Production Manager Resume Examples

Jul 18, 2024

|

12 min read

Master the art of crafting your production manager resume with these simple steps—don’t let your career stage be left in the wings!

Rated by 348 people

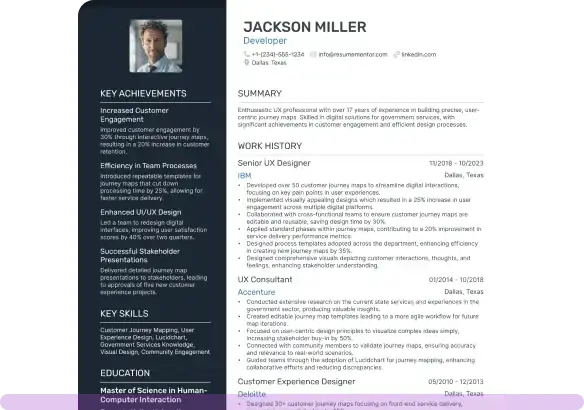

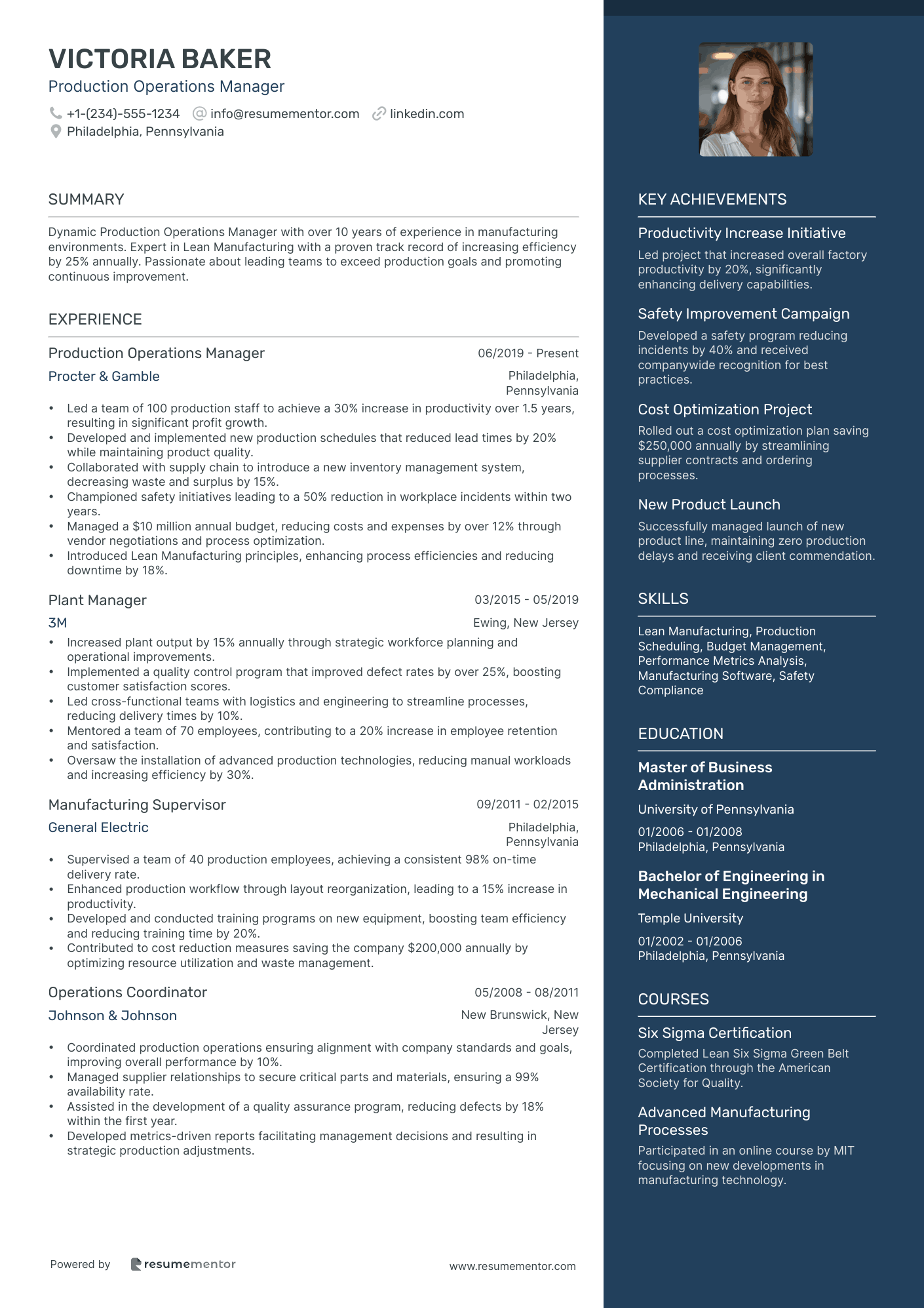

Production Operations Manager

Manufacturing Production Manager

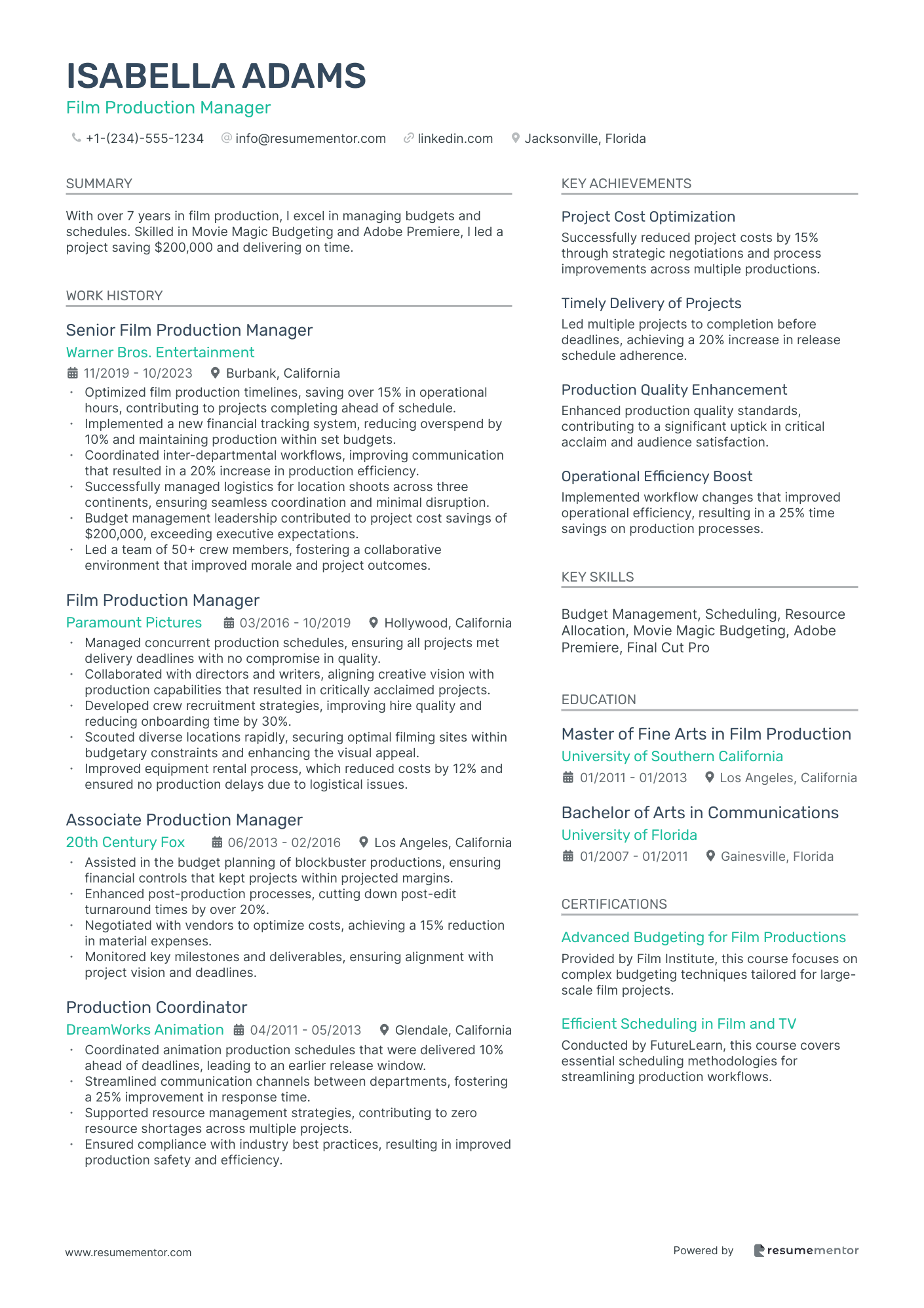

Film Production Manager

Pharmaceutical Production Manager

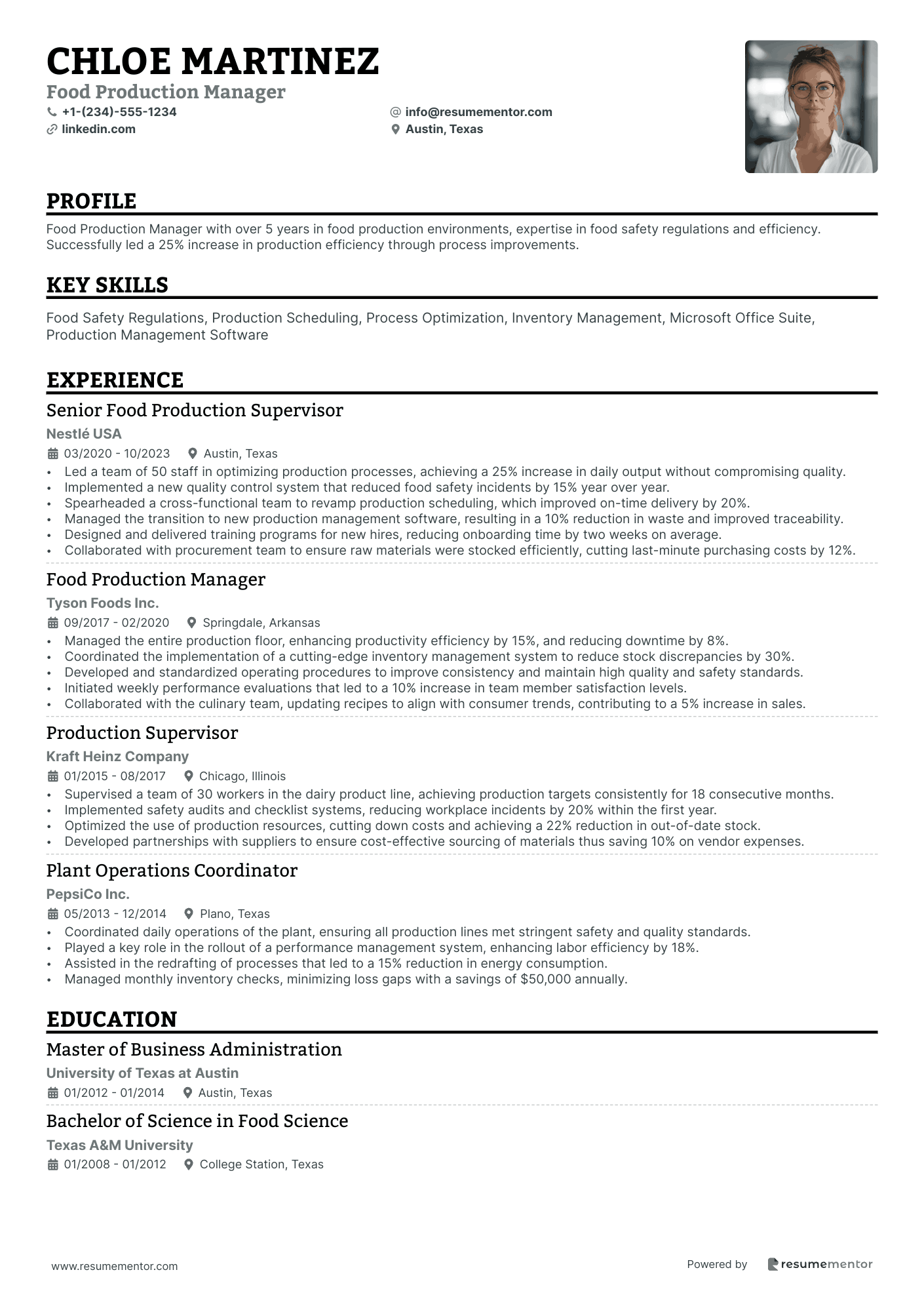

Food Production Manager

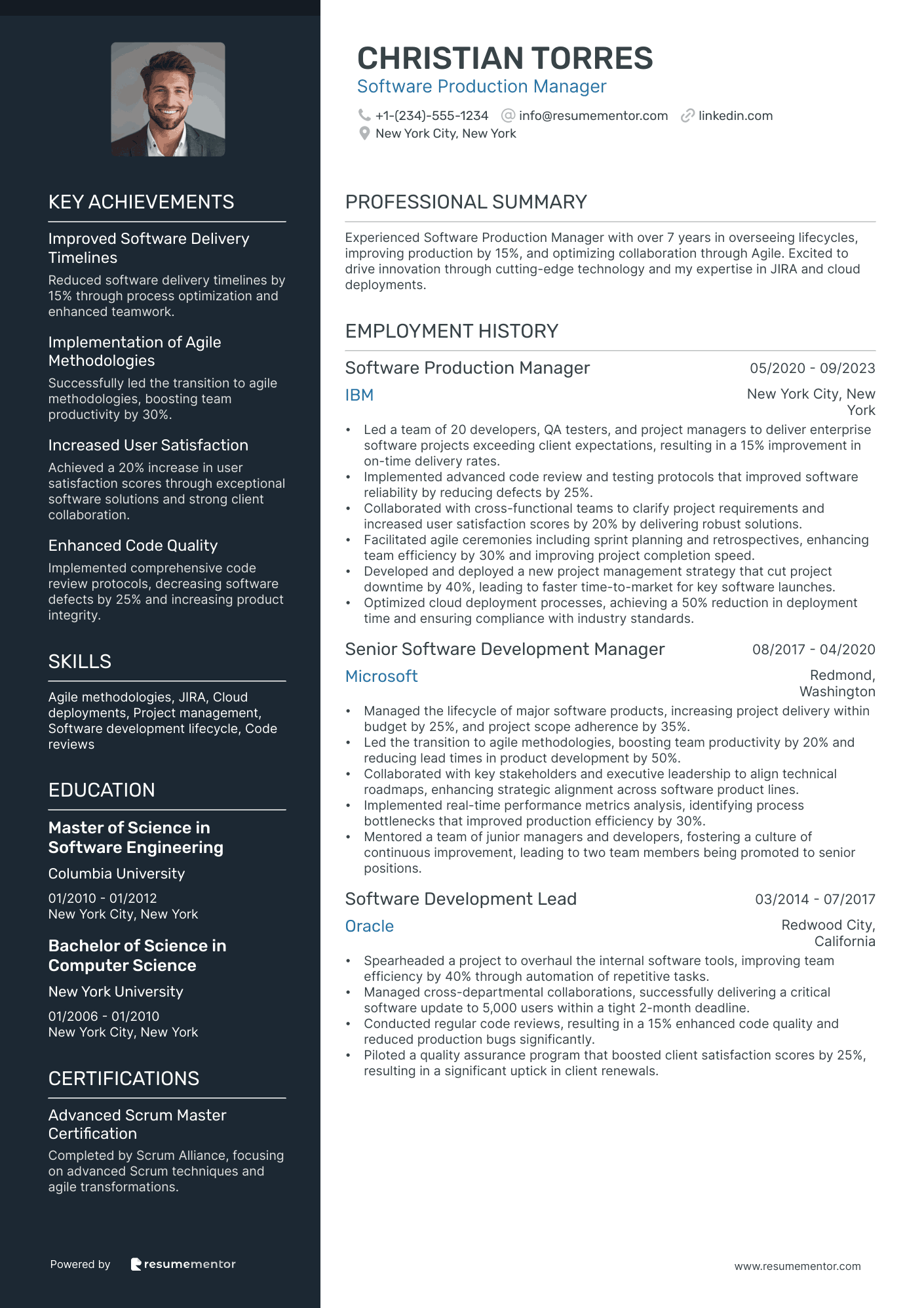

Software Production Manager

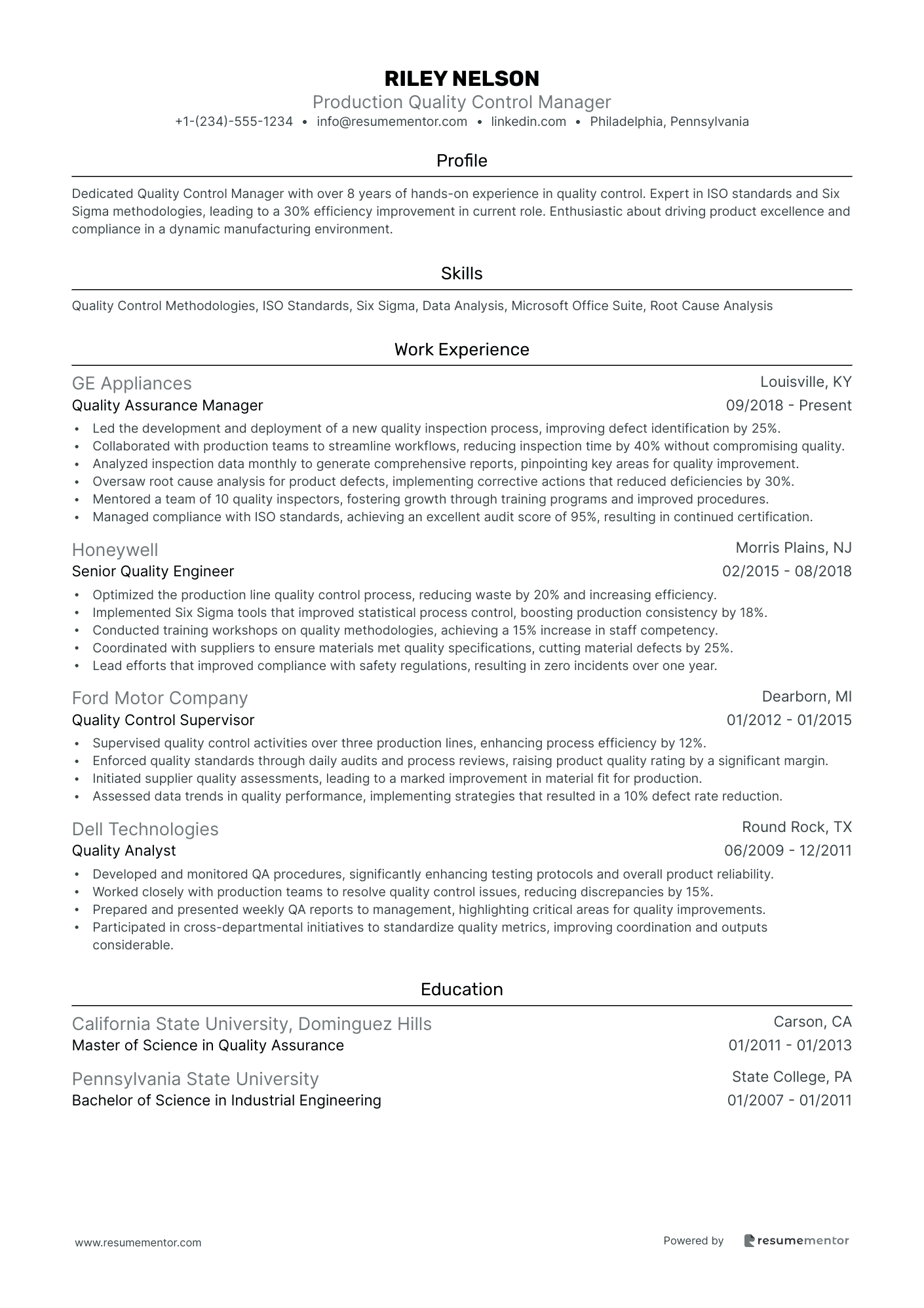

Production Quality Control Manager

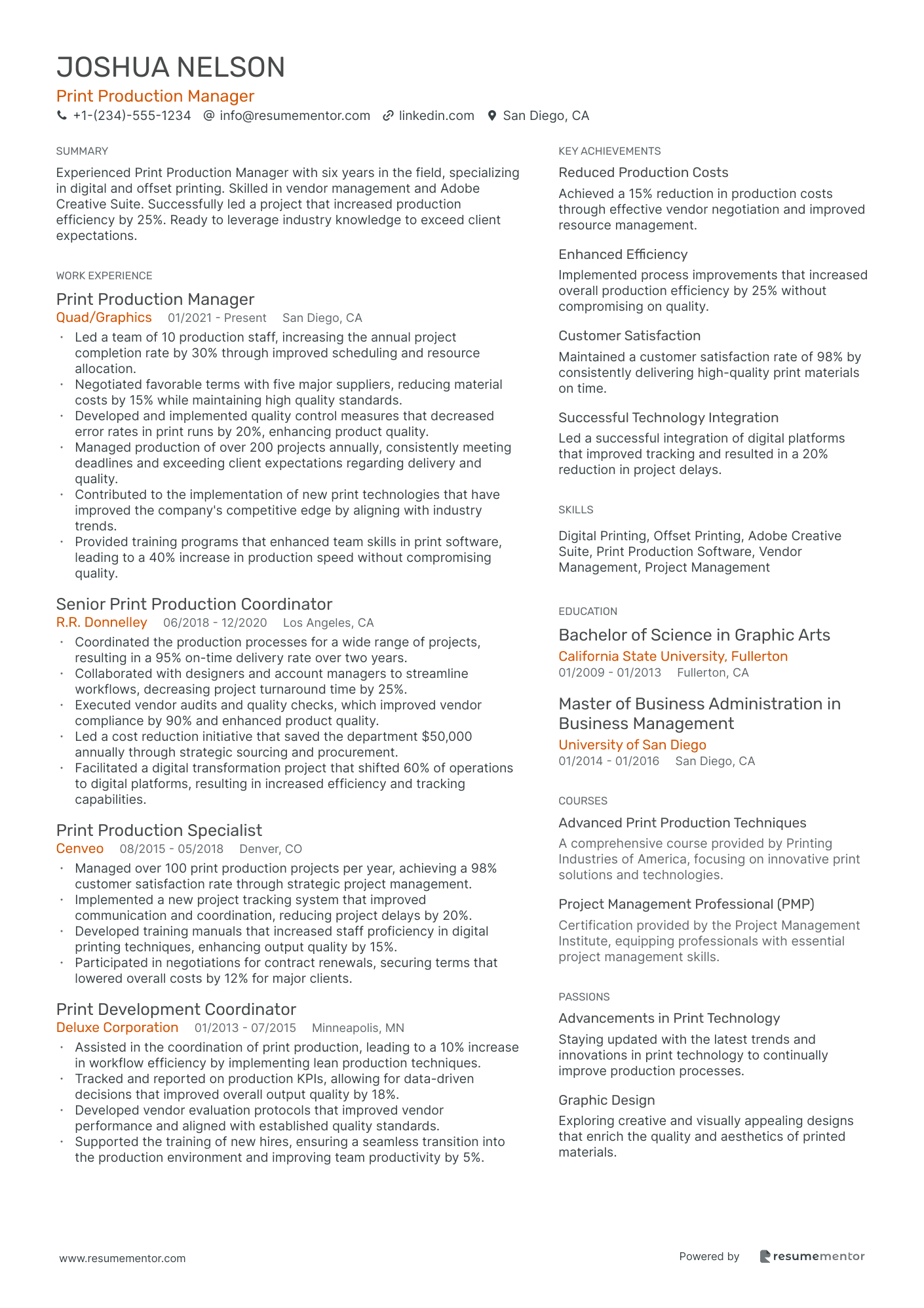

Print Production Manager

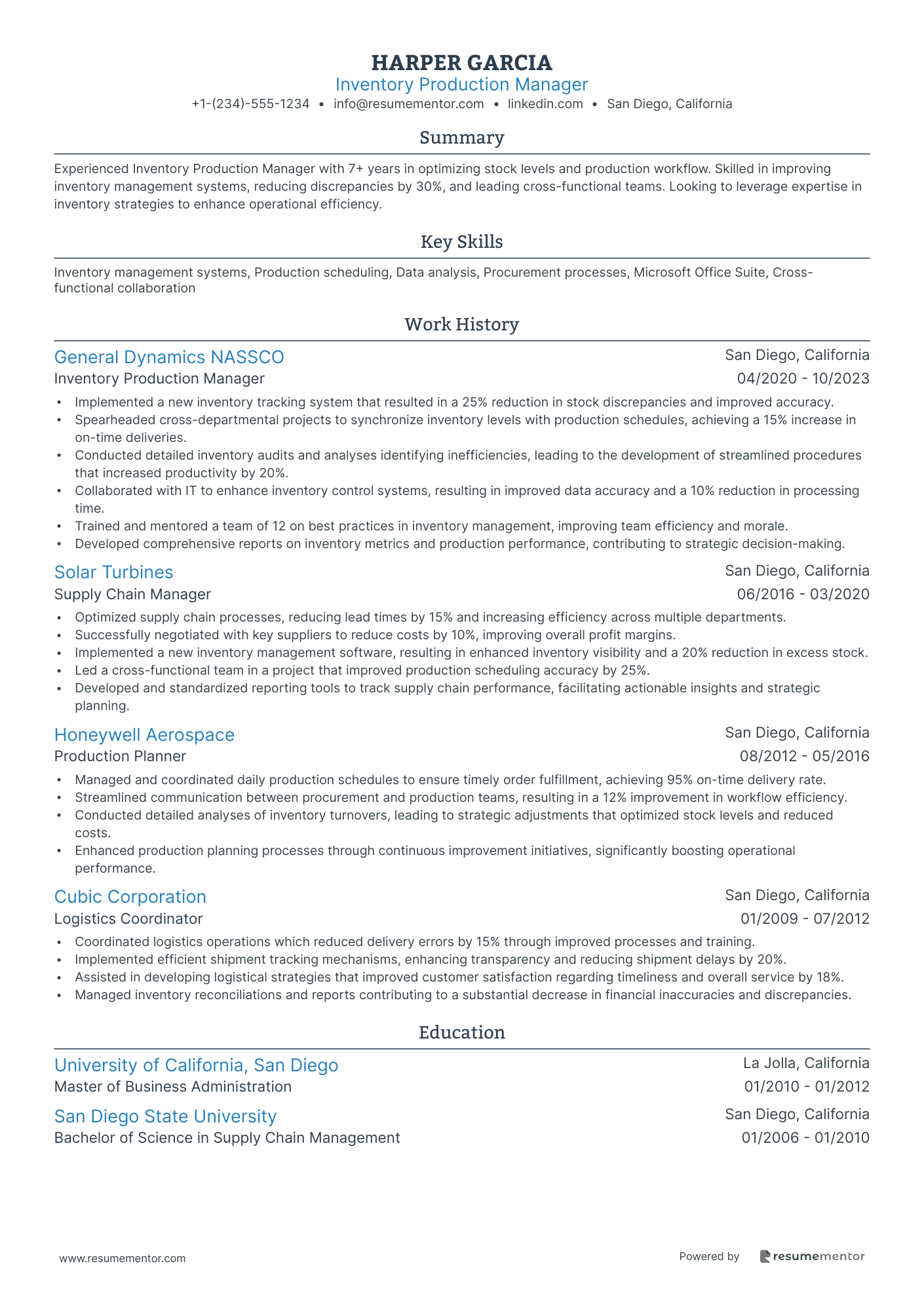

Inventory Production Manager

Automotive Production Manager

Production Operations Manager resume sample

- •Led a team of 100 production staff to achieve a 30% increase in productivity over 1.5 years, resulting in significant profit growth.

- •Developed and implemented new production schedules that reduced lead times by 20% while maintaining product quality.

- •Collaborated with supply chain to introduce a new inventory management system, decreasing waste and surplus by 15%.

- •Championed safety initiatives leading to a 50% reduction in workplace incidents within two years.

- •Managed a $10 million annual budget, reducing costs and expenses by over 12% through vendor negotiations and process optimization.

- •Introduced Lean Manufacturing principles, enhancing process efficiencies and reducing downtime by 18%.

- •Increased plant output by 15% annually through strategic workforce planning and operational improvements.

- •Implemented a quality control program that improved defect rates by over 25%, boosting customer satisfaction scores.

