in final installations.

- •Exceeded company quality standards by consistently delivering ductwork systems that met ASHRAE compliance.

- •Implemented energy-efficient duct designs, reducing client energy costs by an average of 12% per project.

- •Collaborated with engineers to troubleshoot complex installation challenges, cutting down project delays by 30%.

- •Streamlined inventory management for duct components, decreasing material waste by 10% on all projects.

- •Contributed to the successful completion of 15 major commercial installations, enhancing building climate control.

- •Improved team communication by introducing regular briefings, leading to a 50% faster problem resolution rate.

- •Reduced noise levels in duct systems by 20% through precision cutting and sealing techniques.

- •Led the customization of duct fittings, elevating installation quality and reducing time spent on adjustments.

- •Executed sheet metal tasks for 25 residential buildings, contributing to top customer satisfaction ratings.

- •Enhanced duct integrity by improving sealing techniques, resulting in a 15% increase in energy efficiency.

- •Pioneered the adoption of new handheld tools, which significantly reduced material cutting time by 10%.

- •Conducted site inspections for quality assurance, minimizing error detection post-completion by up to 20%.

Sheet Metal Quality Assurance Coordinator resume sample

- •Developed and implemented a rigorous quality management system leading to a 25% increase in compliance with ISO standards.

- •Led cross-functional teams in a critical process re-engineering project, reducing quality failures by 40%.

- •Coordinated comprehensive training programs for production staff, enhancing understanding of quality control measures by 30%.

- •Collaborated with engineering teams on design changes to increase product durability, improving lifecycle by 20%.

- •Analyzed monthly quality metrics, identifying key areas for improvement, presenting actionable insights to senior management, which resulted in decreased production scrap.

- •Spearheaded tool and process audits, turning quality failures into learning opportunities through systematic root cause analysis.

- •Directed daily quality audits, ensuring compliance with ASTM standards, achieving a 15% improvement in product accuracy.

- •Implemented Lean methodologies resulting in a streamlined production process and a 20% reduction in waste.

- •Facilitated corrective action plans to address recurrent deviations, improving process reliability by 22%.

- •Mentored junior quality engineers on advanced inspection techniques fostering a robust quality culture.

- •Designed a quality dashboard leveraging software tools to provide real-time updates on product compliance, improving team responses by 35%.

- •Developed standard operating procedures that enhanced accuracy in inspections, reducing material errors by 28%.

- •Executed quality inspections on incoming materials leading to an improvement in supplier quality performance by 18%.

- •Conducted root cause analysis on non-conformances, implementing corrective strategies that decreased rework by 15%.

- •Collaborated with supply chain teams to enhance vendor quality, boosting overall product quality consistency.

- •Performed detailed inspections of sheet metal products, ensuring adherence to quality specifications.

- •Assisted in the testing and evaluation of new production equipment, enhancing inspection process efficiency by 10%.

- •Maintained meticulous quality documentation providing a basis for continual improvement across quality protocols.

- •Collaborated with engineering teams in identifying and testing process improvements that led to a reduction in defects.

Aerospace Sheet Metal Mechanic resume sample

- •Led the assembly and installation of complex metallic structures, improving efficiency by 30% and reducing production delays.

- •Collaborated with engineering teams to redesign components, enhancing durability and precision, resulting in a 20% reduction in repair frequency.

- •Conducted comprehensive inspections of fabricated parts, ensuring compliance with AS9100 standards and achieving a 95% quality rating.

- •Instrumental in executing machinery maintenance schedules, minimizing downtime by 15%, and ensuring optimal equipment performance.

- •Implemented safety protocol improvements that decreased workplace incidents by 25%, creating a safer environment for all employees.

- •Documented labor hours and material usage meticulously to streamline project resource allocation, boosting productivity by 10%.

- •Fabricated sophisticated aircraft components utilizing advanced tools, achieving a 15% increase in production quality.

- •Managed a team of 5 mechanics, resulting in improved communication and a 20% boost in team efficiency.

- •Developed and executed training programs for new hires, improving the onboarding process and decreasing training time by 25%.

- •Worked directly with quality assurance technicians, resolving component discrepancies and maintaining a 98% pass rate in FAA inspections.

- •Revamped inventory processes for material storage, leading to a 10% reduction in material wastage through precise tracking systems.

- •Developed efficient assembly techniques, reducing assembly time for key aircraft sections by 10%.

- •Revised technical documents with engineering feedback, aiding in smoother transitions between project phases.

