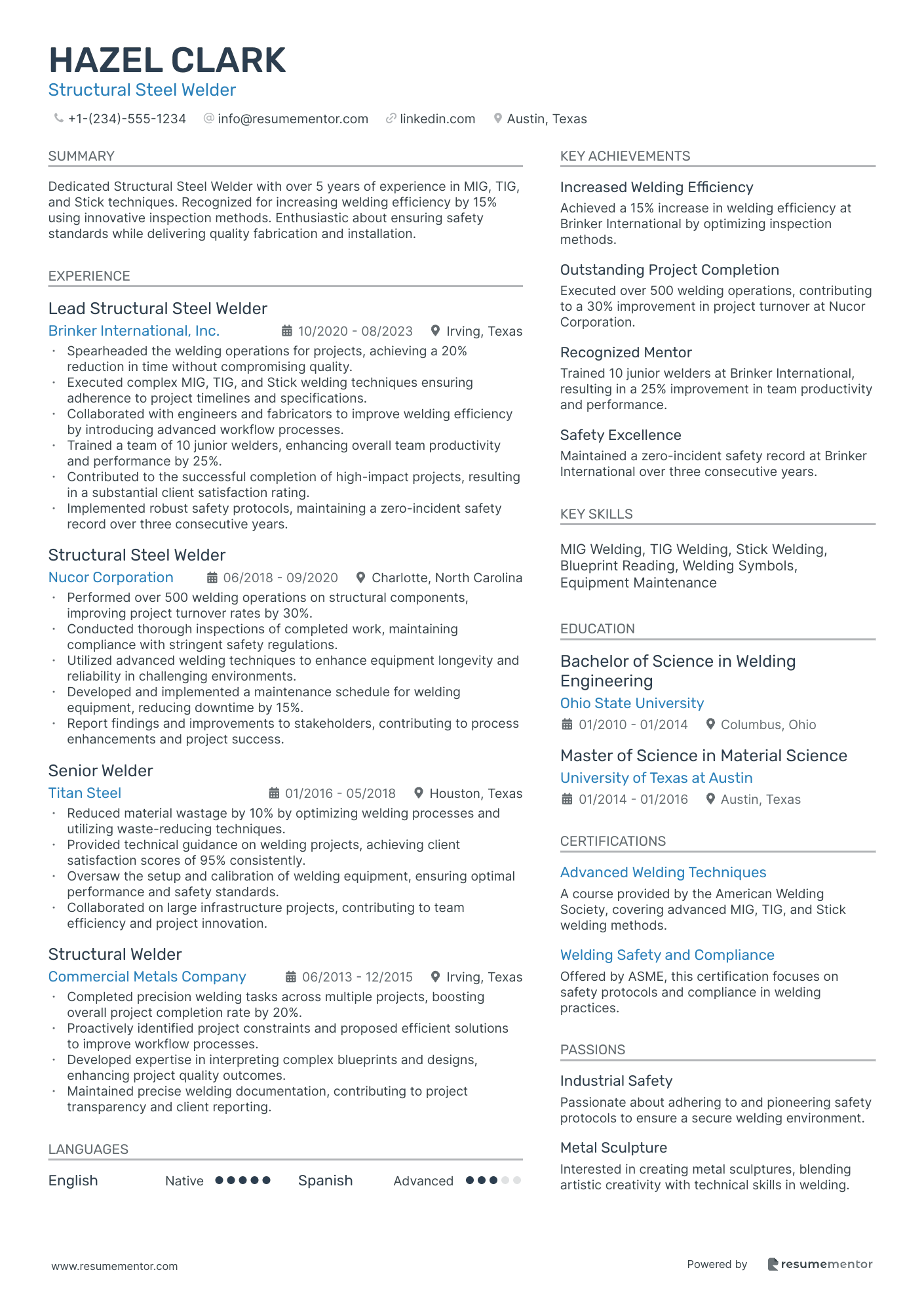

Welder Resume Examples

Mar 25, 2025

|

12 min read

Craft a standout welder resume that sparks employer interest. Highlight your skills and experience, set your application on fire, and weld your way to success in the competitive job market. Forge lasting impressions today.

Rated by 348 people

Underwater Welder

Aerospace Welder

Structural Steel Welder

Pipeline Welder

Fabrication Welder

Automotive Welder

Nuclear Welder

Railroad Welder

Shipyard Welder

Robotics Welding Technician

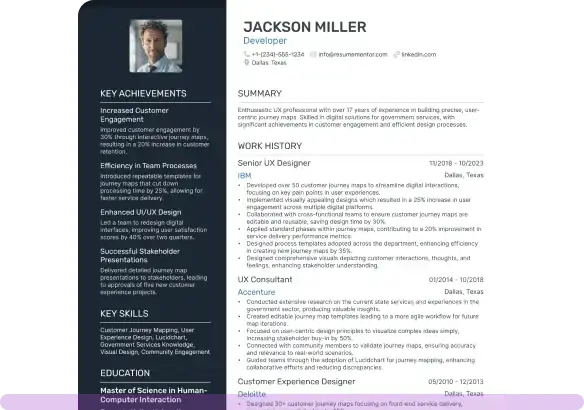

Underwater Welder resume sample

- •Led a team executing critical repairs on submerged pipelines, enhancing operational efficiency by 25% over one year.

- •Improved welding accuracy by 30% through the implementation of advanced techniques, resulting in fewer defects.

- •Conducted over 150 inspections, identifying weaknesses in underwater structures, which improved safety conditions by 40%.

- •Collaborated with engineers to design repair solutions, improving project timelines by 15% on average.

- •Trained and supervised four junior welders in safe diving and welding practices, reducing operational risks by 20%.

- •Enhanced equipment maintenance protocols leading to a 10% reduction in unwanted downtime.

- •Performed underwater welding tasks on offshore platforms, achieving a 98% success rate in repair tasks.

- •Executed emergency welding repairs on a crucial pipeline segment, preventing a potential loss of $500,000.

- •Reduced time taken to complete inspection reports by 15% through the adoption of digital reporting techniques.

- •Managed the maintenance of diving equipment, resulting in a 20% increase in operational readiness.

- •Contributed to a project that restored 300 meters of subsea piping, ensuring pipeline integrity.

- •Assisted in the inspection of underwater structures, documenting findings that led to a 10% reduction in maintenance budgets.

- •Supported the welding team in completing projects ahead of schedule by 20%, enhancing client satisfaction.

- •Implemented safety protocols, leading to zero incidents during a busy project season consisting of 12 engagements.

- •Monitored and maintained diving and welding equipment, increasing equipment life span by 15%.

- •Carried out routine welding maintenance on marina structures, reducing long-term repair costs by 25%.

- •Designed custom welding solutions for client projects, increasing project success rates by 10%.

- •Collaborated with a multidisciplinary team, contributing to projects that secured $2 million in contracts.

- •Maintained a high safety standard, achieving a record of zero safety breaches over two years.

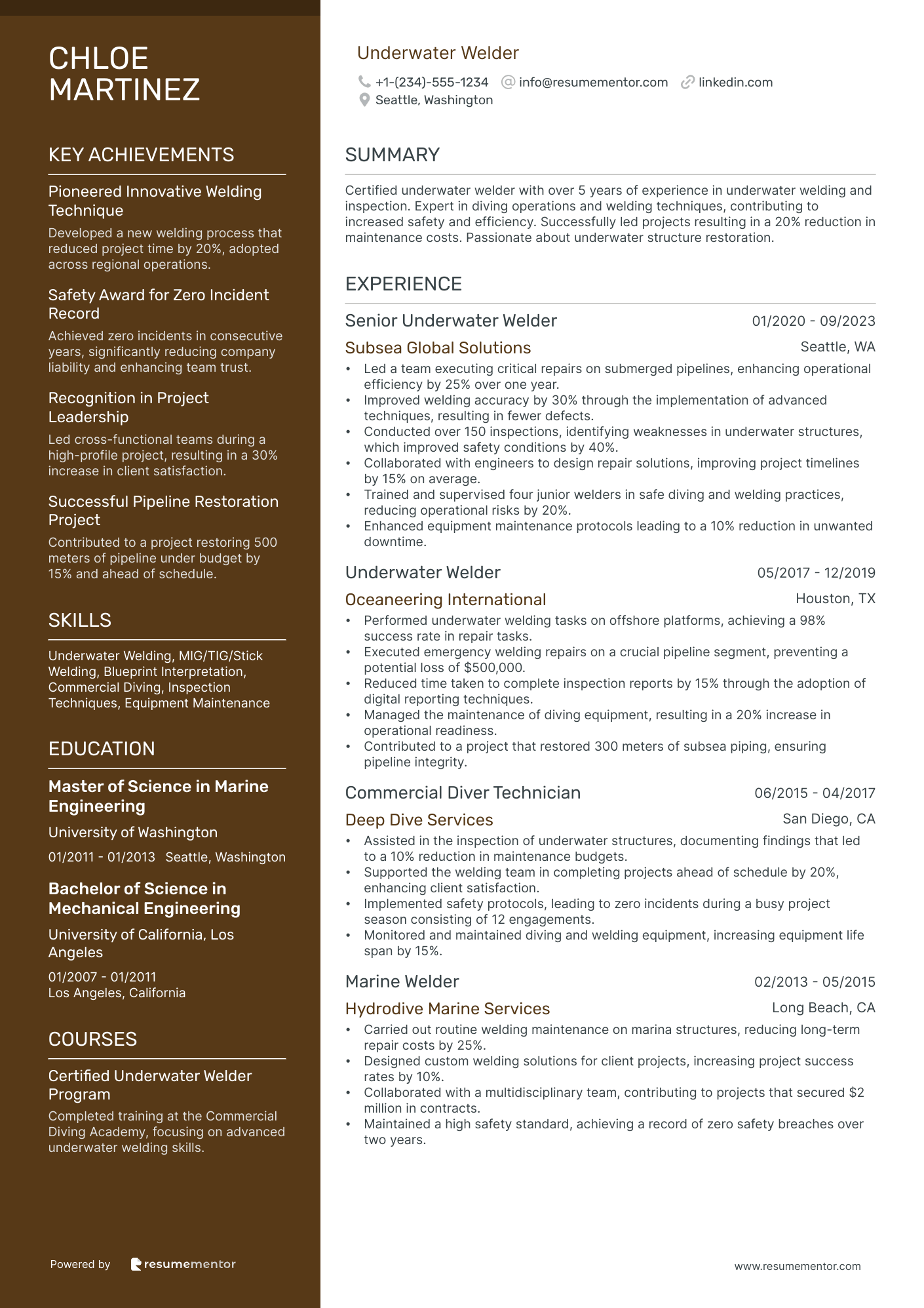

Aerospace Welder resume sample

- •Executed MIG, TIG, and Arc welding on aircraft components, enhancing production speed by 15% over a 12-month project.