- •Led cross-functional teams with logistics and engineering to streamline processes, reducing delivery times by 10%.

- •Mentored a team of 70 employees, contributing to a 20% increase in employee retention and satisfaction.

- •Oversaw the installation of advanced production technologies, reducing manual workloads and increasing efficiency by 30%.

- •Supervised a team of 40 production employees, achieving a consistent 98% on-time delivery rate.

- •Enhanced production workflow through layout reorganization, leading to a 15% increase in productivity.

- •Developed and conducted training programs on new equipment, boosting team efficiency and reducing training time by 20%.

- •Contributed to cost reduction measures saving the company $200,000 annually by optimizing resource utilization and waste management.

- •Coordinated production operations ensuring alignment with company standards and goals, improving overall performance by 10%.

- •Managed supplier relationships to secure critical parts and materials, ensuring a 99% availability rate.

- •Assisted in the development of a quality assurance program, reducing defects by 18% within the first year.

- •Developed metrics-driven reports facilitating management decisions and resulting in strategic production adjustments.

Manufacturing Production Manager resume sample

- •Led a team of 50+ employees, achieving a 20% increase in production efficiency through strategic process optimization and staff training programs.

- •Implemented advanced scheduling software that reduced lead time by 15%, enhancing on-time delivery performance and customer satisfaction.

- •Drove continuous improvement initiatives by establishing KPIs, resulting in a 10% reduction in material waste and cost savings.