- •Conducted comprehensive quality checks on completed work ensuring zero rework requests and boosting department efficiency.

- •Implemented best practices for using composite materials, leading to a 15% improvement in material utilization.

- •Fabricated and assembled lightweight aircraft components, achieving a consistent 95% on-time delivery rate.

- •Enhanced tool maintenance protocols, resulting in a 20% increase in tool lifespan and reliability.

- •Established streamlined documentation processes for work orders, leading to a 10% time saving in administrative tasks.

- •Collaborated in team workshops to optimize design changes, reducing material costs by 5%.

As a sheet metal worker, your expertise in transforming raw materials into essential structures is invaluable on the floor. However, when it comes to the job market, translating those hands-on skills into words can feel challenging. Navigating this process requires you to convey your experience in a clear and concise manner, highlighting the craftsmanship you display daily.

Crafting a resume is an entirely new task, demanding that you effectively showcase your achievements and field expertise. This is where a well-structured resume becomes crucial—acting as your blueprint to guide potential employers through your abilities and experience.

To streamline this process, consider starting with a resume template. It helps you organize your skills and experience, ensuring that your work on HVAC systems or blueprint reading proficiency is communicated effectively. This structure allows your resume to serve as a powerful tool, unveiling your worth to employers even before the first meeting.

By following this guide, you gain practical advice and tips to craft a standout resume. This resume not only captures your abilities but also paves the way for new job opportunities.

Key Takeaways

- Ensure your resume highlights both technical skills and problem-solving abilities to effectively communicate your expertise in metalwork.

- Organize your resume structure with clear sections such as contact information, professional summary, skills, work experience, and education to provide a comprehensive view of your qualifications.

- Choose a reverse chronological format for your resume to emphasize recent work experience, and consider using modern fonts for a professional appearance.

- Focus on quantifiable achievements in your work experience section to demonstrate the impact of your skills and contributions to employers.

- Incorporating certifications, soft and hard skills, and additional sections like volunteer work or languages can enhance your resume's appeal and differentiate you from other candidates.

What to focus on when writing your sheet metal worker resume

A sheet metal worker resume should clearly communicate your technical expertise and hands-on experience, making it easy for recruiters to see your strengths in metalwork. Your resume should highlight not only your skills in metalwork but also your problem-solving abilities, ensuring you can tackle complex projects with safety and precision. When recruiters read your resume, they should quickly recognize your proficiency with industry tools and your knack for delivering quality results efficiently.

How to structure your sheet metal worker resume

- Contact Information—Include your name, phone number, email address, and location. This straightforward section ensures that recruiters can effortlessly reach out to you, giving them all the contact details they need at a glance.

- Professional Summary—Provide a brief overview of your experience and what sets you apart as a skilled sheet metal worker. It's an opportunity to make a strong first impression by highlighting specialized skills like HVAC duct installation or custom metal fabrication, emphasizing your unique expertise in the field.

- Skills—List key skills that are crucial in sheet metal work, such as blueprint reading, welding, or CAD software proficiency. It's essential to highlight your understanding of safety practices, assuring recruiters of your commitment to maintaining a safe and efficient working environment.

- Work Experience—Outline your past jobs in reverse chronological order. Detailing job titles, company names, locations, and dates, followed by bullet points describing tasks and achievements, gives a clear picture of your professional journey. Focus on measurable outcomes and specific projects to demonstrate your impact in previous roles.

- Education—Share details about your educational background, including any certifications or apprenticeship programs related to sheet metal. Highlighting these elements underscores your formal training and dedication to advancing in the field, setting the stage for the section below where we'll cover each aspect in more depth.

Which resume format to choose

Certainly! Let's delve a bit deeper into each topic while keeping everything relevant to creating a sheet metal worker resume:

As a sheet metal worker, the right resume format is key to highlighting your skills effectively. Opting for the reverse chronological format is beneficial because it emphasizes your most recent work experience, which is crucial in showing employers how your current skills apply to their needs. This format lets your career progression shine, helping employers quickly grasp your expertise in the field.

A modern look can enhance your resume's appeal. Choosing fonts like Rubik, Lato, or Montserrat provides a clean and contemporary appearance. While the specific font isn't the most crucial element, these choices reflect a professional yet approachable style. They keep your resume neat, ensuring your skills and accomplishments remain the main focus.

Once your resume content is polished, saving it as a PDF is essential. This file format keeps your layout intact, preventing any shifts or changes when viewed on different devices. PDFs ensure your resume looks professional and consistent, reflecting the precision you bring to your sheet metal work.