- •Interpreted complex blueprints and engineering drawings, ensuring welds adhered to all industry specifications and reducing errors by 10%.

- •Conducted thorough inspections of completed welds, contributing to a 20% reduction in rework rates and improved safety compliance.

- •Maintained high-quality welding standards on titanium and stainless steel parts, achieving a 95% approval rating from quality control audits.

- •Collaborated with engineering team to resolve critical welding challenges, resulting in optimized weld procedures and enhanced material utilization.

- •Documented detailed logs of weld procedures, leading to better tracking of project timelines and a 30% increase in operational transparency.

- •Led a team of welders in a project that reduced production downtime by 25% through effective resource planning and task allocation.

- •Performed high-precision welding on aluminum aircraft structures, enhancing structural integrity and reducing post-inspection failures by 20%.

- •Conducted training workshops to improve team proficiency in aerospace welding standards, which resulted in a 15% increase in team productivity.

- •Implemented new safety protocols that resulted in a 30% reduction in workplace accidents during welding operations over a 6-month period.

- •Managed detailed welding documentation, boosting traceability of welds and enhancing compliance with aerospace regulatory standards.

- •Contributed to the development of welding techniques on prototype spacecraft components, expanding the testing capabilities by 40% over one year.

- •Interpreted engineering schematics to produce precise welds, reducing material wastage by 15% through enhanced accuracy.

- •Collaborated with cross-functional teams to address and resolve technical welding issues, resulting in improved cross-departmental communication.

- •Maintained safety standards and cleanliness in welding zones, leading to a 95% satisfaction score from internal safety audits.

- •Assisted in MIG and TIG welding operations on complex aerospace components, which enhanced product completeness rate by 10%.

- •Executed quality checks on finished welds, contributing to reduced production cycle times and better compliance with quality metrics.

- •Documented and communicated welding process modifications, resulting in a 20% improvement in procedural adherence.

- •Maintained a meticulous log of welded materials and processes, which improved historical tracking of component integrity.

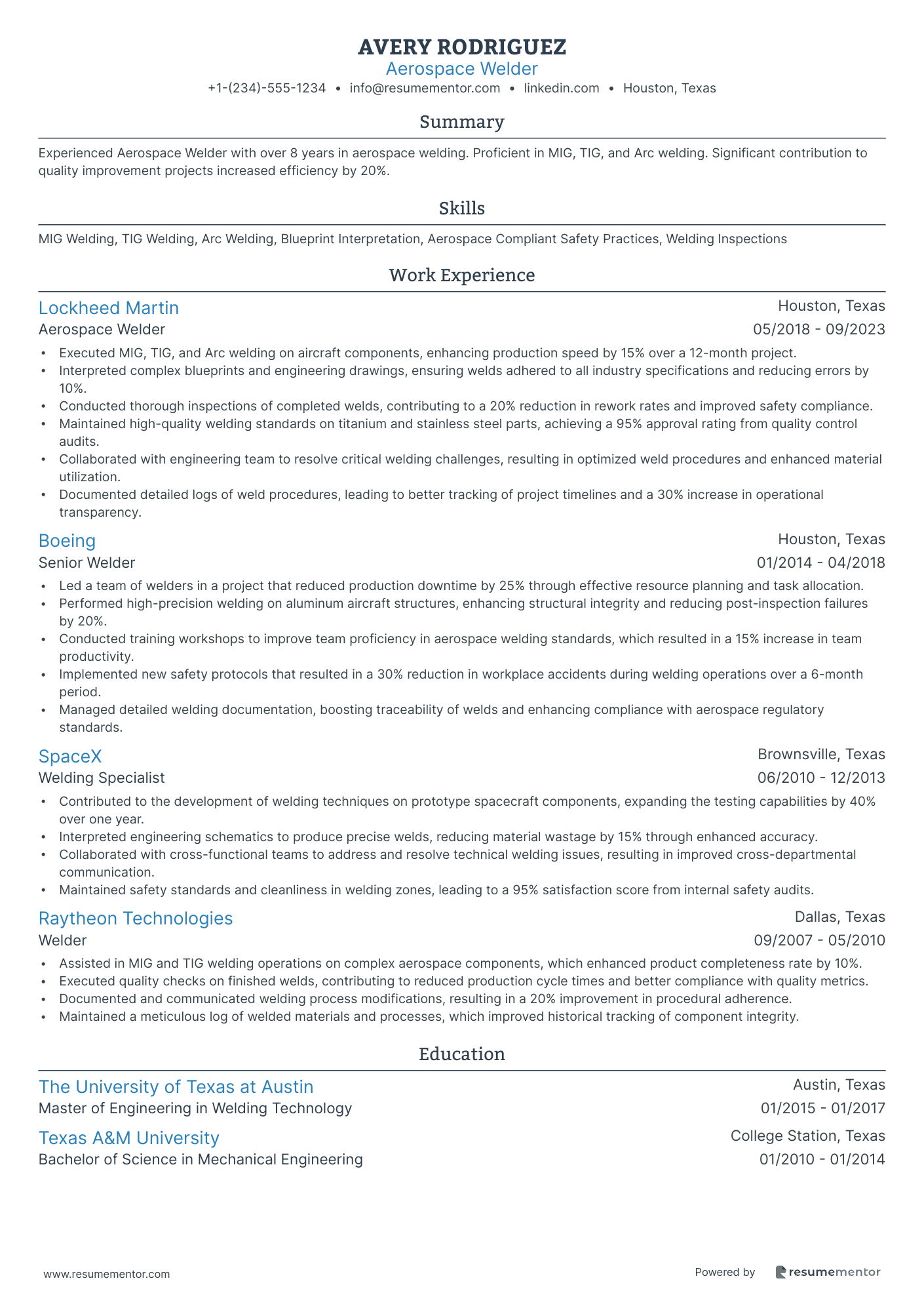

Structural Steel Welder resume sample

- •Spearheaded the welding operations for projects, achieving a 20% reduction in time without compromising quality.

- •Executed complex MIG, TIG, and Stick welding techniques ensuring adherence to project timelines and specifications.

- •Collaborated with engineers and fabricators to improve welding efficiency by introducing advanced workflow processes.

- •Trained a team of 10 junior welders, enhancing overall team productivity and performance by 25%.

- •Contributed to the successful completion of high-impact projects, resulting in a substantial client satisfaction rating.

- •Implemented robust safety protocols, maintaining a zero-incident safety record over three consecutive years.

- •Performed over 500 welding operations on structural components, improving project turnover rates by 30%.

- •Conducted thorough inspections of completed work, maintaining compliance with stringent safety regulations.

- •Utilized advanced welding techniques to enhance equipment longevity and reliability in challenging environments.

- •Developed and implemented a maintenance schedule for welding equipment, reducing downtime by 15%.

- •Report findings and improvements to stakeholders, contributing to process enhancements and project success.

- •Reduced material wastage by 10% by optimizing welding processes and utilizing waste-reducing techniques.

- •Provided technical guidance on welding projects, achieving client satisfaction scores of 95% consistently.

- •Oversaw the setup and calibration of welding equipment, ensuring optimal performance and safety standards.

- •Collaborated on large infrastructure projects, contributing to team efficiency and project innovation.

- •Completed precision welding tasks across multiple projects, boosting overall project completion rate by 20%.

- •Proactively identified project constraints and proposed efficient solutions to improve workflow processes.

- •Developed expertise in interpreting complex blueprints and designs, enhancing project quality outcomes.

- •Maintained precise welding documentation, contributing to project transparency and client reporting.