- •Collaborated with cross-functional teams in QA and maintenance to ensure product quality, leading to a 25% decrease in defects.

- •Championed safety protocols and conducted regular training, achieving a milestone of 500 days without an accident.

- •Orchestrated a sustainability project that lowered energy consumption by 12%, supporting corporate environmental goals.

- •Supervised and mentored a diverse team of 30 employees, improving production output by 18% through targeted training sessions.

- •Streamlined production processes by implementing lean manufacturing techniques, reducing cycle time by 20%.

- •Collaborated with the supply chain and QA teams to ensure seamless operations, resulting in a 30% enhancement in product quality metrics.

- •Managed production schedules effectively, decreasing overtime costs by 25% while still meeting monthly production targets consistently.

- •Enhanced software integration for production tracking, improving real-time data accuracy by 15%.

- •Played a key role in a cross-functional team that launched a new product line, contributing to a 10% increase in annual revenue.

- •Improved process workflows, reducing operational costs by 8% while maintaining quality standards.

- •Conducted regular audits and process evaluations, identifying and resolving bottlenecks to enhance overall efficiency.

- •Utilized analytical tools to perform root-cause analysis, resolving recurring quality issues and decreasing rework by 15%.

- •Coordinated production schedules and resources effectively, leading to a 20% improvement in on-time manufacturing.

- •Worked closely with maintenance teams to reduce equipment downtime by 30%, supporting uninterrupted factory operations.

- •Assisted in implementing a new inventory management system that reduced material shortages by 10%, improving efficiency.