Finally, don’t overlook the importance of margins. Keeping them at 1 inch all around gives your resume a balanced and organized look. Adequate margins also make your text easier to read, ensuring your experiences and qualifications are clear to potential employers. By paying attention to these elements, you enhance your resume's effectiveness, helping you stand out in the competitive job market.

How to write a quantifiable resume experience section

A strong experience section in a sheet metal worker resume highlights your hands-on skills and achievements. Employers want to see how your experience and practical skills can benefit them. Start with your most recent job and work backward, matching job titles closely with those in the job ad. This not only shows your understanding of the role but also your accomplishments.

Tailor each job entry to the specific position you're applying for, using similar language from the ad and showcasing your relevant expertise. Action words like "fabricated," "installed," and "collaborated" add impact to your descriptions. Quantifiable achievements make your resume stand out, so focus on specific examples from the last 10-15 years, unless earlier experience is highly relevant. This approach demonstrates the value you bring to each project.

Here's an example of an effective sheet metal worker experience section:

- •Reduced waste material by 20% by optimizing cutting patterns for sheet metal.

- •Led a team of 5, completing projects 15% ahead of schedule with zero safety incidents.

- •Collaborated with project managers to increase installation efficiency by 30%.

- •Achieved a 95% customer satisfaction rating for high-quality metal installations.

This section efficiently uses numbers to convey your impact, making it clear to employers how you can improve their operations. Each bullet point builds on the last, showing how you not only cut waste but also led teams, improved efficiency, and delighted customers. This cohesive approach makes your contributions undeniable, aligning them closely with the expectations of potential employers. It reinforces your proactive nature and meticulous attention to detail, making your resume a strong contender.

Industry-Specific Focus resume experience section

A sheet metal-focused resume experience section should emphasize your practical skills, precision, and commitment to safety standards. Begin by listing your job title, the company name, and the dates you were employed. In the bullet points, focus on detailing specific tasks and achievements that highlight your expertise in the industry. Each point should seamlessly illustrate your proficiency with tools and materials while showcasing your ability to meet project goals effectively.

Describe how you successfully managed complex projects, enhancing efficiencies or contributing positively to team dynamics. Highlight any specialized techniques you mastered and the innovative solutions you implemented. Include experiences of collaborating with other trades and stepping into leadership roles to provide a comprehensive view of your capabilities. This approach gives potential employers a deeper understanding of your skill set and reliability in the industry.

Sheet Metal Worker

Smith's Mechanical Inc.

March 2018 - June 2023

- Installed, repaired, and maintained HVAC systems with precision, which boosted efficiency by 15% at Smith's Mechanical Inc.

- Skillfully read and interpreted blueprints and technical drawings for various complex projects, ensuring accurate installations.

- Collaborated closely with other trade professionals on large-scale construction projects, achieving seamless integration.

- Led a team of apprentices by providing guidance and training focused on safety protocols and best practices.

Collaboration-Focused resume experience section

A collaboration-focused sheet metal worker resume experience section should begin by highlighting your ability to seamlessly integrate with teams to achieve common goals. Emphasize your teamwork and problem-solving skills by sharing examples of projects where you cooperatively worked with various departments. Explain how effective communication with colleagues, supervisors, and other teams helped ensure tasks were completed smoothly and efficiently. Highlight specific outcomes achieved through your collaborative efforts, such as increased productivity or reduced waste, giving potential employers clear insights into your contributions.

Use bullet points to clearly outline your experiences, focusing on those that best showcase your collaborative abilities. Start each bullet with a strong action verb and provide examples that illustrate how you contributed to team successes. This approach helps paint a complete picture of your ability to work well with others.

Sheet Metal Worker

Ace Fabrication Inc.

June 2018 - Present

- Partnered with a team of 10 to fabricate and install HVAC systems in commercial buildings, effectively reducing project completion times by 15% through enhanced communication.

- Collaborated with engineers and architects to meticulously interpret blueprints and design specifications, boosting accuracy and cutting errors by 20%.

- Facilitated weekly meetings to discuss project progress and exchange ideas for overcoming challenges, contributing to a 10% decrease in material wastage.

- Engaged in cross-training activities to both learn and share new techniques, fostering a culture of continuous learning among team members.