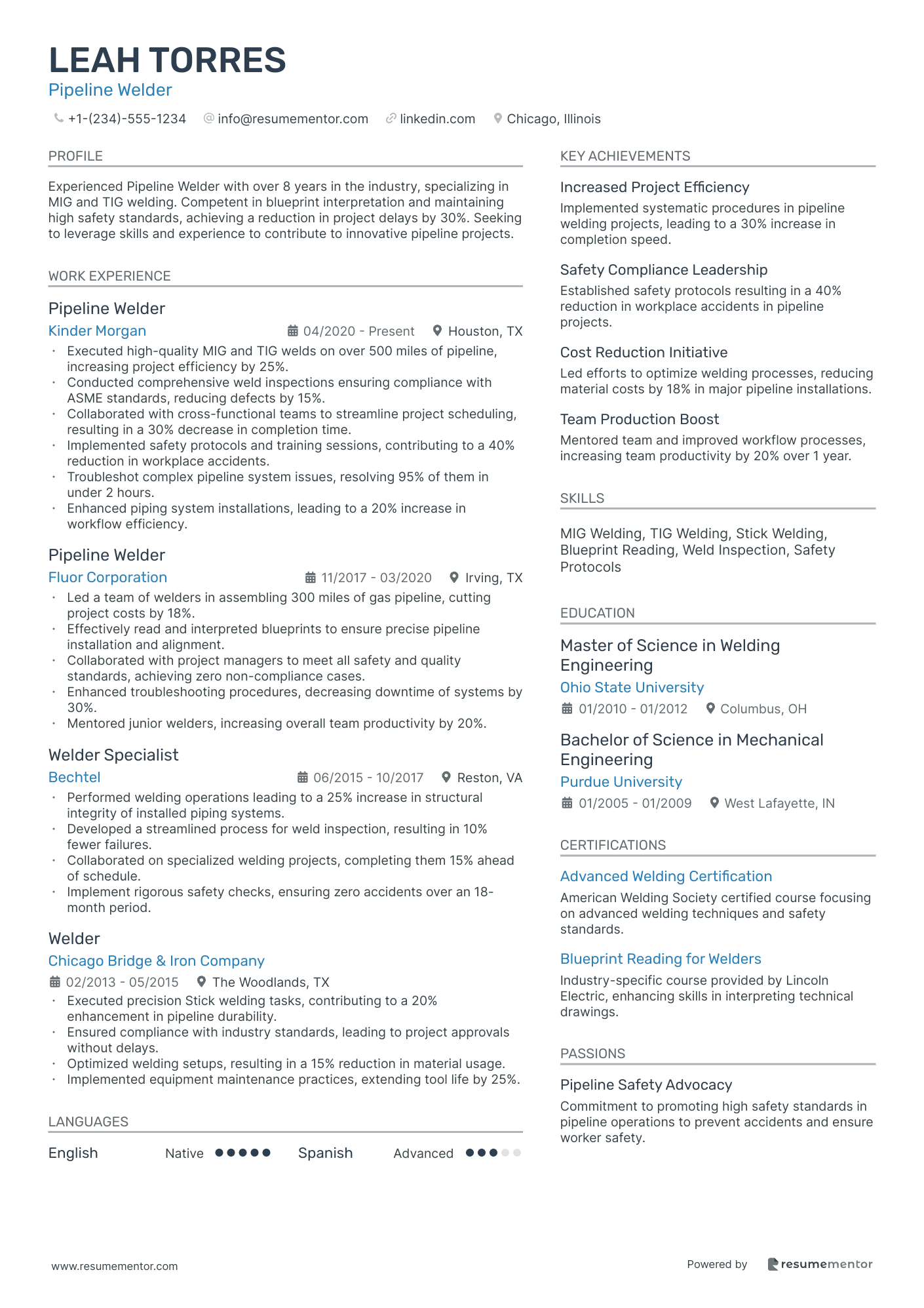

Pipeline Welder resume sample

- •Executed high-quality MIG and TIG welds on over 500 miles of pipeline, increasing project efficiency by 25%.

- •Conducted comprehensive weld inspections ensuring compliance with ASME standards, reducing defects by 15%.

- •Collaborated with cross-functional teams to streamline project scheduling, resulting in a 30% decrease in completion time.

- •Implemented safety protocols and training sessions, contributing to a 40% reduction in workplace accidents.

- •Troubleshot complex pipeline system issues, resolving 95% of them in under 2 hours.

- •Enhanced piping system installations, leading to a 20% increase in workflow efficiency.

- •Led a team of welders in assembling 300 miles of gas pipeline, cutting project costs by 18%.

- •Effectively read and interpreted blueprints to ensure precise pipeline installation and alignment.

- •Collaborated with project managers to meet all safety and quality standards, achieving zero non-compliance cases.

- •Enhanced troubleshooting procedures, decreasing downtime of systems by 30%.

- •Mentored junior welders, increasing overall team productivity by 20%.

- •Performed welding operations leading to a 25% increase in structural integrity of installed piping systems.

- •Developed a streamlined process for weld inspection, resulting in 10% fewer failures.

- •Collaborated on specialized welding projects, completing them 15% ahead of schedule.

- •Implement rigorous safety checks, ensuring zero accidents over an 18-month period.

- •Executed precision Stick welding tasks, contributing to a 20% enhancement in pipeline durability.

- •Ensured compliance with industry standards, leading to project approvals without delays.

- •Optimized welding setups, resulting in a 15% reduction in material usage.

- •Implemented equipment maintenance practices, extending tool life by 25%.

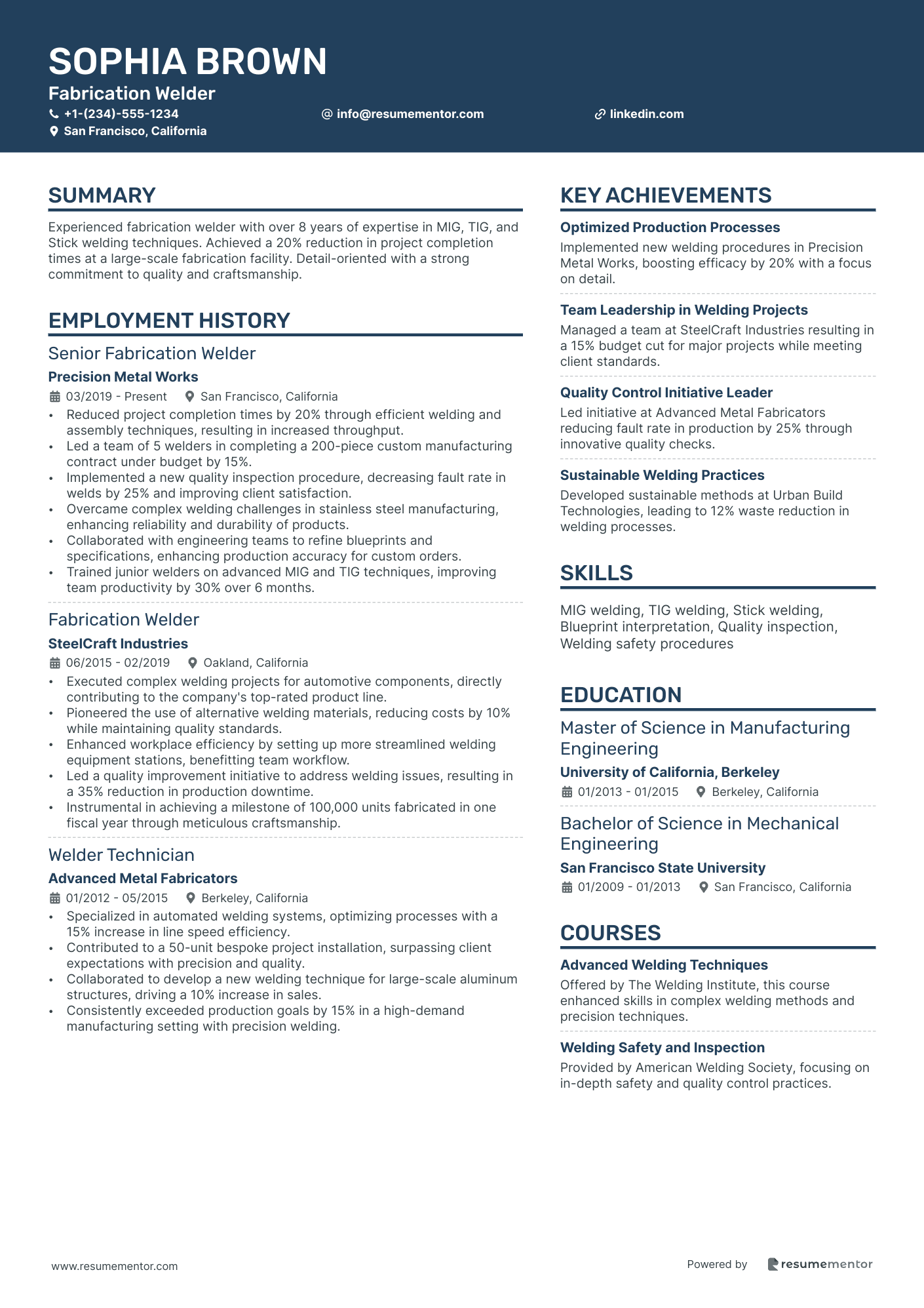

Fabrication Welder resume sample

- •Reduced project completion times by 20% through efficient welding and assembly techniques, resulting in increased throughput.

- •Led a team of 5 welders in completing a 200-piece custom manufacturing contract under budget by 15%.

- •Implemented a new quality inspection procedure, decreasing fault rate in welds by 25% and improving client satisfaction.

- •Overcame complex welding challenges in stainless steel manufacturing, enhancing reliability and durability of products.

- •Collaborated with engineering teams to refine blueprints and specifications, enhancing production accuracy for custom orders.

- •Trained junior welders on advanced MIG and TIG techniques, improving team productivity by 30% over 6 months.

- •Executed complex welding projects for automotive components, directly contributing to the company's top-rated product line.

- •Pioneered the use of alternative welding materials, reducing costs by 10% while maintaining quality standards.

- •Enhanced workplace efficiency by setting up more streamlined welding equipment stations, benefitting team workflow.

- •Led a quality improvement initiative to address welding issues, resulting in a 35% reduction in production downtime.

- •Instrumental in achieving a milestone of 100,000 units fabricated in one fiscal year through meticulous craftsmanship.

- •Specialized in automated welding systems, optimizing processes with a 15% increase in line speed efficiency.

- •Contributed to a 50-unit bespoke project installation, surpassing client expectations with precision and quality.

- •Collaborated to develop a new welding technique for large-scale aluminum structures, driving a 10% increase in sales.

- •Consistently exceeded production goals by 15% in a high-demand manufacturing setting with precision welding.

- •Supported senior welders in constructing and repairing metal fabrications on over 500 diverse projects.

- •Enhanced team efficiency by organizing workshops on welding safety procedures, boosting compliance by 30%.

- •Adapted quickly to varied welding techniques, contributing to a 25% enhancement in team versatility.