- •Developed a training program for new hires that boosted onboarding efficiency by 25%, enhancing workforce readiness.

Film Production Manager resume sample

- •Optimized film production timelines, saving over 15% in operational hours, contributing to projects completing ahead of schedule.

- •Implemented a new financial tracking system, reducing overspend by 10% and maintaining production within set budgets.

- •Coordinated inter-departmental workflows, improving communication that resulted in a 20% increase in production efficiency.

- •Successfully managed logistics for location shoots across three continents, ensuring seamless coordination and minimal disruption.

- •Budget management leadership contributed to project cost savings of $200,000, exceeding executive expectations.

- •Led a team of 50+ crew members, fostering a collaborative environment that improved morale and project outcomes.

- •Managed concurrent production schedules, ensuring all projects met delivery deadlines with no compromise in quality.

- •Collaborated with directors and writers, aligning creative vision with production capabilities that resulted in critically acclaimed projects.

- •Developed crew recruitment strategies, improving hire quality and reducing onboarding time by 30%.

- •Scouted diverse locations rapidly, securing optimal filming sites within budgetary constraints and enhancing the visual appeal.

- •Improved equipment rental process, which reduced costs by 12% and ensured no production delays due to logistical issues.

- •Assisted in the budget planning of blockbuster productions, ensuring financial controls that kept projects within projected margins.

- •Enhanced post-production processes, cutting down post-edit turnaround times by over 20%.

- •Negotiated with vendors to optimize costs, achieving a 15% reduction in material expenses.