Growth-Focused resume experience section

A growth-focused sheet metal worker resume experience section should showcase your achievements and the significant impact of your work. Begin by identifying key tasks from your past roles, like fabricating, installing, or repairing metal structures, and connect these by highlighting improvements you initiated or supported, such as reducing waste, enhancing safety, or boosting production efficiency. Instead of listing tasks independently, illustrate how your actions contributed to noticeable team or company benefits.

In each job entry, use clear bullet points to convey your accomplishments. Share how your expertise and decisions led to saving time, reducing costs, or optimizing resources. By using strong action verbs, you can confidently underscore your contributions while making the narrative engaging. Ensure each experience entry is formatted with a descriptive title, company name, and dates to maintain clarity. Here's a structured example to guide you:

Lead Sheet Metal Worker

Metal Works Inc.

2018 - 2021

- Improved production efficiency by 15% through the implementation of lean manufacturing techniques.

- Developed a new safety protocol that reduced workplace accidents by 20%.

- Oversaw the installation of HVAC systems for large commercial projects, enhancing client satisfaction.

- Trained a team of 10 apprentices, boosting team productivity by 25%.

Achievement-Focused resume experience section

A detailed, achievement-focused sheet metal worker resume experience section should highlight the tangible results you've delivered in your previous roles. Begin by considering the tasks where you excelled, challenges you overcame, and successful projects that underscore your expertise. Reflect on how your efforts positively impacted your employer, perhaps through increased efficiency, cost savings, or enhanced safety, demonstrating your contribution to the team's success. Use strong action words to convey your active role, and where possible, quantify your achievements with specific numbers or details for added impact.

Your descriptions should seamlessly showcase your problem-solving skills, ability to work well in teams, and technical expertise, painting a complete picture of your capabilities. Focus on showcasing achievements that show your ability to adapt to changing work environments while meeting and exceeding expectations. Make sure each point is tailored to highlight skills relevant to the job you're targeting. Keep your language clear and concise, avoiding jargon, so that potential employers can quickly grasp the value you bring to the table.

Sheet Metal Worker

Metro Fabrication Ltd.

June 2018 - April 2023

- Installed over 150 HVAC systems, boosting efficiency by 30% for commercial clients.

- Worked with design teams to improve duct layouts, saving 20% in material costs.

- Set up safety protocols leading to zero on-site accidents over two years.

- Guided and trained new hires, enhancing team productivity and cohesion.

Write your sheet metal worker resume summary section

A summary-focused sheet metal worker resume experience section should immediately capture an employer’s attention by highlighting your most valuable skills and experience. This part of your resume is your chance to stand out by emphasizing your expertise in the field. If you have significant experience, spotlight your accomplishments and specialized skills that align with the job you’re applying for. Consider this example of a strong summary:

This summary not only outlines your extensive experience but also demonstrates your skill set, relates directly to the job, and underscores your dedication to safety and quality.

Describing yourself effectively involves using concise, powerful language that highlights your achievements. Rather than just listing duties, bring your accomplishments to the forefront. Connecting your skills to the job you’re targeting, and providing measurable results where possible, can enhance your persuasive edge.

Grasping the nuances of different resume sections allows for a more tailored application. A resume summary provides a quick snapshot of your career and capabilities, whereas a resume objective zeroes in on your future aspirations—ideal for career newcomers or changers. A resume profile merges goals with experience, while a summary of qualifications lists key skills. Deciding which format best matches your experience will significantly boost your job prospects.

Listing your sheet metal worker skills on your resume

A skills-focused sheet metal worker resume should effectively showcase your expertise and capabilities. Your skills section can stand alone or be integrated into your experience and summary sections. By highlighting strengths and soft skills, you demonstrate personal qualities that make you a valuable team member, while hard skills represent your technical abilities acquired through training. These skills and strengths serve as keywords to enhance your resume’s visibility to employers and applicant tracking systems, making their importance clear in capturing attention.

Here’s an example of how a standalone skills section might look:

This list is effective because it’s clear and relevant, offering both technical and soft skills that give a well-rounded view of your abilities. Each skill is directly tied to sheet metal work, ensuring employers quickly understand your strengths.

Best hard skills to feature on your sheet metal worker resume

Hard skills are essential in showing your technical capabilities and competence in handling specific tasks. For sheet metal workers, these skills should emphasize your proficiency with metals and machinery which impacts work quality, safety, and productivity.