- •Played a key role in pioneering sustainable practices within metal welding operations, reducing waste by 12%.

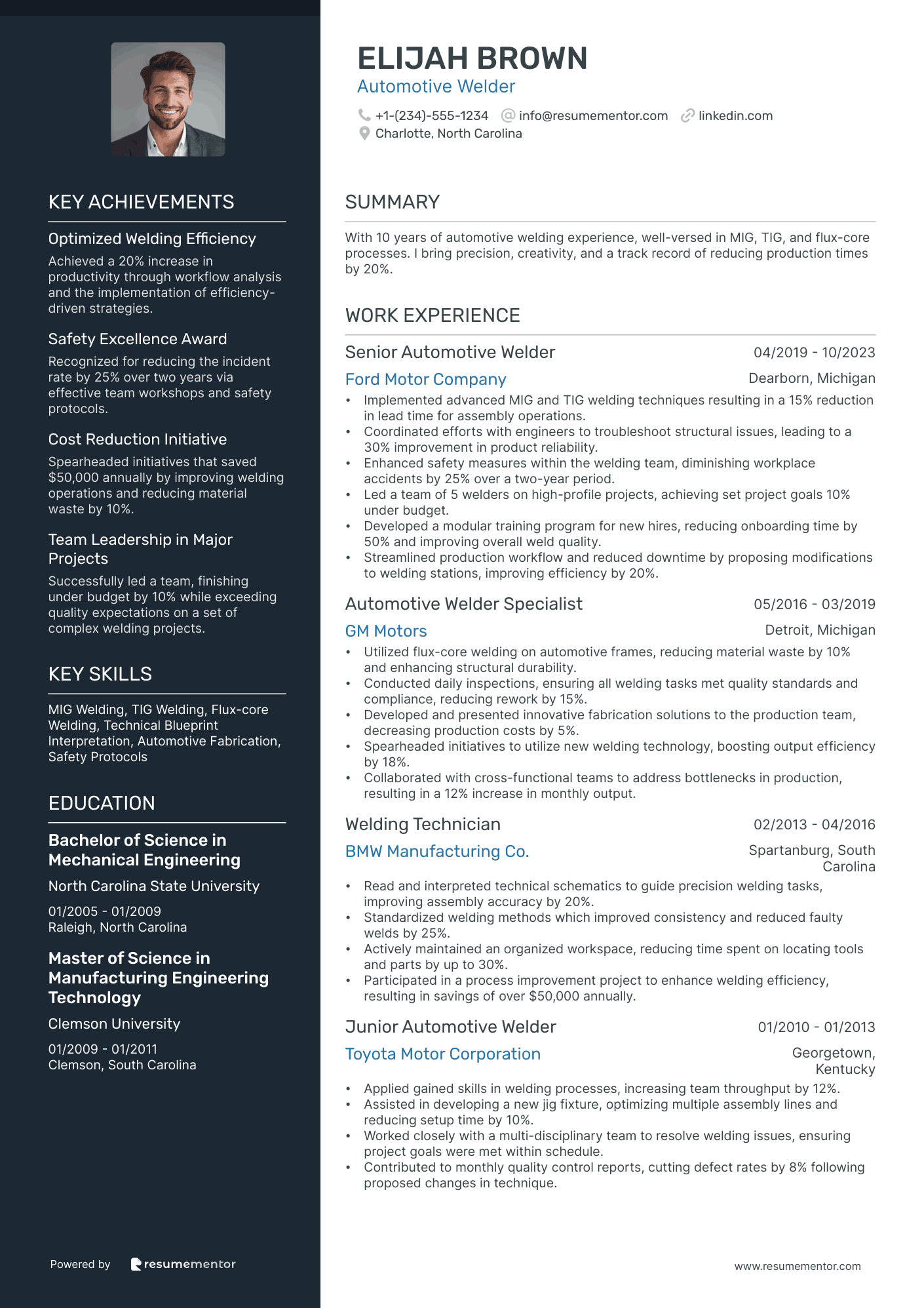

Automotive Welder resume sample

- •Implemented advanced MIG and TIG welding techniques resulting in a 15% reduction in lead time for assembly operations.

- •Coordinated efforts with engineers to troubleshoot structural issues, leading to a 30% improvement in product reliability.

- •Enhanced safety measures within the welding team, diminishing workplace accidents by 25% over a two-year period.

- •Led a team of 5 welders on high-profile projects, achieving set project goals 10% under budget.

- •Developed a modular training program for new hires, reducing onboarding time by 50% and improving overall weld quality.

- •Streamlined production workflow and reduced downtime by proposing modifications to welding stations, improving efficiency by 20%.

- •Utilized flux-core welding on automotive frames, reducing material waste by 10% and enhancing structural durability.

- •Conducted daily inspections, ensuring all welding tasks met quality standards and compliance, reducing rework by 15%.

- •Developed and presented innovative fabrication solutions to the production team, decreasing production costs by 5%.

- •Spearheaded initiatives to utilize new welding technology, boosting output efficiency by 18%.

- •Collaborated with cross-functional teams to address bottlenecks in production, resulting in a 12% increase in monthly output.

- •Read and interpreted technical schematics to guide precision welding tasks, improving assembly accuracy by 20%.

- •Standardized welding methods which improved consistency and reduced faulty welds by 25%.

- •Actively maintained an organized workspace, reducing time spent on locating tools and parts by up to 30%.

- •Participated in a process improvement project to enhance welding efficiency, resulting in savings of over $50,000 annually.

- •Applied gained skills in welding processes, increasing team throughput by 12%.

- •Assisted in developing a new jig fixture, optimizing multiple assembly lines and reducing setup time by 10%.

- •Worked closely with a multi-disciplinary team to resolve welding issues, ensuring project goals were met within schedule.

- •Contributed to monthly quality control reports, cutting defect rates by 8% following proposed changes in technique.

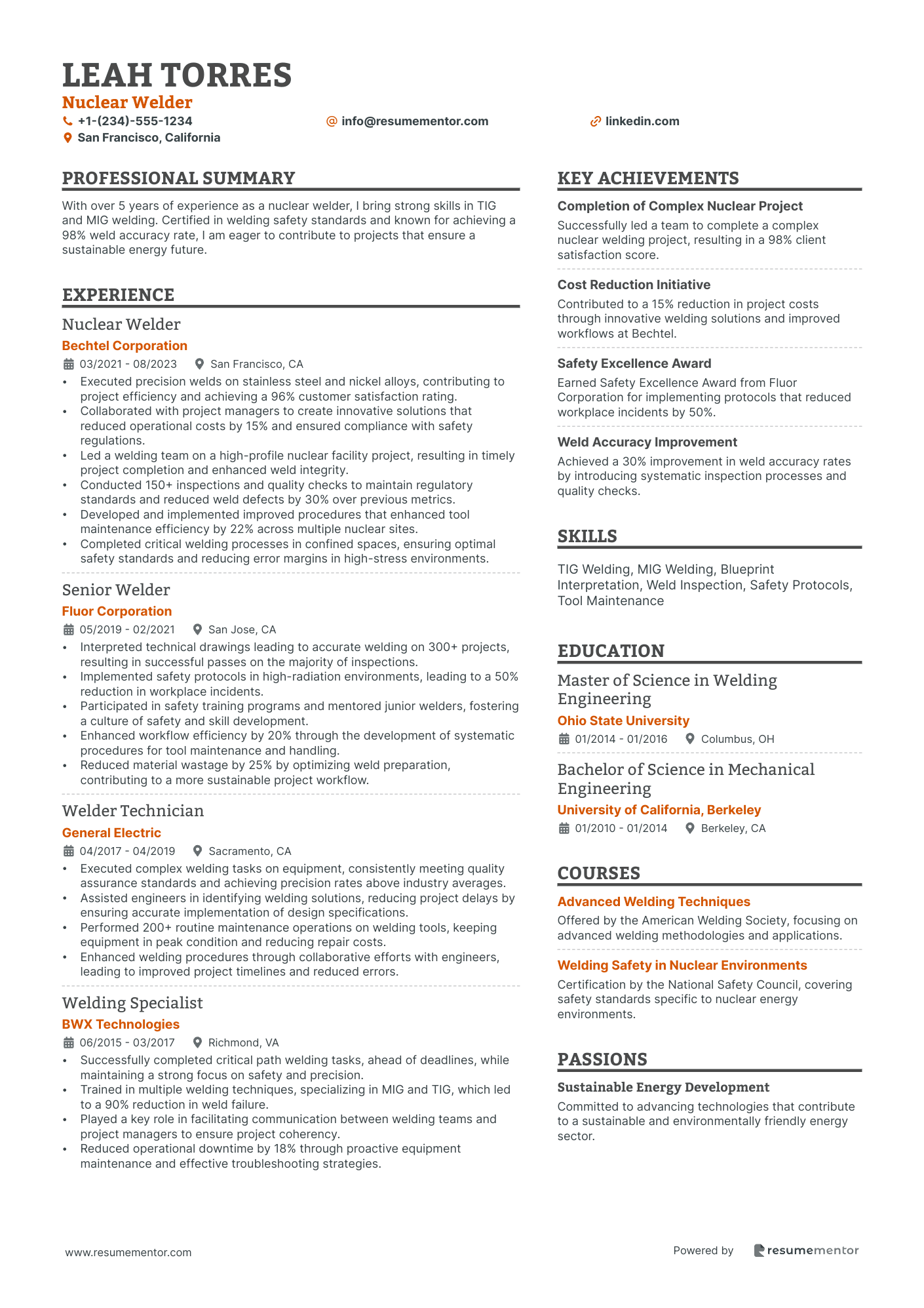

Nuclear Welder resume sample

- •Executed precision welds on stainless steel and nickel alloys, contributing to project efficiency and achieving a 96% customer satisfaction rating.

- •Collaborated with project managers to create innovative solutions that reduced operational costs by 15% and ensured compliance with safety regulations.