- •Monitored key milestones and deliverables, ensuring alignment with project vision and deadlines.

- •Coordinated animation production schedules that were delivered 10% ahead of deadlines, leading to an earlier release window.

- •Streamlined communication channels between departments, fostering a 25% improvement in response time.

- •Supported resource management strategies, contributing to zero resource shortages across multiple projects.

- •Ensured compliance with industry best practices, resulting in improved production safety and efficiency.

Pharmaceutical Production Manager resume sample

- •Led a team of 25 professionals, improving production efficiency by 20% through strategic scheduling and process optimization.

- •Developed production schedules that resulted in meeting 98% of quarterly manufacturing targets across multiple lines.

- •Collaborated with Quality Assurance and Control to reduce defect rates by 15%, enhancing product quality and compliance.

- •Implemented a comprehensive staff training program, increasing staff proficiency in cGMP standards by 30%.

- •Streamlined manufacturing processes by automating key procedures, reducing production time by 25%.

- •Oversaw regulatory audits with a success rate of 100%, maintaining compliance with all industry standards and guidelines.

- •Managed the production shift of 50 staff, resulting in a 15% decrease in downtime.

- •Optimized the production line, resulting in a 10% reduction in production costs.

- •Coordinated with multiple departments, enhancing workflow efficiency by 18%.

- •Improved production line quality control processes, resulting in a 10% reduction in product recalls.

- •Increased employee retention by implementing innovative mentoring and training programs, ensuring career development for team members.

- •Supervised a team of 30 operators, achieving an 85% on-time delivery rate for all production orders.

- •Implemented a new material tracking system, reducing wastage by 22%.

- •Collaborated with engineering to design and test new equipment protocols, enhancing operational safety by 15%.

- •Facilitated cross-training initiatives, vastly improving team skill breadth and operational flexibility.

- •Assisted in developing a production workflow plan, resulting in a 12% increase in manufacturing output.

- •Coordinated daily operations, ensuring compliance with strict FDA regulations.

- •Successfully implemented a continuous improvement program that improved performance by 10%.

- •Monitored production metrics to drive consistent quality assurance and reduce defect rates by 8%.

Food Production Manager resume sample

- •Led a team of 50 staff in optimizing production processes, achieving a 25% increase in daily output without compromising quality.

- •Implemented a new quality control system that reduced food safety incidents by 15% year over year.

- •Spearheaded a cross-functional team to revamp production scheduling, which improved on-time delivery by 20%.

- •Managed the transition to new production management software, resulting in a 10% reduction in waste and improved traceability.

- •Designed and delivered training programs for new hires, reducing onboarding time by two weeks on average.

- •Collaborated with procurement team to ensure raw materials were stocked efficiently, cutting last-minute purchasing costs by 12%.

- •Managed the entire production floor, enhancing productivity efficiency by 15%, and reducing downtime by 8%.

- •Coordinated the implementation of a cutting-edge inventory management system to reduce stock discrepancies by 30%.

- •Developed and standardized operating procedures to improve consistency and maintain high quality and safety standards.

- •Initiated weekly performance evaluations that led to a 10% increase in team member satisfaction levels.

- •Collaborated with the culinary team, updating recipes to align with consumer trends, contributing to a 5% increase in sales.

- •Supervised a team of 30 workers in the dairy product line, achieving production targets consistently for 18 consecutive months.

- •Implemented safety audits and checklist systems, reducing workplace incidents by 20% within the first year.

- •Optimized the use of production resources, cutting down costs and achieving a 22% reduction in out-of-date stock.

- •Developed partnerships with suppliers to ensure cost-effective sourcing of materials thus saving 10% on vendor expenses.

- •Coordinated daily operations of the plant, ensuring all production lines met stringent safety and quality standards.

- •Played a key role in the rollout of a performance management system, enhancing labor efficiency by 18%.

- •Assisted in the redrafting of processes that led to a 15% reduction in energy consumption.

- •Managed monthly inventory checks, minimizing loss gaps with a savings of $50,000 annually.

Software Production Manager resume sample

- •Led a team of 20 developers, QA testers, and project managers to deliver enterprise software projects exceeding client expectations, resulting in a 15% improvement in on-time delivery rates.

- •Implemented advanced code review and testing protocols that improved software reliability by reducing defects by 25%.

- •Collaborated with cross-functional teams to clarify project requirements and increased user satisfaction scores by 20% by delivering robust solutions.

- •Facilitated agile ceremonies including sprint planning and retrospectives, enhancing team efficiency by 30% and improving project completion speed.

- •Developed and deployed a new project management strategy that cut project downtime by 40%, leading to faster time-to-market for key software launches.

- •Optimized cloud deployment processes, achieving a 50% reduction in deployment time and ensuring compliance with industry standards.

- •Managed the lifecycle of major software products, increasing project delivery within budget by 25%, and project scope adherence by 35%.

- •Led the transition to agile methodologies, boosting team productivity by 20% and reducing lead times in product development by 50%.

- •Collaborated with key stakeholders and executive leadership to align technical roadmaps, enhancing strategic alignment across software product lines.

- •Implemented real-time performance metrics analysis, identifying process bottlenecks that improved production efficiency by 30%.

- •Mentored a team of junior managers and developers, fostering a culture of continuous improvement, leading to two team members being promoted to senior positions.

- •Spearheaded a project to overhaul the internal software tools, improving team efficiency by 40% through automation of repetitive tasks.

- •Managed cross-departmental collaborations, successfully delivering a critical software update to 5,000 users within a tight 2-month deadline.

- •Conducted regular code reviews, resulting in a 15% enhanced code quality and reduced production bugs significantly.

- •Piloted a quality assurance program that boosted client satisfaction scores by 25%, resulting in a significant uptick in client renewals.

- •Oversaw project planning and execution for complex software systems, ensuring all projects were delivered on time and exceeded client expectations.

- •Coordinated the work of teams across multiple geographies to deliver international projects with reduced project costs by 20%.

- •Analyzed project risk, implemented mitigation strategies, and maintained a 95% success rate in project outcomes.

- •Utilized JIRA for project tracking which streamlined workflows and kept the team on schedule.

Production Quality Control Manager resume sample

- •Led the development and deployment of a new quality inspection process, improving defect identification by 25%.

- •Collaborated with production teams to streamline workflows, reducing inspection time by 40% without compromising quality.

- •Analyzed inspection data monthly to generate comprehensive reports, pinpointing key areas for quality improvement.

- •Oversaw root cause analysis for product defects, implementing corrective actions that reduced deficiencies by 30%.

- •Mentored a team of 10 quality inspectors, fostering growth through training programs and improved procedures.

- •Managed compliance with ISO standards, achieving an excellent audit score of 95%, resulting in continued certification.

- •Optimized the production line quality control process, reducing waste by 20% and increasing efficiency.

- •Implemented Six Sigma tools that improved statistical process control, boosting production consistency by 18%.

- •Conducted training workshops on quality methodologies, achieving a 15% increase in staff competency.

- •Coordinated with suppliers to ensure materials met quality specifications, cutting material defects by 25%.

- •Lead efforts that improved compliance with safety regulations, resulting in zero incidents over one year.

- •Supervised quality control activities over three production lines, enhancing process efficiency by 12%.

- •Enforced quality standards through daily audits and process reviews, raising product quality rating by a significant margin.

- •Initiated supplier quality assessments, leading to a marked improvement in material fit for production.

- •Assessed data trends in quality performance, implementing strategies that resulted in a 10% defect rate reduction.

- •Developed and monitored QA procedures, significantly enhancing testing protocols and overall product reliability.

- •Worked closely with production teams to resolve quality control issues, reducing discrepancies by 15%.

- •Prepared and presented weekly QA reports to management, highlighting critical areas for quality improvements.

- •Participated in cross-departmental initiatives to standardize quality metrics, improving coordination and outputs considerable.

Print Production Manager resume sample

- •Led a team of 10 production staff, increasing the annual project completion rate by 30% through improved scheduling and resource allocation.

- •Negotiated favorable terms with five major suppliers, reducing material costs by 15% while maintaining high quality standards.

- •Developed and implemented quality control measures that decreased error rates in print runs by 20%, enhancing product quality.

- •Managed production of over 200 projects annually, consistently meeting deadlines and exceeding client expectations regarding delivery and quality.

- •Contributed to the implementation of new print technologies that have improved the company's competitive edge by aligning with industry trends.