Hard Skills

- Metalsmithing

- Blueprint Reading

- Welding and Soldering

- Sheet Metal Machinery Operation

- Fabrication Techniques

- CNC Machine Operation

- HVAC Systems

- AutoCAD

- Precision Measurement

- Metal Bending and Shaping

- Riveting and Fastening

- Laser Cutting

- MIG/TIG Welding

- Troubleshooting and Repair

- Quality Control

Best soft skills to feature on your sheet metal worker resume

Soft skills are crucial for illustrating your ability to collaborate and manage challenges within the workplace. As a sheet metal worker, focusing on these skills will reflect your capability to work well with a team, solve problems, and maintain organization.

Soft Skills

- Teamwork

- Communication

- Time management

- Problem-solving

- Attention to detail

- Adaptability

- Reliability

- Conflict Resolution

- Critical Thinking

- Leadership

- Initiative

- Dependability

- Stress Management

- Patience

- Organization

How to include your education on your resume

The education section is a vital part of your sheet metal worker resume. It shows employers the relevant skills and knowledge you have gained through formal education. Make sure this section is tailored to the job you're applying for, and exclude any irrelevant education. When mentioning GPA on your resume, include it if it's 3.0 or above, such as "GPA: 3.6/4.0". For honors like cum laude, write it next to your degree, for example, "Bachelor of Science, cum laude". Always list your degree starting with the type, like "Associate of Applied Science in Sheet Metal Technology."

Here's an example of how not to write your education section:

Here's a proper way to list your education for a sheet metal worker position:

The second example is good because it focuses on relevant education, showcasing your specialized training in sheet metal technology. Including honors like cum laude and a strong GPA further highlights your dedication and academic achievement. Displaying the timeline of your studies helps employers gauge your educational journey and experience.

How to include sheet metal worker certificates on your resume

To make your resume stand out, including a certificates section is essential. Certificates show your qualifications and dedication to skill development in the metalworking industry. List the name of every certificate clearly in your resume. Include the date when you earned each certificate. Add the issuing organization to give credibility to your certificates.

Certificates can also be placed in the header of your resume if they are key highlights. For instance, you can write: "OSHA Certified | Welding Certificate | Blueprint Reading Proficiency."

A strong standalone certificates section can demonstrate your expertise effectively. Here is an example written in JSON format:

This example is effective because it includes relevant certifications for a sheet metal worker. It demonstrates expertise in safety and specialized skills, which are crucial qualities for the role. Each item includes the title and issuer, helping employers verify your qualifications easily. Certificates like these reassure potential employers of your readiness to perform the job safely and skillfully.

Extra sections to include on your sheet metal worker resume

Crafting a standout resume for a sheet metal worker involves more than just listing your job history. Highlighting diverse sections can set you apart and provide a fuller picture of your skills and experiences. Including a mix of interests, skills, and activities will make your resume more engaging.

Language section — Mention any languages you speak fluently or have a good command of, as this can help in communication with diverse teams or clients.

Hobbies and interests section — Show your personality and highlight interests that may transfer skills relevant to sheet metal work, such as model building which can demonstrate attention to detail.

Volunteer work section — Detail any volunteer work you've done where you've applied skills similar to those in sheet metal work, such as building or repairing facilities, to showcase dedication and community involvement.

Books section — Note any books related to your trade or personal development that you've read to indicate a commitment to ongoing learning and staying informed about industry trends.

Enhancing your resume with these sections will help convey your unique qualities and dedication to your field and personal growth. By providing a well-rounded view of who you are, you create the potential for deeper connections during interviews.

In Conclusion

In conclusion, crafting a standout resume as a sheet metal worker is a valuable skill that showcases your hands-on expertise and readiness for new opportunities. By organizing your skills and experiences effectively, you highlight your craftsmanship and ability to deliver quality results. A well-structured resume not only outlines your technical know-how but also illustrates your problem-solving skills and attention to safety, making you an appealing candidate to employers. Using a reverse chronological format helps emphasize your recent achievements, while a sleek modern look adds to your professional image. Including a variety of sections such as skills, certifications, and unique interests can provide a more comprehensive view of your capabilities. Remember, quantifiable achievements and strong action verbs can turn your tasks into tangible contributions, showcasing the value you bring to each project. Tailoring your resume to each job application by aligning your experiences with the employer's needs further enhances your chances of standing out in a competitive market. By focusing on clarity and precision, much like in your craft, your resume becomes a powerful tool to communicate your worth. Embrace the opportunity to present your capabilities confidently, ensuring that when employers see your resume, they see potential.

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2026. All rights reserved.

Made with love by people who care.