- •Led a welding team on a high-profile nuclear facility project, resulting in timely project completion and enhanced weld integrity.

- •Conducted 150+ inspections and quality checks to maintain regulatory standards and reduced weld defects by 30% over previous metrics.

- •Developed and implemented improved procedures that enhanced tool maintenance efficiency by 22% across multiple nuclear sites.

- •Completed critical welding processes in confined spaces, ensuring optimal safety standards and reducing error margins in high-stress environments.

- •Interpreted technical drawings leading to accurate welding on 300+ projects, resulting in successful passes on the majority of inspections.

- •Implemented safety protocols in high-radiation environments, leading to a 50% reduction in workplace incidents.

- •Participated in safety training programs and mentored junior welders, fostering a culture of safety and skill development.

- •Enhanced workflow efficiency by 20% through the development of systematic procedures for tool maintenance and handling.

- •Reduced material wastage by 25% by optimizing weld preparation, contributing to a more sustainable project workflow.

- •Executed complex welding tasks on equipment, consistently meeting quality assurance standards and achieving precision rates above industry averages.

- •Assisted engineers in identifying welding solutions, reducing project delays by ensuring accurate implementation of design specifications.

- •Performed 200+ routine maintenance operations on welding tools, keeping equipment in peak condition and reducing repair costs.

- •Enhanced welding procedures through collaborative efforts with engineers, leading to improved project timelines and reduced errors.

- •Successfully completed critical path welding tasks, ahead of deadlines, while maintaining a strong focus on safety and precision.

- •Trained in multiple welding techniques, specializing in MIG and TIG, which led to a 90% reduction in weld failure.

- •Played a key role in facilitating communication between welding teams and project managers to ensure project coherency.

- •Reduced operational downtime by 18% through proactive equipment maintenance and effective troubleshooting strategies.

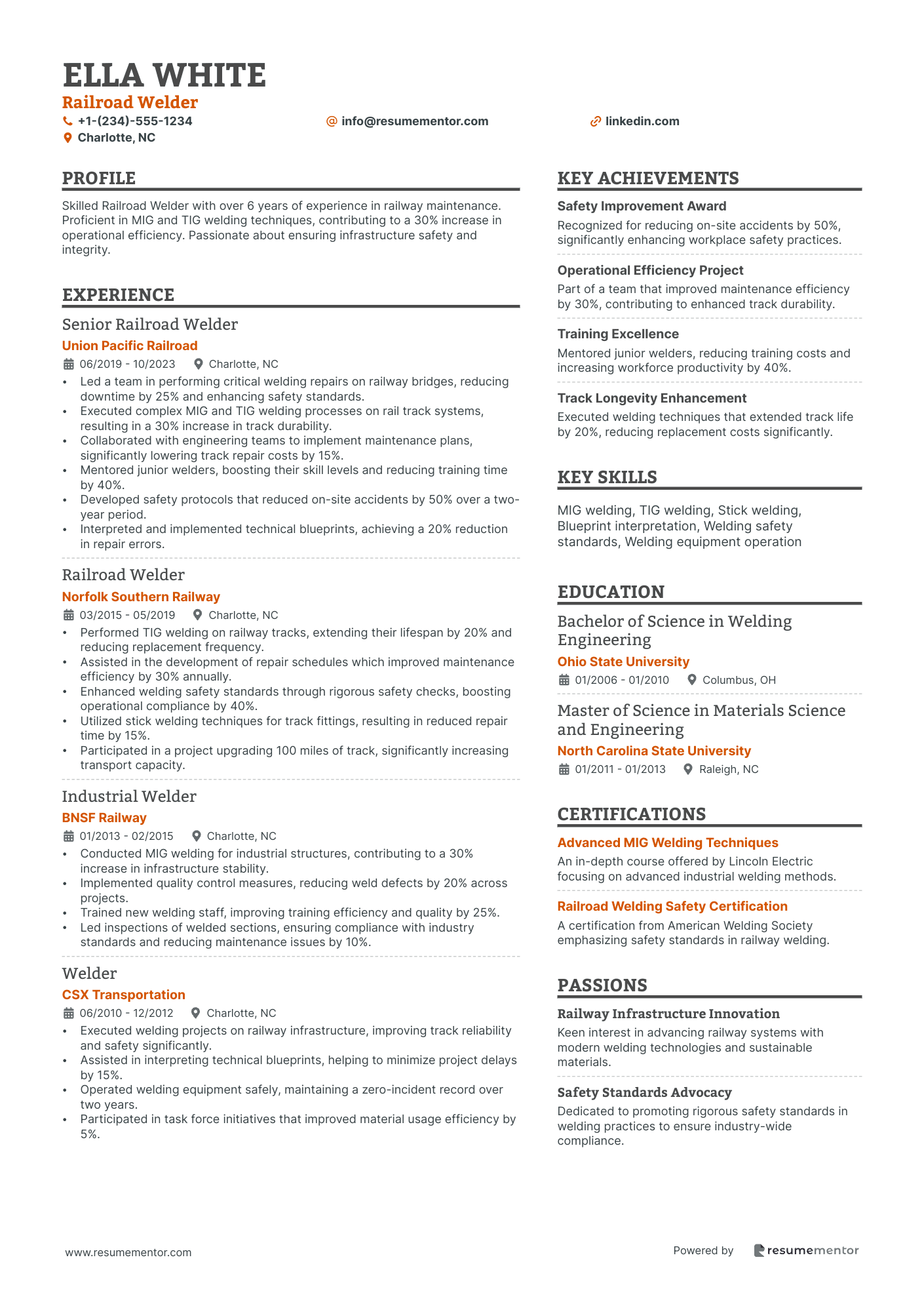

Railroad Welder resume sample

- •Led a team in performing critical welding repairs on railway bridges, reducing downtime by 25% and enhancing safety standards.

- •Executed complex MIG and TIG welding processes on rail track systems, resulting in a 30% increase in track durability.

- •Collaborated with engineering teams to implement maintenance plans, significantly lowering track repair costs by 15%.

- •Mentored junior welders, boosting their skill levels and reducing training time by 40%.

- •Developed safety protocols that reduced on-site accidents by 50% over a two-year period.

- •Interpreted and implemented technical blueprints, achieving a 20% reduction in repair errors.

- •Performed TIG welding on railway tracks, extending their lifespan by 20% and reducing replacement frequency.

- •Assisted in the development of repair schedules which improved maintenance efficiency by 30% annually.

- •Enhanced welding safety standards through rigorous safety checks, boosting operational compliance by 40%.

- •Utilized stick welding techniques for track fittings, resulting in reduced repair time by 15%.

- •Participated in a project upgrading 100 miles of track, significantly increasing transport capacity.

- •Conducted MIG welding for industrial structures, contributing to a 30% increase in infrastructure stability.

- •Implemented quality control measures, reducing weld defects by 20% across projects.

- •Trained new welding staff, improving training efficiency and quality by 25%.

- •Led inspections of welded sections, ensuring compliance with industry standards and reducing maintenance issues by 10%.

- •Executed welding projects on railway infrastructure, improving track reliability and safety significantly.

- •Assisted in interpreting technical blueprints, helping to minimize project delays by 15%.

- •Operated welding equipment safely, maintaining a zero-incident record over two years.

- •Participated in task force initiatives that improved material usage efficiency by 5%.

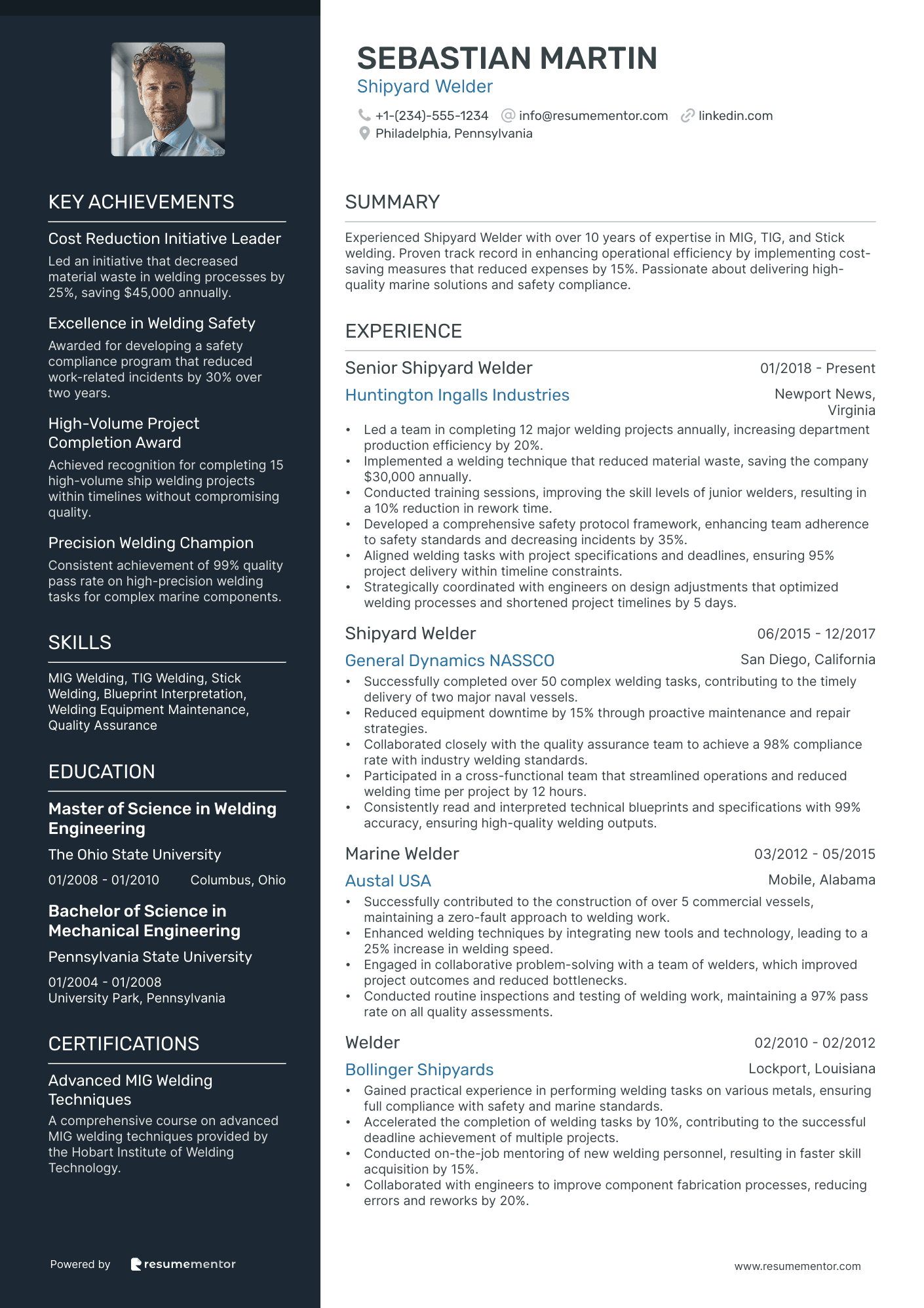

Shipyard Welder resume sample

- •Led a team in completing 12 major welding projects annually, increasing department production efficiency by 20%.