- •Provided training programs that enhanced team skills in print software, leading to a 40% increase in production speed without compromising quality.

- •Coordinated the production processes for a wide range of projects, resulting in a 95% on-time delivery rate over two years.

- •Collaborated with designers and account managers to streamline workflows, decreasing project turnaround time by 25%.

- •Executed vendor audits and quality checks, which improved vendor compliance by 90% and enhanced product quality.

- •Led a cost reduction initiative that saved the department $50,000 annually through strategic sourcing and procurement.

- •Facilitated a digital transformation project that shifted 60% of operations to digital platforms, resulting in increased efficiency and tracking capabilities.

- •Managed over 100 print production projects per year, achieving a 98% customer satisfaction rate through strategic project management.

- •Implemented a new project tracking system that improved communication and coordination, reducing project delays by 20%.

- •Developed training manuals that increased staff proficiency in digital printing techniques, enhancing output quality by 15%.

- •Participated in negotiations for contract renewals, securing terms that lowered overall costs by 12% for major clients.

- •Assisted in the coordination of print production, leading to a 10% increase in workflow efficiency by implementing lean production techniques.

- •Tracked and reported on production KPIs, allowing for data-driven decisions that improved overall output quality by 18%.

- •Developed vendor evaluation protocols that improved vendor performance and aligned with established quality standards.

- •Supported the training of new hires, ensuring a seamless transition into the production environment and improving team productivity by 5%.

Inventory Production Manager resume sample

- •Implemented a new inventory tracking system that resulted in a 25% reduction in stock discrepancies and improved accuracy.

- •Spearheaded cross-departmental projects to synchronize inventory levels with production schedules, achieving a 15% increase in on-time deliveries.

- •Conducted detailed inventory audits and analyses identifying inefficiencies, leading to the development of streamlined procedures that increased productivity by 20%.

- •Collaborated with IT to enhance inventory control systems, resulting in improved data accuracy and a 10% reduction in processing time.

- •Trained and mentored a team of 12 on best practices in inventory management, improving team efficiency and morale.

- •Developed comprehensive reports on inventory metrics and production performance, contributing to strategic decision-making.

- •Optimized supply chain processes, reducing lead times by 15% and increasing efficiency across multiple departments.

- •Successfully negotiated with key suppliers to reduce costs by 10%, improving overall profit margins.

- •Implemented a new inventory management software, resulting in enhanced inventory visibility and a 20% reduction in excess stock.

- •Led a cross-functional team in a project that improved production scheduling accuracy by 25%.

- •Developed and standardized reporting tools to track supply chain performance, facilitating actionable insights and strategic planning.

- •Managed and coordinated daily production schedules to ensure timely order fulfillment, achieving 95% on-time delivery rate.

- •Streamlined communication between procurement and production teams, resulting in a 12% improvement in workflow efficiency.

- •Conducted detailed analyses of inventory turnovers, leading to strategic adjustments that optimized stock levels and reduced costs.

- •Enhanced production planning processes through continuous improvement initiatives, significantly boosting operational performance.

- •Coordinated logistics operations which reduced delivery errors by 15% through improved processes and training.

- •Implemented efficient shipment tracking mechanisms, enhancing transparency and reducing shipment delays by 20%.

- •Assisted in developing logistical strategies that improved customer satisfaction regarding timeliness and overall service by 18%.

- •Managed inventory reconciliations and reports contributing to a substantial decrease in financial inaccuracies and discrepancies.

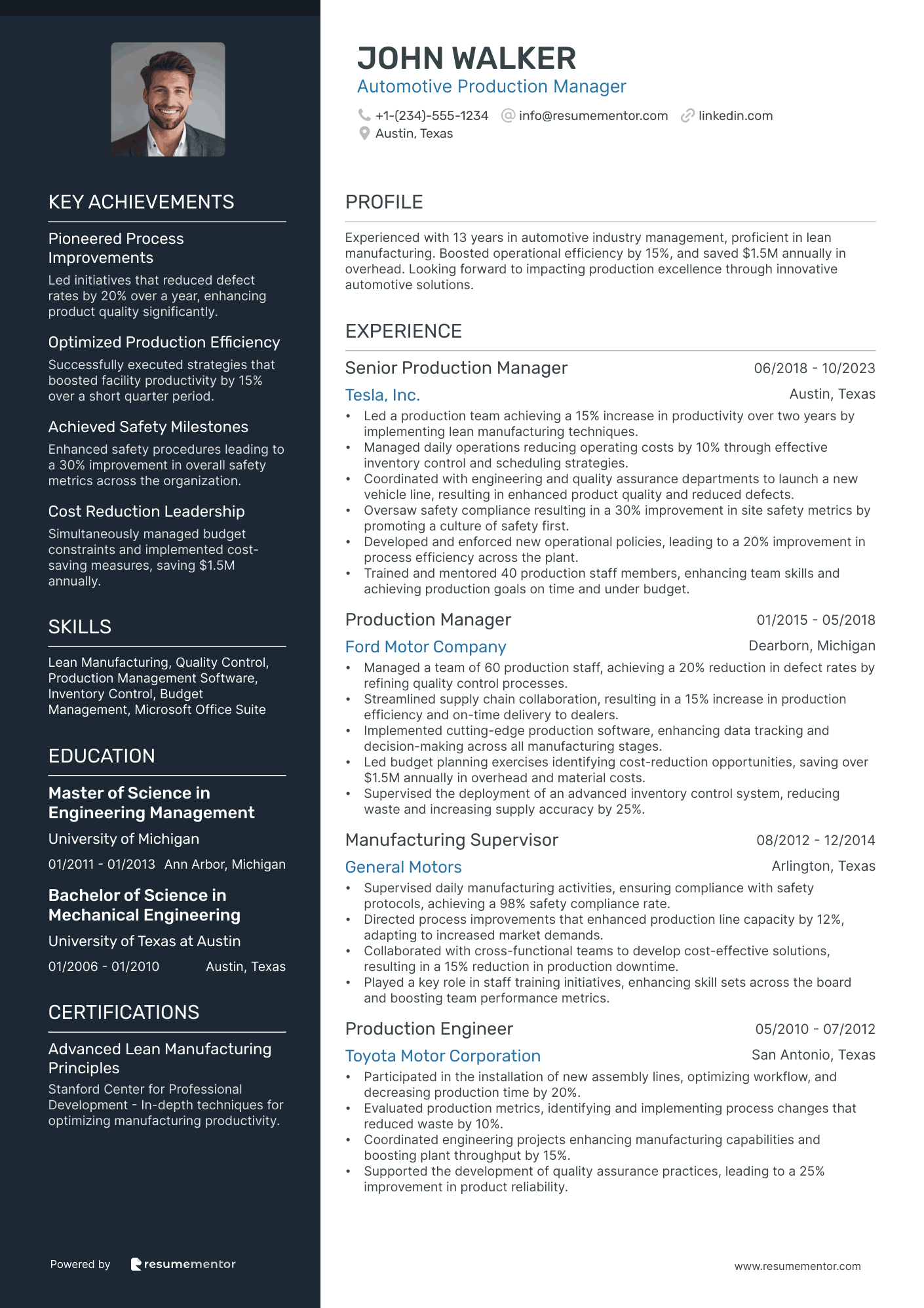

Automotive Production Manager resume sample

- •Led a production team achieving a 15% increase in productivity over two years by implementing lean manufacturing techniques.

- •Managed daily operations reducing operating costs by 10% through effective inventory control and scheduling strategies.

- •Coordinated with engineering and quality assurance departments to launch a new vehicle line, resulting in enhanced product quality and reduced defects.

- •Oversaw safety compliance resulting in a 30% improvement in site safety metrics by promoting a culture of safety first.

- •Developed and enforced new operational policies, leading to a 20% improvement in process efficiency across the plant.

- •Trained and mentored 40 production staff members, enhancing team skills and achieving production goals on time and under budget.

- •Managed a team of 60 production staff, achieving a 20% reduction in defect rates by refining quality control processes.

- •Streamlined supply chain collaboration, resulting in a 15% increase in production efficiency and on-time delivery to dealers.

- •Implemented cutting-edge production software, enhancing data tracking and decision-making across all manufacturing stages.

- •Led budget planning exercises identifying cost-reduction opportunities, saving over $1.5M annually in overhead and material costs.