- •Implemented a welding technique that reduced material waste, saving the company $30,000 annually.

- •Conducted training sessions, improving the skill levels of junior welders, resulting in a 10% reduction in rework time.

- •Developed a comprehensive safety protocol framework, enhancing team adherence to safety standards and decreasing incidents by 35%.

- •Aligned welding tasks with project specifications and deadlines, ensuring 95% project delivery within timeline constraints.

- •Strategically coordinated with engineers on design adjustments that optimized welding processes and shortened project timelines by 5 days.

- •Successfully completed over 50 complex welding tasks, contributing to the timely delivery of two major naval vessels.

- •Reduced equipment downtime by 15% through proactive maintenance and repair strategies.

- •Collaborated closely with the quality assurance team to achieve a 98% compliance rate with industry welding standards.

- •Participated in a cross-functional team that streamlined operations and reduced welding time per project by 12 hours.

- •Consistently read and interpreted technical blueprints and specifications with 99% accuracy, ensuring high-quality welding outputs.

- •Successfully contributed to the construction of over 5 commercial vessels, maintaining a zero-fault approach to welding work.

- •Enhanced welding techniques by integrating new tools and technology, leading to a 25% increase in welding speed.

- •Engaged in collaborative problem-solving with a team of welders, which improved project outcomes and reduced bottlenecks.

- •Conducted routine inspections and testing of welding work, maintaining a 97% pass rate on all quality assessments.

- •Gained practical experience in performing welding tasks on various metals, ensuring full compliance with safety and marine standards.

- •Accelerated the completion of welding tasks by 10%, contributing to the successful deadline achievement of multiple projects.

- •Conducted on-the-job mentoring of new welding personnel, resulting in faster skill acquisition by 15%.

- •Collaborated with engineers to improve component fabrication processes, reducing errors and reworks by 20%.

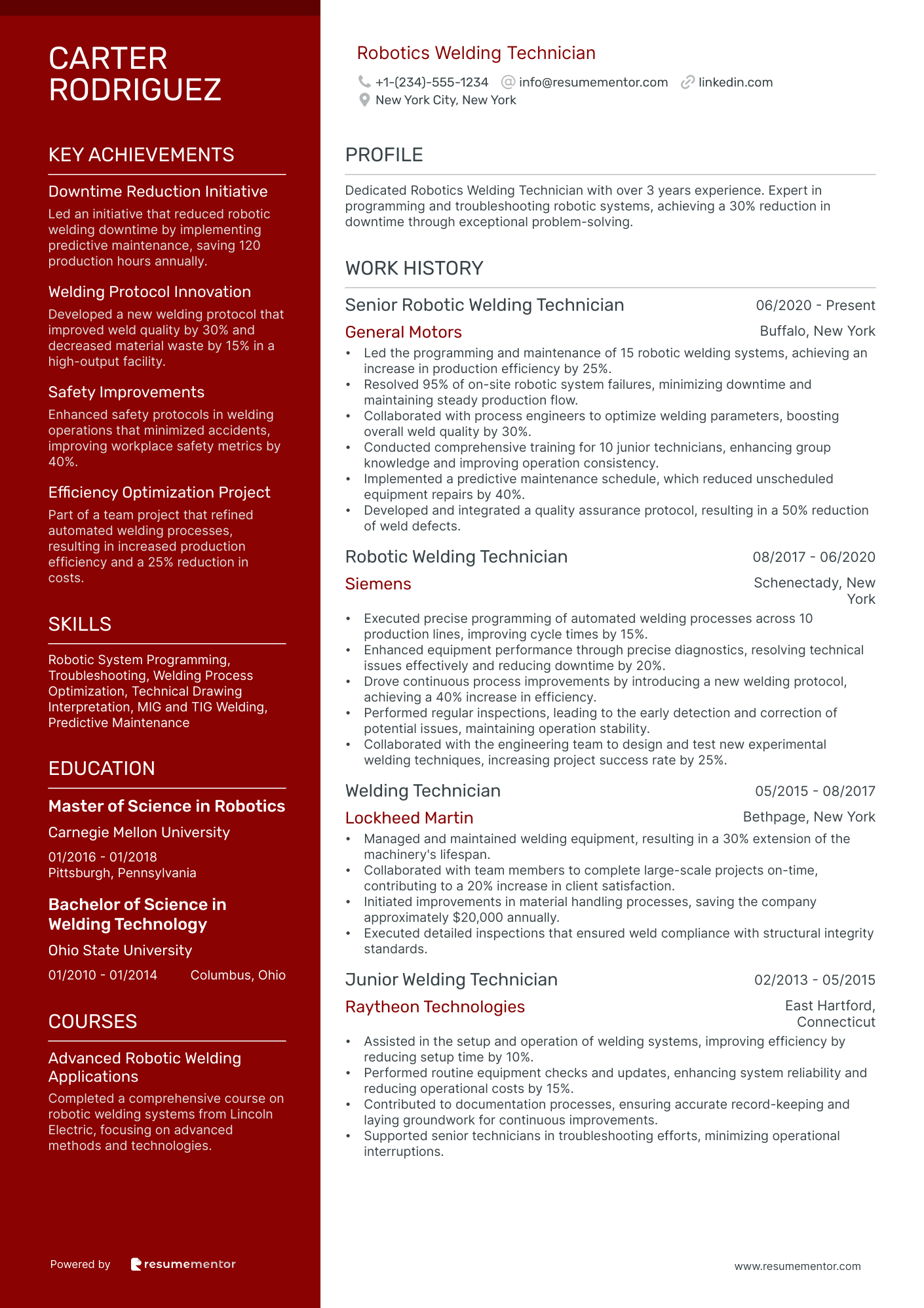

Robotics Welding Technician resume sample

- •Led the programming and maintenance of 15 robotic welding systems, achieving an increase in production efficiency by 25%.

- •Resolved 95% of on-site robotic system failures, minimizing downtime and maintaining steady production flow.

- •Collaborated with process engineers to optimize welding parameters, boosting overall weld quality by 30%.

- •Conducted comprehensive training for 10 junior technicians, enhancing group knowledge and improving operation consistency.

- •Implemented a predictive maintenance schedule, which reduced unscheduled equipment repairs by 40%.

- •Developed and integrated a quality assurance protocol, resulting in a 50% reduction of weld defects.

- •Executed precise programming of automated welding processes across 10 production lines, improving cycle times by 15%.

- •Enhanced equipment performance through precise diagnostics, resolving technical issues effectively and reducing downtime by 20%.

- •Drove continuous process improvements by introducing a new welding protocol, achieving a 40% increase in efficiency.

- •Performed regular inspections, leading to the early detection and correction of potential issues, maintaining operation stability.

- •Collaborated with the engineering team to design and test new experimental welding techniques, increasing project success rate by 25%.

- •Managed and maintained welding equipment, resulting in a 30% extension of the machinery's lifespan.

- •Collaborated with team members to complete large-scale projects on-time, contributing to a 20% increase in client satisfaction.

- •Initiated improvements in material handling processes, saving the company approximately $20,000 annually.

- •Executed detailed inspections that ensured weld compliance with structural integrity standards.

- •Assisted in the setup and operation of welding systems, improving efficiency by reducing setup time by 10%.

- •Performed routine equipment checks and updates, enhancing system reliability and reducing operational costs by 15%.

- •Contributed to documentation processes, ensuring accurate record-keeping and laying groundwork for continuous improvements.

- •Supported senior technicians in troubleshooting efforts, minimizing operational interruptions.

As a welder, your skills are the torch that cuts through challenges, turning raw materials into masterpieces. In the job market, showcasing these skills with clarity becomes essential, and that's where your resume comes into play. Just like a precise weld, your resume needs to come together seamlessly, with each part connecting smoothly to the next.

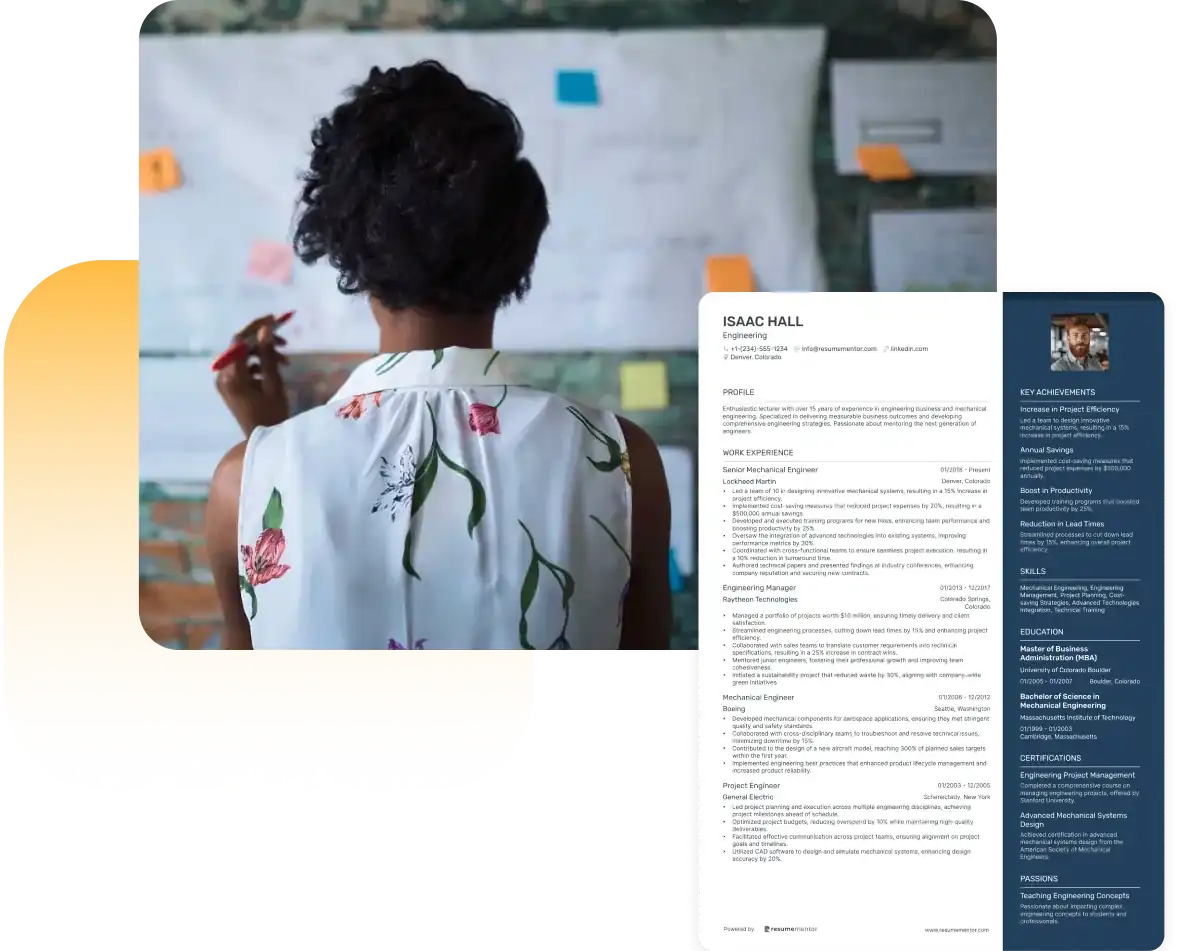

Choosing the right resume template is like setting the correct voltage on your welding machine—it’s crucial. A professional template gives your resume a clean, organized look, helping employers easily grasp your experience and welding expertise. Explore effective resume templates to get the structure that best highlights your career.

Crafting a resume might feel overwhelming, like packing years of hands-on experience and certifications into a single page. You might wonder how to effectively convey your tool-handling skills and safety knowledge. By approaching it step by step, much like you plan out a welding project, you can build a resume that’s as precise and durable as your strongest work.

Your resume should be more than just a list of jobs; it should narrate your career journey and development in the welding field. This narrative should reflect not only your welding techniques but also your ability to solve problems and adapt in dynamic environments. With the right storytelling, your resume can illuminate paths to new opportunities, giving you the competitive edge in the industry.

Key Takeaways

- Writing a welder resume is akin to assembling a precise weld, requiring a seamless integration of skills and experiences tailored to the job market.

- A clean, professional resume template, like setting the correct voltage on a welding machine, is crucial for effectively showcasing your expertise and making a strong impression.

- Your resume should narrate your welding career journey, highlighting not just job responsibilities, but also problem-solving abilities and adaptability to dynamic environments.

- Utilizing a chronological resume format is ideal for welders as it clearly highlights work history, growth, and dedication in the field over time.

- Including quantifiable achievements in your experience section can significantly enhance your resume by illustrating your expertise and competence to potential employers.

What to focus on when writing your welder resume

A welder resume should clearly communicate your welding skills and experience to a recruiter, effectively highlighting your expertise in various welding techniques while emphasizing your commitment to safety standards. This information reflects your ability to work both independently and as part of a team on diverse projects.

How to structure your welder resume

- Contact Information: Start with your full name, phone number, email address, and city/state. These details are crucial for potential employers to reach you, so ensure they are accurate. A professional email address creates a positive impression and ensures you come across as organized and approachable.

- Professional Summary: This is your chance to present a snapshot of your skills and experience—highlight how many years you’ve been in the field and the specific welding techniques, like MIG or TIG, that you excel in. A well-crafted summary can grab attention quickly and set the tone for the rest of your resume by highlighting your most impressive strengths.

- Skills: In this section, detail specific welding skills such as blueprint reading, metal fabrication, and your familiarity with welding codes. Include certifications like AWS Certified Welder to reinforce your qualifications. Prioritize the skills that align most closely with the job description you're targeting, ensuring your resume matches the employer's needs.

- Experience: Here, detail your relevant work history by listing company names, dates of employment, job titles, and key duties—emphasize your achievements, such as improving efficiency or completing complex projects, to showcase your impact. Use quantifiable metrics when possible to provide a clear picture of your contributions and verify your competence.

- Education: Include your educational background, noting the institution name, degrees earned, and any particularly relevant coursework or welding training programs. Mention any honors or distinctions, as these can further validate your dedication and expertise in welding.

- Certifications and Licenses: Listing your certifications, such as American Welding Society credentials, underscores your dedication to your craft and can strengthen your resume further. These credentials can set you apart from other candidates, proving your commitment to maintaining industry standards and improving your skills. To wrap up our focus on resume format—below we'll cover each section more in-depth and explore how to enhance each part effectively.

Which resume format to choose

Crafting the perfect welder resume is all about choosing the right elements to make a strong impression. For welders, a chronological format is ideal because it clearly presents your work history and demonstrates your experience in the field. This format helps potential employers see your growth and dedication over time.

When it comes to font choice, using modern options like Exo 2, Raleway, or Oswald ensures your resume is readable and contemporary. These fonts offer a refreshing alternative to older, overused fonts, helping your resume stand out while maintaining a professional appearance.

Saving your resume as a PDF is crucial. It preserves your formatting so that potential employers view your resume exactly as you intended, regardless of the device or software they use. This consistency is key to making a solid first impression.

Setting one-inch margins on all sides provides a clean, organized look that is easy on the eyes. It allows for enough white space to separate sections and make your text stand out, promoting a more pleasant reading experience for hiring managers.

Focusing on these elements—format, font, file type, and margins—ensures your welder resume is not only clear and easy to read but also presents you as a polished and professional candidate.

How to write a quantifiable resume experience section

In the welding field, a strong experience section on your resume can truly set you apart. Start with your most recent position and work backward, highlighting skills and achievements that align with the job you're targeting. Focus on specific roles that are relevant to welding and use job titles similar to those in the job ad. Tailoring your resume to each application by aligning your skills and experiences with the job description shows your attention to employer needs. Use powerful action verbs like "fabricated," "designed," "enhanced," and "executed" to convey your contributions effectively, demonstrating your impact with quantifiable achievements. Go back about 10-15 years or cover the last 3-5 relevant positions to keep your experience section concise and focused. This part of your resume serves as a testament to your expertise and competence, directly illustrating why you're a strong candidate.

- •Increased team productivity by 25% with new assembly methods.

- •Reduced material waste by 15% through improved processes.

- •Maintained a 98% compliance rate with industry standards.

- •Trained 10 junior welders, boosting team skills and performance.

Your experience section stands out because it directly addresses employer wants with clear, measurable achievements that underscore your abilities. Using action words grabs attention and the description highlights your leadership and impact in past roles. By aligning job titles with the job ad, you optimize your resume for both tracking systems and human readers, ensuring it's easily noticed. The concise bullet points effectively demonstrate your ability to improve productivity and ensure compliance, emphasizing your value to employers. Structuring in reverse order means your most recent and relevant experience is seen first, strengthening an employer's confidence in your current skills and contributions. This tailored and focused approach maximizes your chances of securing an interview.

Collaboration-Focused resume experience section

A collaboration-focused welder resume experience section should highlight instances when teamwork enhanced your performance. Begin by emphasizing projects where your welding skills complemented the efforts of others. Describe how working closely with team members allowed you to solve challenges, improve processes, or meet deadlines effectively. By showcasing how your collaborative efforts led to better results and smoother workflows, you underline your ability to work well with others.

Organize this information using a clear and straightforward format. Start with the dates and your job title, then list your achievements or responsibilities using bullet points. This format allows employers to quickly grasp your strengths in teamwork and communication. By providing specific examples, you illustrate your team-oriented skills, reinforcing how effectively you collaborate within a team setting.

Welder

ABC Manufacturing Co.

June 2020 - September 2023

- Worked with a team to complete welding projects on time, increasing output by 15%.

- Communicated effectively with engineers and other team members to solve design issues.

- Participated in team meetings to brainstorm and implement more efficient workflows.

- Helped train new team members in collaborative techniques to improve overall team performance.

Project-Focused resume experience section

A project-focused welder resume experience section should clearly showcase the projects you've participated in, underscoring your skills and achievements. You should start with the dates you worked, followed by your job title and the name of your workplace. This is immediately followed by a succinct description of each project's objective, providing employers with a thorough understanding of your role. Place an emphasis on accomplishments and moments where your skills truly made a difference, supplementing these points with numbers or statistics to add depth. Each bullet point should begin with an action verb, ensuring clarity and relevance to the welding field.