- •Supervised the deployment of an advanced inventory control system, reducing waste and increasing supply accuracy by 25%.

- •Supervised daily manufacturing activities, ensuring compliance with safety protocols, achieving a 98% safety compliance rate.

- •Directed process improvements that enhanced production line capacity by 12%, adapting to increased market demands.

- •Collaborated with cross-functional teams to develop cost-effective solutions, resulting in a 15% reduction in production downtime.

- •Played a key role in staff training initiatives, enhancing skill sets across the board and boosting team performance metrics.

- •Participated in the installation of new assembly lines, optimizing workflow, and decreasing production time by 20%.

- •Evaluated production metrics, identifying and implementing process changes that reduced waste by 10%.

- •Coordinated engineering projects enhancing manufacturing capabilities and boosting plant throughput by 15%.

- •Supported the development of quality assurance practices, leading to a 25% improvement in product reliability.

Writing a production manager resume can feel like producing a blockbuster movie with no script. You know you have the skills, but putting them on paper is another story. Balancing technical expertise with leadership qualities while showcasing achievements is no small feat. Often, your resume either ends up too cluttered or not detailed enough. If you’re stuck, you’re not alone. Many production managers face the same problems when crafting their resumes. But don’t worry, this guide will help you ace it.

Using the right resume template is crucial. As a production manager, you need a format that highlights your unique blend of skills and accomplishments. The ideal template not only organizes your information but also makes your resume stand out.

Discover over 700 resume examples that you can use to write your own resume, tailored specifically for production managers like you.

Key Takeaways

- Choose a reverse-chronological resume format and a modern font to highlight your most recent experience first, ensuring your resume is up-to-date and professional.

- Incorporate specific achievements and metrics in your experience section, using action words like "led," "managed," and "improved" to showcase your impact.

- Include key sections such as Contact Information, Professional Summary, Work Experience, Skills, Education, and Certifications to organize your resume effectively and highlight your qualifications.

- Use clear and concise language in your resume summary to highlight your skills, experience, and measurable achievements, differentiating yourself from other candidates.

- Highlight both hard and soft skills relevant to production management and ensure your education and certifications are tailored to the job you're applying for, with specific industry-related qualifications included.

What to focus on when writing your production manager resume

Your production manager resume should highlight your ability to oversee and streamline manufacturing processes to ensure efficient operations. Demonstrating a strong track record in managing teams, improving productivity, and reducing costs will catch a recruiter's eye. Emphasize key metrics like reduced downtime, increased output, and successful project completions.

- Include specific achievements, such as "Reduced production costs by 20% through process optimization."

- Highlight technical skills, like proficiency with production software or equipment.

- Mention leadership experiences, such as "Led a team of 50 employees."

- Showcase any industry certifications or relevant education.

Must have information on your production manager resume

When creating a resume for a production manager role, it's crucial to include sections that highlight your expertise and experience effectively. Make sure your resume has the following must-have sections:

- Contact Information

- Professional Summary

- Work Experience

- Skills

- Education

- Certifications

You might also consider adding sections for Awards and Achievements, or Professional Associations if applicable. These can provide extra leverage and showcase your dedication to the field.

Which resume format to choose

For a production manager resume, the best format is the reverse-chronological layout. This highlights your most recent experience first, which is crucial in demonstrating your up-to-date skills and industry knowledge. Choose modern fonts like Rubik or Montserrat to give your resume a fresh and professional look, instead of traditional fonts like Arial or Times New Roman. Always save your resume as a PDF to ensure it retains its formatting across different devices and software. Keep your margins between 0.5 to 1 inch to ensure your resume is not too cramped but still makes good use of space. Use clear section headings like "Experience" and "Skills," which help both hiring managers and Applicant Tracking Systems (ATS) understand your resume better.

Your production manager resume should include several key sections. List everything important:

- Contact Information

- Professional Summary

- Work Experience

- Skills

- Education

- Certifications

- Projects

- Awards

Resume Mentor's free resume builder handles all this for you, ensuring your resume is polished and professional.

How to write a quantifiable resume experience section

Your experience section is where you really get to shine as a production manager. You should start by listing the most recent job first and work your way back. This helps employers see what you're currently doing and allows them to follow your career path. Focus on your last 10-15 years of work experience, or up to 3-5 jobs, whichever seems more appropriate. Be selective about the jobs you include; make sure they are related to the production management field.

When tailoring your resume, customize it to fit the job description. Use action words like "led," "managed," "improved," and "optimized." These words grab attention and show you took initiative. Quantify your achievements whenever possible; numbers help paint a clear picture of your accomplishments.

Here's an example of a poorly written experience section:

- •Responsible for managing production schedules.

- •Supervised a team of production workers.

- •Ensured that production goals were met.

This example is bad because it focuses on responsibilities instead of accomplishments. It does not use action words and is vague. The recruiter won’t know how well you did your job.

Now, let's look at a well-written experience section:

- •Increased production efficiency by 25% by streamlining workflow.

- •Decreased production costs by 15% by negotiating better supplier contracts.

- •Led a team of 50+ workers to consistently achieve monthly production targets.

This example shines because it highlights achievements with numbers and uses action words. It shows what you accomplished and how it benefited the company. Recruiters can easily see the impact you made, making you a more attractive candidate.

Production manager resume experience examples

Ready to boost your career as a production manager? This section brings you a smorgasbord of ways to highlight your achievements, skills, and qualities on your resume, one pun at a time. So, suit up, production manager — it's time to get a head start on reel success!

Achievement-focused

Highlighting your accomplishments can make your resume stand out. Focus on tangible achievements that showcase your impact in previous roles.

Production Manager

ABC Manufacturing Inc.

June 2018 - August 2023

- Reduced production costs by 15% through optimizing resources and workflow

- Implemented a quality control system that decreased defects by 20%

- Increased production output by 25% by restructuring assembly lines

Skills-focused

Showcase your skill set tailored to the production management role. Highlight both hard and soft skills.

Senior Production Manager

XYZ Industries

May 2015 - April 2021

- Proficient in ERP systems and Lean Manufacturing methodologies

- Skilled in team leadership and conflict resolution

- Expert in cost control and budget management

Responsibility-focused

Emphasize the scope of your responsibilities. Show potential employers that you can handle a wide range of duties.

Production Supervisor

Production Pros, LLC

January 2012 - December 2017

- Supervised a team of 50+ production line workers

- Managed inventory and supply chain coordination

- Ensured compliance with safety regulations and quality standards

Project-focused

Detail specific projects you have led or contributed to. Focus on the objectives, your role, and the outcomes.

Production Manager

Tech Assembly Inc.

March 2018 - Present

- Led a successful initiative to automate assembly lines, reducing labor costs by 10%

- Managed project timelines and budgets, consistently achieving milestones

- Collaborated with engineering to design and implement new machinery

Result-focused

Highlight outcomes and results of your efforts. Use metrics to make your successes quantifiable.

Operations Manager

Eco Green Products

July 2016 - June 2021

- Increased production efficiency by 30% through workflow optimization

- Achieved 98% customer order fulfillment rate

- Reduced wastage by 15% with sustainable practices

Industry-Specific Focus

Tailor your experience to the specific industry you are targeting. Highlight relevant industry knowledge.

Production Coordinator

ElectroWorks Inc.

August 2014 - September 2022

- Specialized in high-volume electronics manufacturing

- Oversaw assembly line reconfiguration for new product launches

- Maintained compliance with industry-specific regulatory standards

Problem-Solving focused

Detail your ability to solve problems effectively. Describe challenges, actions taken, and results.

Production Manager

Superior Solutions

October 2017 - December 2022

- Identified and resolved production bottlenecks, reducing downtime by 25%

- Developed a troubleshooting guide, leading to 40% faster issue resolution

- Implemented proactive maintenance schedules, lowering equipment failure rates

Innovation-focused

Highlight your capability to innovate and introduce new ideas. Discuss initiatives that brought fresh perspectives.

Production Manager

FutureTech Fabricators

February 2016 - November 2021

- Developed a modular production system, increasing flexibility and scalability

- Introduced augmented reality (AR) for training, reducing onboarding time by 30%

- Implemented predictive analytics to foresee and mitigate production issues

Leadership-focused

Emphasize your leadership qualities. Focus on team management, mentorship, and leading initiatives.

Production Manager

Innovative Productions Inc.