It's important to highlight tasks that show your ability to interpret blueprints, efficiently use welding equipment, solve complex problems, and collaborate within teams. Explaining any enhancements in safety measures or operational efficiency can draw a direct line to your proactive efforts. Make sure to emphasize how your contributions led to tangible impacts, such as meeting deadlines ahead of schedule or improving product quality. This approach helps employers envision how your documented past successes can bring value to their team.

Lead Welder

ABC Constructions

June 2019 - August 2022

- Collaborated with a team to fabricate and install over 500 steel columns for a commercial high-rise, finishing the project two weeks early.

- Implemented safety protocols that reduced workplace injuries by 20%, boosting team efficiency.

- Utilized MIG and TIG welding techniques to improve the quality and durability of structures.

- Monitored and maintained equipment to ensure it functioned correctly and minimized downtime.

Innovation-Focused resume experience section

An innovation-focused welder resume experience section should demonstrate how you’ve moved the needle in your field by introducing fresh ideas and achieving impactful results. Begin by showcasing roles where you've implemented changes that boosted performance, efficiency, or quality. Dive into specific achievements where you've pioneered new techniques or technologies that resulted in significant improvements. Your goal is to illustrate how your forward-thinking approach has led to tangible benefits such as enhanced safety, reduced costs, and increased productivity in your workplace.

To make your achievements stand out, use clear and concise bullet points that offer concrete examples. Each bullet should smoothly communicate the scope and positive outcomes of your actions. By using action-oriented language, you can add an engaging and proactive tone to your descriptions. Keep the narrative straightforward yet powerful to captivate potential employers. Emphasize not just what you achieved, but how these accomplishments brought about meaningful change and made a lasting impact.

Senior Welder

FutureTech Fabrications

March 2020 - Present

- Developed a new welding technique that cut material waste by 15%, saving over $10,000 each year.

- Introduced a safety protocol that reduced workplace accidents by 25%, boosting worker safety.

- Pioneered the use of advanced welding tools, boosting productivity by 30% for faster project completions.

- Worked with the design team to implement cutting-edge welding software, improving project precision and accuracy.

Achievement-Focused resume experience section

A welder-focused resume experience section should clearly highlight your standout achievements. Start by specifying the kind of work you did to give a foundational understanding. Then, detail the specific tasks and skills you used, underlining the methods that led to success. Using numbers helps illustrate the tangible impact you made, so be sure to quantify how you added value. Keep explanations concise and engaging, utilizing action verbs like "led," "reduced," or "improved" to clearly show your effectiveness.

Additionally, make sure to tailor your achievements to resonate with the job you're applying for, adjusting entries as needed across different applications. Each bullet point should focus on your strengths and results, making your accomplishments easy to read and understand. This way, you can highlight not only your everyday responsibilities but also exceptional moments when you surpassed expectations to benefit your workplace.

Senior Welder

Precision Welding Inc.

June 2020 - Present

- Enabled a 15% reduction in production time by streamlining welding procedures.

- Developed safety protocols that led to zero accidents for a full year across the team.

- Trained five new team members on advanced welding techniques, boosting overall team efficiency.

- Improved quality checks, decreasing defects by 10% in final products.

Write your welder resume summary section

A welder-focused resume summary should clearly communicate your skills and experience to make you stand out. This section is your chance to show who you are and the value you bring to a job. If you are an experienced welder, you can highlight your core skills, achievements, and unique attributes. Consider this example for a seasoned welder:

This summary draws attention because it pinpoints specific skills and achievements. Mentioning the types of welding you do and your focus on safety is appealing to employers. It also highlights important traits like teamwork, attention to detail, and the ability to read blueprints, vital for welding roles. If you're just starting, focus on your ambitions and willingness to learn. Here's an example for a beginner welder:

[here was the JSON object 2]

This approach works because it highlights your eagerness to grow and recent training, traits that attract employers looking for motivated candidates. It's important to grasp the difference between a resume summary and other sections. While a summary highlights your career achievements, an objective focuses on your career goals. A profile offers more detailed insights, and a summary of qualifications is a bullet list of key skills and achievements. Each serves a specific purpose, allowing you to showcase your career status effectively. Tailor your summary to align with your experience level for the best impact.

Listing your welder skills on your resume

A skill-focused welder resume skills section should effectively showcase both technical and interpersonal abilities to potential employers. When deciding how to present your skills, consider whether a standalone section or an integration within your experience and summary sections better highlights your strengths. While strengths and soft skills demonstrate your teamwork and communication abilities, hard skills like mastering specific welding techniques and equipment prove your technical expertise.

Including these skills and strengths not only highlights your qualifications but also acts as key phrases that catch the eye of employers and Applicant Tracking Systems (ATS). These keywords play a critical role in ensuring your resume stands out among many applicants.

Consider this example of a standalone skills section in JSON format:

The effectiveness of this example lies in its clear listing of industry-relevant skills. Highlighting welding techniques like MIG, TIG, and Arc Welding establishes your proficiency. Meanwhile, skills such as reading blueprints and following safety protocols reassure employers of your commitment to accuracy and safety in your work. Additionally, expertise in precision measurement and equipment maintenance showcases your attention to detail and ability to handle tools efficiently.

Best hard skills to feature on your welder resume

Your ability to master specific techniques and equipment is communicated through welder hard skills. These skills focus on the essential technical tasks needed for a welding job.

Hard Skills

- MIG Welding

- TIG Welding

- Arc Welding

- Resistance Welding

- Plasma Cutting

- Oxy-fuel Cutting

- Fabrication Techniques

- Blueprint Reading

- Metal Identification

- Welding Inspection

- Pipe Welding

- Underwater Welding

- CNC Machining

- Grinding and Finishing

- Safety Regulations Compliance

Best soft skills to feature on your welder resume

Your adaptability and interaction with others are highlighted through welder soft skills, emphasizing how you manage tasks and relationships within different work environments.

Soft Skills

- Attention to Detail

- Problem-solving

- Communication

- Teamwork

- Time Management

- Adaptability

- Patience

- Leadership

- Dependability

- Multitasking

- Stress Management

- Initiative

- Work Ethic

- Creativity

- Learning Ability

How to include your education on your resume

An education section is an important part of your resume, especially for a welder, because it showcases your qualifications and relevant training. Tailor this section to the job you are applying for, focusing on education and courses directly related to welding. Only include relevant education, leaving out anything not applicable to the position. If your GPA is noteworthy and above 3.0, you can include it to demonstrate your academic performance. When including cum laude honors, you can place it right after your degree. List your degree clearly, mentioning the field of study and institution.

Consider this incorrect example of an education section, which includes irrelevant information and lacks focus:

This improved example aligns better with a welding career:

- •Completed advanced MIG and TIG welding courses

The second example is effective because it highlights education crucial to welding. It demonstrates the candidate's focus on skills valued by employers in the field, includes additional pertinent training, and shows clear progression through the relevant degree.

How to include welder certificates on your resume

Including a certificates section in your welder resume is vital. This section showcases your qualifications and highlights your commitment to continuous learning. List the name of each certificate, include the date you earned it, and add the issuing organization to provide potential employers with full details.

Certification details can also be included in the header to immediately grab attention. For instance, you might write: "John Doe, Certified Welder, American Welding Society, 2021." This concise format quickly communicates your credentials.

A standalone certificates section offers a clear view of your professional qualifications. Here is an example:

This example is effective as it includes relevant certifications that demonstrate your expertise as a welder. The certifications are pertinent, enhancing your qualifications. Recognized organizations, such as the American Welding Society, increase your credibility with potential employers. Each certificate is displayed neatly, ensuring easy readability and understanding of your skills. Utilizing structured detail in your resume can significantly impact hiring decisions.

Extra sections to include on your welder resume

When creating a resume for a welder, it's essential to showcase both technical skills and unique personal attributes. A well-structured resume can make you stand out to employers, especially in a competitive field. Each section of your resume can highlight different strengths and aspects of your personality and work ethic.

- Language section — Highlight any additional languages you speak fluently as this can make you more versatile in diverse work environments.

- Hobbies and interests section — Share relevant hobbies like metalworking or DIY projects, which can demonstrate your passion and dedication to craftsmanship.

- Volunteer work section — Include volunteer projects that involve welding or community service to show your commitment to social responsibility and teamwork.

- Books section — List influential books related to welding, engineering, or self-improvement to highlight your commitment to ongoing learning and improvement.

In Conclusion

In conclusion, assembling a standout welder resume requires attention to detail and a structured approach. Just as the precision of a weld is crucial, so too is the clarity and organization of your resume. By strategically showcasing your skills, experience, and achievements, you highlight your readiness for advanced responsibilities. Tailoring each section—from contact information to certificates—ensures you communicate your expertise effectively to potential employers. Furthermore, crafting a descriptive professional summary can swiftly convey your value and set the tone for the document. The inclusion of quantifiable accomplishments strengthens your case as a candidate, showing tangible contributions in past roles.

Choosing the correct resume format and font helps maintain a polished, professional appearance, while saving your resume as a PDF preserves your efforts across devices. Accentuating both hard and soft skills underlines your technical prowess and teamwork abilities, vital in a field that thrives on collaboration. Not to be overlooked, your education and any relevant certifications are key sections that reinforce your qualifications and dedication to your craft. Also, consider adding extra sections like language fluencies, hobbies, or volunteer experiences to provide a fuller picture of your abilities and interests. Closing the resume loop, each aspect of your application should narrate your journey and potential in the welding industry, offering a comprehensive view that is both engaging and informative. With these tactics, your resume can stand as a well-crafted piece of your professional toolkit, paving the way for new career opportunities.

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2026. All rights reserved.

Made with love by people who care.