November 2015 - October 2023

- Led a team of over 100 employees, fostering a culture of continuous improvement

- Mentored junior managers, contributing to their professional development

- Coordinated cross-functional teams for successful product launches

Customer-focused

Show how you prioritize customer satisfaction. Discuss initiatives or processes you put in place to improve the customer experience.

Production Manager

Happy Customers Manufacturing

March 2016 - July 2022

- Developed a customer feedback loop to continuously improve product quality

- Implemented strict quality control measures, achieving a 99% satisfaction rate

- Reduced complaint resolution time by 60% through streamlined processes

Growth-focused

Showcase your role in fostering growth within the company. Focus on strategies you employed to drive growth.

Production Manager

Growth Gears Ltd.

January 2013 - December 2020

- Spearheaded expansion into new markets, increasing revenue by 50%

- Developed scalable processes to accommodate a 25% annual growth rate

- Implemented a continuous improvement program, fostering innovation and growth

Efficiency-focused

Emphasize your efforts in improving efficiency. Showcase your ability to optimize resources and processes.

Production Manager

Efficient Enterprises Inc.

September 2017 - Present

- Streamlined production workflows, reducing cycle times by 20%

- Introduced lean manufacturing practices, cutting waste by 18%

- Optimized resource allocation, saving the company $200,000 annually

Technology-focused

Show how proficient you are with technology relevant to production management. Discuss new technologies you have implemented or utilized effectively.

Production Manager

High-Tech Productions Ltd.

May 2015 - November 2022

- Introduced IoT-based monitoring systems, enhancing predictive maintenance capabilities

- Implemented ERP systems for better coordination across departments

- Leveraged machine learning for demand forecasting, reducing inventory costs by 10%

Collaboration-focused

Showcase your ability to collaborate and work well with others. Highlight your role in team-based successes.

Production Manager

Synergy Solutions

June 2018 - October 2023

- Coordinated with marketing and R&D teams for successful product launches

- Fostered a collaborative work environment, leading to a 15% increase in team productivity

- Led cross-departmental improvement projects, saving the company $500,000

Training and Development focused

Emphasize your role in training and developing employees. Show how your efforts led to improved skills and team performance.

Production Manager

Grow Together Industries

February 2016 - September 2022

- Created a comprehensive training program, reducing onboarding time by 40%

- Developed leadership training modules, promoting 10 employees to managerial positions

- Implemented continuous learning initiatives, increasing overall team productivity by 20%

Write your production manager resume summary section

Writing a resume summary section can be simple and effective if done right. The goal is to give a snapshot of who you are and what you bring to the table. You should focus on your skills, experience, and what makes you unique in your field.

Using clear and concise language is the best way to describe yourself in a resume summary. Mention your key strengths and how they have led to tangible results in your previous roles. Focus on what you do best and how it can benefit your potential employer.

For clarity, a resume summary is a brief statement that highlights your experience and skills. A resume objective, on the other hand, focuses on your career goals and why you’re interested in the position. A resume profile is similar to a summary but usually longer and more detailed. A summary of qualifications is a bullet-point list of your best achievements.

This example is bad because it lacks specifics and fails to demonstrate real achievements. Words like "experienced" and "skilled" are too vague. It does not give a clear picture of your abilities or what you’ve accomplished in past roles.

This example is good because it includes specific details and measurable achievements. It shows your experience in lean manufacturing, leadership skills, and your success in improving efficiency. It also highlights your ability to manage budgets and maintain quality, making it clear what you bring to the role.

Writing a great resume summary can set you apart by clearly showing your potential employer why you are the best fit for the job. Use clear language and be specific about your achievements to make your summary impactful.

Listing your production manager skills on your resume

To effectively write the skills section of your production manager resume, consider that skills can be both a standalone section and incorporated into other sections like your experience and summary. Highlighting your strengths and soft skills will help showcase your comprehensive capabilities. Hard skills are specific, teachable abilities you have acquired, such as technical knowledge and industry-specific competencies.

Skills and strengths on your resume can serve as keywords. Employers often scan resumes for keywords that match the job description, so including relevant skills can increase your chances of getting noticed.

This skills section is effective because it clearly lists key competencies relevant to a production manager role. Each skill is specific and aligns with industry needs, improving your chances of catching a potential employer’s eye.

Best hard skills to feature on your production manager resume

A production manager should possess essential hard skills that convey their ability to manage operations effectively. These skills indicate technical proficiency and industry-specific knowledge.

Hard Skills

- Project Management

- Production Planning

- Lean Manufacturing

- Quality Control

- Supply Chain Management

- Process Improvement

- Budget Management

- Data Analysis

- Operational Efficiency

- Six Sigma Certification

- Inventory Management

- Safety Compliance

- ERP Systems Knowledge

- Machinery Maintenance

- Scheduling

Best soft skills to feature on your production manager resume

Production managers also need key soft skills that demonstrate their ability to lead and interact effectively. These skills highlight your interpersonal strengths and ability to manage a team successfully.

Soft Skills

- Team Leadership

- Communication

- Problem-Solving

- Time Management

- Conflict Resolution

- Negotiation Skills

- Adaptability

- Decision-Making

- Critical Thinking

- Motivation

- Collaboration

- Attention to Detail

- Patience

- Customer Focus

- Interpersonal Skills

How to include your education on your resume

The education section is an important part of your production manager resume. Tailor it to the job you're applying for — exclude any irrelevant education. Include information like the name of the degree, the institution, location, and graduation date. If your GPA is above 3.5, include it to show academic excellence. Listing honors like cum laude can also highlight your achievements. Specify the degree clearly for the hiring manager.

This first example is not a good fit. The degree in Fine Arts is not relevant to a production manager position. It does not include a GPA or any honors and the date range is realistic but does not fit the job's requirements.

The second example suits the production manager role better. The degree in Industrial Engineering is highly relevant. The GPA of 3.8 indicates strong academic performance. The date range is appropriate for a recent graduate applying for a management role.

How to include production manager certificates on your resume

Including a certificates section in your production manager resume is essential. Certificates showcase your specialized skills and qualifications. You can list certificates in a distinct section or even include them in the header if space allows.

List the name of each certificate clearly. Include the date you received the certification to show its recency. Add the issuing organization to validate its authenticity.

A good example of a certificates section includes certificates relevant to production management, such as Lean Six Sigma or Project Management Professional (PMP).

This example is effective as it highlights key qualifications directly related to production management. Lean Six Sigma Black Belt shows proficiency in process improvement. Project Management Professional indicates advanced skills in managing projects and teams. Both certificates are issued by well-known organizations, proving their credibility.

Extra sections to include in your production manager resume

Crafting a compelling resume is essential for those looking to secure a position as a production manager. Your resume should highlight your qualifications while also showcasing your unique skills and interests. Including a few key sections can make your resume stand out and show a potential employer that you are well-rounded and motivated.

- Language section—demonstrate your proficiency in multiple languages, which can be valuable in global production environments.

- Hobbies and interests section—reveal your personal interests, showing that you are a well-rounded individual with passions beyond work.

- Volunteer work section—highlight your commitment to your community and your ability to work collaboratively in diverse settings.

- Books section—showcase your dedication to continuous learning by listing industry-related books you have read.

Pair your production manager resume with a cover letter

A cover letter is a brief document accompanying your resume that introduces you to potential employers, highlighting your skills, experiences, and enthusiasm for the role you're applying for. It serves as a personalized pitch, giving insight into why you're the right fit for the job.

For applicants, a well-crafted cover letter can set you apart from other candidates. It allows you to explain gaps in your employment, showcase your communication skills, and provide context to your achievements in a way a resume can't. This personal touch can help you make a strong impression and pique the employer's interest in you.

As a production manager, your cover letter should focus on your ability to oversee manufacturing processes, manage teams, and ensure production efficiency. Highlight your experience in coordinating with various departments, improving production workflows, and achieving quality standards. Mention specific achievements, such as increasing output or reducing waste, to demonstrate your effectiveness in the role.

Ready to create your perfect cover letter? Use Resume Mentor's cover letter builder for a hassle-free experience. Effortlessly export your document as a PDF to keep your content and formatting intact and professional-looking.

Mia Williams

Jacksonville, Florida

+1-(234)-555-1234

help@resumementor.com

Related Articles

Continue Reading

Check more recommended readings to get the job of your dreams.

Resume

Resources

Tools

© 2026. All rights reserved.

Made with love by people who care.